The efficient functioning of a flame-producing device relies on a variety of essential elements, each playing a crucial role in its operation. Grasping how these components interact can enhance both safety and performance for users.

From the fuel source to the ignition mechanism, every piece contributes to the ultimate effectiveness of the tool. By exploring the intricate relationships between these components, one can delve deeper into the mechanics that power such devices.

Familiarity with these crucial aspects not only aids in maintenance but also enriches the overall experience of using this versatile equipment. A comprehensive understanding fosters confidence and promotes effective use, ensuring optimal results in various applications.

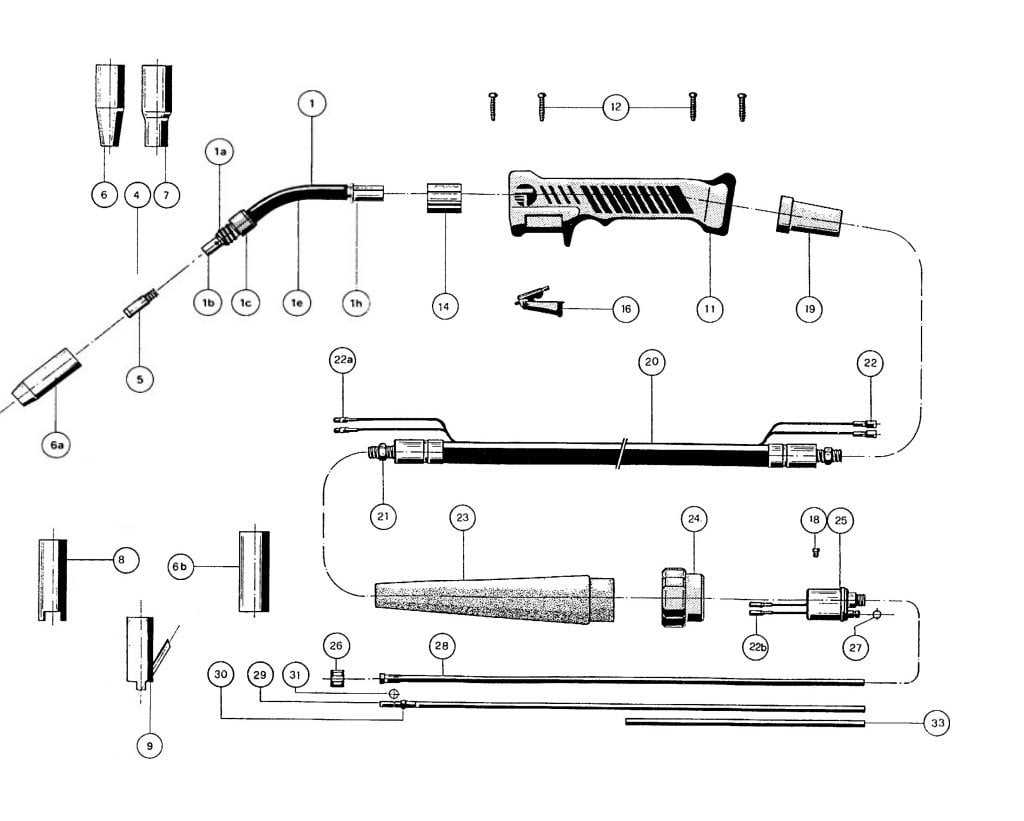

Understanding Propane Torch Components

Exploring the various elements of a heating device reveals the intricate design and functionality that contribute to its effectiveness. Each component plays a crucial role in ensuring safety and optimal performance, making it essential to understand their individual purposes and interactions.

