Every mechanical tool consists of numerous elements that work in harmony to achieve optimal performance. Familiarity with these components can significantly enhance your understanding of how to maintain and troubleshoot your machinery. By exploring the intricate layout of these essential pieces, you can ensure your device operates efficiently and effectively.

In this section, we will delve into the various segments of your machine, highlighting their functions and interconnections. This knowledge is crucial for anyone looking to improve their skills in handling and servicing their equipment. Understanding the ultimate role each element plays will empower you to take charge of your maintenance routine.

By grasping the relationships between these components, you’ll be better equipped to identify potential issues and perform necessary repairs. Whether you’re a seasoned user or a newcomer, this exploration will provide valuable insights that can enhance your overall experience.

Understanding Predator Auger Functionality

Grasping the principles behind this powerful drilling mechanism is essential for users aiming to enhance their operational efficiency. By comprehending how this equipment operates, one can effectively utilize its capabilities to perform various tasks, from digging holes to installing posts. A thorough understanding of its components and their interactions ensures optimal performance and longevity.

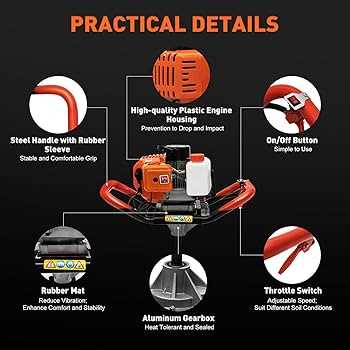

Core Components and Their Roles

Every effective drilling apparatus comprises several crucial elements that contribute to its overall performance. The primary unit, responsible for penetrating the ground, is designed to create a clean and precise bore. Additionally, the mechanism’s rotational system allows for smooth and controlled movement, enabling users to adjust speed and torque according to the task’s requirements. Furthermore, the structure’s design facilitates easy maintenance and replacement of components, which is vital for sustained operation.

Operational Mechanism

The functionality of this machinery relies on a harmonious interplay of mechanical forces. When activated, the motor generates torque, which is transmitted to the drilling unit. This rotation, combined with the downward pressure applied by the user, enables effective excavation. The design also ensures that debris is efficiently removed from the hole, preventing clogs and maintaining operational efficiency. Understanding this interplay is crucial for maximizing the effectiveness of the equipment during various applications.

