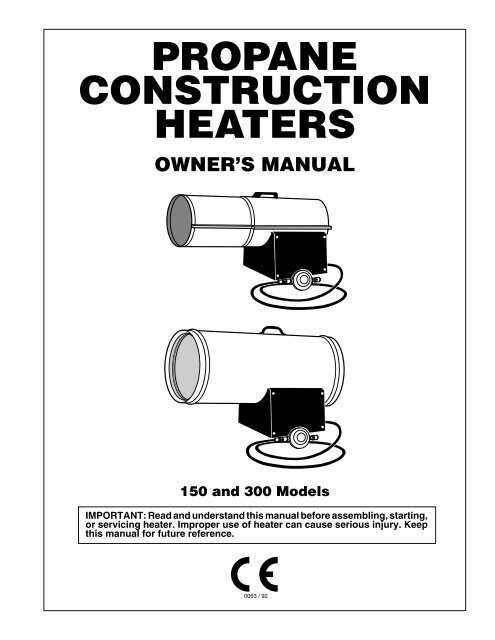

Understanding the various elements that make up a device designed for heating is crucial for both proper maintenance and effective operation. Each unit is composed of several essential elements, each playing a specific role in ensuring the system functions as intended. By familiarizing yourself with these individual elements, you can gain better insight into how the entire system works together seamlessly.

The arrangement of these components can vary depending on the model and manufacturer, but the fundamental elements remain largely consistent. Knowing how these parts interact can help you troubleshoot any issues that may arise, ensuring safe and efficient performance.

This guide will walk you through the main features of the system, detailing their specific roles and how they contribute to the overall operation. Whether you are performing routine checks or trying to resolve a malfunction, having a clear understanding of these elements will make the task significantly easier.

Understanding Propane Heater Components

To efficiently operate any fuel-powered device for warmth, it’s essential to recognize the key elements that ensure safe and consistent performance. Each mechanism, regardless of size or complexity, is built from interconnected units that work together, guiding the overall functionality. Understanding how these units interact is crucial for maintenance, troubleshooting, and optimizing efficiency.

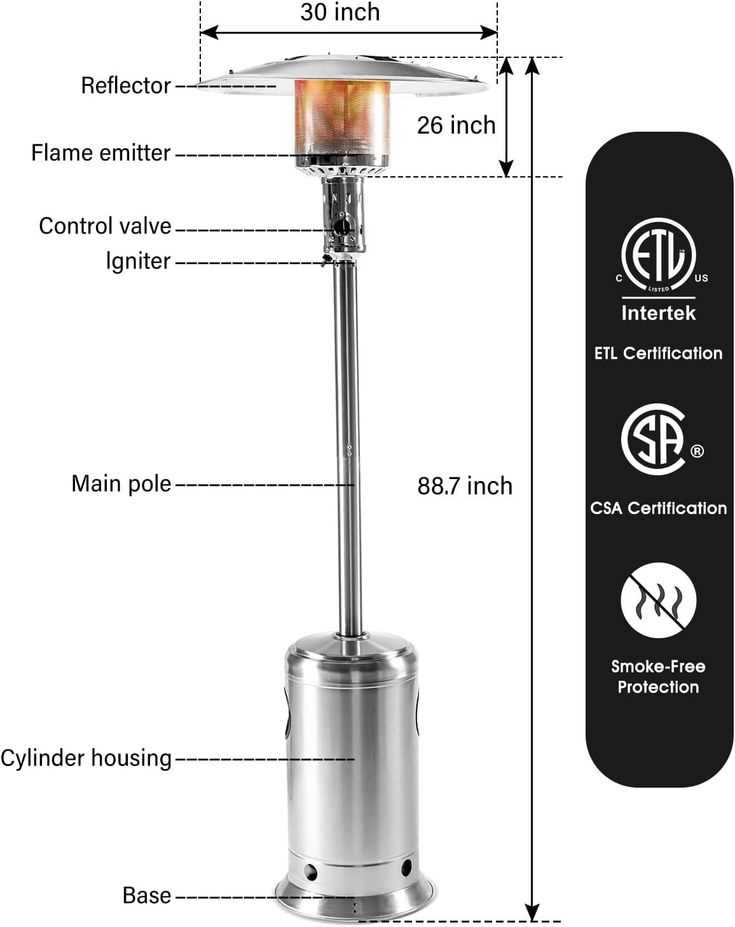

Main Fuel Control

The primary control system regulates the flow of gas to the device. This component is responsible for adjusting the amount of energy released, ensuring that the desired level of heat is reached without wasting fuel. Maintaining proper control settings is critical to avoid excessive consumption and maintain operational safety.

