In the realm of automotive maintenance, the efficiency and functionality of specialized machinery are paramount. This article aims to explore the intricacies involved in the assembly and operation of crucial devices used in wheel servicing. By breaking down various components, readers will gain insight into how each element contributes to overall performance.

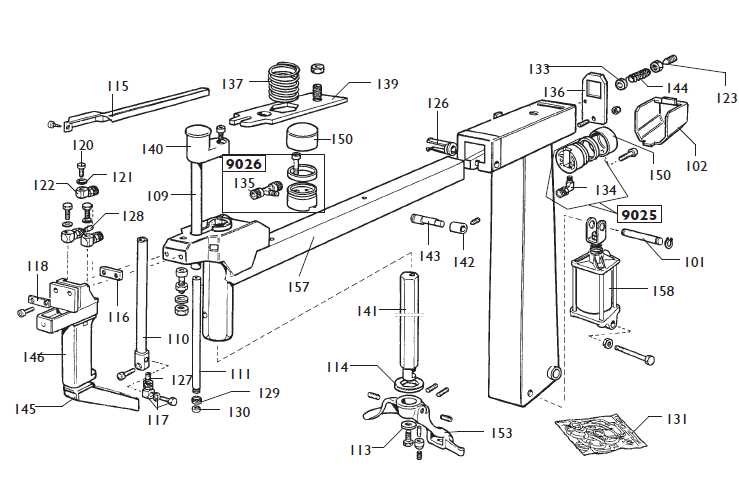

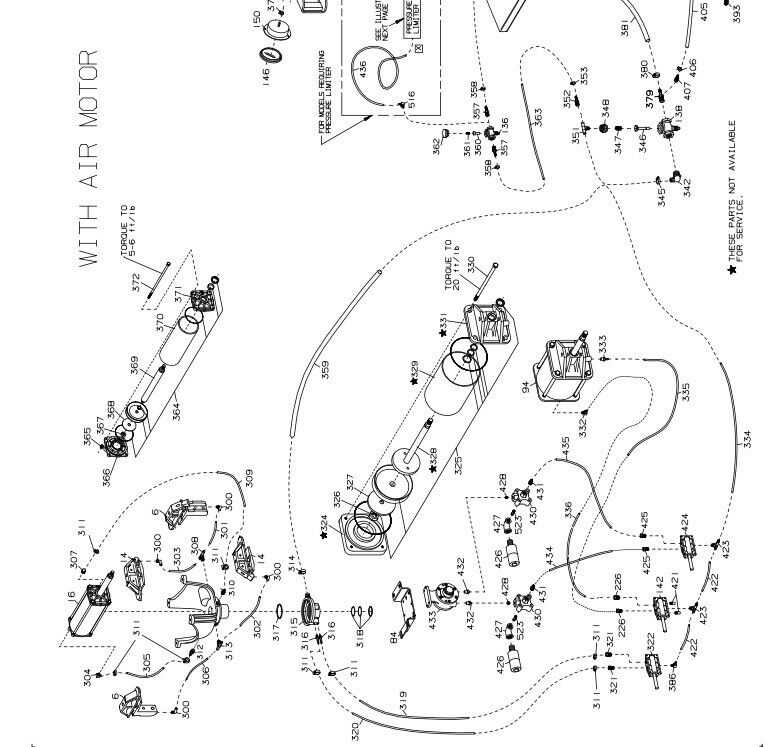

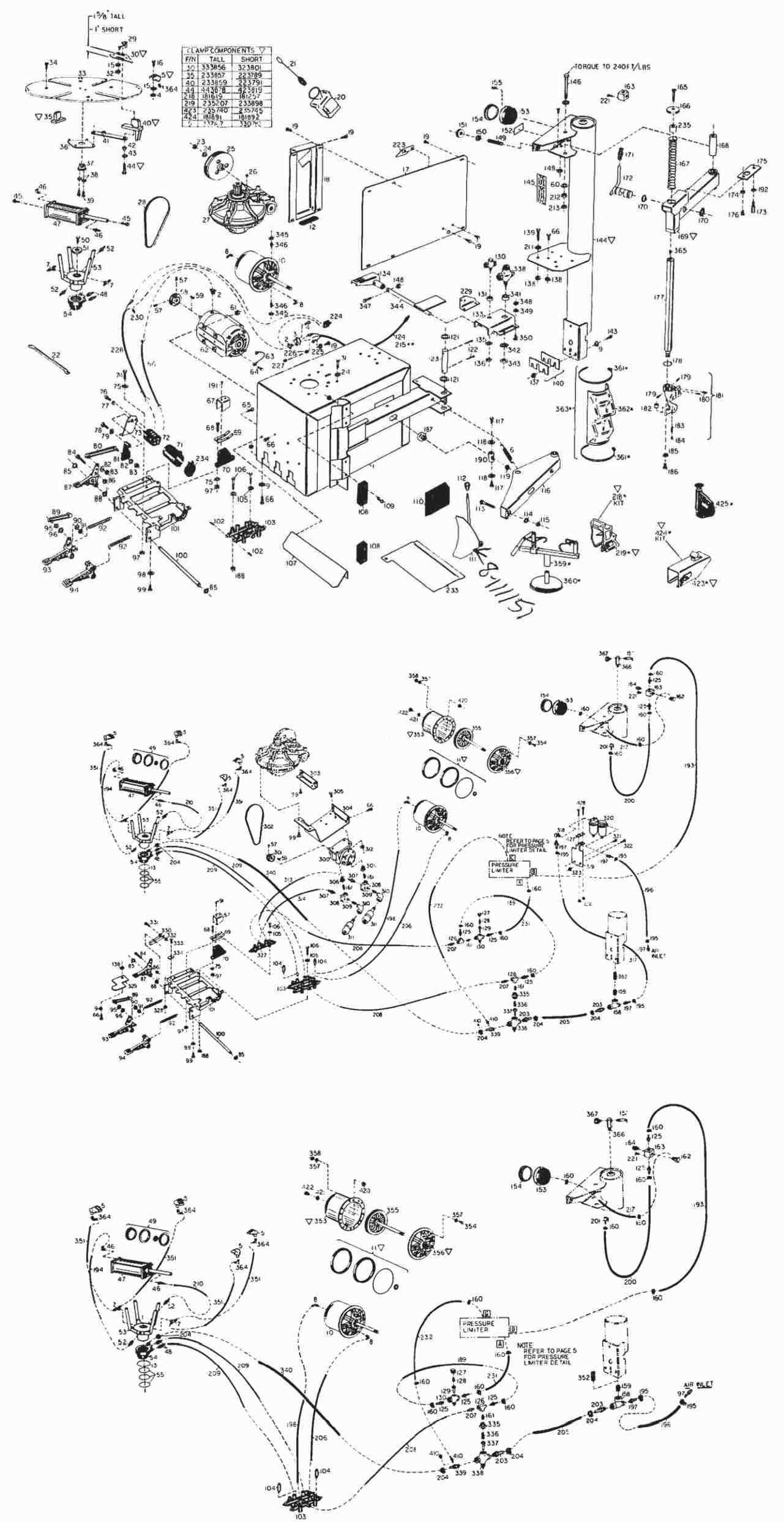

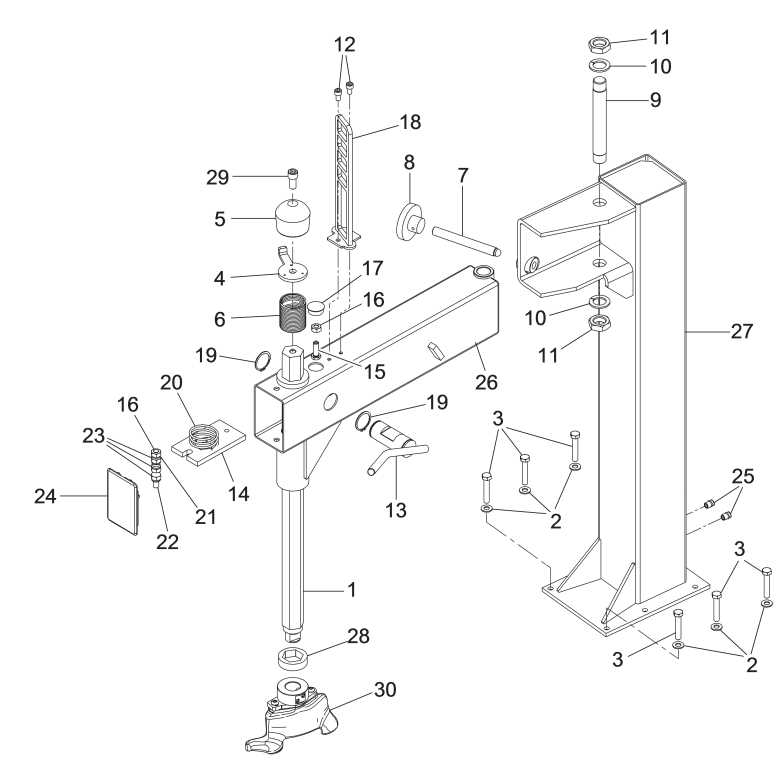

Visual aids play a significant role in comprehending complex machinery. Detailed representations allow for an enhanced understanding of the relationships between different elements. This exploration will delve into the unique configurations and mechanisms that ensure smooth operation.

Ultimately, mastering the layout of these essential tools not only fosters better maintenance practices but also equips users with the knowledge to troubleshoot issues effectively. Embracing this understanding leads to improved efficiency and longevity of the equipment.