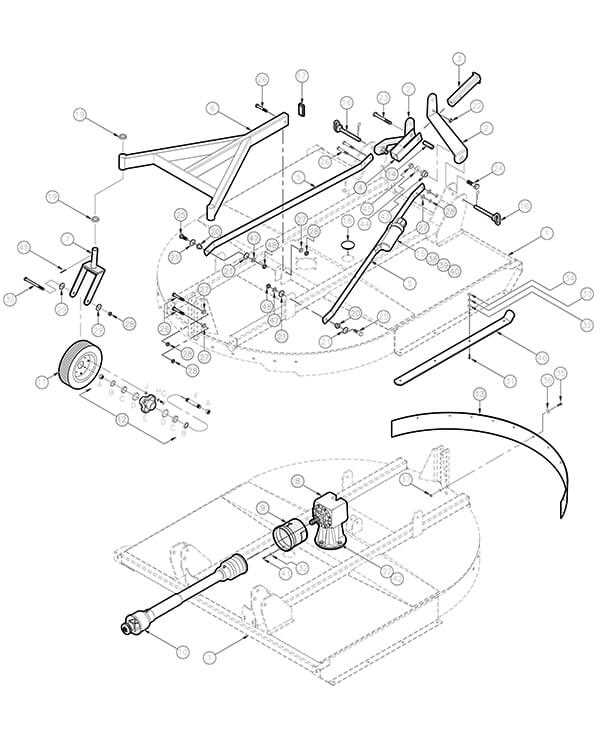

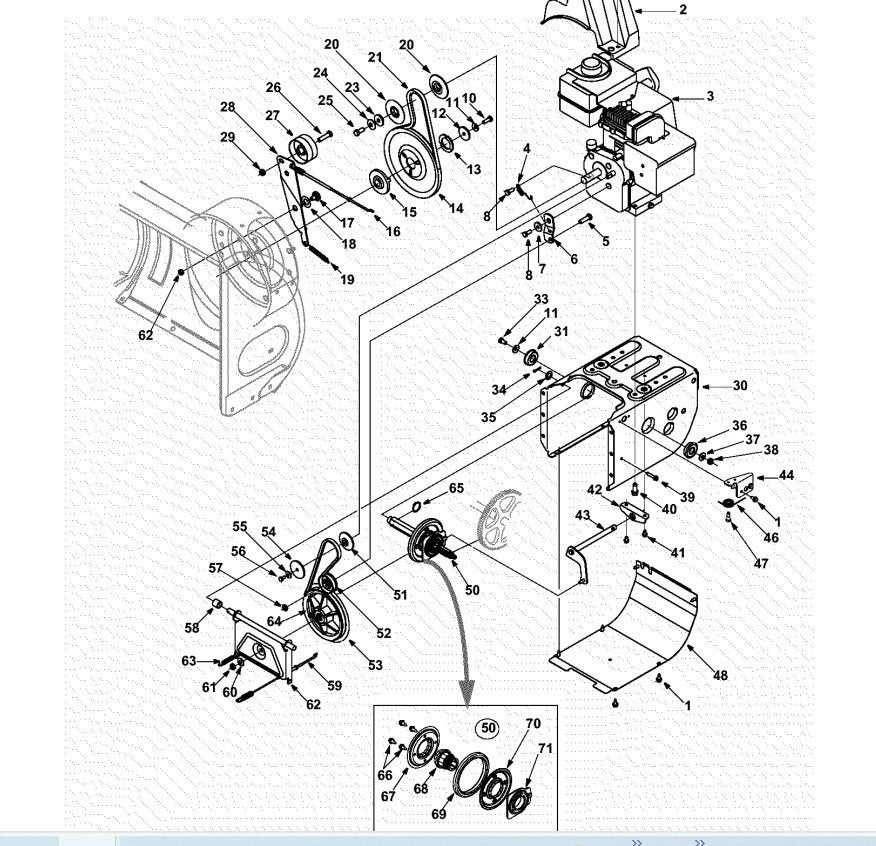

Components of an Auger System

An efficient drilling mechanism comprises several essential elements that work together to ensure optimal performance. Understanding these components can enhance the operation and maintenance of the system, allowing for improved productivity and longevity.

Main Elements

- Drill Bit: The cutting tool that penetrates the material.

- Shaft: Connects the drill bit to the power source, transmitting rotational force.

- Motor: Powers the entire assembly, driving the shaft and bit.

- Feed System: Controls the downward pressure applied to the drill bit during operation.

Additional Features

- Gearbox: Adjusts the speed and torque of the motor output.

- Housing: Encloses the internal components, protecting them from debris and damage.

- Stabilizers: Help maintain alignment and stability while drilling.

- Clutch: Prevents damage by disengaging the motor under excessive load.

Common Issues with Predator Parts

When utilizing equipment components, various challenges may arise that can hinder performance and efficiency. Understanding these typical problems can aid users in addressing issues promptly and maintaining optimal functionality.

Wear and Tear: Over time, components may experience degradation due to regular usage. This can lead to decreased performance, making it essential to monitor for signs of wear regularly.

Compatibility Concerns: Some individuals may face difficulties when trying to match replacement components with existing machinery. Ensuring compatibility is crucial to avoid further complications.

Assembly Errors: Incorrect assembly of various elements can result in malfunction. Following the manufacturer’s guidelines closely can help mitigate this risk.

Lubrication Issues: Insufficient lubrication can lead to increased friction and potential overheating. Regular maintenance and lubrication are vital for the longevity of the equipment.

Corrosion: Exposure to moisture and harsh conditions can result in corrosion, affecting the integrity of various elements. Protective measures should be taken to preserve the equipment.