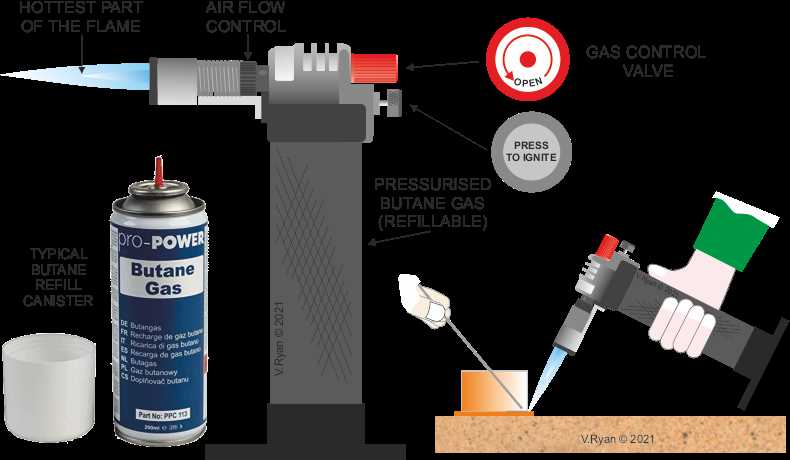

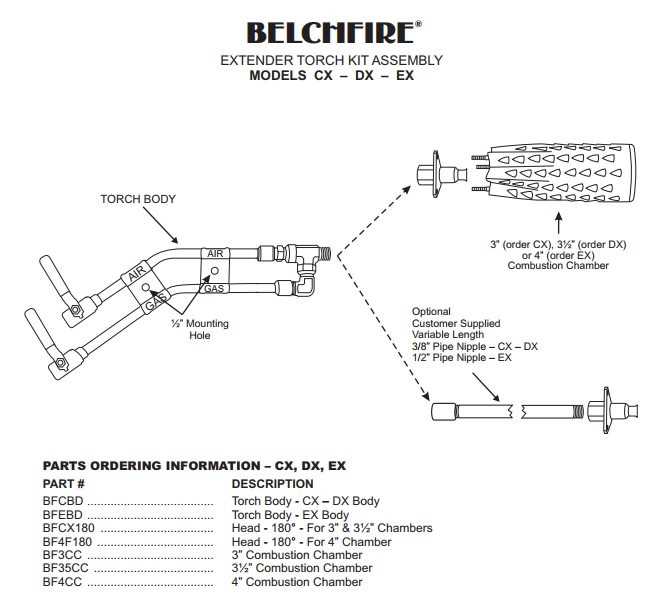

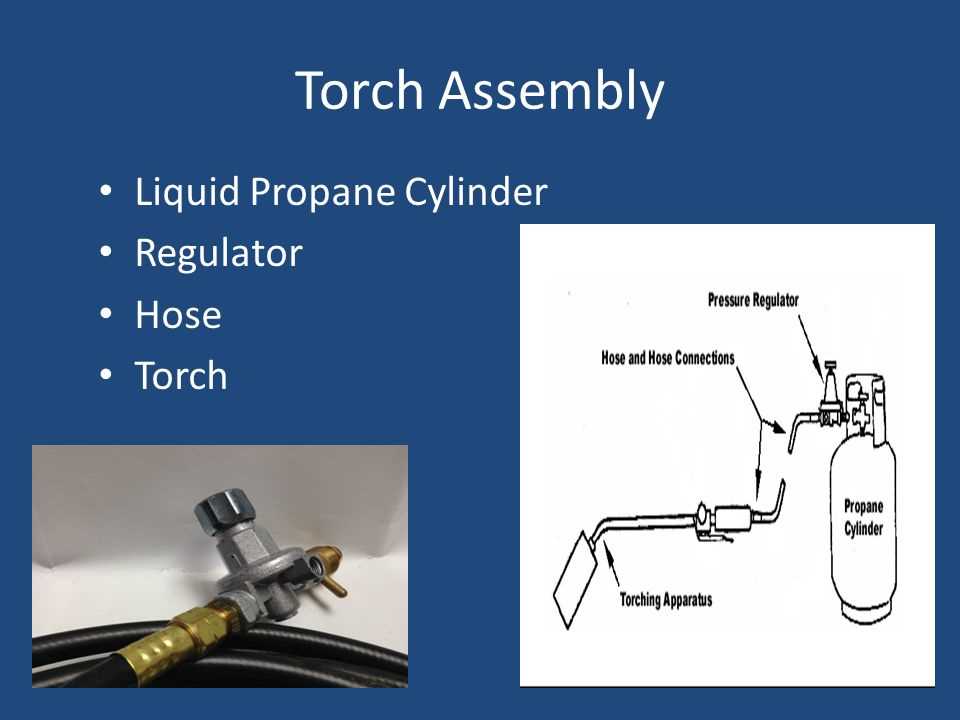

Key elements of such devices include fuel sources, ignition systems, and delivery mechanisms. By grasping how these parts work together, users can achieve better control and efficiency in their tasks.

