When it comes to maintaining and repairing machinery, a clear visualization of its elements is crucial. Knowing how each part interacts not only facilitates effective troubleshooting but also enhances overall performance. This section aims to provide insights into the intricate layout of essential components.

Having a comprehensive reference enables operators to navigate through the complexities of their equipment with ease. It serves as a guide for identifying specific items and understanding their functions within the larger system. With the right information, users can ensure optimal operation and longevity.

Diving into the specifics allows for a deeper understanding of how to best care for your machinery. Whether you’re a seasoned professional or a new operator, mastering the details will empower you to tackle any challenges that arise confidently.

Kubota LA525 Overview

This section provides an insight into a compact yet powerful piece of machinery designed for a variety of agricultural and landscaping tasks. Its robust build and innovative features make it a reliable choice for professionals and hobbyists alike. Understanding its key components and functionalities can enhance the overall efficiency of operations.

Key Features

The equipment boasts several significant characteristics that contribute to its versatility. Efficient engine performance ensures optimal power output while maintaining fuel economy. Additionally, the ergonomic design of the operator’s station enhances comfort during prolonged use, allowing for improved productivity.

Applications

This machinery is well-suited for a range of applications, from landscaping to agricultural chores. Its ability to maneuver in tight spaces makes it ideal for small-scale farming and residential projects. Moreover, the compatibility with various attachments extends its utility, making it a valuable asset in diverse environments.

