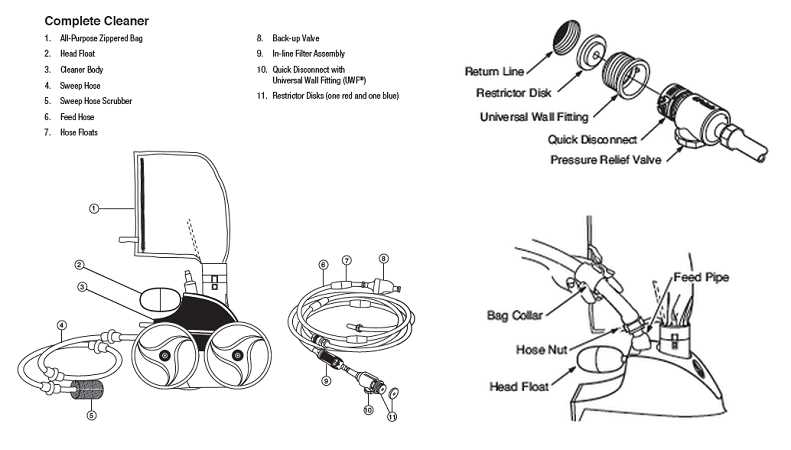

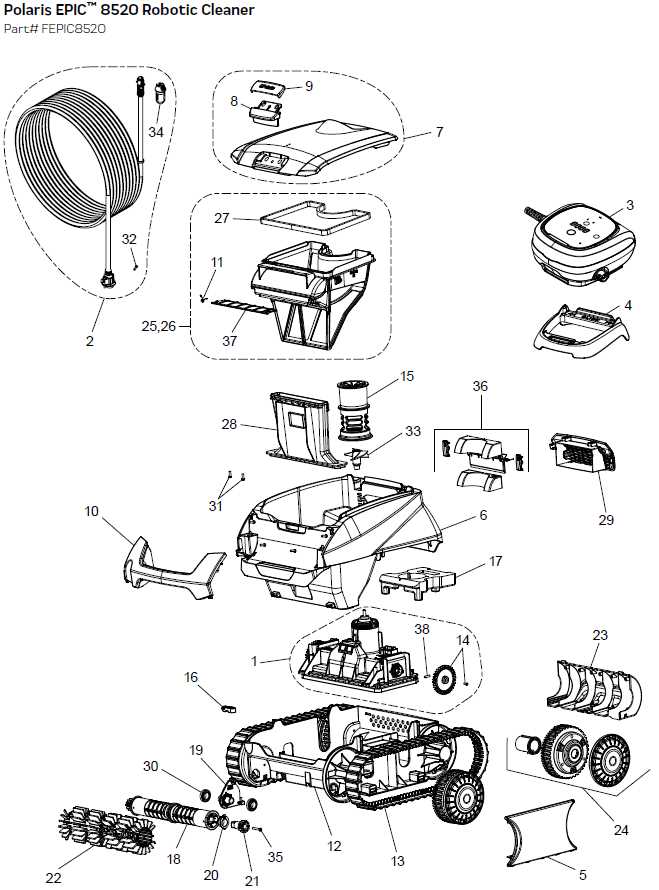

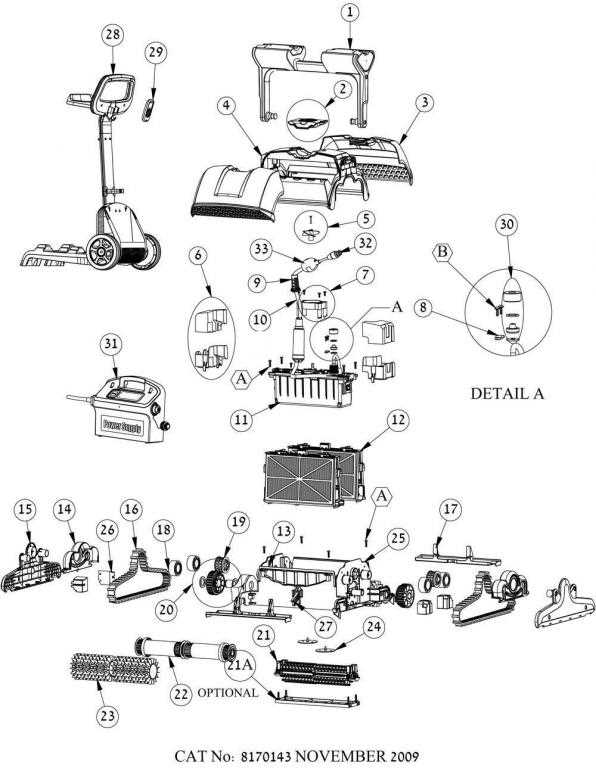

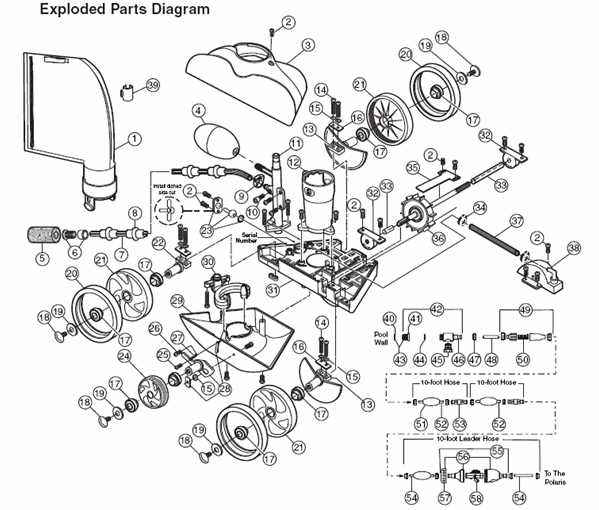

Every advanced swimming pool cleaning system consists of a series of interconnected elements that work in harmony to ensure efficient operation. Understanding how these individual components come together is crucial for maintaining the device and ensuring long-term functionality. The intricate assembly of parts forms a cohesive unit, but knowing each part’s role and how they interact with others allows for informed decisions when servicing or upgrading your equipment.

