In the realm of winter maintenance, the efficiency of your equipment greatly depends on the intricate interplay of its various elements. Each component plays a critical role in ensuring optimal performance during the harshest conditions. A thorough understanding of these elements is paramount for effective operation and maintenance.

Exploring the intricate layout of these essential mechanisms can provide valuable insights for operators and technicians alike. By familiarizing oneself with the arrangement and functionality of each unit, users can enhance their troubleshooting capabilities and streamline repair processes. Such knowledge not only prolongs the life of the equipment but also ensures reliable operation when it matters most.

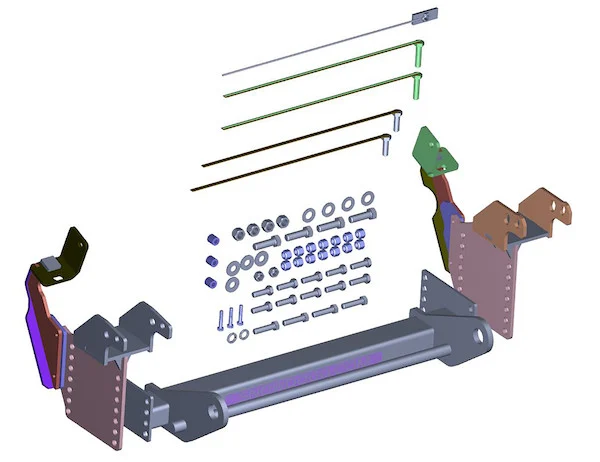

Moreover, having access to a comprehensive visual representation can serve as a beneficial reference for anyone involved in the upkeep of these tools. It allows for a clearer comprehension of how each part interacts within the larger system, paving the way for more informed decisions regarding repairs and upgrades. This understanding fosters greater confidence in managing winter challenges effectively.