Ignition and Burners

At the heart of the heating process are the ignition mechanism and burners, which work together to ignite and sustain the flame. The ignition unit initiates the process, while the burners distribute heat evenly across the surface. Ensuring both are clean and functional helps in achieving optimal performance

Main Parts of a Propane Heater

Understanding the key components of a gas-powered warming device is essential for proper use and maintenance. These systems are composed of several interconnected elements that work together to ensure safe and efficient operation. Each piece plays a specific role, from fuel supply to heat distribution, creating a reliable source of warmth for various settings.

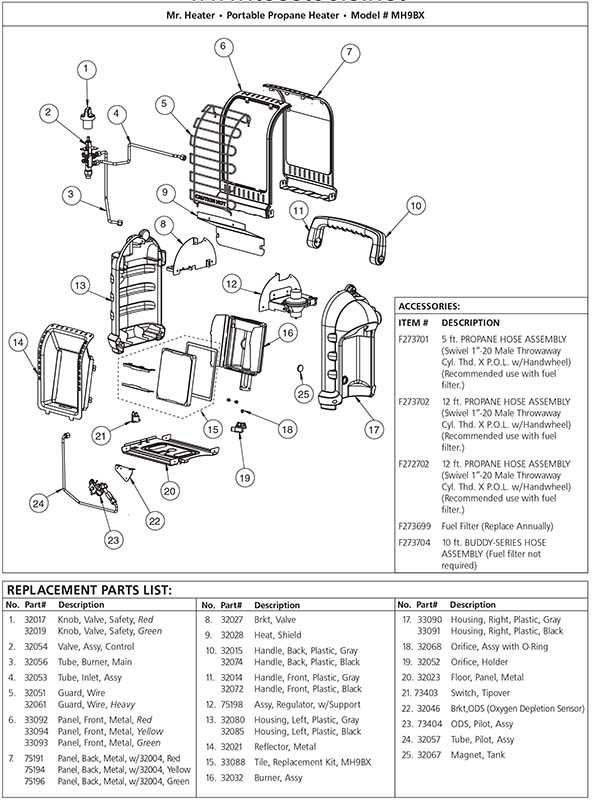

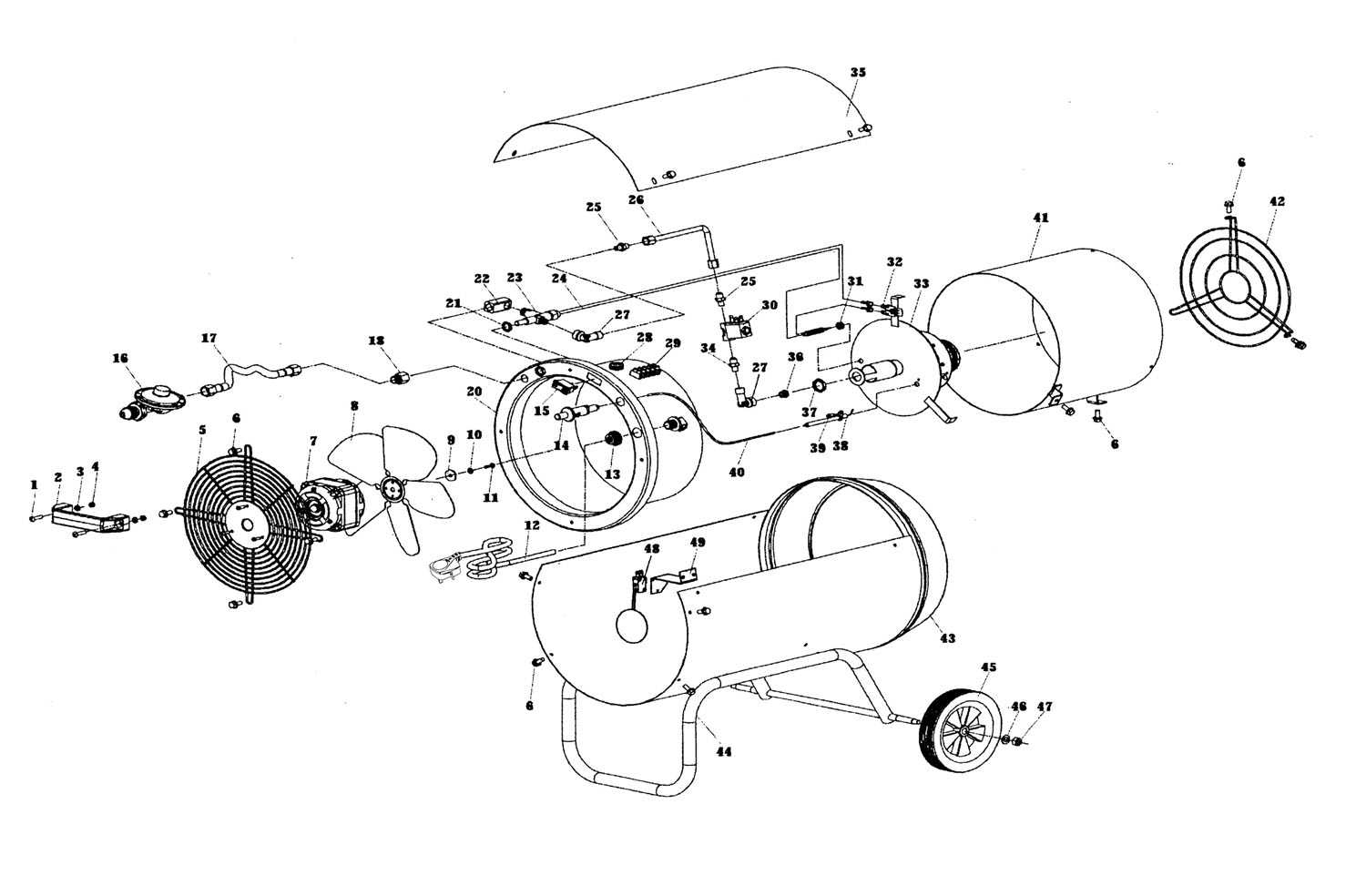

Fuel Delivery System

- Valve: Controls the flow of gas into the device, allowing for adjustable heat output.

- Regulator: Maintains consistent pressure within the system to ensure smooth fuel delivery.

- Hose: Connects the fuel source to the unit, facilitating the safe transfer of gas.

Ignition and Heating Mechanism

- Igniter: Sparks the fuel mixture to initiate the combustion process.

- Burner: Where the combustion oc

How the Gas Valve Operates

The gas valve is a key component that controls the flow of fuel into the system. It ensures that fuel is delivered safely and efficiently when needed. Understanding its basic function is important for ensuring proper operation of any fuel-powered device. The valve mechanism itself is designed to regulate and manage fuel supply based on specific conditions.

Opening and Closing Mechanism

When activated, the valve opens to allow fuel to flow through. This process is triggered by a signal from a control system or a manual input. The valve remains open as long as the conditions for fuel delivery are met. Once these conditions change, the valve automatically closes to stop the flow, ensuring safety and efficiency.

- The valve opens in response to a control signal.

- Fuel flows through the system when the valve is open.

- The valve closes when the desired conditions are met or no longer required.

Safety Features

The valve incorporates several safety features to prevent malfunctions. These can include automatic shutoff mechanisms in case of pressure imbalances or if no ignition occurs. The goal is to prevent any risks associated with uncontrolled fuel flow.

- Shuts off in case of a malfunction.