Understanding Coats Tire Changer Basics

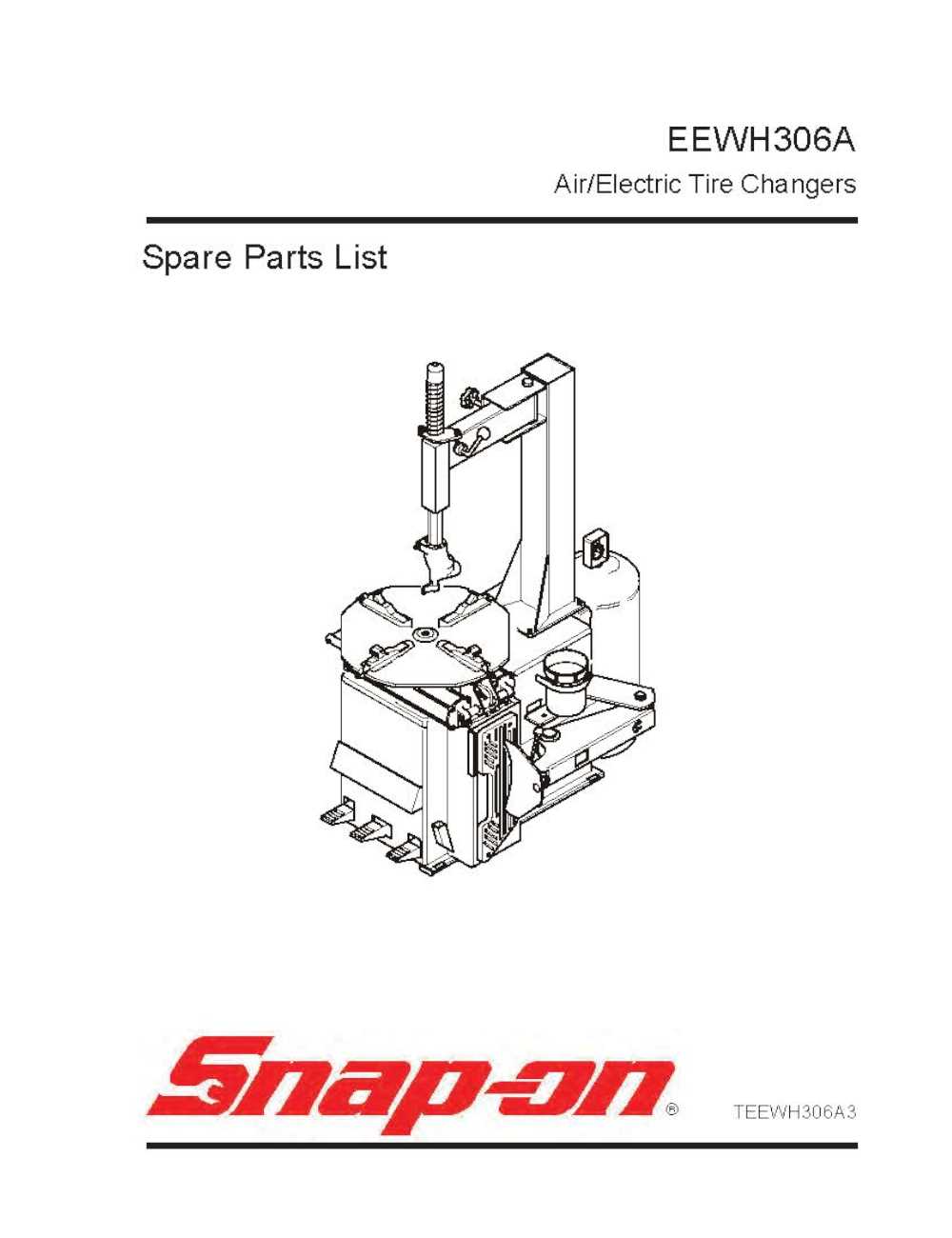

This section provides an overview of essential components and functionalities of a specific type of machinery used for wheel servicing. A thorough grasp of these elements is vital for effective operation and maintenance, ensuring efficiency and longevity.

Key Components

Every machine consists of several crucial elements that work in unison. Recognizing the role of each piece can enhance user experience and streamline processes. Operational efficiency largely depends on understanding how these components interact.

Maintenance Tips

Regular upkeep is critical to prevent breakdowns and prolong the life of the equipment. Routine checks and proper lubrication are fundamental practices that can significantly reduce wear and tear, ultimately leading to optimal performance.

Importance of Tire Changer Parts

The functionality of equipment designed for wheel maintenance hinges on its components. Each element plays a vital role in ensuring that the overall system operates smoothly and efficiently. Understanding the significance of these individual pieces is essential for optimal performance and longevity.