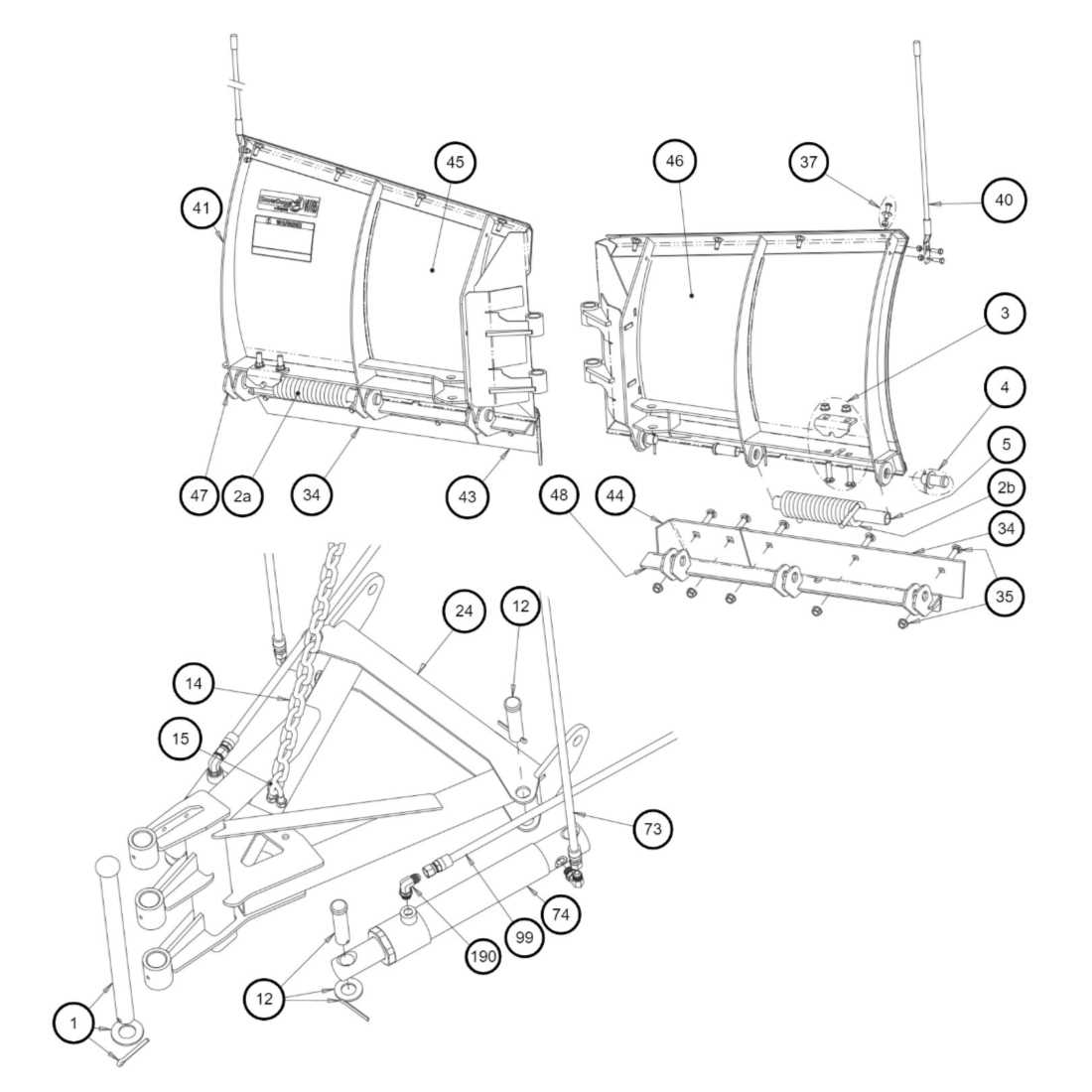

Understanding Snowdogg Plow Components

This section aims to explore the essential elements of a snow-clearing apparatus, focusing on their functions and interactions. A thorough comprehension of these components enhances operational efficiency and maintenance practices.

Key Elements of the System

The primary elements include the blade, mounting system, and hydraulic components. Each plays a crucial role in ensuring effective snow removal, providing the ultimate performance during winter conditions.

Maintenance and Upkeep

Regular inspection and timely replacement of worn components are vital. Understanding how each part contributes to overall functionality can lead to better decision-making regarding upkeep and enhancements, ensuring long-lasting use.

Benefits of Using Authentic Parts

When it comes to maintaining equipment, opting for genuine components is crucial. These original elements are specifically designed to ensure optimal performance, enhancing the longevity and efficiency of the machinery. By choosing authentic replacements, users can avoid the risks associated with substandard alternatives.

Quality Assurance: Genuine components undergo rigorous testing and quality control, ensuring they meet high standards. This guarantees reliability and durability, which are vital for successful operation, especially in demanding conditions.

Perfect Fit: Original parts are crafted to fit seamlessly with existing machinery. This compatibility minimizes the likelihood of installation issues and potential damage, promoting a smoother operation.

Warranty Protection: Using authentic replacements often ensures that warranties remain intact. Manufacturers typically stipulate that only original elements should be used, protecting the investment in the equipment.

Improved Safety: Genuine components are designed with safety in mind, reducing the risk of malfunctions that could lead to accidents. Prioritizing authentic items enhances overall user safety.

Long-Term Savings: While genuine components may have a higher initial cost, they often lead to lower maintenance expenses over time. The durability and reliability of these products can significantly reduce the frequency of replacements.

Common Issues with Snowdogg Plows

Operating winter equipment can present several challenges that users often encounter. Understanding these frequent problems can help ensure better performance and longevity. This section delves into some typical concerns, offering insights into their causes and potential solutions.