- Prevents fuel flow when ignition fails.

- Reducing fuel consumption

- Lowering operational costs

- Improving system reliability

- Industrial processes where heat recovery is essential

- HVAC systems for climate control

- Power generation facilities to optimize output

Ignition System and Its Role

The ignition system is a crucial component in ensuring the effective operation of various devices that rely on combustion for energy generation. It is responsible for initiating the process that transforms stored fuel into usable power, driving the entire system. Without proper activation, the device would fail to function, as the key process that starts the energy cycle would not occur.

Key Functions of the Ignition System

The ignition mechanism serves several vital functions, primarily ensuring a reliable and safe spark or activation at the right moment. This initial action triggers the combustion cycle, making it possible to generate consistent power. The system is designed to regulate the precise timing and intensity of the ignition, which is essential for smooth operation and efficiency.

Importance of Maintenance

Maintaining the ignition system is critical for long-term performance and safety. Over time, components can wear down, leading to delays or failures in the ignition process. Regular inspection and servicing can prevent malfunctions, ensuring that the system remains dependable and operates as intended.

Burner Mechanism in Propane Heaters

The operation of a burner system is critical to delivering warmth effectively. This section outlines the core function and structure of the combustion mechanism, which plays a key role in converting fuel into heat energy. The focus here is on how the system initiates and sustains the flame, ensuring efficient energy output. Understanding this component is crucial for maintaining performance and safety.