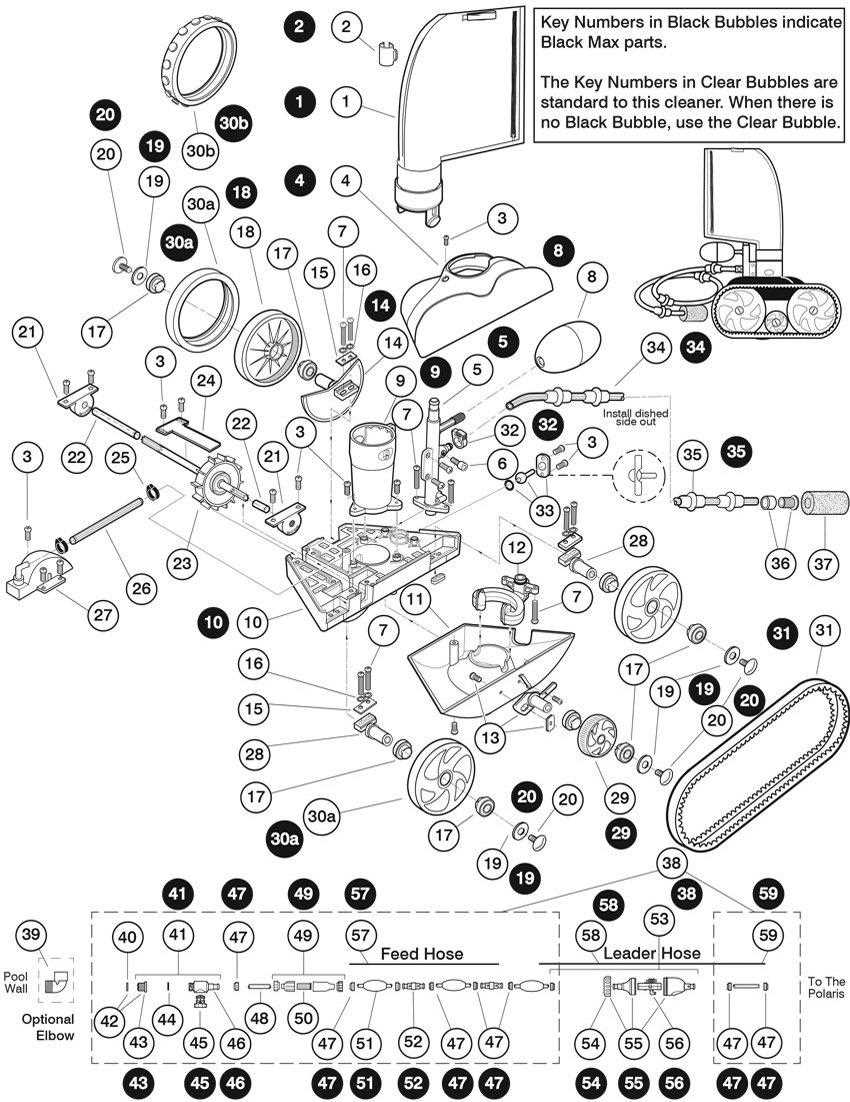

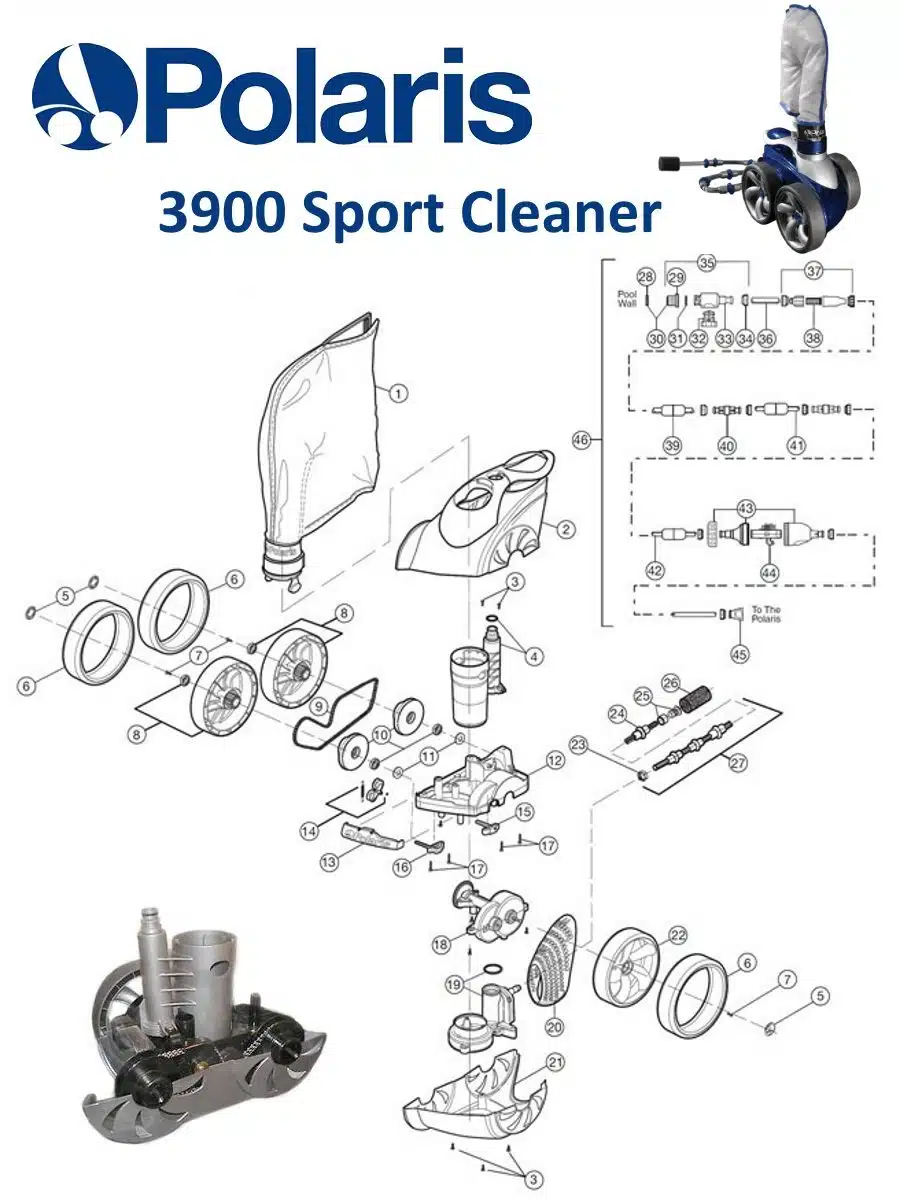

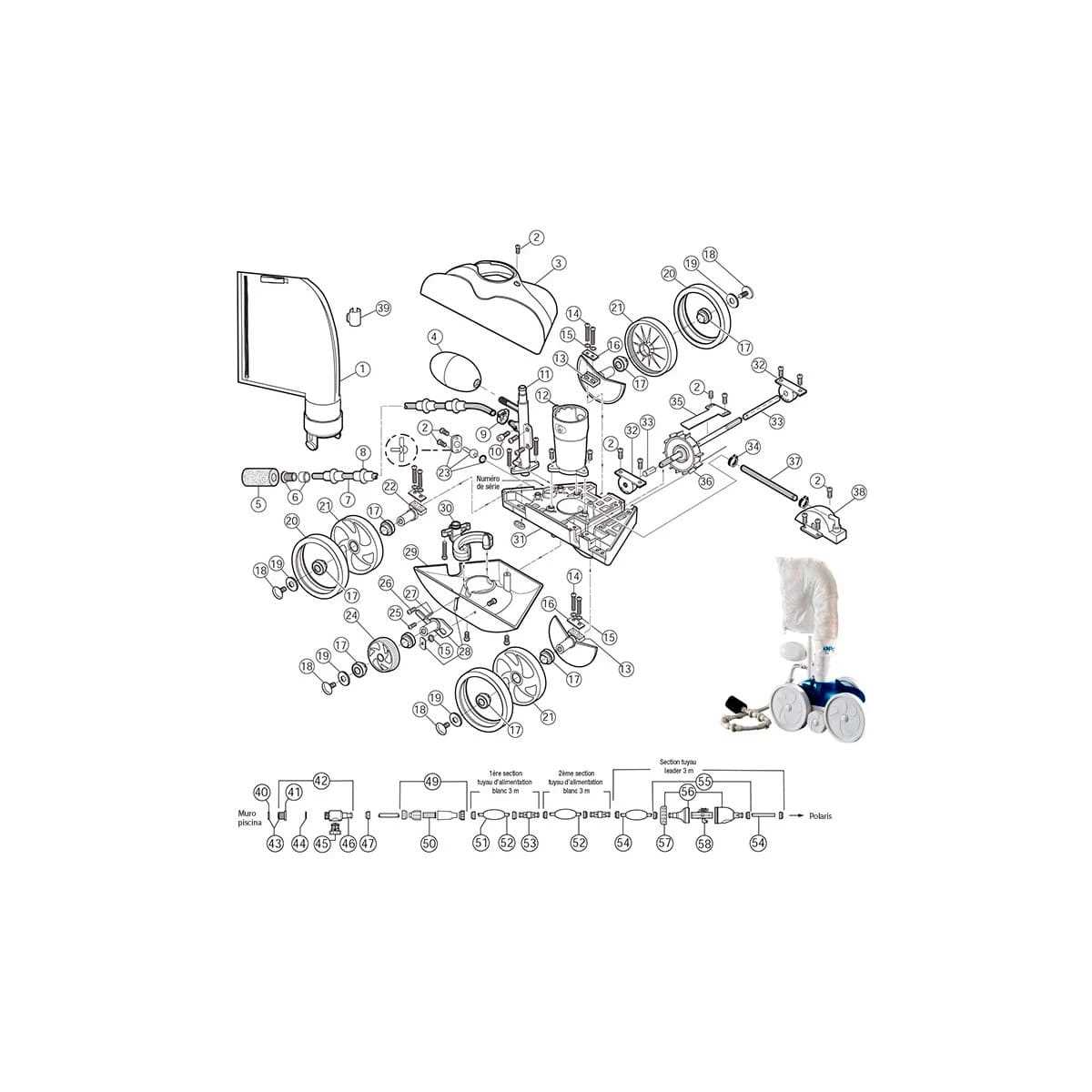

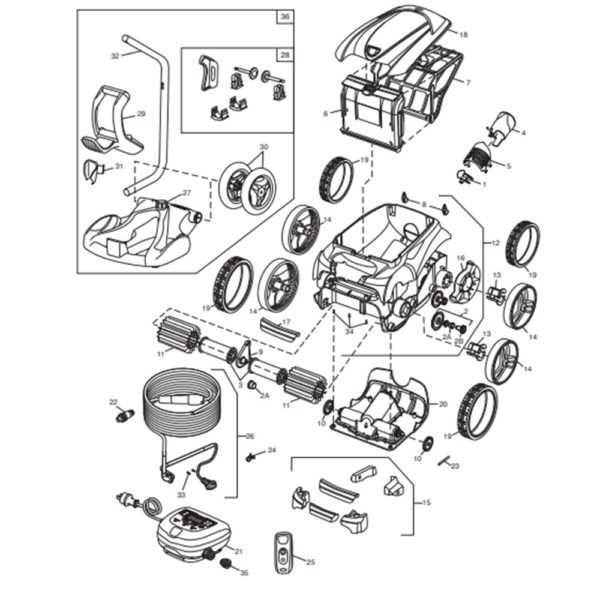

In this section, we’ll explore the essential pieces that make up this robotic cleaner, outlining their specific functions and how they contribute to overall performance. A visual representation of these key elements helps simplify the maintenance process, making it easier to identify