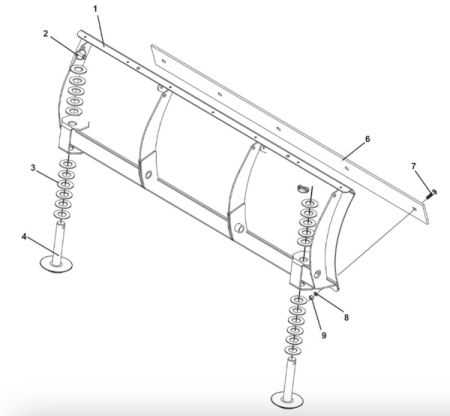

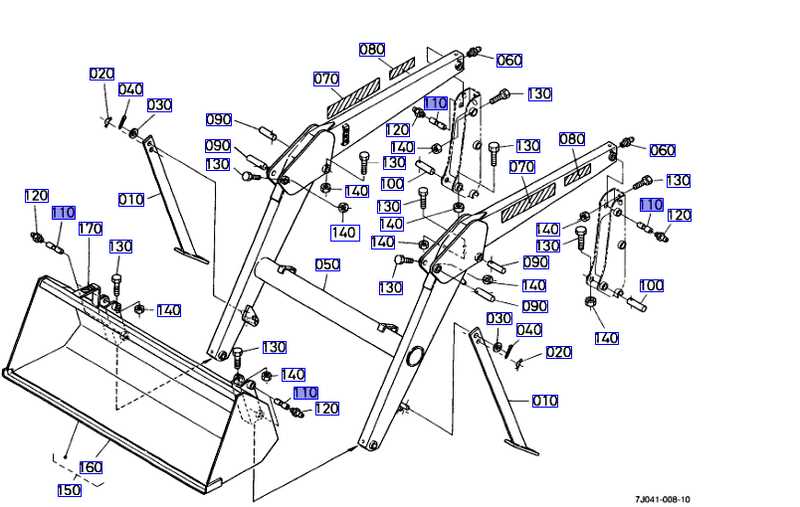

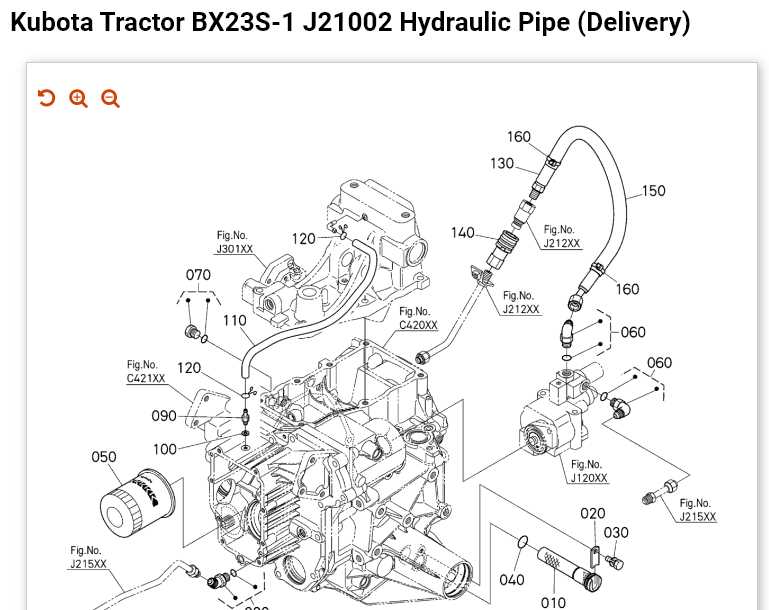

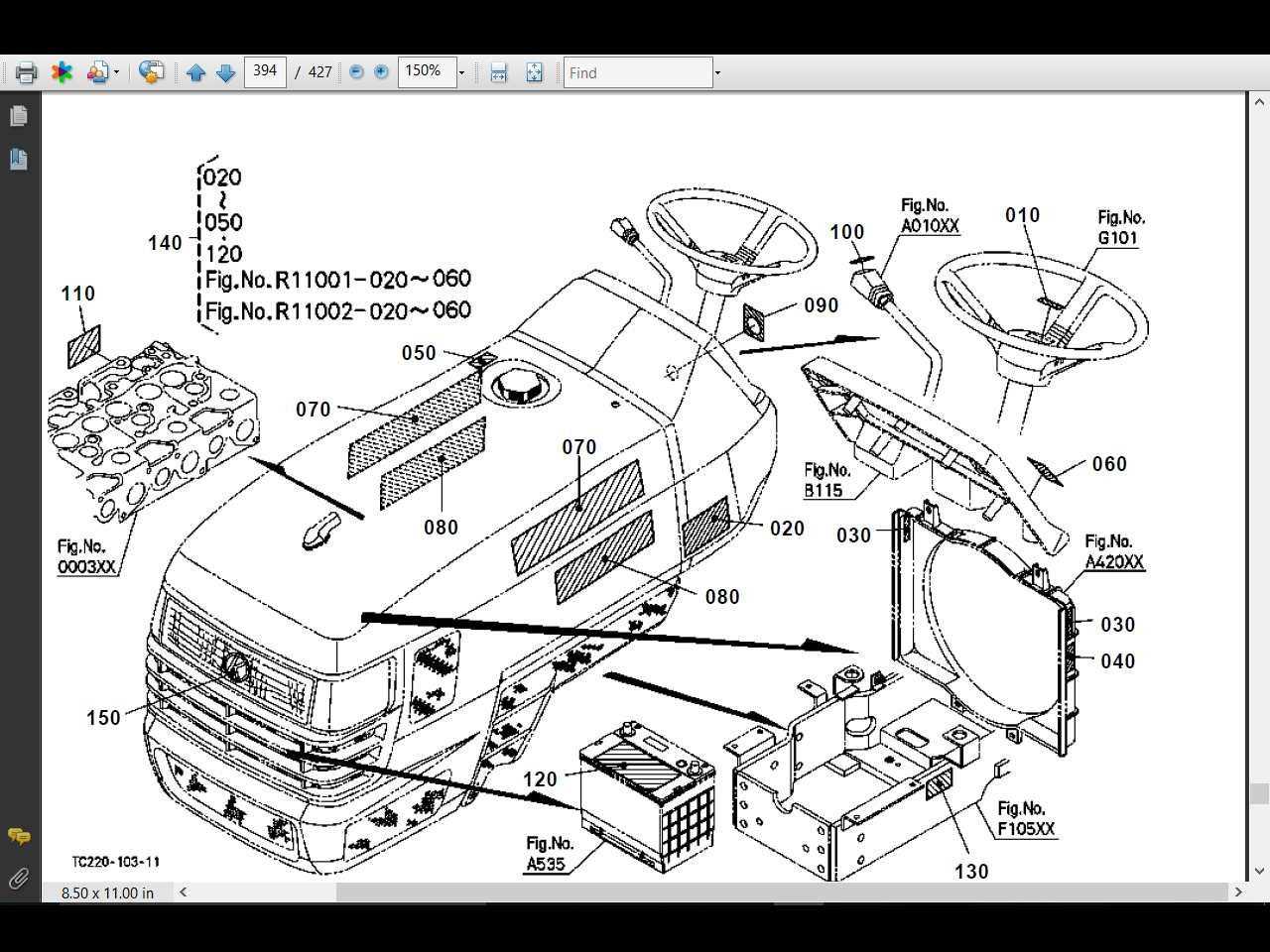

Understanding Parts Diagrams

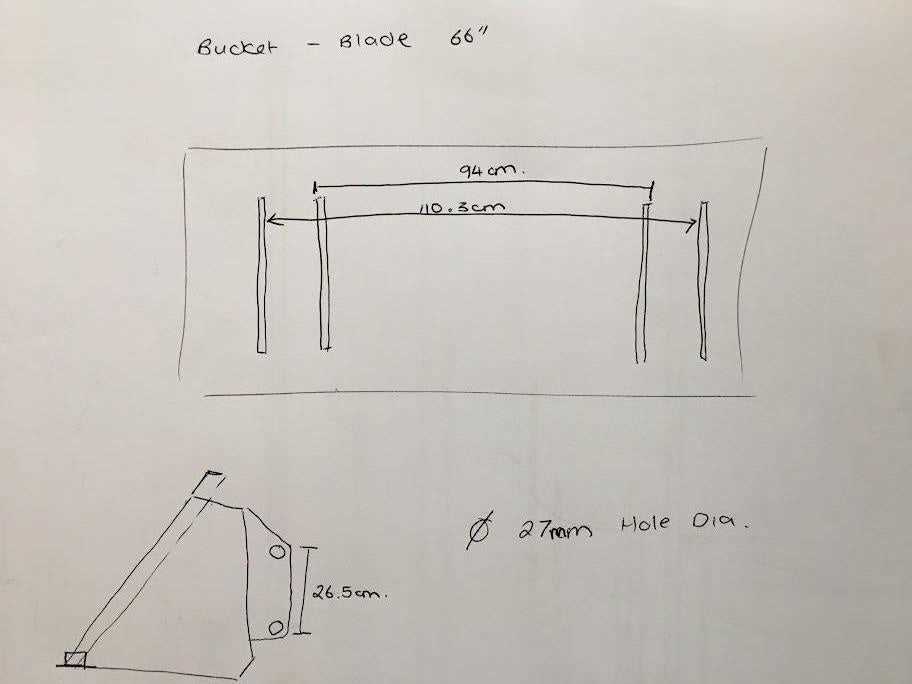

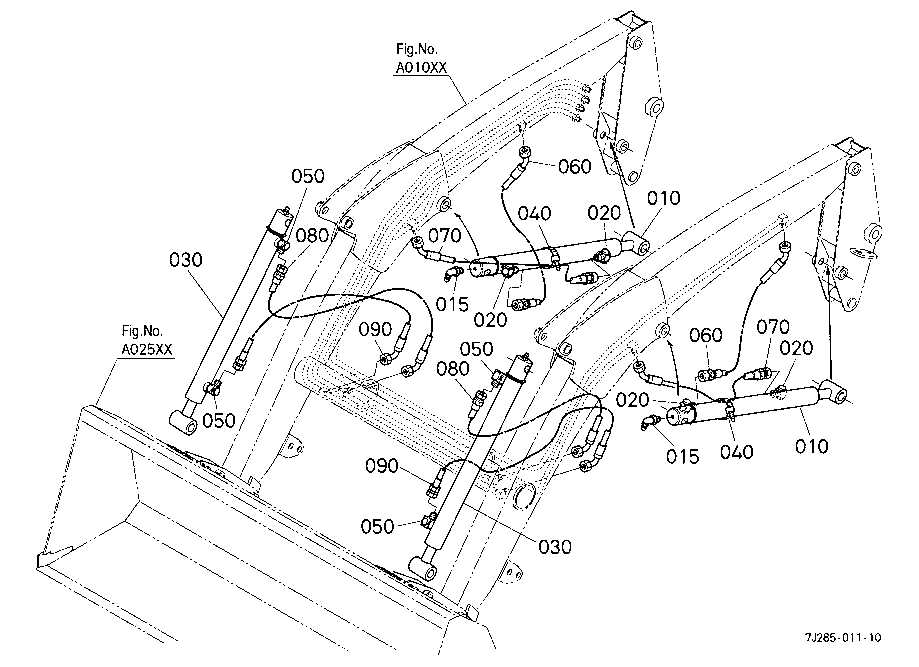

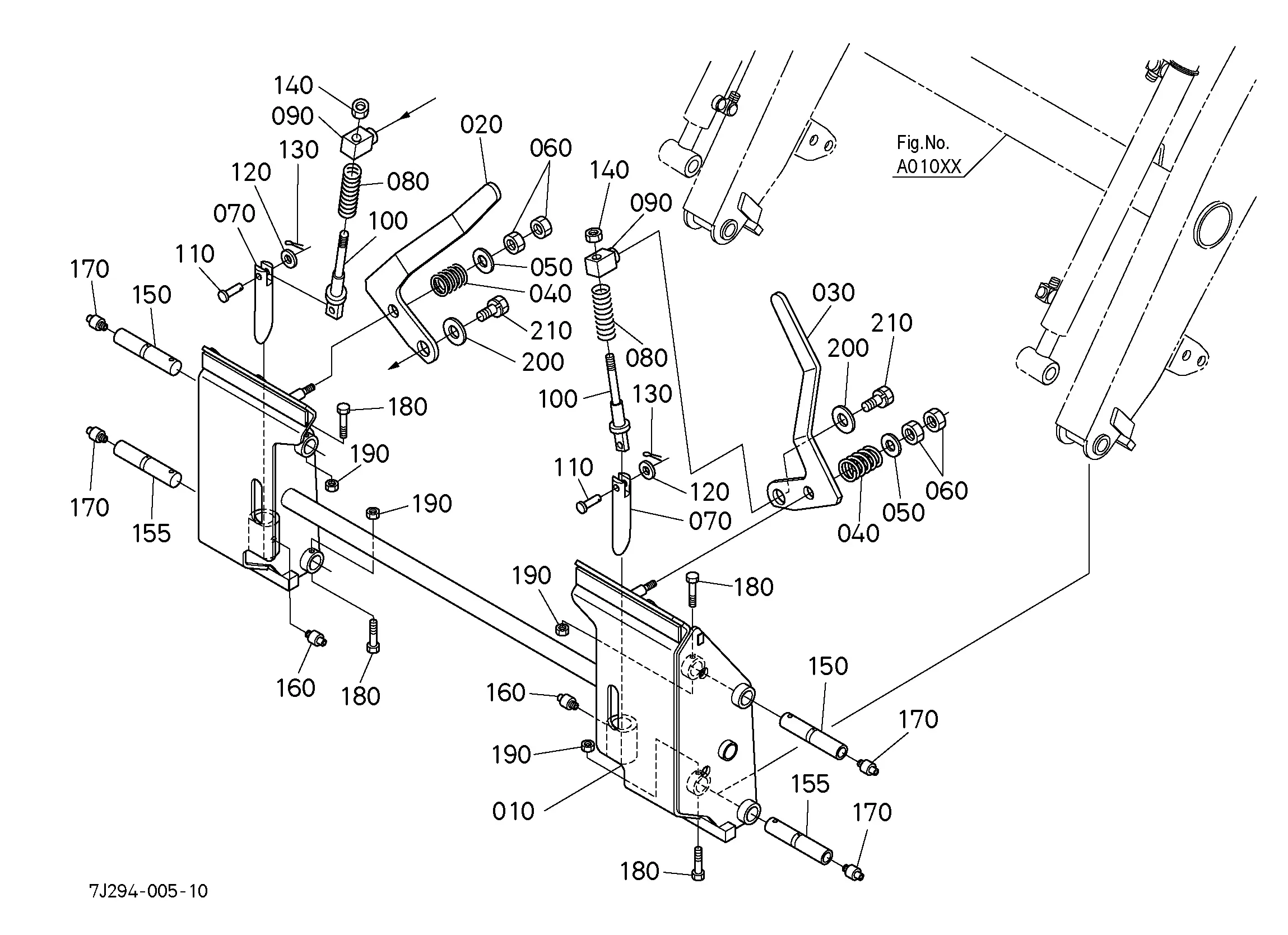

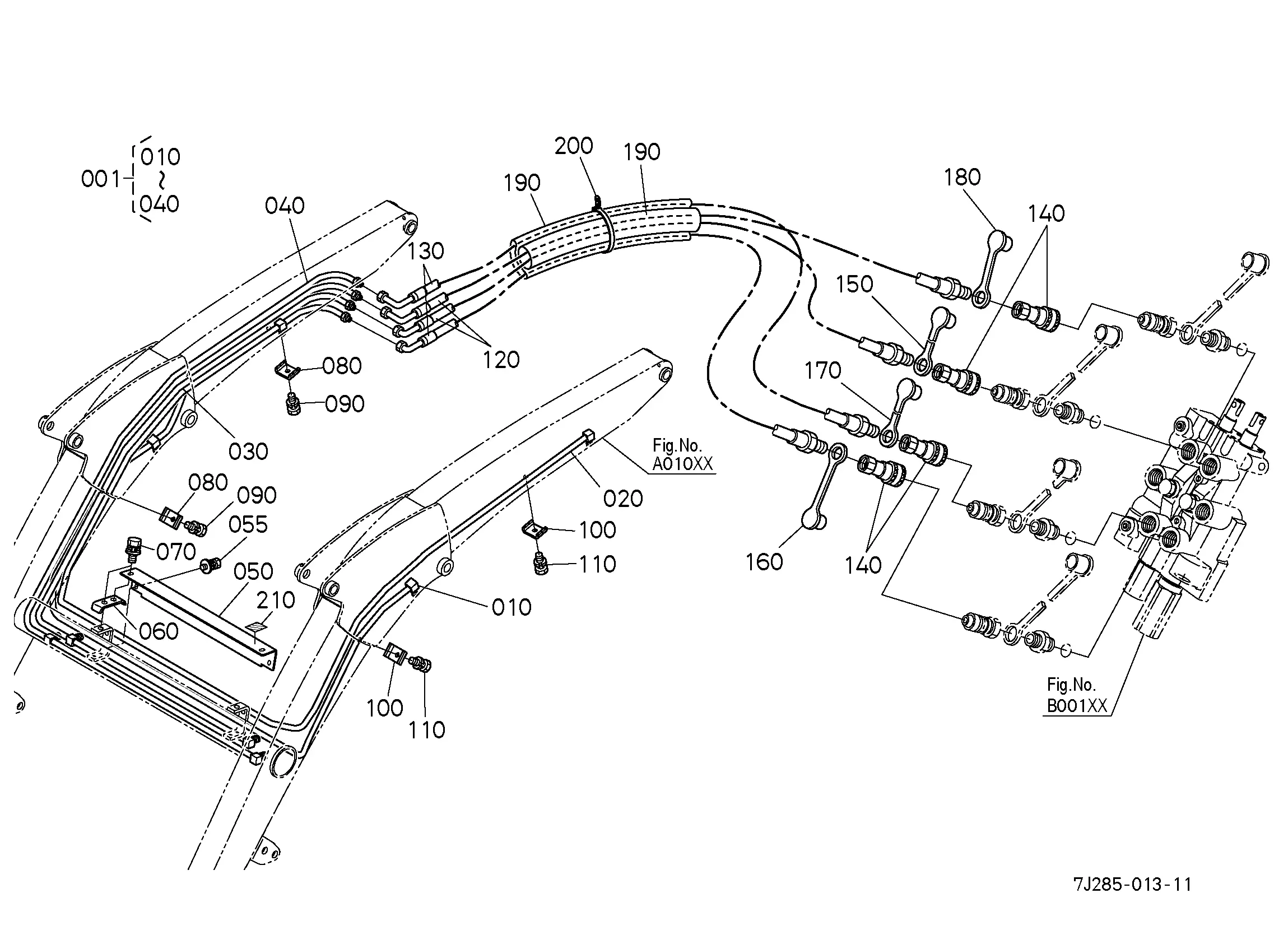

Visual representations of components play a crucial role in understanding the assembly and functionality of machinery. They