In the realm of industrial equipment, a thorough grasp of the various elements that contribute to its operation is essential for efficiency and safety. This section aims to unravel the intricate details of machinery assemblies, focusing on how each component interacts within the system.

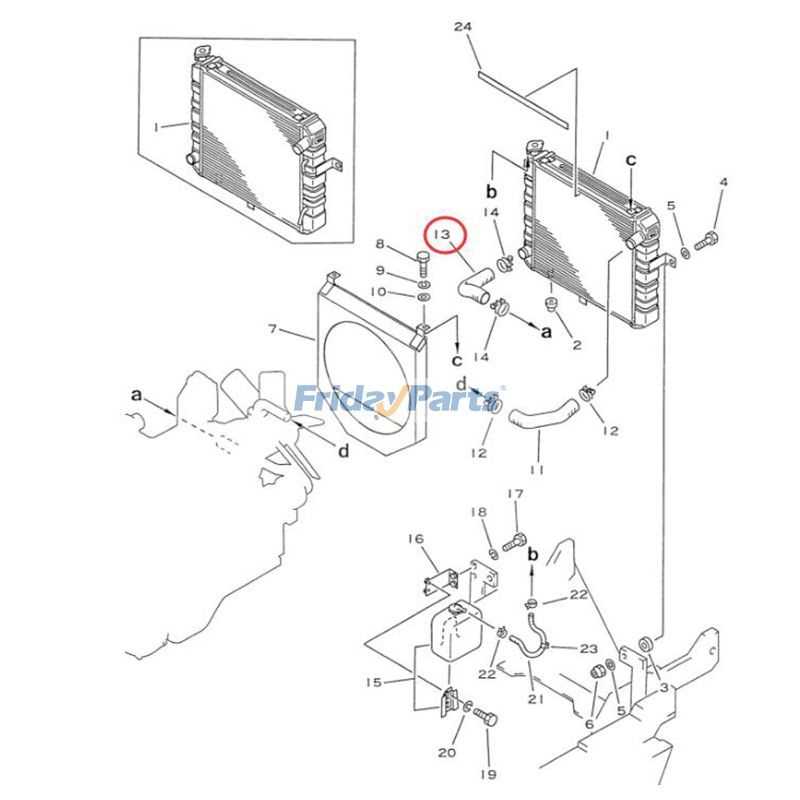

With the complexity of these machines, visual aids can significantly enhance comprehension. Illustrations showcasing the arrangement and function of each segment allow users to navigate through the mechanics with greater ease, ultimately leading to improved maintenance and performance.

By exploring these visual representations, one can delve into the specifics of each unit, understanding not just their individual roles but also the ultimate synergy that enables the equipment to function effectively. Such insights empower operators and technicians alike, fostering a more knowledgeable and capable workforce.

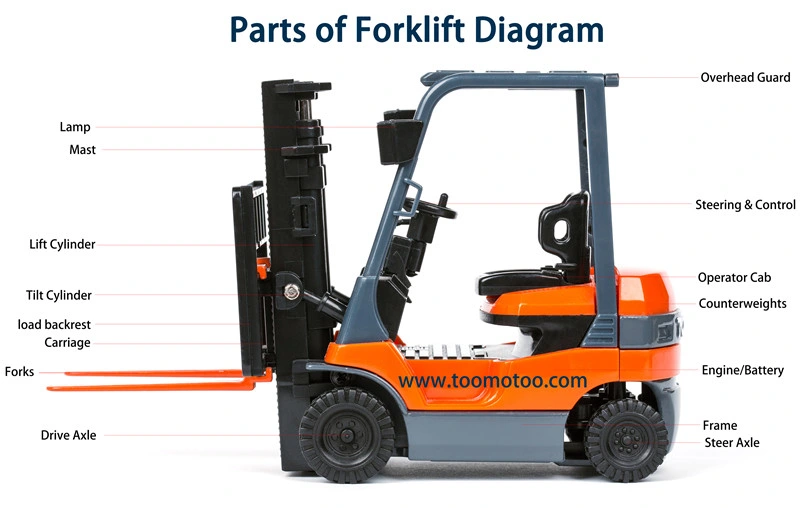

Understanding Komatsu Forklift Components

Grasping the intricacies of industrial lifting machinery is crucial for effective operation and maintenance. Each element plays a vital role in the overall functionality, ensuring seamless performance in various tasks. Familiarity with these components enhances both safety and efficiency.