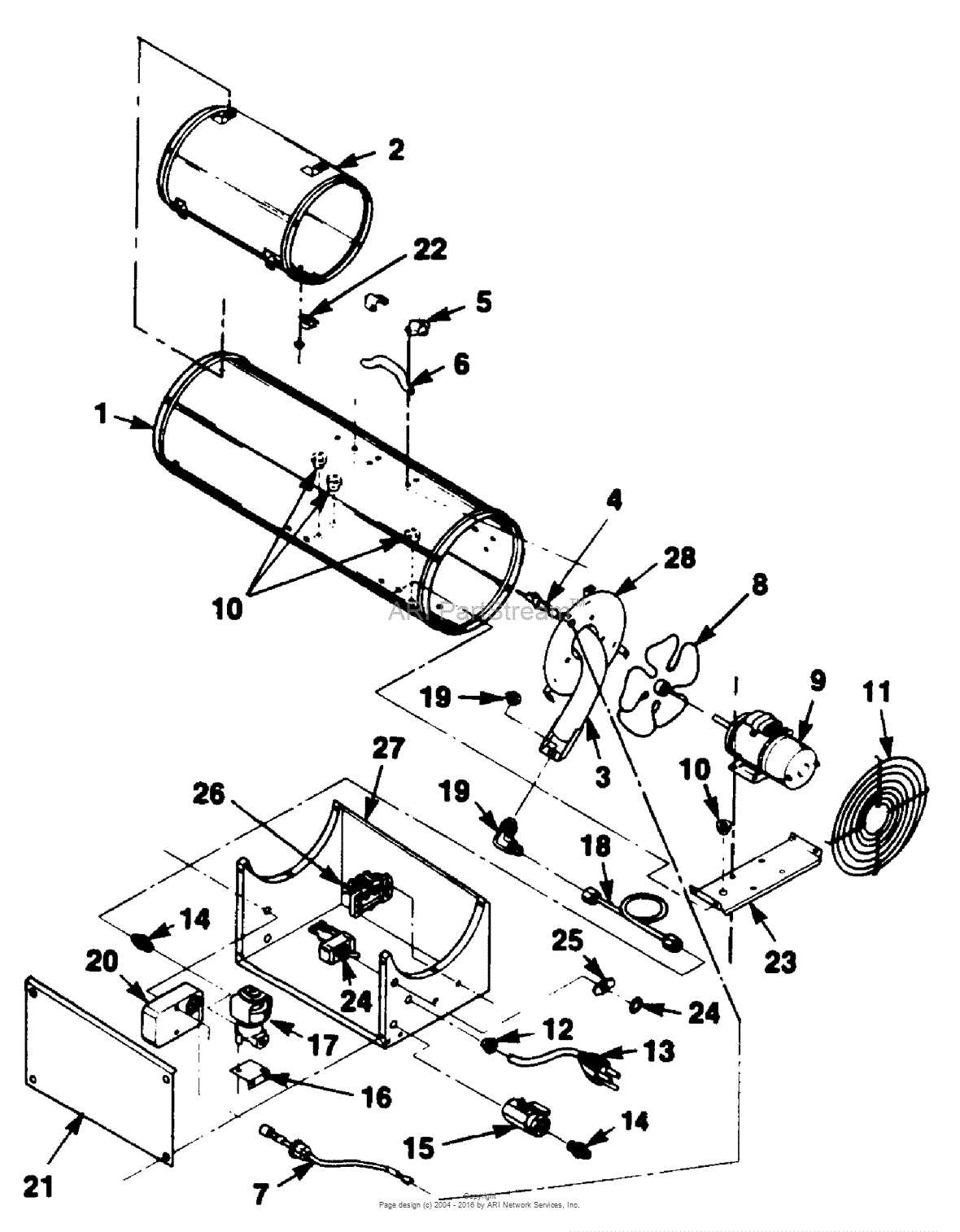

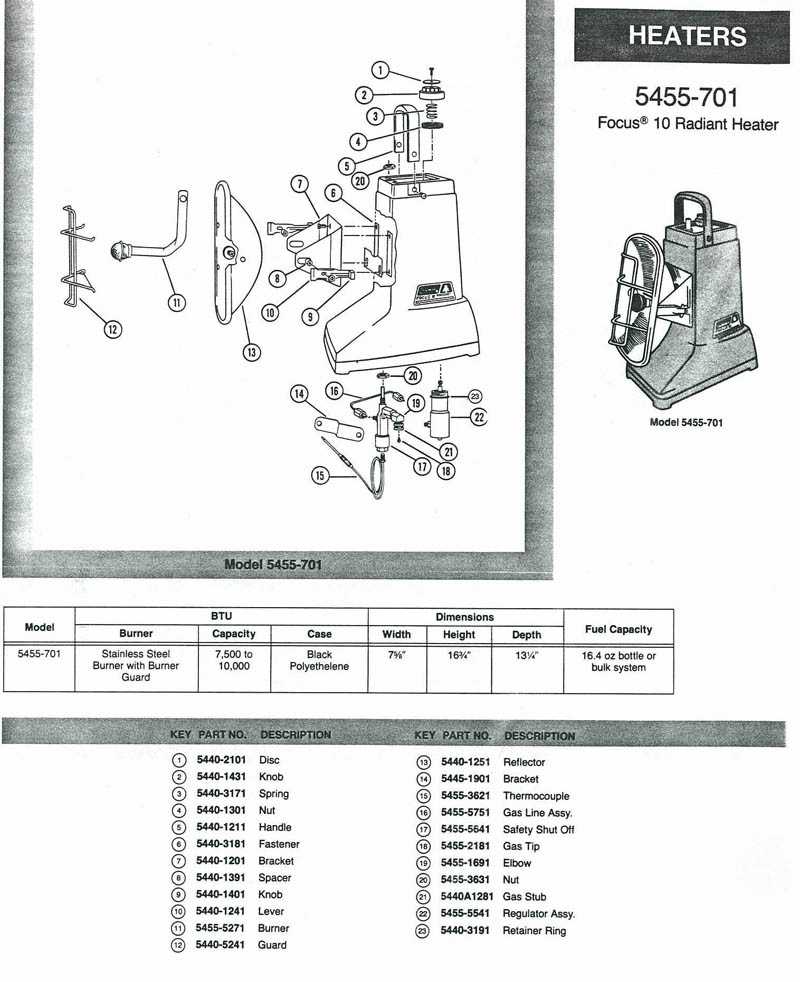

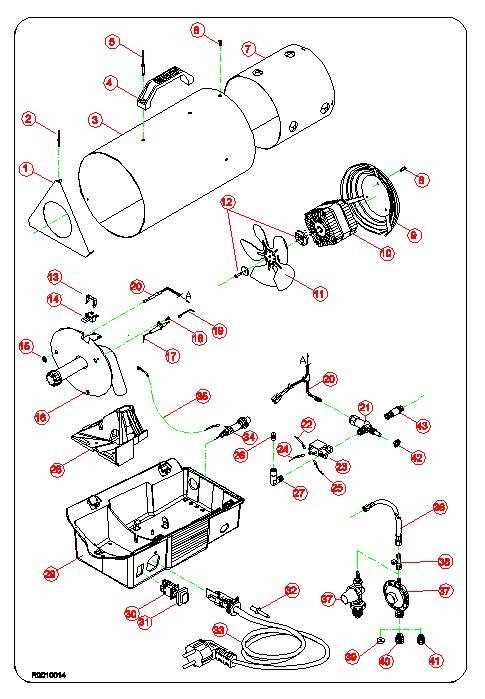

Components and Functionality

The burner system is comprised of various interconnected elements that work together to regulate airflow and fuel distribution. These components ensure that the combustion process remains stable and efficient. The ignition system, valves, and nozzles form the primary structure, each contributing to the precise control of heat production.

Efficiency and Safety Features

In addition to controlling heat output, the system incorporates various safety features. These include mechanisms to monitor flame presence, manage excess gas flow, and prevent overheating. Maintaining these features is essential for ensuring long-term operation and preventing accidents.

