The efficient operation of water circulation systems relies on a variety of essential elements. These components work together seamlessly to ensure optimal performance and longevity. Familiarizing oneself with the layout and function of these parts can significantly enhance maintenance and troubleshooting efforts.

In this section, we will delve into the intricacies of a specific water management mechanism, focusing on its individual components. By exploring their roles and interconnections, we can better appreciate how they contribute to the overall effectiveness of the system. This knowledge is invaluable for anyone looking to improve their understanding of water circulation technology.

Moreover, recognizing the significance of each element within the assembly enables users to identify potential issues and implement timely solutions. A comprehensive overview of these crucial parts will empower individuals to maintain and optimize their water circulation systems efficiently.

Understanding the inner workings of a specific fluid circulation mechanism is essential for maintenance and optimal performance. This guide aims to elucidate the various components of these devices, providing insights into their functions and interrelations. A comprehensive overview can enhance troubleshooting and repair processes.

Key Components and Their Functions

- Motor: Acts as the driving force, converting electrical energy into mechanical energy.

- Impeller: Responsible for moving the liquid through the system, creating flow and pressure.

- Volute: Guides the flow of liquid from the impeller to the discharge pipe.

- Strainer: Filters out debris and contaminants to protect the internal mechanisms.

- Seal Assembly: Prevents leaks by ensuring a tight fit between rotating and stationary parts.

Maintenance Tips for Longevity

- Regularly check and clean the strainer to ensure efficient operation.

- Inspect electrical connections for wear or damage to prevent power loss.

- Lubricate moving parts as per the manufacturer’s recommendations to reduce friction.

- Monitor for unusual noises or vibrations, indicating potential issues.