Key elements to consider include:

- Power Source: This could be electric or combustion-based, providing the necessary energy for operation.

- Chassis: The framework that supports all other elements, ensuring stability and durability.

- Lifting Mechanism: Responsible for raising and lowering loads, typically involving hydraulic systems.

- Steering System: Allows maneuverability, crucial for navigating tight spaces.

- Safety Features: Essential for protecting operators and surrounding personnel, including alarms and stability controls.

Understanding the function and interaction of these components is essential for troubleshooting and optimizing performance. Regular inspections and maintenance of each section contribute significantly to the longevity of the equipment.

- Regularly review the power source for efficiency.

- Inspect the chassis for signs of wear or damage.

- Ensure the lifting mechanism is properly calibrated.

- Test the steering system for responsiveness.

- Check safety features to ensure they are operational.

By prioritizing knowledge of these fundamental elements, operators can significantly enhance their skills and contribute to a safer, more productive work environment.

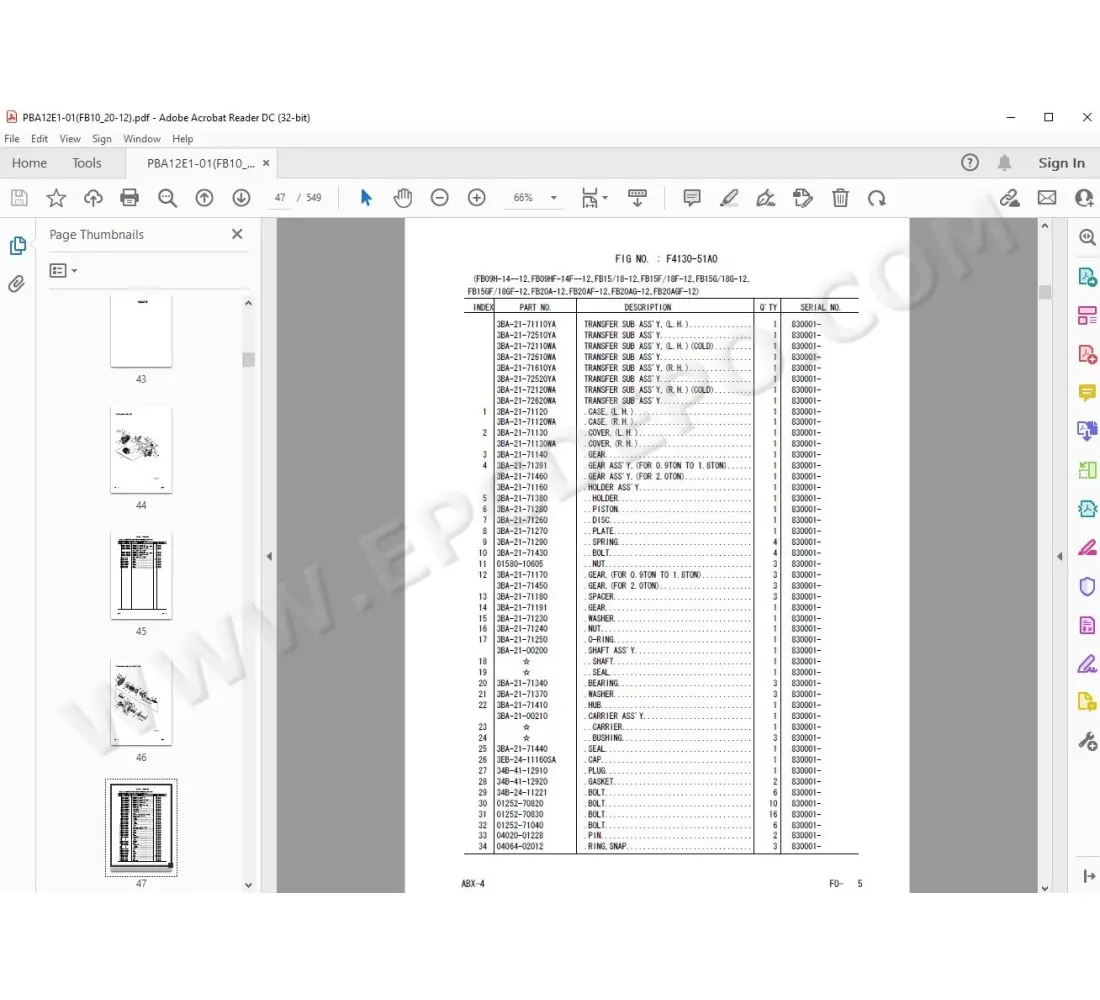

Importance of Accurate Parts Diagrams

Clear and precise visual representations of components are crucial for effective maintenance and repair. These illustrations serve as invaluable resources for technicians, enabling them to identify individual elements and understand their interconnections. When details are accurate, the likelihood of successful repairs increases significantly, minimizing the risk of errors that can lead to further complications.

Efficiency is another key benefit of having well-crafted visuals. When workers can easily reference specific components, they can expedite the diagnostic process and reduce downtime. This efficiency not only saves time but also enhances overall productivity, allowing operations to run smoothly.

Furthermore, training and onboarding new personnel become more manageable with reliable visual aids. Having detailed representations helps newcomers quickly familiarize themselves with the machinery, fostering a deeper understanding and confidence in their tasks. As a result, the entire team benefits from improved knowledge and skill sets.

In summary, accurate representations of components are essential for effective maintenance, efficiency, and successful training. They empower technicians to perform their roles competently, ultimately contributing to the longevity and reliability of equipment.