Efficiency is one of the primary benefits derived from well-functioning components. When each part works harmoniously, the process of replacing or servicing wheels becomes significantly faster and more reliable. This not only saves time but also enhances customer satisfaction.

Furthermore, durability is crucial. Quality components withstand the rigors of frequent use, reducing the likelihood of breakdowns and costly repairs. Investing in robust materials ensures that the equipment remains operational for years, minimizing disruptions in service.

Additionally, proper maintenance of these elements is essential for preventing wear and tear. Regular checks and timely replacements help maintain the integrity of the entire system. This proactive approach safeguards against unexpected failures that could hinder productivity.

Ultimately, understanding the significance of each component fosters better maintenance practices, leading to improved performance and reliability of the entire setup. A well-maintained machine translates to increased efficiency and a better experience for both operators and customers.

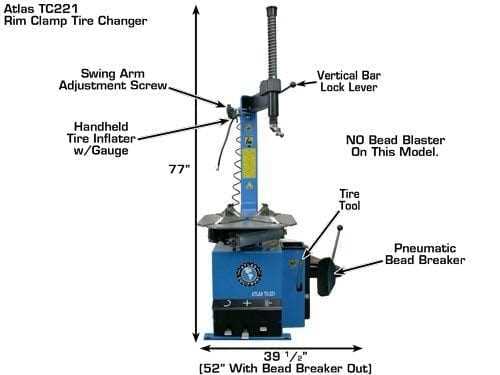

Key Components of Coats Machines

Understanding the essential elements of these specialized machines is crucial for their effective operation and maintenance. Each component plays a vital role in ensuring the smooth functionality and efficiency of the entire system.

