The functionality of any surface preparation device hinges on its intricate assembly. Each element plays a pivotal role, ensuring efficient operation and optimal results. A thorough comprehension of these components can enhance maintenance and repair efforts.

In this section, we will explore the critical elements that make up this powerful tool. By examining each segment closely, users can gain insights into their respective functions and interconnections, which ultimately leads to improved usage and longevity.

Furthermore, understanding the layout of these components aids in troubleshooting common issues, allowing for quicker resolutions. This knowledge not only empowers users but also promotes effective upkeep, ensuring that the tool remains reliable over time.

Understanding Porter Cable 7800 Sander

This section explores the features and functionality of a specific finishing tool designed for surface preparation. Ideal for both professionals and DIY enthusiasts, this equipment simplifies the task of achieving smooth surfaces, enhancing overall project quality. By grasping its components and operation, users can optimize performance and extend the lifespan of the tool.

Key Features

- Efficient motor for high-performance sanding

- Adjustable speed settings for various applications

- Dust collection system for cleaner work environment

- Ergonomic design for comfortable handling

Maintenance Tips

- Regularly clean the dust collection system to ensure efficiency.

- Inspect and replace worn-out sanding pads to maintain performance.

- Store the tool in a dry place to prevent rust and damage.

- Check electrical connections periodically for safety.

Understanding these elements will not only improve your experience but also enhance the results of your finishing tasks.

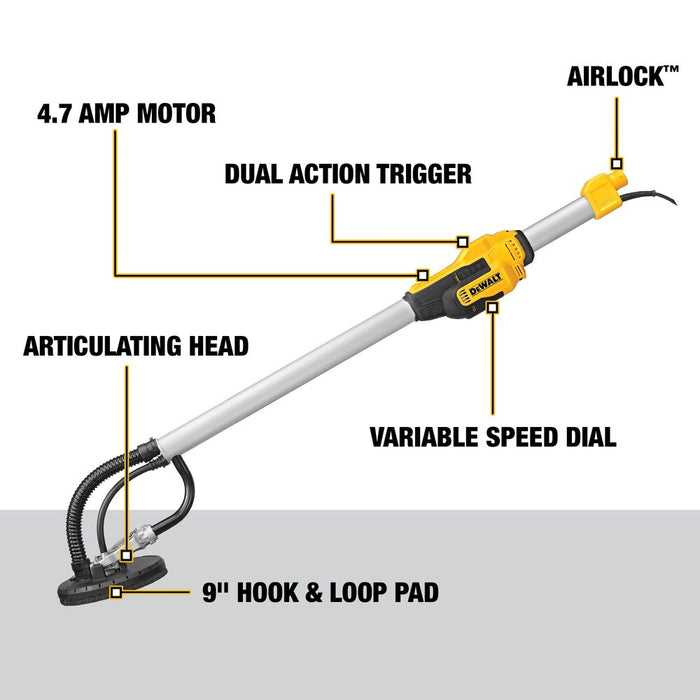

Essential Components of the Sander

Understanding the key elements of a sanding tool is crucial for effective operation and maintenance. Each component plays a vital role in ensuring optimal performance, durability, and user comfort. By familiarizing yourself with these essential parts, you can enhance your experience and prolong the lifespan of your equipment.

Key Elements

The motor serves as the powerhouse, driving the entire mechanism and providing the necessary force for sanding tasks. A well-designed motor not only enhances efficiency but also reduces the risk of overheating during prolonged use.

Attachments and Accessories

Sandpaper is another critical component, available in various grits to suit different surfaces and finishing requirements. Additionally, a robust dust collection system helps maintain a clean workspace, minimizing cleanup time and ensuring better visibility while working.