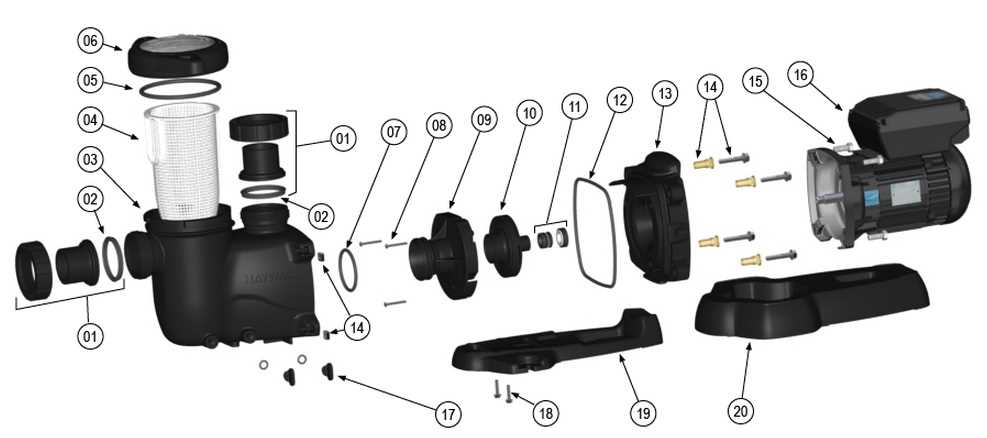

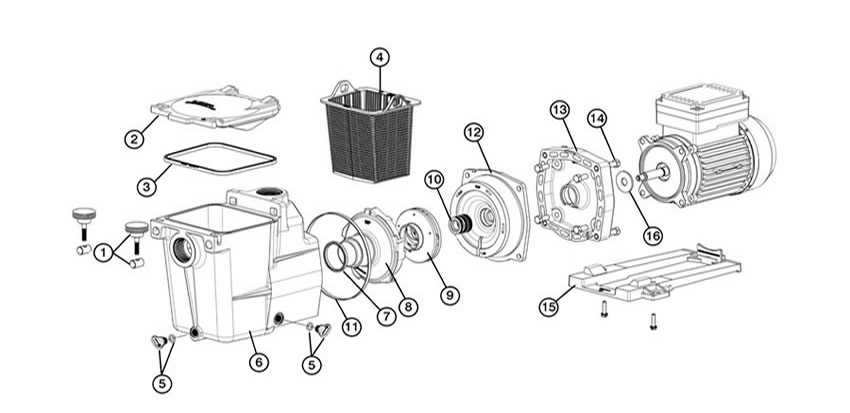

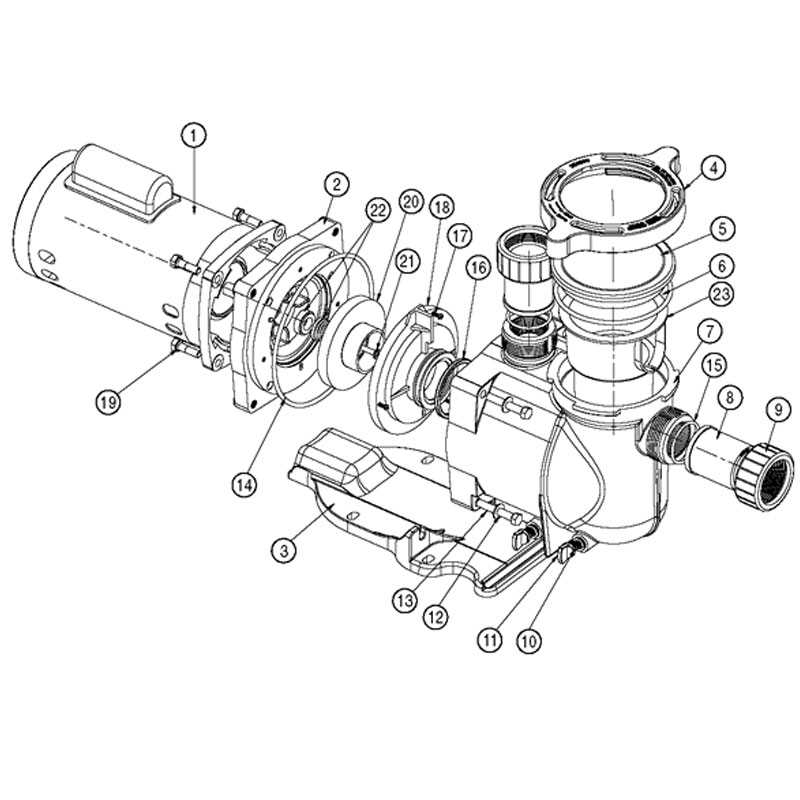

Components of Northstar Pump Assembly

The assembly of this essential device consists of various crucial elements that work together to ensure optimal performance and reliability. Each component plays a significant role in the overall functionality, contributing to the efficient circulation of water. Understanding these elements can enhance maintenance practices and prolong the lifespan of the entire system.

Main Elements

Key components include the motor, which drives the entire mechanism, and the volute, responsible for directing water flow. Additionally, seals are vital for preventing leaks, while the strainer filters out debris, maintaining clean operation. The impeller, designed for creating necessary pressure, ensures effective movement of fluids throughout the setup.

Supporting Features

Auxiliary features such as the diffuser assist in optimizing performance by enhancing fluid distribution. Couplings provide a secure connection between the motor and the impeller, while brackets stabilize the assembly, minimizing vibrations during operation. Together, these elements create a harmonious system that meets the demands of various applications.

Common Issues and Solutions

In any mechanical system, a range of complications can arise, leading to inefficiencies and operational challenges. Understanding these potential pitfalls and their corresponding remedies is crucial for maintaining optimal functionality. This section outlines some prevalent concerns and offers practical solutions to enhance performance.

Frequent Complications

Users may encounter several issues, such as inadequate flow rates, unusual noises, or leaks. Each problem can stem from various factors, including wear and tear, improper installation, or blockages within the system. Identifying the root cause is essential for effective resolution.

Proposed Solutions

Addressing these complications often requires specific approaches. Below is a table summarizing common challenges and their recommended solutions:

| Issue | Recommended Action |

|---|---|

| Low water flow | Check for obstructions in the inlet and outlet. Clean or replace filters as needed. |

| Strange noises | Inspect for loose components. Tighten screws and ensure all fittings are secure. |

| Leaks | Examine seals and gaskets for damage. Replace any worn parts promptly. |

| Overheating | Ensure proper ventilation. Check for blocked air intakes and clean as necessary. |

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended life of your aquatic system components. Implementing a consistent maintenance routine can prevent potential issues and enhance overall performance, making it crucial for any owner. By adhering to a few simple strategies, you can significantly prolong the effectiveness of your equipment.

Routine Inspection

Frequent checks are vital for identifying wear and tear before they escalate into significant problems. Look for signs of corrosion, wear, or any unusual noises during operation. Early detection of minor issues can lead to easier and more cost-effective repairs.

Cleaning and Lubrication

Keeping the interior and exterior clean is fundamental. Regularly remove debris and build-up to maintain optimal performance. Additionally, applying lubricant to moving parts can reduce friction and wear, helping to ensure smooth operation over time.