- Base Structure: Provides stability and support for the entire unit, allowing for optimal performance during use.

- Mounting Arm: Facilitates the secure attachment of the wheel, ensuring precision and safety throughout the process.

- Drive Motor: Powers the mechanism, enabling various operations required for the task at hand.

- Control Panel: Allows the operator to manage settings and monitor the machine’s performance with ease.

- Bead Breaker: Assists in separating the tire from the rim, a critical step in the process.

By familiarizing yourself with these fundamental elements, you can enhance your understanding of the machine’s capabilities and troubleshooting techniques.

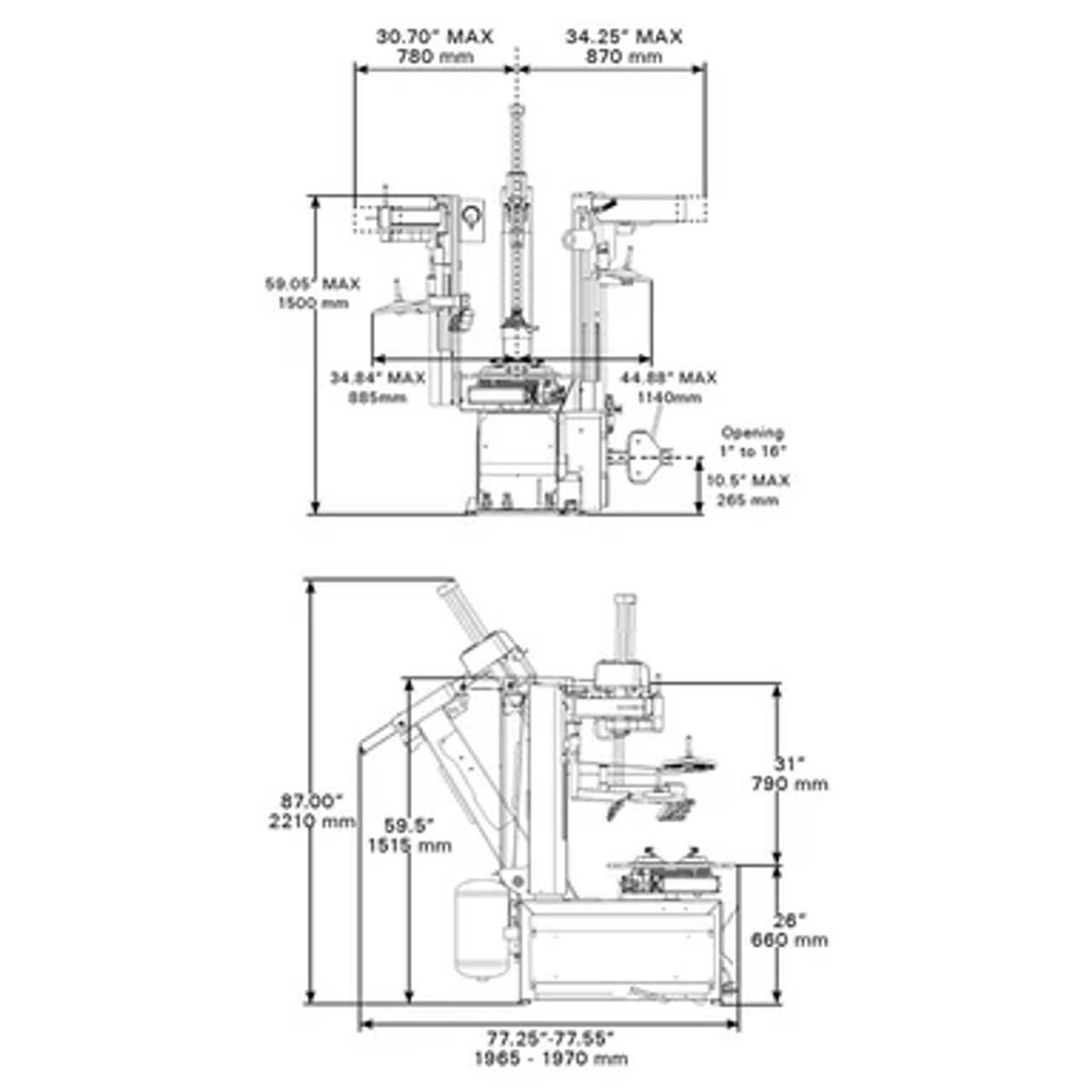

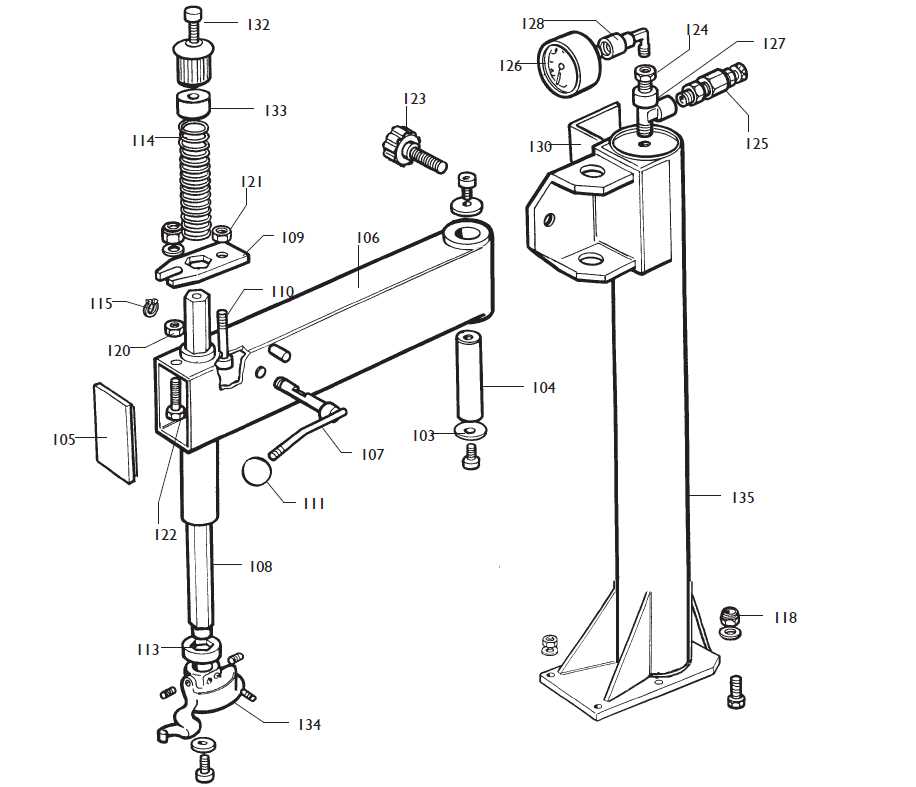

How to Read Parts Diagrams

Understanding technical illustrations is crucial for anyone working with machinery. These visual representations offer insights into component relationships, making maintenance and repairs more efficient. A well-read illustration can save time and reduce errors by clearly showing how each element fits together.

Key Elements of Technical Illustrations

Familiarizing yourself with the basic components of these visuals can greatly enhance your comprehension. Typically, you’ll find various symbols, labels, and numbers that correspond to specific pieces. Here are some common elements:

| Element | Description |

|---|---|

| Numbers | Identify specific components and often refer to a parts list. |

| Lines | Indicate connections and alignments between parts. |

| Labels | Provide additional information about functionality or specifications. |

Steps to Interpret the Illustrations

To effectively analyze these representations, follow a systematic approach. Start by reviewing the entire image to get an overview. Then, focus on individual components by referring to the associated numbers and labels. This method allows you to build a mental model of how everything integrates.

