When it comes to maintaining your snow removal machinery, having a comprehensive grasp of its various components is essential. Knowing how these elements interact not only enhances performance but also ensures longevity and efficiency during the harsh winter months.

This section aims to provide clarity on the intricate assembly of your snow clearing apparatus. By visualizing each part and understanding its function, operators can troubleshoot issues effectively and carry out necessary repairs with confidence.

Furthermore, an organized overview of the individual elements aids in the process of upgrades and customizations, enabling users to tailor their equipment to meet specific needs. Mastery of these components can transform the way you approach snow management tasks, leading to a more streamlined and successful experience.

Overview of Polaris Glacier Pro Plow

This section provides a comprehensive look at an essential tool designed for snow management and efficient terrain handling. Its robust construction and innovative features make it a favored choice among enthusiasts and professionals alike. Understanding its components and functionality is key to maximizing performance and ensuring durability during usage.

Key Features

Engineered for versatility, this equipment excels in various conditions, offering adjustable angles and heights to tackle different challenges. The durable materials ensure longevity, while the intuitive design facilitates easy attachment and detachment, enhancing user experience. Additionally, the enhanced control mechanisms contribute to precision, making operations smooth and effective.

Maintenance Tips

Regular upkeep is crucial for optimal functioning. Ensure all moving components are lubricated to prevent wear and tear. Checking for any signs of damage or corrosion can prolong its lifespan. Moreover, following the manufacturer’s guidelines for seasonal storage will help maintain its integrity and readiness for future tasks.

Importance of Plow Parts Diagram

A clear representation of components is crucial for effective maintenance and repair of equipment used in snow removal. Understanding the layout and function of each element not only streamlines the process of troubleshooting but also enhances the overall efficiency of the machinery. This knowledge empowers users to identify issues swiftly and to ensure that their tools remain in optimal condition.

Facilitating Maintenance

Regular upkeep is essential for the longevity of any machinery. A well-structured visual guide enables operators to perform necessary checks and replacements with confidence. It reduces the likelihood of errors and minimizes downtime, ensuring that the equipment operates smoothly when needed most.

Enhancing Safety

Proper comprehension of individual components contributes significantly to safety during operation. When users can recognize the purpose and location of various elements, they are less prone to accidents and malfunctions. Awareness of potential hazards associated with specific parts can lead to better precautionary measures and a safer working environment.

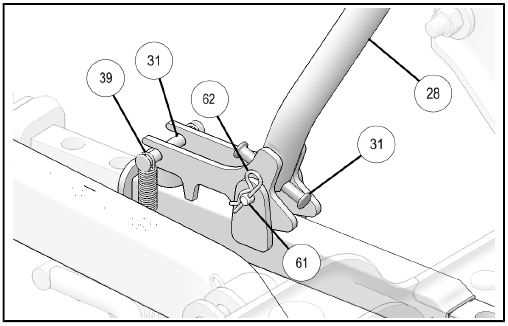

Key Components of the Plow System

The functionality of a snow-clearing apparatus relies on several crucial elements that work together to ensure efficient operation. Understanding these components is essential for maintaining optimal performance and ensuring longevity. Each part plays a specific role, contributing to the overall effectiveness of the system.

Main Elements

The main elements of the snow-clearing apparatus can be categorized into mechanical and hydraulic systems. The mechanical components are responsible for the physical movement and positioning, while the hydraulic parts manage the force and control the height and angle.

| Component | Description |

|---|---|

| Blade | The primary surface that contacts the snow, designed for optimal cutting and moving. |

| Frame | Supports the blade and connects it to the vehicle, ensuring stability during operation. |

| Hydraulic Cylinder | Controls the lifting and lowering of the blade, allowing for adjustable height settings. |

| Control System | Provides the operator with the ability to maneuver the blade easily from within the vehicle. |

Additional Considerations

Beyond the core components, there are additional elements that enhance performance, such as wear strips for durability and lights for visibility during operation. Regular maintenance of these parts is vital for ensuring the apparatus functions effectively under various conditions.

Maintenance Tips for Your Snow Plow Equipment

Regular upkeep of your snow-clearing gear is crucial to ensure optimal performance and longevity. By following these maintenance guidelines, you can extend the lifespan of your equipment and minimize the risk of breakdowns during critical winter operations.

Inspecting and Cleaning

Regular inspection of all components is essential. Check for any signs of wear, corrosion, or damage that may affect functionality. Use appropriate tools to clean debris and salt residue, as these can accelerate deterioration.