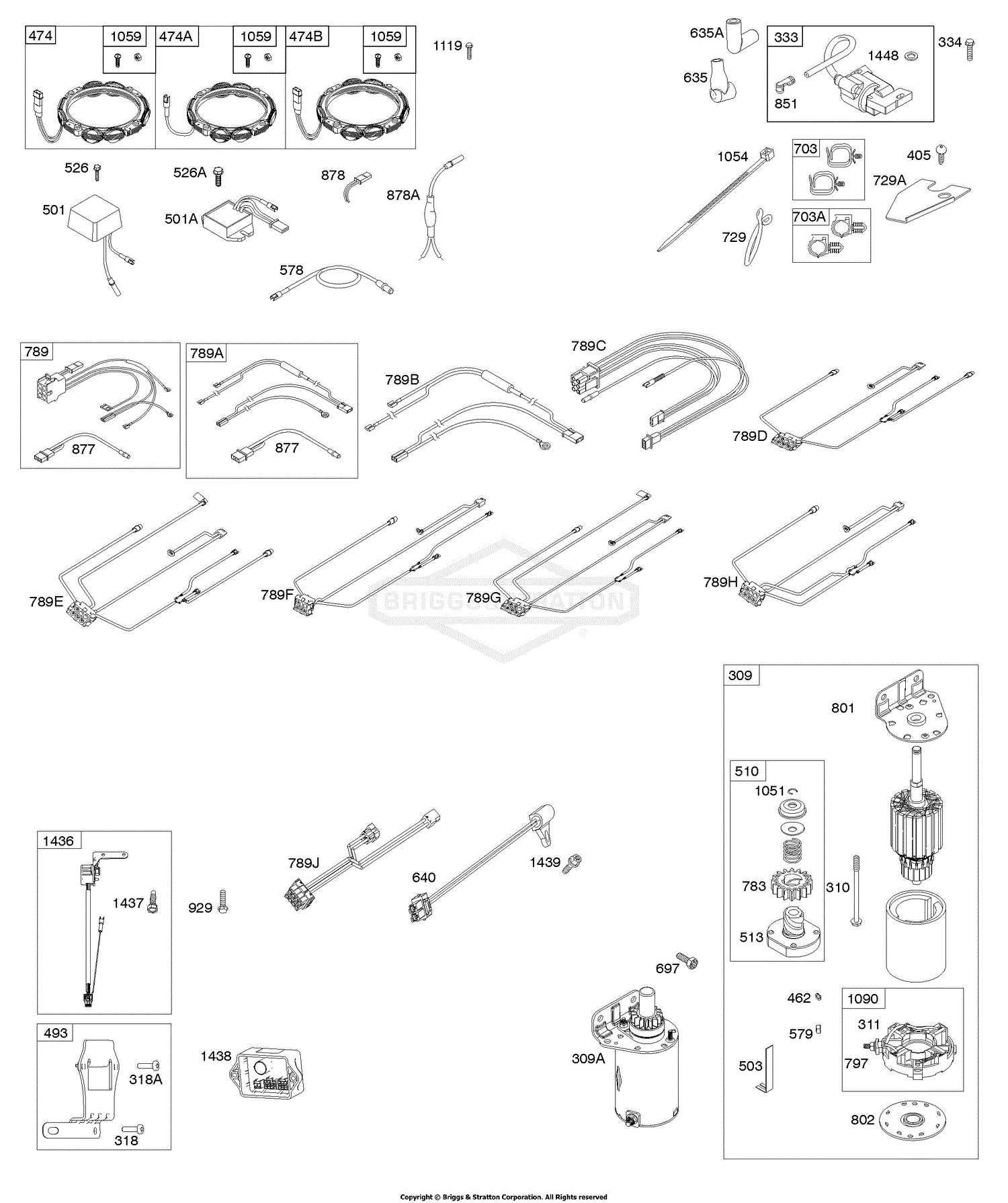

How to Interpret Parts Diagrams

Understanding component illustrations is crucial for effective maintenance and repair of various tools. These visual guides serve as valuable references, allowing users to identify and locate individual elements within a machine. Familiarity with these illustrations not only streamlines the repair process but also enhances overall equipment functionality.

Key Elements of Illustrations

Component representations typically include labels, numbers, and reference codes. These features facilitate easy identification of each part and its corresponding function within the assembly. By breaking down these elements, users can gain insights into the tool’s structure and assembly process.

Utilizing Reference Tables

Often, component illustrations are accompanied by reference tables that provide additional details. These tables might include information such as part numbers, descriptions, and specifications. To utilize these resources effectively, it’s important to understand how to cross-reference the visual elements with the corresponding details in the table.

| Label | Description | Part Number |

|---|---|---|

| A1 | Motor Assembly | 12345 |

| B2 | Handle Grip | 67890 |

| C3 | Dust Collection Bag | 11223 |

By becoming proficient in reading these diagrams and tables, users can effectively troubleshoot issues, order the correct replacements, and perform maintenance with confidence.

Common Issues with Drywall Sanders

Power tools designed for wall finishing often encounter various challenges during operation. Users frequently report difficulties that can hinder performance and affect the overall quality of their work. Understanding these common problems is essential for effective maintenance and optimal results.

One prevalent issue is excessive dust generation, which can obscure visibility and compromise air quality. Many tools struggle with effective dust collection, leading to messy work environments. Regularly checking and replacing filters can mitigate this problem.