| Component | Description |

|---|---|

| Fuel Cylinder | Stores the flammable substance needed for combustion, providing a reliable energy source. |

| Regulator | Controls the flow and pressure of the fuel, ensuring a steady output for consistent performance. |

| Igniter | Initiates the combustion process, producing a flame for heating or soldering tasks. |

| Nozzle | Directs the flow of the flame, allowing for precision and control in various applications. |

| Handle | Provides a comfortable grip and control over the device during operation. |

Understanding these components enhances safety and effectiveness, enabling users to make informed decisions about their equipment and techniques.

Functionality of Each Part Explained

This section delves into the roles played by various components within a common heating device, highlighting their individual functions and interactions. Understanding these elements is essential for effective operation and maintenance.

Ignition Mechanism

The ignition mechanism is crucial for initiating combustion. It generates a spark or flame that ignites the fuel, enabling the device to produce a steady heat source. This component must be reliable to ensure seamless operation, as any failure can impede functionality.

Fuel Delivery System

The fuel delivery system regulates the flow of gas to the combustion area. It consists of valves and hoses that control pressure and volume, ensuring an optimal mixture for efficient burning. Proper maintenance of this system is vital for safety and performance, as leaks or blockages can lead to hazardous situations.

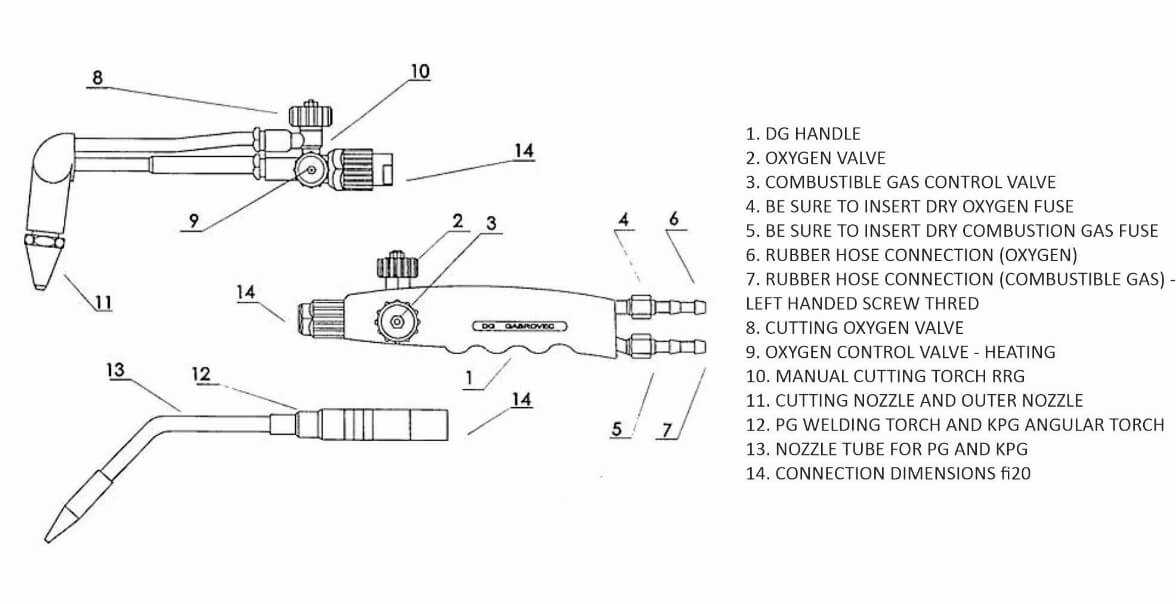

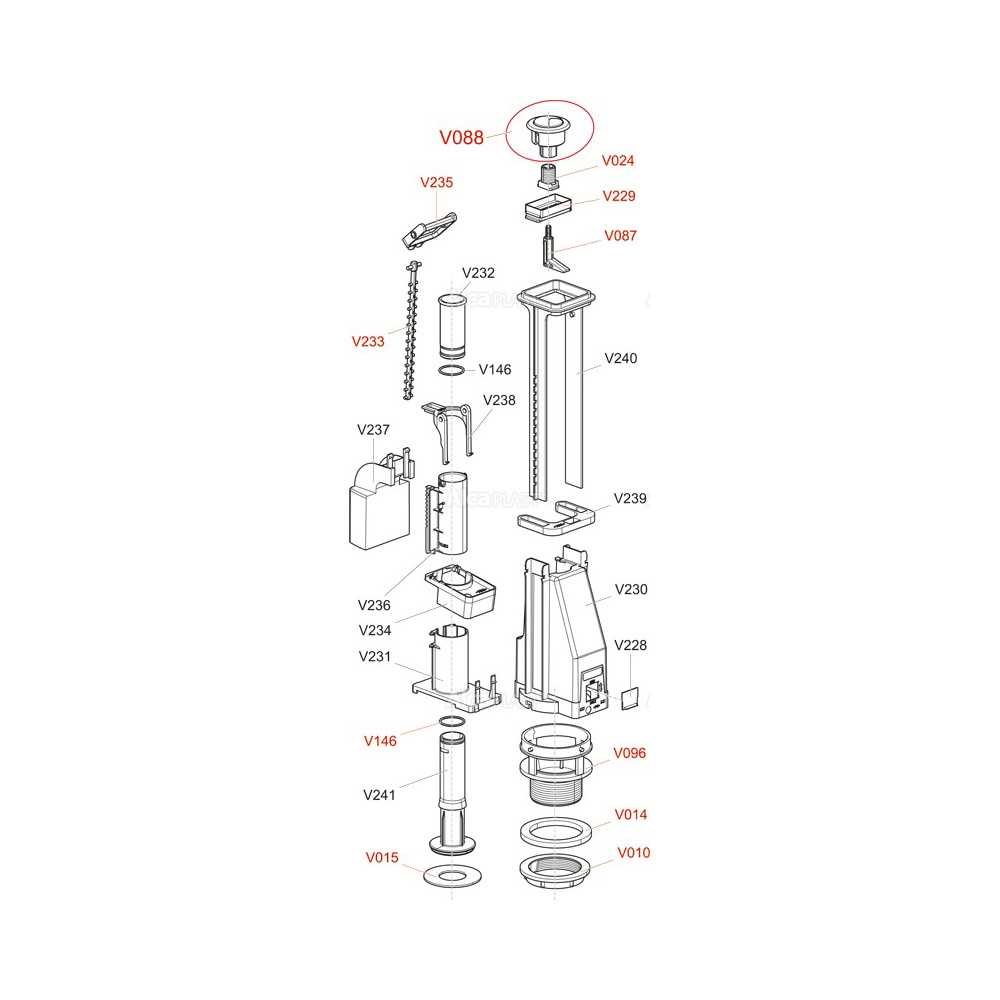

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective assembly, maintenance, or troubleshooting. This guide will help you navigate the visual layout, making it easier to identify individual elements and their relationships.

Key Elements to Identify

- Labels: Look for annotations that indicate the names or numbers of specific components.

- Connections: Pay attention to lines or arrows that show how elements are interconnected.

- Legends: Some illustrations include a legend that explains symbols or color coding used throughout the image.

Steps to Interpret the Visual

- Start from the top-left corner, usually where the main element is displayed.

- Follow the connections to trace the flow or structure of the system.

- Refer to the legend to clarify any symbols or terminology you don’t understand.

- Cross-reference with manuals or additional resources for further insights.