Lubrication and Adjustment

Proper lubrication of moving parts such as hinges and pivots is necessary to maintain smooth operation and prevent rust. Make adjustments as needed to maintain optimal blade alignment and ground clearance, ensuring efficient snow removal.

Common Issues with Plow Parts

When it comes to snow removal equipment, various challenges can arise, impacting performance and efficiency. Understanding these common problems can help in maintaining functionality and prolonging the lifespan of the machinery. Identifying issues early ensures smooth operation during harsh winter conditions.

Frequent Challenges

Several recurring difficulties can affect the efficiency of snow management equipment. These may include mechanical failures, wear and tear, and environmental factors. Below are some of the most common issues that users may encounter:

| Issue | Description | Possible Solutions |

|---|---|---|

| Worn Components | Parts may degrade over time due to constant use, leading to ineffective operation. | Regular inspections and timely replacements can mitigate this issue. |

| Hydraulic Leaks | Fluid leaks can result in reduced pressure, affecting lifting and lowering capabilities. | Check hoses and fittings regularly; replace damaged items immediately. |

| Electrical Failures | Faulty wiring or connections may disrupt power supply to essential systems. | Routine checks of electrical components can prevent unexpected shutdowns. |

| Corrosion | Exposure to moisture and salt can lead to rust and deterioration. | Proper cleaning and protective coatings can help reduce this risk. |

Preventative Maintenance Tips

To avoid many of the issues outlined above, consistent upkeep is essential. Regular maintenance not only enhances performance but also prevents costly repairs down the line. Ensuring equipment is clean and stored correctly after use is a simple yet effective strategy to maintain operational integrity.

Finding Authentic Replacement Parts

When it comes to maintaining your equipment, sourcing genuine components is crucial for ensuring optimal performance and longevity. Authentic replacements not only guarantee compatibility but also uphold the quality standards necessary for efficient operation. Whether you’re upgrading or fixing, knowing where to find these reliable elements can save you time and money in the long run.

Identifying Trusted Suppliers

Start by researching reputable dealers who specialize in your equipment type. Look for established businesses with positive customer reviews and a history of providing original components. Online marketplaces can also be a valuable resource, but it’s essential to verify the authenticity of the sellers and their products.

Understanding Part Specifications

Familiarize yourself with the specific requirements of your machinery. Consult user manuals or official resources to understand the specifications of the components you need. This knowledge will help you avoid counterfeit items and ensure you acquire the exact replacements necessary for seamless operation.

Installation Guide for New Components

In this section, we provide a detailed overview of how to integrate the latest additions to your vehicle’s snow plowing system. Our aim is to streamline the incorporation process, ensuring seamless integration without reliance on specific terms or visual aids.

Component Overview

Before proceeding with installation, acquaint yourself with the new parts. This step is crucial for understanding their functionality within the broader framework of your snow removal setup.

| Component | Description | Installation Steps |

| Blade Extension Kit | Enhances blade reach and performance | Refer to manual for mounting instructions |

| Mounting Bracket Assembly | Provides secure attachment to vehicle | Align bracket with existing framework; fasten securely |

| Lift Frame Extension | Improves lift capability for heavier loads | Adjust hydraulic system accordingly; test for functionality |

Installation Steps

Follow these general steps to effectively incorporate the new components:

- Prepare the workspace and ensure all tools are readily accessible.

- Begin with disassembling any existing components that might interfere with the installation.

- Install each new component sequentially, following specific instructions provided for each.

- Verify connections and alignments before finalizing installation.

- Test the functionality of the entire system to ensure optimal performance.

By adhering to these guidelines, you ensure a smooth transition to upgraded equipment, enhancing the efficacy of your snow plowing operations.

Safety Precautions During Operation

Ensuring safety during operation is paramount to prevent accidents and injuries. Proper preparation and adherence to guidelines can significantly reduce risks. Operators should familiarize themselves with the equipment and its functionalities to maintain a secure working environment.

Pre-Operational Checks

Before engaging in any tasks, conduct thorough inspections of the machinery. Verify that all components are in optimal condition, ensuring there are no loose parts or potential hazards. Additionally, check fluid levels and ensure that safety devices are functional. Having the right equipment for personal protection, such as helmets and gloves, is also essential.

Operational Best Practices

During operation, maintain awareness of your surroundings and adhere to established protocols. Avoid overloading the equipment and ensure that it is used within its specified limits. Operators should remain focused, avoiding distractions to maintain control and precision. Following these best practices will promote a safer working environment for everyone involved.