provide clarity on how various elements fit together and interact, serving as a roadmap for both repair and maintenance tasks.

These illustrations allow users to easily identify individual elements and their relationships, enhancing the overall comprehension of the equipment’s design. This is particularly beneficial when it comes to troubleshooting or replacing specific components, as users can quickly locate the necessary parts without confusion.

Moreover, a clear visual guide can prevent errors during assembly or disassembly, saving time and reducing the risk of damage. By delving into these graphical resources, operators can ensure optimal performance and longevity of their machinery.

Common Components of LA525

Understanding the essential elements of this equipment is crucial for maintenance and efficiency. These parts work in unison to ensure optimal performance, making it vital to recognize their functions and interrelationships.

Engine: The heart of the machinery, providing the necessary power to operate various functions.

Hydraulic System: This system facilitates movement and operation of attachments, enhancing versatility.

Transmission: Responsible for transferring power from the engine to the wheels, ensuring smooth mobility.

Chassis: The structural framework that supports all components, contributing to durability and stability.

Controls: The interface for operators, allowing for precise handling and maneuvering of the equipment.

Each of these components plays a pivotal role in the overall functionality, making a thorough understanding essential for effective usage.

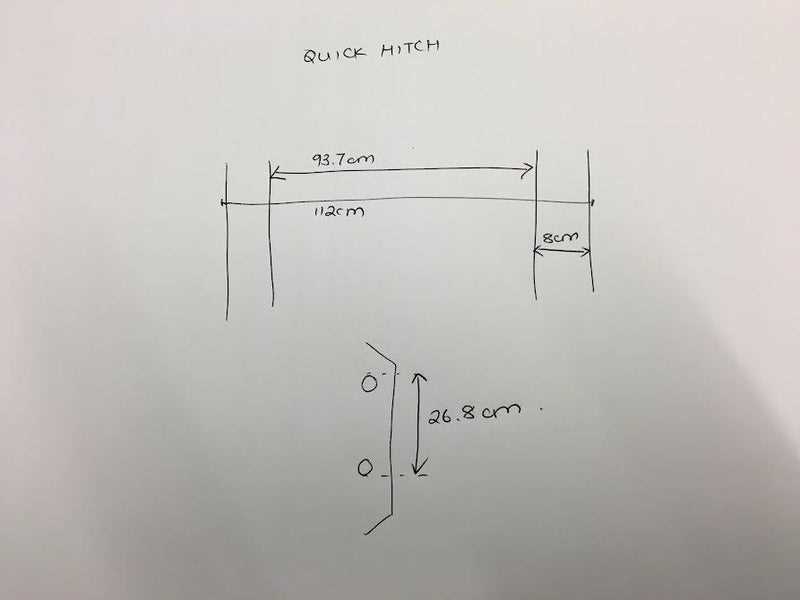

How to Use the Diagram

Understanding the schematic representation of components is essential for effective maintenance and repair tasks. This visual guide aids in identifying various elements, streamlining the troubleshooting process, and ensuring accurate reassembly after disassembly.