Maintenance Tips for Longevity

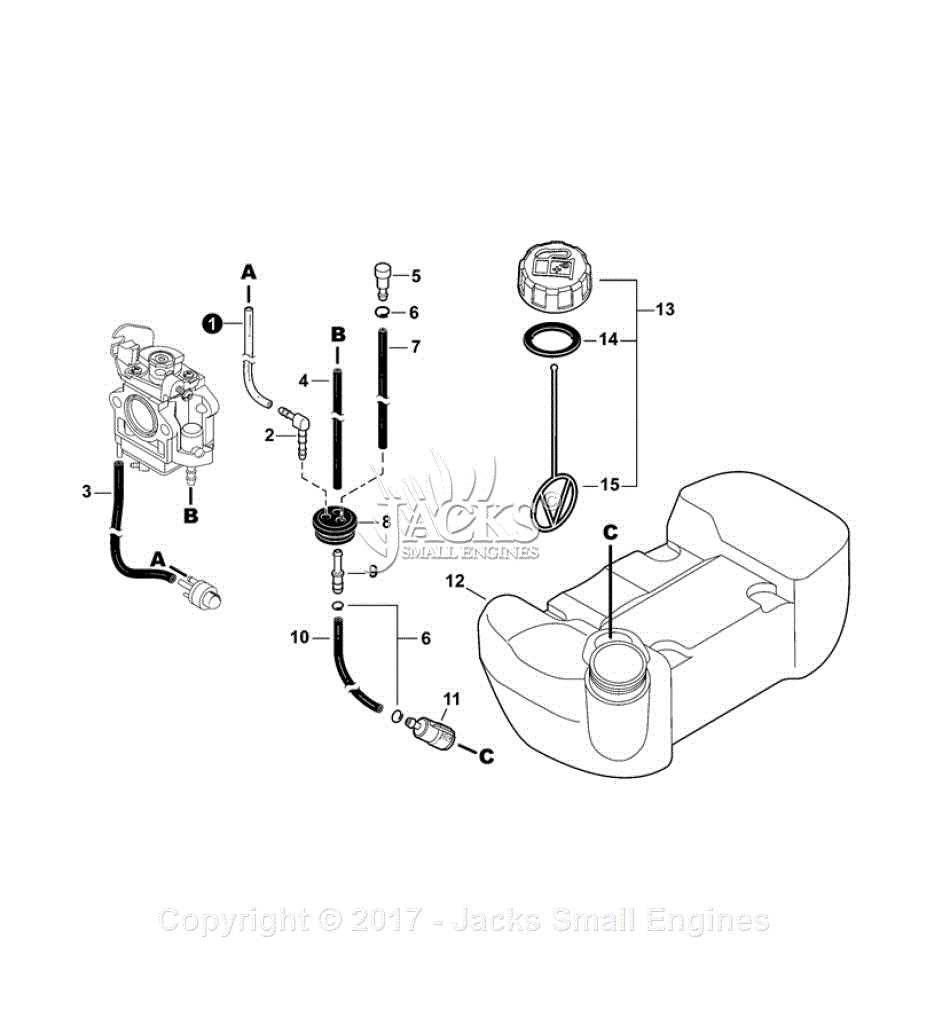

Ensuring the durability of your equipment requires consistent care and attention. Regular maintenance not only enhances performance but also extends the lifespan of essential components. By implementing a few simple practices, you can keep your machinery in optimal condition for years to come.

Regular Inspections

Routine checks are crucial for identifying wear and tear early. Examine all moving parts and connections for any signs of damage or excessive friction. Keeping an eye on these details allows for timely repairs, preventing costly breakdowns.

Proper Lubrication

Applying the right type and amount of lubricant is essential for smooth operation. Ensure that all relevant areas are adequately greased, as this minimizes friction and reduces the risk of overheating. Adhering to a lubrication schedule can significantly enhance the efficiency of your machinery.