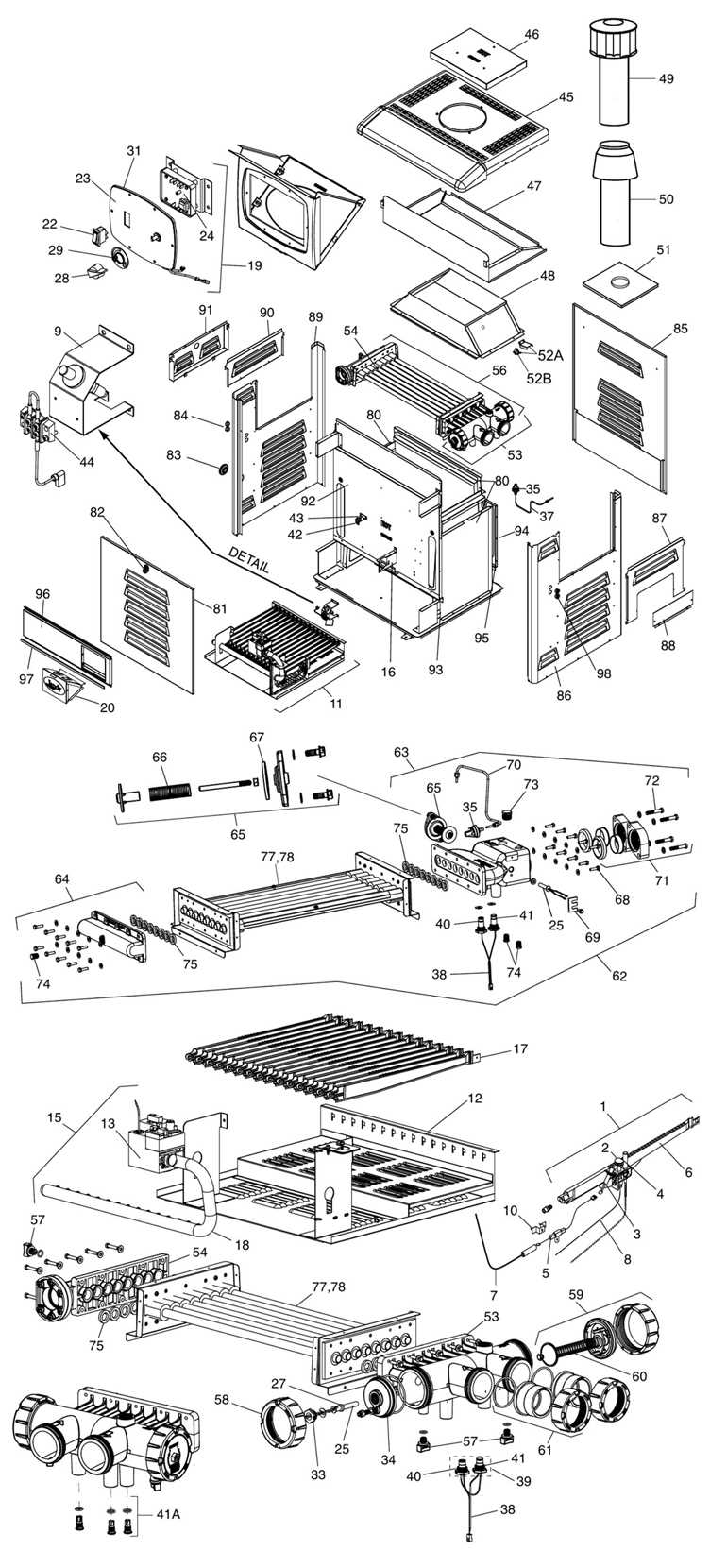

Component Function Ignition System Initiates the combustion process. Valve Importance of Heat Exchangers

Heat exchangers play a crucial role in the efficient transfer of thermal energy between two or more fluids. They are designed to maximize contact between the fluids while minimizing energy loss, ensuring optimal performance in various applications.

Efficiency and Performance

One of the primary benefits of using heat exchangers is their ability to enhance energy efficiency. By facilitating effective thermal transfer, they help in:

Applications Across Industries

Heat exchangers are widely utilized in numerous fields, each benefiting from their unique capabilities. Common applications include:

In summary, the integration of heat exchangers into various systems significantly contributes to enhanced performance and energy conservation, making them indispensable components in modern technology.

How Safety Features Work

Understanding the functionality of safety mechanisms in heating appliances is crucial for ensuring user protection. These mechanisms are designed to prevent hazardous situations and promote safe operation. By incorporating various technologies, they help manage potential risks associated with heat generation.

Key Mechanisms

Several essential features contribute to the overall safety of these systems. Automatic shut-off valves, temperature sensors, and flame detection devices play vital roles in monitoring and controlling operation. These components work together to create a secure environment, minimizing the likelihood of accidents.

Functionality Overview

The primary function of safety features is to detect anomalies and respond accordingly. For instance, if a specific temperature threshold is exceeded, sensors can trigger an automatic shut-off, ceasing operation immediately. Similarly, flame detection devices ensure that if the flame is extinguished, the gas supply is cut off, preventing leaks.

Feature Function Automatic Shut-Off Ceases operation when unsafe conditions are detected Temperature Sensor Monitors heat levels and triggers responses to prevent overheating Flame Detection Identifies if the flame is present and shuts off gas supply if not Maintenance Tips

Proper care and upkeep of your heating appliance ensure efficient performance and longevity. Regular attention to various components can prevent issues and enhance safety. Here are some essential suggestions to keep in mind for effective maintenance.

Task Frequency Description Inspect Connections Monthly Check all gas connections for leaks or wear, ensuring a secure fit. Clean Filters Every 3 Months Remove and clean filters to maintain airflow and efficiency. Check Ventilation Seasonally Ensure proper ventilation is clear and unobstructed to allow for safe operation. Inspect Burners Annually Clean burners to prevent blockages and ensure even heating. Test Safety Features Yearly Check all safety mechanisms to confirm they are functioning properly. Common Issues with Propane Heaters

Devices that utilize combustible gas for warmth can encounter various challenges that affect their performance and safety. Understanding these common problems can help users maintain optimal function and extend the lifespan of their equipment.

Insufficient Heating

One prevalent issue is inadequate warmth output. This can result from several factors, including obstructed airflow or inadequate fuel supply. Regular maintenance and checks on ventilation systems are essential to ensure proper functionality.

Unusual Noises

Another concern is the presence of strange sounds during operation. These noises may indicate mechanical issues or loose components. It’s important to investigate and address these sounds promptly to prevent further damage. Ignoring such signs can lead to more severe problems down the line.