potential issues and replace any worn or damaged sections with precision.

By familiarizing yourself with the internal layout and structure, you’ll be better equipped to tackle troubleshooting tasks and ensure that your system remains in peak condition throughout the year. Whether you’re an experienced technician or a first-time user, having a clear understanding of the overall design is an invaluable asset in the care of your pool cleaner.

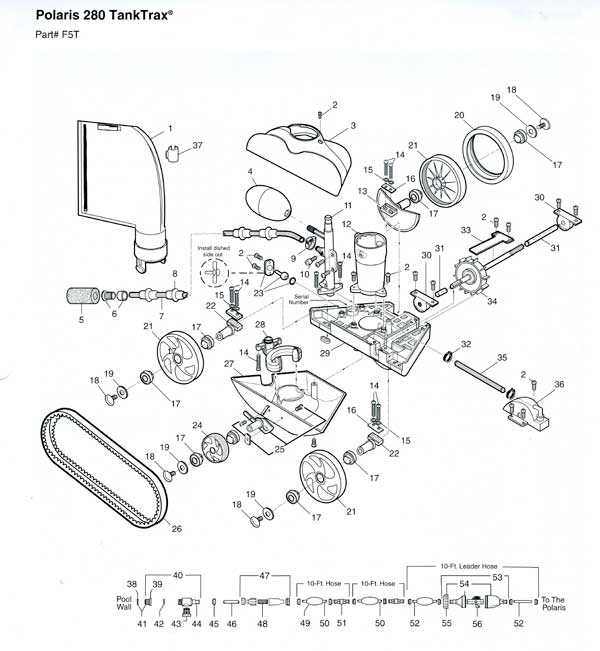

Overview of Polaris 280 Components

The system in question is designed with various key elements that work in harmony to deliver high performance and efficiency. Understanding how each individual piece contributes to the overall functionality is essential for proper maintenance and optimal use. This section provides an overview of the crucial parts that come together to create a cohesive and effective system.