By familiarizing yourself with these aspects, you’ll be better equipped to work with any schematic representation you encounter.

Common Types of Propane Torches

In the realm of flame-producing tools, various designs serve distinct purposes, catering to both professional and DIY needs. Understanding these types can enhance efficiency and safety in various applications, from soldering to culinary arts.

Types Based on Application

Different styles are tailored for specific tasks. Below are some prevalent categories:

| Type | Description | Common Uses |

|---|---|---|

| Handheld | Compact and portable units, ideal for quick tasks. | Repair work, lighting grills |

| Plumbing | Designed for soldering pipes with precision. | Soldering joints in plumbing systems |

| Heavy-duty | Robust models for industrial applications. | Metalwork, large-scale repairs |

| Culinary | Specialized for cooking, offering control over flame intensity. | Crème brûlée, caramelizing |

Choosing the Right Model

Selecting the appropriate variant depends on the intended use. Assessing factors like flame size, portability, and fuel efficiency can significantly influence performance and outcomes in projects.

Safety Features in Torch Design

Ensuring user protection is a fundamental aspect of designing high-temperature tools. Various innovations have been integrated into these devices to minimize risks and enhance safe operation. These features play a crucial role in preventing accidents and ensuring the well-being of the operator and surrounding environment.

Flame Control Mechanisms

One of the primary safety attributes includes advanced flame regulation systems. These mechanisms allow for precise control over the intensity and stability of the flame, reducing the likelihood of unintentional ignition and overheating. By providing the user with the ability to adjust the output, the risk of fire hazards is significantly lowered.

Built-in Safety Locks

Another essential feature is the incorporation of safety locks. These locks are designed to prevent accidental activation, making it safer to store and transport the equipment. This functionality is vital, especially in environments where multiple users may interact with the device, as it ensures that only intentional use occurs.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your heating tool requires regular upkeep and attention. By following a few essential guidelines, you can significantly extend its lifespan and maintain optimal performance for various applications. Routine checks and proper care can prevent common issues and enhance your overall experience.

Regular Inspections

Conduct frequent assessments of your device to identify any wear or damage. Pay close attention to hoses, connectors, and other components. Look for cracks, leaks, or signs of corrosion that may compromise functionality. Addressing these concerns early can save you time and money in repairs.

Proper Storage and Handling

Storing your equipment in a safe and dry place is crucial. Avoid exposure to extreme temperatures or moisture, as these factors can deteriorate materials over time. When handling your tool, be gentle to prevent unnecessary strain on connections and mechanisms. Following these practices will help maintain its integrity and readiness for use.