Common Issues and Solutions

In the world of equipment maintenance, encountering problems is a normal part of the process. Understanding typical challenges and their resolutions can significantly enhance efficiency and prolong the lifespan of machinery. This section highlights frequent concerns and practical solutions that users may face.

| Issue | Description | Solution |

|---|---|---|

| Inconsistent Performance | The machine may operate irregularly, affecting productivity. | Check for proper calibration and ensure all components are securely fastened. |

| Unusual Noises | Strange sounds during operation may indicate wear or misalignment. | Inspect bearings and drive systems, lubricate where necessary, and replace worn parts. |

| Slow Operation | A noticeable decrease in speed can hinder tasks. | Examine power supply and ensure all settings are correctly configured. Clean or replace filters if applicable. |

| Leakages | Fluid leaks can pose safety risks and reduce efficiency. | Identify the source of the leak, replace damaged seals or hoses, and check fluid levels regularly. |

| Electrical Issues | Problems with electrical components can disrupt functionality. | Inspect wiring for damage, ensure connections are secure, and test fuses or circuit breakers. |

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular care and attention. Implementing a few straightforward maintenance strategies can significantly extend its lifespan and enhance efficiency. This section outlines essential practices to keep your machinery in top condition.

Regular Inspections

Conducting periodic assessments is crucial. Check for any signs of wear, loose components, or debris accumulation. Addressing minor issues promptly can prevent major malfunctions in the future.

Proper Lubrication

Maintaining adequate lubrication levels is vital for smooth operation. Use high-quality oils and greases suitable for your machinery. Regularly scheduled lubrication helps minimize friction and reduces the risk of overheating.

Upgrading Your Tire Changer

Enhancing your equipment can significantly improve efficiency and performance. By integrating the latest technology and features, you can ensure a smoother operation and reduce wear on your machinery. Upgrading components not only extends the life of the machine but also enhances safety and accuracy in your processes.

| Component | Upgrade Option | Benefits |

|---|---|---|

| Motor | High-torque model | Faster operation, better power management |

| Control System | Digital interface | User-friendly, enhanced diagnostics |

| Clamping System | Hydraulic upgrade | Improved grip, reduced manual effort |

| Wheel Lift | Automatic lift | Increased safety, reduced physical strain |

Where to Find Replacement Parts

Locating components for machinery can often feel daunting, yet several reliable avenues exist for sourcing these essentials. Whether you’re seeking original equipment or aftermarket solutions, understanding where to look can streamline the process.

| Source | Description |

|---|---|

| Manufacturer’s Website | The most direct option, typically offering genuine components with detailed information. |

| Authorized Distributors | These suppliers specialize in specific brands and provide authentic items along with expert advice. |

| Online Marketplaces | Platforms such as eBay or Amazon can feature a range of products, but ensure the credibility of the seller. |

| Local Repair Shops | Often have inventory or can order specific items, and their expertise may help in selecting the right component. |

| Industry Trade Shows | A great opportunity to connect with various suppliers and discover new products or solutions. |

Safety Practices During Tire Changing

Ensuring a secure environment while replacing wheels is crucial for preventing accidents and injuries. Adopting specific safety measures not only protects the individual performing the task but also safeguards the surrounding area and equipment.

| Practice | Description |

|---|---|

| Wear Protective Gear | Utilize gloves, goggles, and steel-toed boots to shield against potential hazards. |

| Inspect Equipment | Check all tools and machinery for defects before use to ensure proper functionality. |

| Maintain Stability | Ensure that vehicles are securely elevated on a level surface to prevent movement. |

| Keep Area Clear | Maintain a tidy workspace free of clutter to minimize trip hazards. |

| Follow Instructions | Adhere strictly to manufacturer guidelines for equipment operation and maintenance. |