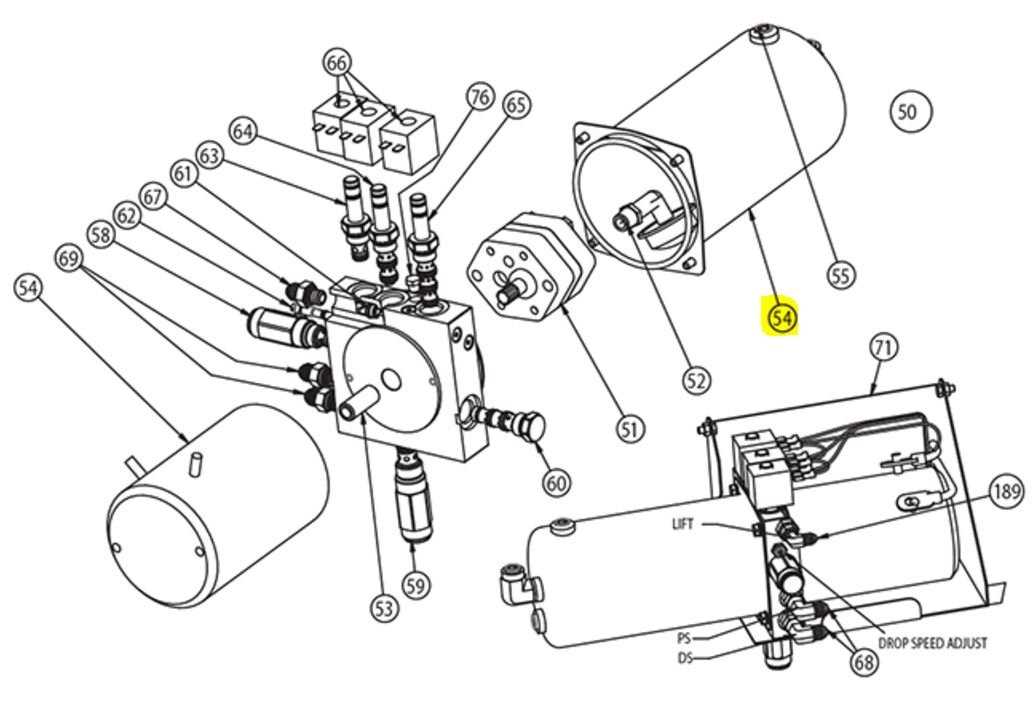

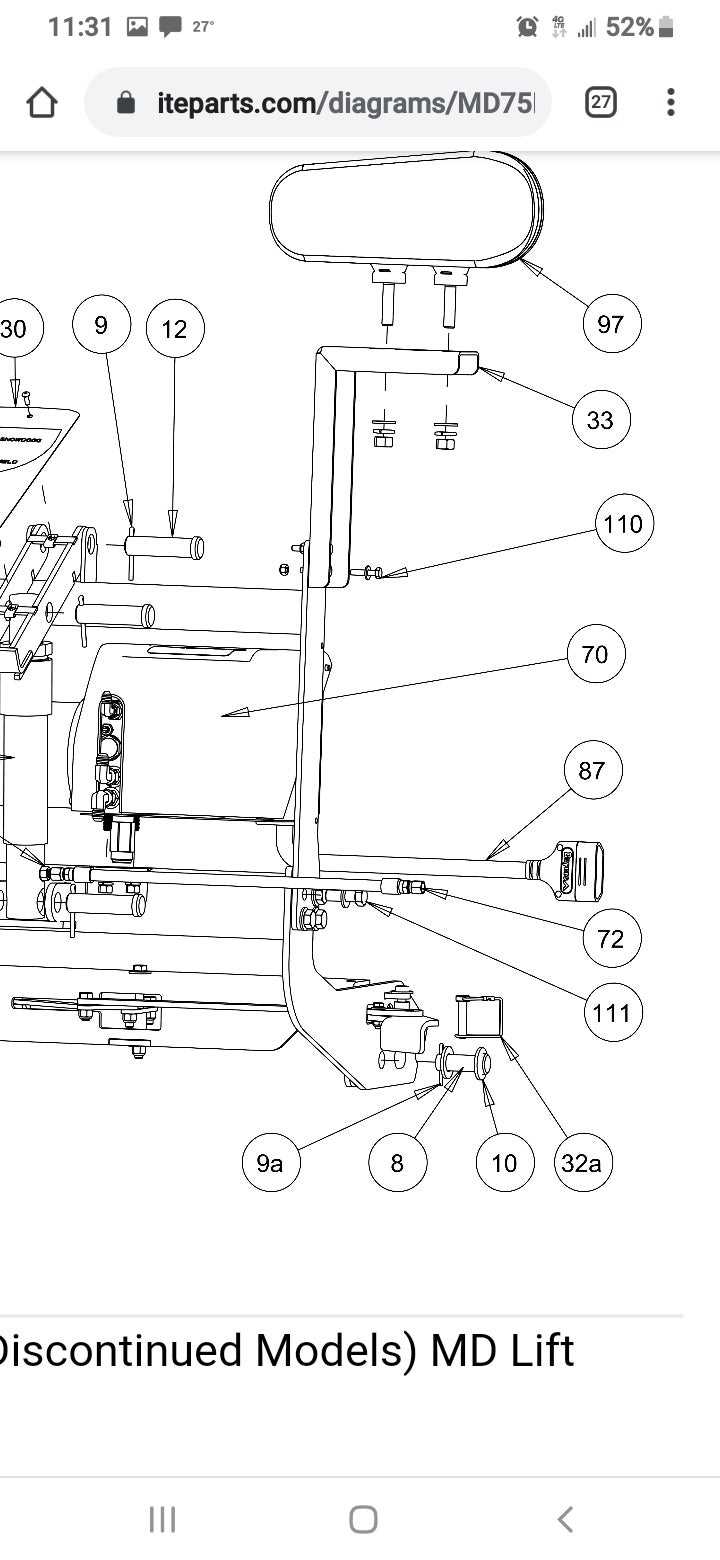

Hydraulic System Problems

One of the primary areas where difficulties may arise is within the hydraulic system. Common issues include leaks, unresponsive controls, and insufficient lifting power. Regular maintenance and timely inspections are essential to prevent these complications.