- Drive Mechanism: Responsible for the movement and propulsion, ensuring smooth operation across different surfaces.

- Jets and Nozzles: These components control water flow, helping to guide the movement and clean surfaces effectively.

- Filter Assembly: Essential for trapping debris and ensuring that only clean water is circulated within the system.

- Control Unit: The central hub that manages the various functions, ensuring coordinated activity between the different components.

- Wheel System: Facilitates movement and helps maintain balance, adapting to obstacles encountered during operation.

- Pump: Critical for maintaining water circulation and providing the necessary pressure for cleaning tasks.

Each of these elements plays an important role in achieving the desired outcome. Proper care and attention to the details of these components ensure that the system remains in good working order and continues to deliver high-quality performance over time.

Essential Parts for Polaris 280 Maintenance

Regular upkeep of your automatic pool cleaner ensures its longevity and optimal performance. To maintain the efficiency of this cleaning device, it is crucial to be familiar with key components that require occasional attention or replacement. Each element plays a vital role in the smooth operation, and knowing how to address any wear or malfunction can help extend the lifespan of your equipment.

Key Components for Regular Upkeep

- Drive belts: Essential for the movement and rotation of the cleaner.

- Hoses: Responsible for water flow and mobility within the pool.

- Wheels: These allow the cleaner to navigate the surface efficiently.

- Filter bag: Collects debris and ensures clean water circulation.

- Vanes: Control the cleaner’s direction and help in maneuvering through corners.

Maintenance Tips for Longevity

- Inspect drive belts regularly for signs of wear or cracks.

- Check the hose for leaks and replace any damaged sections to prevent loss of suction.

- Lubricate the wheels to maintain smooth movement and avoid friction damage.

- Empty and clean the filter bag to ensure efficient debris collection.

- Examine the vanes for any blockages or damage that could impede movement.

Understanding the Polaris 280 Assembly

In order to efficiently maintain and troubleshoot your cleaning device, it is essential to understand its internal structure and how the various components work together. By familiarizing yourself with the assembly, you can ensure that each part is functioning correctly and make any necessary adjustments or replacements with ease. This knowledge also allows for quicker diagnostics when issues arise, saving both time and effort in the long run.