Another concern is overheating, particularly during extended use. Continuous operation can cause the motor to overheat, resulting in diminished performance and potential damage. Allowing the equipment to cool down periodically can help maintain its functionality.

Additionally, uneven surface finishing is a frequent complaint. Operators may find it challenging to achieve a smooth, uniform surface, often due to improper technique or inadequate tool adjustment. Familiarity with the tool’s settings and practicing on scrap materials can improve results.

Finally, wear and tear on components such as pads and belts can lead to suboptimal operation. Regular inspections and timely replacements of worn parts are crucial to ensuring the tool remains efficient and effective in delivering high-quality finishes.

Maintenance Tips for Longevity

Proper care is essential to ensure the durability and effectiveness of your equipment. Regular maintenance not only extends the lifespan but also enhances performance, allowing you to achieve optimal results in your projects.

Routine Cleaning

- Always remove dust and debris after each use.

- Utilize a damp cloth for thorough cleaning of surfaces.

- Check and clean filters regularly to maintain airflow.

Inspection and Replacement

- Examine components for wear and tear regularly.

- Replace worn parts promptly to prevent further damage.

- Keep spare parts on hand for quick replacements.

Where to Find Replacement Parts

When it comes to maintaining and repairing your tools, locating high-quality components is essential. Whether you need a specific element or a complete set, there are various reliable sources to consider. This guide highlights the best places to find what you need for optimal performance.

Online Retailers

- Manufacturer’s Website: Often the most reliable source, providing genuine components that ensure compatibility.

- Third-Party E-commerce Sites: Websites like Amazon or eBay can offer competitive pricing and a wide selection.

- Specialized Tool Shops: Online stores dedicated to tools frequently stock a variety of necessary components.

Local Stores

- Home Improvement Centers: Chains like Home Depot or Lowe’s often have a dedicated section for tool maintenance.

- Local Hardware Stores: Smaller shops may carry essential items or can order them for you.

- Repair Shops: These establishments not only repair tools but may also sell components directly.

Upgrading Your Drywall Sanding Tools

Enhancing your sanding equipment can significantly improve the efficiency and quality of your finishing projects. By investing in advanced tools and accessories, you can achieve smoother surfaces and save time during preparation. This section explores various aspects to consider when updating your sanding arsenal.

Choosing the Right Equipment

Selecting high-quality machinery tailored to your specific needs is crucial. Look for tools that offer adjustable speeds, ergonomic designs, and effective dust collection systems. These features can make a notable difference in performance, allowing you to work more comfortably and maintain a cleaner environment.

Investing in Accessories

Comparing Models: 7800 vs. Others

This section aims to provide an overview of different models available in the market, highlighting key features and differences. Understanding these variations helps consumers make informed choices based on their specific needs.

When considering various models, several factors come into play:

- Performance: Different devices offer varying levels of power and efficiency, impacting the speed and quality of work.

- Weight and Maneuverability: Some models are lighter, making them easier to handle for extended periods, while others may be bulkier but offer more stability.

- Dust Collection: Efficient dust collection systems are crucial for maintaining a clean workspace, with some models outperforming others in this area.

To better understand how these models stack up against each other, let’s examine some popular alternatives:

- Model A: Known for its lightweight design and excellent maneuverability, it is ideal for small projects.

- Model B: This variant boasts superior power, making it suitable for larger, more demanding tasks.

- Model C: Offers an advanced dust collection system, ensuring a cleaner work environment, but may be heavier.

In conclusion, evaluating these key aspects allows users to select the right equipment tailored to their project requirements, whether they prioritize power, ease of use, or cleanliness.

User Reviews and Experiences

This section delves into the feedback and insights shared by individuals who have utilized the tool in various projects. User experiences can provide invaluable perspectives, highlighting both strengths and areas for improvement, ultimately guiding potential buyers in their decision-making process.

Positive Feedback

- Efficiency: Many users have praised the tool for its ability to significantly reduce time spent on surface preparation.

- Ease of Use: Reviews frequently mention the comfortable grip and lightweight design, making it accessible for extended periods of work.

- Quality Finish: Several individuals noted the smooth finish achieved, resulting in less time required for additional sanding and touch-ups.

Areas for Improvement

- Durability: Some users expressed concerns regarding the longevity of certain components, suggesting a need for more robust materials.

- Noise Levels: Feedback indicates that the operating noise can be quite high, which might be an issue for use in residential areas.

- Replacement Parts: A few reviewers highlighted difficulties in sourcing replacement components, indicating a desire for improved accessibility.