Wear and Tear on Components

Another significant issue is the wear and tear of various components over time. Components such as the cutting edge and frame can become worn out, leading to reduced efficiency. Monitoring and replacing these elements when necessary is crucial to maintain optimal functionality.

| Issue | Possible Causes | Recommended Actions |

|---|---|---|

| Hydraulic leaks | Damaged hoses, loose fittings | Inspect and replace damaged parts |

| Unresponsive controls | Faulty wiring, fluid levels | Check wiring connections, refill fluid |

| Worn cutting edge | Prolonged use, hard surfaces | Regularly check and replace as needed |

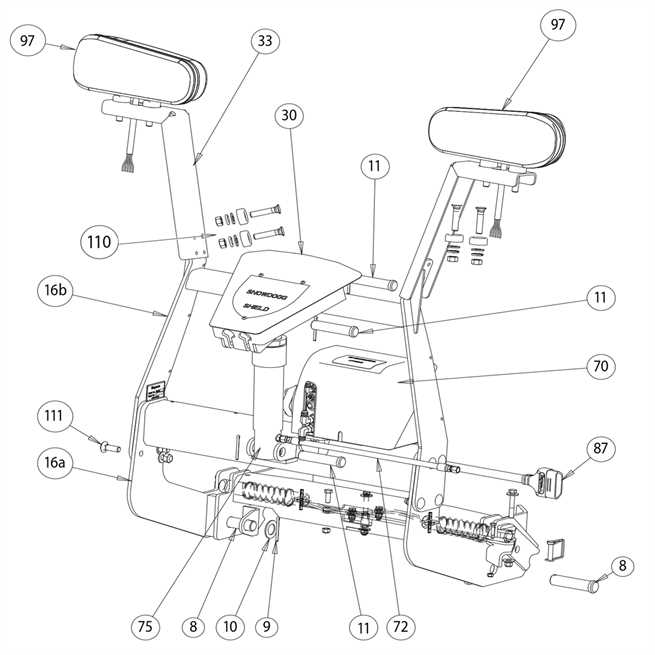

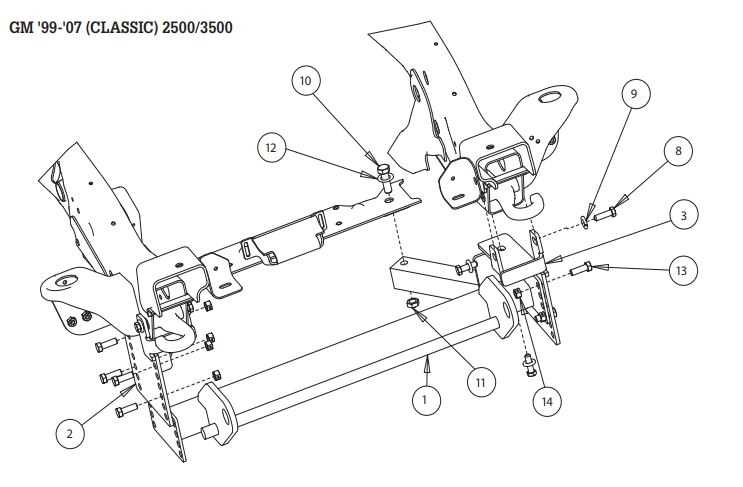

How to Interpret the Diagram

Understanding a technical illustration requires a clear approach to its components and layout. This guide will assist you in deciphering the visual representation, ensuring that you can effectively identify and utilize each section.

Identifying Key Components

Begin by familiarizing yourself with the main elements depicted. Each section will typically be labeled, allowing you to connect the visual cues with their corresponding functions. Pay attention to symbols and numbers that indicate specific features.