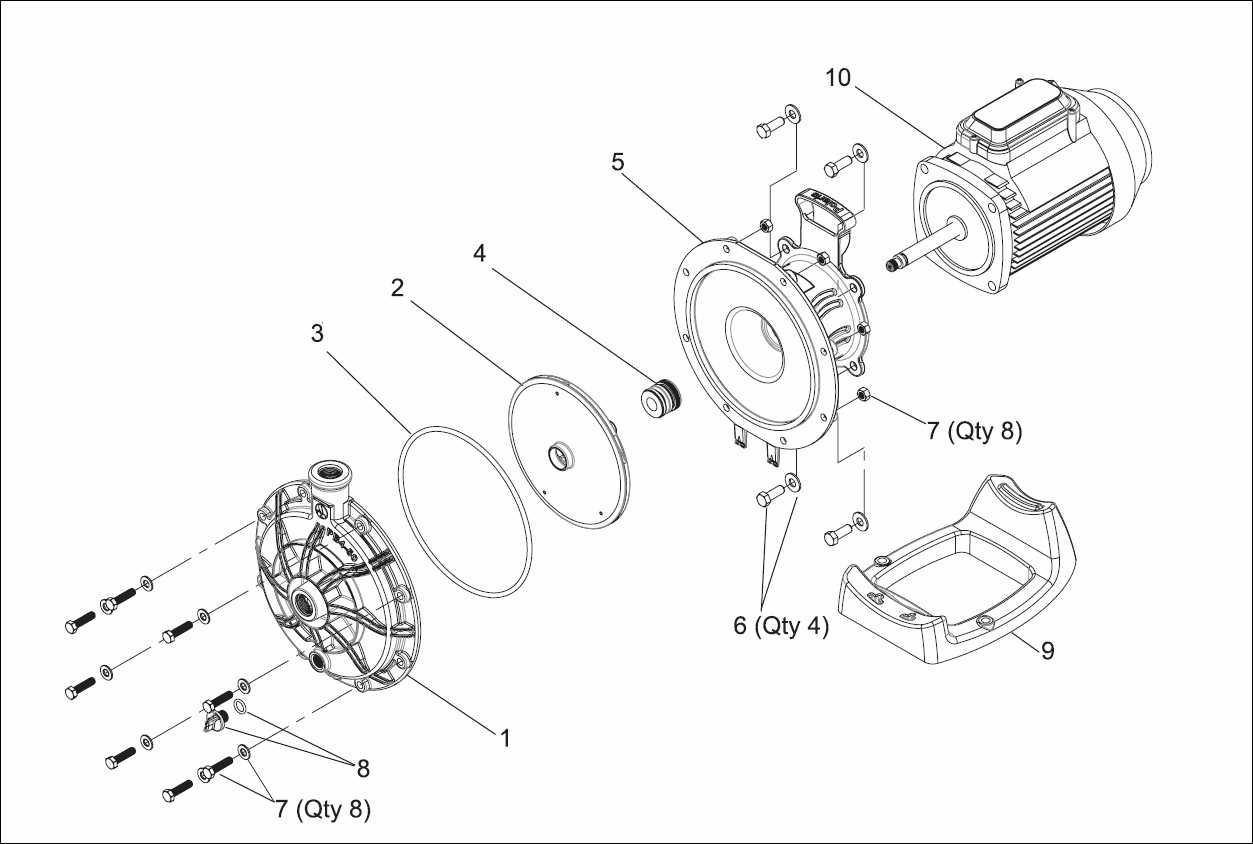

Key Components

The key to effective maintenance lies in recognizing the critical elements of the system. The primary units include the propulsion system, filtration components, and the cleaning mechanisms. Each part has a specific role in ensuring optimal performance. Understanding how these components interconnect and operate will give you greater control over the performance and longevity of the unit.

Assembly Process Overview

During assembly, each piece fits into a specific location, contributing to the overall functionality. This process involves connecting the drive mechanism to the filtration system, ensuring that the device moves smoothly while maintaining efficiency in collecting debris. Each unit is designed for easy removal and replacement, making repairs and upgrades straightforward for any user.

Regular maintenance is recommended to keep the device running smoothly. Cleaning and checking each part periodically ensures that you avoid major malfunctions.

Common Polaris 280 Replacement Parts

Regular maintenance is crucial for keeping your cleaning device in top condition. Over time, certain components may wear out and need to be replaced. Identifying these key elements can help ensure optimal performance and extend the life of your equipment.

- Drive Belt: Essential for the movement of the unit, the drive belt can stretch or break after extended use.

- Scrubber Brushes: These are responsible for agitating the water and cleaning surface, often needing replacement when they show signs of wear.

- Wheel Assemblies: The wheels support mobility and stability. Replacing damaged or worn wheels ensures smooth operation.

- Seal Kits: Important for maintaining water resistance, seal kits should be checked regularly to prevent leaks.

- Hoses: These carry water to the cleaner’s various components. Replacing damaged hoses ensures efficient water flow.

- Jets and Nozzles: Over time, nozzles and jets may become clogged or corroded, impacting water pressure and cleaning effectiveness.

Regular inspection and timely replacement of these components can help avoid downtime and keep your cleaner working effectively. Be sure to use high-quality replacements to maintain the device’s efficiency and reliability.

How to Identify Polaris 280 Spare Parts

When maintaining or repairing a pool cleaner, it is crucial to correctly identify the individual components to ensure smooth operation. Each component serves a unique function, and understanding what each part does can help in selecting the correct replacements. This section will guide you through the process of recognizing the essential elements and their specific roles.