Common Issues with Forklift Parts

In the realm of material handling equipment, various components can encounter problems that hinder performance and safety. Understanding these common challenges is crucial for maintenance and effective operation. From wear and tear to operational inefficiencies, several factors can contribute to the deterioration of essential machinery elements.

| Issue | Description | Possible Solutions |

|---|---|---|

| Hydraulic Leaks | Fluid escaping from hoses or fittings can lead to reduced lifting capabilities. | Inspect and replace damaged hoses; ensure proper sealing. |

| Battery Failure | Inconsistent power supply can result in unreliable operation. | Regularly check battery health; replace if necessary. |

| Tire Wear | Degraded tires can affect stability and traction. | Monitor tire condition; replace worn tires promptly. |

| Electrical Issues | Faulty wiring or connectors may lead to malfunctions. | Conduct routine electrical inspections; repair or replace damaged components. |

| Engine Overheating | Excessive heat can cause engine failure and operational downtime. | Ensure proper cooling system function; check coolant levels regularly. |

How to Read Parts Diagrams

Understanding visual representations of components is crucial for efficient maintenance and repair tasks. These illustrations provide a comprehensive overview of each element and how they fit together, facilitating easier identification and replacement.

To effectively interpret these illustrations, follow these key steps:

- Familiarize Yourself with Symbols: Each representation utilizes specific icons to denote various elements. Take time to learn what each symbol represents.

- Identify the Legend: Most illustrations include a legend that explains the symbols and lines used. Refer to this section often for clarity.

- Follow the Assembly Order: Many visuals depict components in the sequence they should be assembled. Pay attention to any directional arrows indicating the assembly process.

- Note the Parts Numbers: Each element is usually assigned a unique identifier. Use these numbers when ordering replacements to ensure compatibility.

- Cross-Reference with Manuals: Combine your understanding of the visuals with manufacturer manuals for additional context and detailed instructions.

By mastering these techniques, you can enhance your ability to interpret visual component representations, ultimately leading to more effective maintenance and repair processes.