Identifying Pump Model Variations

Understanding the distinctions between different models in the same series is crucial for effective maintenance and repair. Each version may have unique features and components, which can significantly impact performance and compatibility. Recognizing these variations can aid in selecting the correct replacements and ensuring optimal functionality.

To effectively differentiate between the available variations, it’s essential to examine the specifications and design elements. Factors such as size, horsepower, and flow rates often indicate model differences. Additionally, unique serial numbers or codes can provide valuable insights into the specific version, allowing for more accurate identification.

Consulting manufacturer resources, including technical manuals and support websites, can further enhance understanding. These resources typically offer detailed information about the unique characteristics of each variant, facilitating informed decisions when it comes to repairs and upgrades.

Replacement Parts and Compatibility

When maintaining and repairing your equipment, understanding the necessary components and their interchangeability is crucial. The right elements ensure optimal functionality and longevity, while compatible substitutes can save time and resources.

Here are key aspects to consider when selecting components for your unit:

- Original Equipment Manufacturer (OEM) vs. Aftermarket Options: Evaluate whether to use original elements or third-party alternatives, considering quality, warranty, and support.

- Specifications: Review the specifications of each component, including size, material, and performance ratings, to ensure a proper fit and reliable operation.

- Compatibility: Verify that the components you choose are compatible with your existing setup to avoid operational issues or malfunctions.

- Availability: Check the availability of components from various suppliers to find the best prices and delivery options.

In summary, making informed decisions about replacements and understanding their compatibility is vital for effective equipment management. By considering these factors, you can ensure that your system operates smoothly and efficiently.

Wiring and Electrical Connections

This section focuses on the intricate relationships between the electrical components and their connections, emphasizing the significance of proper wiring techniques for optimal performance. Understanding these connections is vital for ensuring the system operates safely and efficiently.

Understanding the Wiring Components

Different elements within the system require careful attention when it comes to their electrical connections. Below are the essential components to consider:

- Power Supply: The source providing electrical energy to the unit.

- Control Switch: A mechanism to activate or deactivate the system.

- Motor Connections: Links that connect the motor to the power supply.

- Grounding Wire: Essential for safety, preventing electrical shocks.

Proper Wiring Practices

To ensure reliability and safety, follow these recommended practices:

- Always turn off the power before making any connections.

- Use the correct gauge of wire to handle the expected load.

- Secure all connections to prevent loose wiring, which can lead to failures.

- Regularly inspect the wiring for any signs of wear or damage.

Adhering to these guidelines will help maintain a safe and functional system, ultimately extending its lifespan.

Step-by-Step Disassembly Guide

This section provides a comprehensive overview of how to methodically dismantle a specific model of water circulation equipment. Following these steps will help you identify individual components and understand their functions, ultimately facilitating effective maintenance and repairs.

Begin by ensuring the device is completely powered off and disconnected from any electrical sources. Gather the necessary tools, such as screwdrivers and wrenches, to streamline the disassembly process. A clean workspace will help keep track of the removed components.

Start with the outer casing by locating and removing the screws securing it in place. Gently lift the casing off to expose the internal assembly. Next, identify the motor and any connecting elements. Disconnect wires carefully, taking note of their positions for reassembly.

Once the motor is freed, proceed to detach the impeller and any additional fittings. Utilize appropriate tools to avoid damaging the components. Keep all screws and parts organized to ensure a smooth reassembly.

By following these detailed instructions, you can successfully disassemble the equipment, paving the way for thorough inspection and necessary repairs.

Resources for Troubleshooting Assistance

When facing difficulties with your equipment, having access to the right resources can make all the difference. Various materials are available to guide users through common challenges, ensuring smooth operation and maintenance. Whether you are dealing with a malfunction or seeking to optimize performance, reliable support is essential.

Online Forums and Communities: Engaging with fellow enthusiasts in dedicated online communities can provide valuable insights. Users often share their experiences, tips, and solutions to common problems. Participating in these discussions can enhance your understanding and offer new perspectives on issues you might encounter.

Manufacturer’s Documentation: Referring to official manuals and documentation is crucial for accurate information regarding your device. These resources typically include troubleshooting steps, maintenance guidelines, and specifications, helping you identify and resolve issues effectively.

Video Tutorials: Visual aids can significantly improve your troubleshooting experience. Numerous video tutorials are available that walk you through specific repairs and adjustments. Watching these guides can clarify complex procedures and boost your confidence in handling repairs.

Professional Services: If problems persist or seem beyond your capability, seeking assistance from professionals is advisable. Certified technicians possess the expertise to diagnose and fix more complicated issues, ensuring that your system operates efficiently.