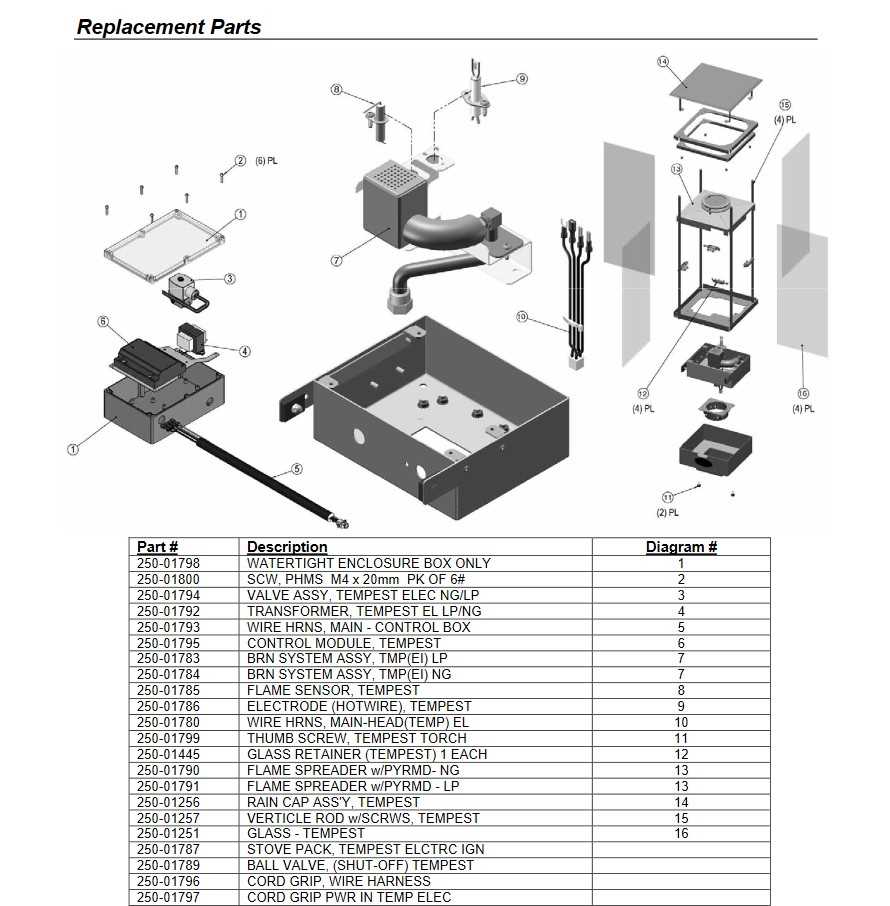

Replacing Worn or Damaged Parts

Maintaining the functionality of your equipment is essential for optimal performance and safety. Over time, components can wear down or become damaged, leading to decreased efficiency and potential hazards. Recognizing when to replace these elements is crucial for preserving the integrity of your device.

When assessing the condition of your equipment, consider the following indicators of wear or damage:

- Visible cracks or breaks in components

- Increased difficulty in operation

- Unusual noises during use

- Signs of corrosion or rust

- Leaks or irregular flow of materials

To ensure a successful replacement process, follow these steps:

- Identify the specific component that needs replacement.

- Consult the user manual for compatibility and specifications.

- Gather necessary tools and new components before starting the repair.

- Carefully disassemble the equipment as per the manual instructions.

- Replace the damaged or worn component with the new one.

- Reassemble the device and conduct a thorough inspection.

- Test the equipment to confirm that it operates correctly.

Regular maintenance and timely replacements not only enhance performance but also extend the lifespan of your device. By staying vigilant and proactive, you can ensure your equipment remains in peak condition.

Tools Needed for Repairs

When it comes to maintaining and fixing various equipment, having the right instruments is essential for efficient and effective work. Proper tools not only facilitate the repair process but also ensure safety and precision in handling tasks.

Basic Hand Tools: A good set of wrenches, pliers, and screwdrivers is vital. These instruments provide the necessary leverage and grip to tackle different components.

Safety Gear: Always prioritize safety by using gloves and goggles. This protective equipment safeguards against potential hazards during repairs.

Cleaning Supplies: Keeping components clean is crucial. Use brushes, cloths, and suitable solvents to remove debris and ensure optimal performance.

Specialized Tools: Depending on the complexity of the task, you may require unique instruments, such as a pressure gauge or a blowtorch, to achieve the ultimate results.

Measuring Devices: Accurate measurements are key. Calipers and rulers help ensure that all parts fit together correctly during assembly.

By gathering these essential tools, you’ll be well-prepared to tackle any repair project with confidence and skill.

Applications of Propane Torches

This versatile tool finds numerous applications across various industries and hobbies. Its ability to generate intense heat makes it indispensable for tasks that require precision and efficiency. From metalworking to culinary arts, the utility of this flame-emitting device is profound and multifaceted.

Industrial Uses

In manufacturing and construction, this tool is often employed for soldering and brazing metals. It facilitates the joining of components with ease, providing a strong bond while ensuring minimal heat distortion. Additionally, it is widely used for tasks like pipe thawing in cold climates, making it essential for maintaining operational efficiency.

Home and DIY Applications

For hobbyists and homeowners, this tool is perfect for a range of projects. Whether it’s loosening rusted bolts, lighting outdoor grills, or even creating art with glass, the applications are diverse. Moreover, it serves as a valuable asset in gardening, particularly for tasks such as weed removal, where precision is key.