To maximize the benefits of this resource, follow these steps:

| Step | Action |

|---|---|

| 1 | Familiarize yourself with the layout, noting the organization of different sections. |

| 2 | Cross-reference the components with your equipment to identify necessary parts. |

| 3 | Use the visual guide while disassembling and reassembling to ensure accuracy. |

| 4 | Consult the guide whenever uncertain about specific functions or locations. |

Utilizing this approach will enhance your efficiency and effectiveness in handling repairs and maintenance. Ultimately, a thorough understanding leads to improved performance and longevity of your machinery.

Benefits of Regular Maintenance

Routine upkeep is essential for the longevity and efficiency of any machinery. By adhering to a consistent maintenance schedule, users can ensure that their equipment operates at peak performance while minimizing unexpected breakdowns.

One of the primary advantages of regular service is the enhancement of reliability. Machines that are well-maintained are less likely to suffer from operational failures, which can lead to costly downtime.

Additionally, consistent maintenance helps identify potential issues before they escalate, allowing for timely repairs. This proactive approach not only saves money but also extends the lifespan of the equipment.

Moreover, routine checks can improve safety, as well-maintained machines are less likely to malfunction, reducing the risk of accidents in the workplace.

In conclusion, prioritizing regular maintenance is a wise investment that yields long-term benefits, ensuring optimal functionality, safety, and cost-effectiveness.

Finding Genuine Replacement Parts

Locating authentic components for machinery is crucial for ensuring optimal performance and longevity. When equipment requires servicing, it’s essential to source high-quality replacements to maintain efficiency and safety. This section delves into strategies for identifying reliable suppliers and verifying the authenticity of the items needed.

Identifying Reliable Suppliers

Start by researching authorized distributors who specialize in machinery components. Look for those with positive reviews and a reputation for providing original products. Networking within industry forums can also help uncover trustworthy sources.

Verifying Authenticity

Before making a purchase, always check for proper documentation and labeling. Genuine items typically come with certifications and warranty details. Additionally, compare prices and features to avoid counterfeit alternatives that may harm your equipment.

| Criteria | Importance |

|---|---|

| Supplier Reputation | High |

| Documentation | High |

| Warranty | Medium |

| Price Comparison | Medium |

Troubleshooting with Parts Diagram

Understanding the components of machinery is essential for effective problem-solving. By analyzing the layout of different elements, users can quickly identify issues, leading to more efficient repairs and maintenance.

Common Issues and Solutions

- Engine Starting Problems: Check the ignition system and fuel supply.

- Hydraulic Failures: Inspect hoses and connections for leaks.

- Electrical Malfunctions: Examine wiring and fuses for damage.

Steps to Follow

- Identify the symptoms of the issue.

- Refer to the layout to locate relevant components.

- Test each part systematically to find the fault.

- Replace or repair the faulty components as needed.

Resources for Further Information

This section aims to provide valuable references and tools for those seeking deeper insights into equipment components and their maintenance. A range of materials is available to help enhance understanding and facilitate effective repairs.

- Official Manufacturer Websites: These platforms often feature detailed guides and user manuals.

- Online Forums: Engaging with community discussions can yield practical tips and shared experiences.

- YouTube Tutorials: Visual aids can simplify complex tasks, showcasing step-by-step processes.

- Technical Service Publications: Accessing specialized documentation can offer in-depth technical knowledge.

- Local Dealerships: Consult with experts who can provide tailored advice and resources.