Connecting the Dots

Once you have recognized the elements, the next step is to link them logically. Consider how each component interacts with others, forming a cohesive system. This holistic understanding will empower you to troubleshoot and make informed decisions during maintenance.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires regular attention and care. By following a few simple practices, you can significantly enhance performance and durability. Implementing a proactive approach will minimize the likelihood of issues arising and maximize efficiency.

| Tip | Description |

|---|---|

| Regular Inspections | Check components frequently for signs of wear or damage to catch problems early. |

| Proper Cleaning | Clean after use to prevent rust and corrosion from accumulated debris. |

| Lubrication | Apply appropriate lubricants to moving parts to reduce friction and wear. |

| Storage | Store in a dry, sheltered location to protect from the elements when not in use. |

| Scheduled Maintenance | Follow a maintenance schedule for routine checks and part replacements as necessary. |

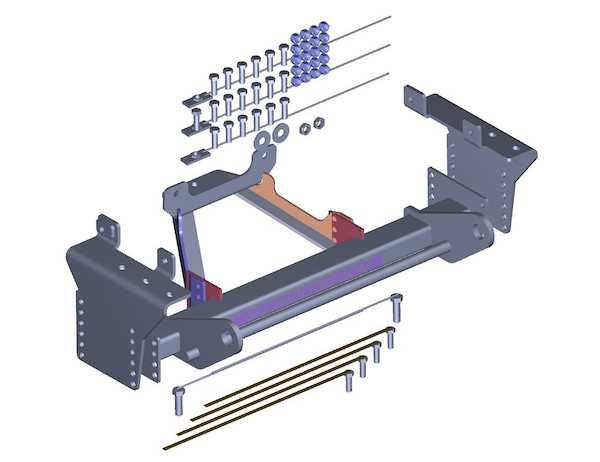

Installation Guide for New Parts

This section provides essential steps to assist in the setup of newly acquired components. A clear understanding of the installation process ensures optimal functionality and durability of your equipment. Following these guidelines will help you achieve the best results.

Preparation Steps

Before beginning the installation, ensure you have all necessary tools and components on hand. Proper preparation minimizes downtime and facilitates a smooth transition to the new setup.

Installation Procedure

Follow the steps outlined below to effectively integrate the new elements:

| Step | Description |

|---|---|

| 1 | Disconnect the current assembly to prevent any electrical issues. |

| 2 | Carefully remove any old components that may obstruct installation. |

| 3 | Align the new items with existing brackets or connections. |

| 4 | Securely fasten all elements according to the manufacturer’s specifications. |

| 5 | Reconnect power sources and conduct a thorough functionality test. |

By adhering to these steps, you ensure a successful integration of your new components, ultimately enhancing performance and reliability.

Where to Purchase Replacement Parts

When it comes to maintaining your equipment, finding reliable sources for necessary components is essential. There are several avenues available that cater to different preferences and needs. Understanding where to look can make the process more efficient and cost-effective.

Authorized Dealers

One of the most dependable options is to visit authorized dealers. These establishments often carry a wide selection of original components, ensuring compatibility and quality. Additionally, purchasing from authorized sources can provide peace of mind, as these vendors are familiar with the specific requirements of your machinery.

Online Retailers

The internet offers a plethora of online retailers that specialize in aftermarket solutions. Many websites provide comprehensive catalogs, allowing you to compare prices and read reviews. When choosing this route, ensure you select reputable sites to guarantee that you receive quality items that meet your standards.

Comparing Snowdogg Models and Accessories

In the world of winter equipment, various models and add-ons serve distinct purposes, enhancing performance and versatility. Understanding the differences between these options is crucial for users seeking the best fit for their needs.

Each model features unique specifications that cater to different tasks, ranging from light-duty to heavy-duty applications. Accessories can further enhance these capabilities, providing additional functionalities tailored to specific environments.

When evaluating options, it’s important to consider compatibility with existing vehicles, operational efficiency, and overall durability. A thoughtful comparison allows users to make informed choices, maximizing the benefits of their investment.

Expert Advice on Plow Performance

When it comes to maximizing the efficiency of your snow-clearing equipment, understanding the various elements that influence its operation is crucial. Ensuring optimal functionality not only enhances performance but also extends the longevity of your machinery. Here, we share key insights that can help you achieve the best results in winter conditions.

Regular Maintenance and Inspection

Consistent upkeep is vital for reliable operation. Periodically checking essential components for wear and tear can prevent unexpected failures during crucial moments. Make it a habit to inspect the framework, hydraulic systems, and attachment mechanisms. Addressing minor issues before they escalate can save you time and resources.

Choosing the Right Equipment Settings

Understanding the specific requirements of the terrain you’re working on can greatly affect your equipment’s performance. Adjusting the angle and height can optimize snow displacement and minimize the risk of damage to the surface underneath. Tailoring these settings based on conditions will result in a more effective clearing process.