Examine the Physical Features

Start by inspecting the shape, size, and material of the component. Most cleaning machines have distinct features, such as specific connectors, nozzles, or wheels. Comparing these physical attributes with the known characteristics of various elements can help narrow down the possibilities. Pay close attention to markings, part numbers, or any embossed labels that might provide further information about the part.

Use a Manual or Online Resources

If physical inspection does not yield sufficient information, consult the user manual or online resources. Many manufacturers offer manuals with detailed lists of components, including images and descriptions. Cross-referencing these resources with the part in question can provide clarity. Additionally, online forums or official websites may offer advice from other users who have dealt with similar situations.

Finally, when in doubt, seek expert assistance. A professional service provider can often identify the component quickly and recommend the right replacement.

Step-by-Step Guide for Polaris 280 Repair

Repairing your automatic cleaning device can seem daunting, but with the right approach and a clear step-by-step process, it becomes manageable. This guide will walk you through the essential steps to restore functionality to your machine, ensuring it runs smoothly once again. Whether you’re facing issues with poor suction or irregular movement, these instructions will help troubleshoot and resolve common problems effectively.

Tools and Materials You Will Need

Before you begin, gather the necessary tools and replacement parts. This will ensure you have everything at hand to complete the repair without interruptions.

| Tool | Description |

|---|---|

| Screwdriver | A basic tool for opening the housing and removing screws. |

| Wrench | For loosening and tightening various fittings. |

| Replacement Gaskets | Necessary for sealing joints and preventing leaks. |

| Brush | To clean debris from internal components. |

| Lubricant | For smooth movement of moving parts. |

Step 1: Disassemble the Unit

Start by removing the outer casing carefully. Use the screwdriver to remove the screws, and ensure that no small parts are misplaced during disassembly. This will expose the internal components that need to be inspected.

Step 2: Inspect and Clean the Internal Components

Once the device is open, check for debris buildup in the hoses, filters, and other compartments. Gently brush off any dirt or grime that could impair performance. Make sure all moving parts are free from obstruction to allow smooth functionality.

Step 3: Replace Damaged or Worn-out Parts

If you notice any parts that are damaged or excessively worn, replace them with the new ones you’ve gathered. Ensure all replacement components are properly fitted and sealed to avoid leaks or misalignment.

Step 4: Reassemble and Test the Unit

Once all necessary parts have been replaced and cleaned, reassemble the machine by reversing the disassembly process. Make sure all screws are tightened securely, and the unit is properly aligned. Finally, test the machine to ensure that it operates correctly and efficiently.

Following this step-by-step approach will not only help you restore the device’s functionality but also ensure that it runs optimally for a longer period. Regular maintenance and timely repairs are essential for keeping your equipment in top condition.

Choosing Quality Polaris 280 Accessories

When enhancing your aquatic experience, selecting high-quality components is essential for optimal performance and longevity. Investing in reliable additions not only improves functionality but also ensures a smoother and more enjoyable time in the water.

Here are key factors to consider when choosing accessories:

- Material Quality: Look for durable materials that resist wear and tear.

- Brand Reputation: Opt for trusted brands known for their reliability.

- Compatibility: Ensure that the accessories are specifically designed for your equipment.

- Customer Reviews: Read feedback from other users to gauge performance.

By focusing on these elements, you can delve deeper into the world of aquatic enhancements and make the ultimate choice for your needs.

Maintaining Optimal Performance with Polaris Parts

Ensuring peak efficiency of your equipment requires diligent upkeep and the right components. Regular attention to the mechanisms involved can significantly enhance longevity and effectiveness.

- Conduct frequent inspections to identify wear and tear.

- Replace worn components promptly to prevent further damage.

- Utilize high-quality replacements for better performance.

By prioritizing these practices, you can delve deeper into maintaining functionality and achieving the ultimate performance of your machinery.

- Schedule regular maintenance checks.

- Keep a record of all replacements and repairs.

- Consult professional resources when needed.

Adhering to these guidelines will ensure your equipment remains reliable and efficient throughout its lifespan.