Choosing Quality Replacement Parts

Selecting high-quality components is essential for maintaining the efficiency and longevity of any machinery. The right replacements not only ensure optimal performance but also enhance safety and reliability. As machinery ages, it becomes crucial to identify trustworthy sources that offer durable alternatives to original items.

When searching for substitutes, prioritize reputable suppliers known for their commitment to excellence. Investigate their product offerings and read reviews to gauge the experiences of other users. Additionally, consider the materials used in manufacturing the replacements, as superior materials often lead to better durability and performance.

It’s also wise to evaluate warranties and guarantees provided by suppliers. A solid warranty reflects confidence in the product’s quality and can offer peace of mind. Moreover, consulting with industry experts can provide insights into which components are most reliable and suitable for your specific needs.

Maintenance Tips for Forklift Longevity

Ensuring the extended life of industrial equipment requires a proactive approach to upkeep and care. By implementing effective maintenance strategies, operators can minimize downtime, enhance performance, and significantly extend the service life of their machinery.

Regular Inspections

Conducting routine inspections is crucial for identifying potential issues before they escalate. Consider the following practices:

- Check fluid levels, including hydraulic and engine oils.

- Inspect tires for wear and proper inflation.

- Examine the battery condition and clean terminals.

- Look for signs of leaks or corrosion on components.

Scheduled Maintenance

Establishing a regular maintenance schedule can prevent unexpected breakdowns. Key elements to include are:

- Follow manufacturer recommendations for servicing intervals.

- Replace filters and fluids as specified.

- Lubricate moving parts to reduce friction and wear.

- Test and calibrate safety features periodically.

By adhering to these maintenance tips, operators can ensure their equipment remains in optimal condition, promoting efficiency and safety in daily operations.

Finding Genuine Komatsu Parts Online

Locating authentic components for heavy machinery can be a challenging task, especially when reliability and performance are critical. The online marketplace offers a plethora of options, but discerning genuine items from counterfeit ones is essential for ensuring optimal functionality and longevity of your equipment.

To streamline your search, consider the following steps:

- Research Reputable Suppliers: Start by identifying well-known retailers and distributors who specialize in machinery components.

- Check Reviews: Look for customer feedback and ratings to gauge the trustworthiness of the supplier.

- Verify Authenticity: Ensure that the seller provides information about the origin and certification of the components.

Moreover, using specific search terms related to your equipment can help narrow down your results. This approach can lead to more accurate findings.

It’s also beneficial to:

- Utilize manufacturer websites, which often have sections dedicated to genuine items.

- Join online forums and communities where enthusiasts and professionals share insights and recommendations.

- Consider contacting customer service representatives to ask about authenticity guarantees.

By following these guidelines, you can enhance your chances of acquiring quality components that meet your machinery’s needs effectively.

Forklift Parts Identification Techniques

Identifying components of industrial machinery can be crucial for maintenance and repair tasks. Effective techniques can help operators and technicians ensure that the right elements are utilized, enhancing the longevity and performance of the equipment. Understanding various methods for recognizing and categorizing these elements is essential for anyone involved in machinery upkeep.

Visual Inspection: A thorough visual assessment is often the first step. By familiarizing oneself with the appearance and characteristics of each component, individuals can quickly identify what they need. Attention to detail is key; noting variations in color, size, and shape can significantly aid in recognition.

Reference Manuals: Utilizing comprehensive guides or reference materials can streamline the identification process. These documents often contain illustrations and descriptions that can serve as a valuable resource for distinguishing between similar-looking elements.

Manufacturer Codes: Many components feature unique identification codes or part numbers. These identifiers can be crucial in ensuring that the correct replacement is sourced. Keeping a log of these codes can facilitate efficient procurement and reduce the likelihood of errors.

Online Resources: The internet offers a wealth of information, including forums and websites dedicated to machinery support. Engaging with these platforms can provide insights from other users and industry experts, further aiding in the identification process.

Consultation with Experts: When in doubt, reaching out to experienced professionals can save time and prevent costly mistakes. Their expertise can provide clarity on complex or obscure components, ensuring that maintenance is performed accurately.