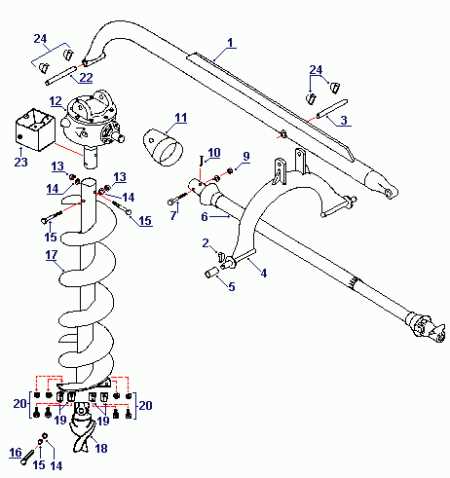

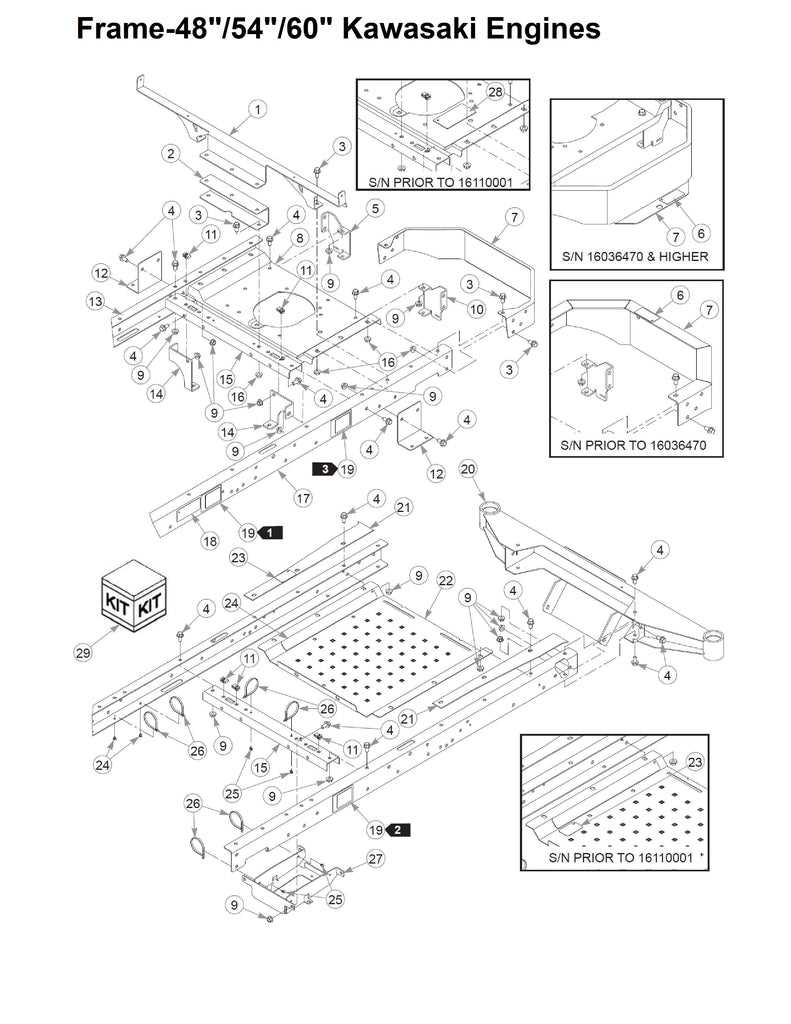

How to Identify Auger Parts

Understanding the components of a drilling tool is essential for effective operation and maintenance. By familiarizing yourself with the various elements, you can enhance the performance and longevity of your equipment. This section outlines key aspects of recognizing and distinguishing different elements associated with a drilling mechanism.

Key Components Overview

The main segments of a drilling instrument typically include the rotating section, the housing, and the cutting edge. Each component plays a crucial role in the overall functionality. The rotating section is responsible for creating motion, while the housing provides support and stability. The cutting edge interacts directly with the material, facilitating the boring process.

Identifying Specific Features

To accurately recognize these segments, pay attention to specific characteristics. The rotating section often features distinct markings or grooves that indicate its purpose. The housing may have reinforced areas to withstand stress, and the cutting edge is usually designed with sharp angles to maximize efficiency. Familiarity with these traits can greatly assist in troubleshooting and repairs.

Benefits of Quality Replacement Parts

Choosing high-quality alternatives for essential components can significantly enhance the performance and longevity of your equipment. Utilizing superior replacements ensures that the machinery operates smoothly, leading to increased efficiency and reduced downtime.

Some advantages of opting for quality alternatives include:

- Durability: Well-crafted replacements are designed to withstand wear and tear, providing a longer lifespan than cheaper options.

- Performance: Quality components contribute to optimal functioning, ensuring that the equipment operates at its best.

- Cost-effectiveness: Investing in reliable replacements can save money in the long run by reducing the frequency of repairs and replacements.

- Safety: High-quality parts are less likely to fail, minimizing the risk of accidents and injuries during operation.

- Compatibility: Quality alternatives are often designed to fit seamlessly with your equipment, ensuring better integration and function.

In summary, selecting top-notch replacements is crucial for maintaining the efficiency and safety of your machinery while also offering long-term financial benefits.

Where to Buy Predator Components

Finding the right components for your equipment can significantly enhance its performance and longevity. Various sources are available for acquiring high-quality replacements that meet specific needs.

- Online Retailers: Numerous e-commerce platforms offer a wide selection of replacement items. Popular sites include:

- Amazon

- eBay

- Specialty websites focused on outdoor tools

- Local Hardware Stores: Many local stores stock essential components. Check with:

- Home improvement chains

- Independent hardware shops

- Manufacturer’s Website: The official website of the equipment manufacturer often has a dedicated section for replacement items, ensuring compatibility and quality.

- Second-hand Marketplaces: Consider looking for pre-owned components in online classifieds or community groups.

By exploring these avenues, you can find the necessary components to keep your equipment in optimal condition.

DIY Repairs for Auger Users

For individuals working with drilling devices, performing maintenance and repairs can significantly enhance efficiency and prolong the lifespan of the equipment. Understanding common issues and basic troubleshooting techniques can empower users to address minor problems without professional assistance.

Here are some typical repairs that can be undertaken by users:

- Replacing Worn Components: Over time, certain elements may wear out due to regular use. Identifying these components and replacing them promptly can prevent further damage.

- Tightening Loose Fasteners: Regular inspection can reveal loose screws or bolts. Ensuring that all connections are secure can improve performance and safety.

- Cleaning and Lubricating: Keeping the machinery clean and well-lubricated can prevent rust and ensure smooth operation. Regular maintenance is key to avoiding costly repairs.

Implementing these simple repairs not only saves time and money but also fosters a deeper understanding of the equipment, making users more adept at handling challenges as they arise.