In the realm of machinery maintenance, a thorough comprehension of the various components that contribute to optimal performance is crucial. This knowledge empowers operators and technicians to identify potential issues and implement effective solutions, ensuring longevity and efficiency.

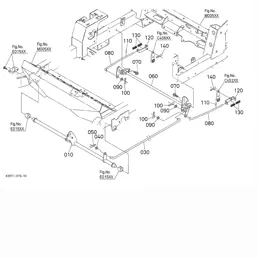

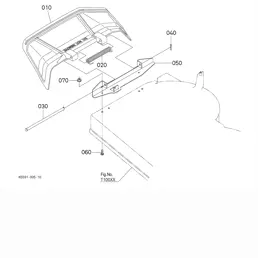

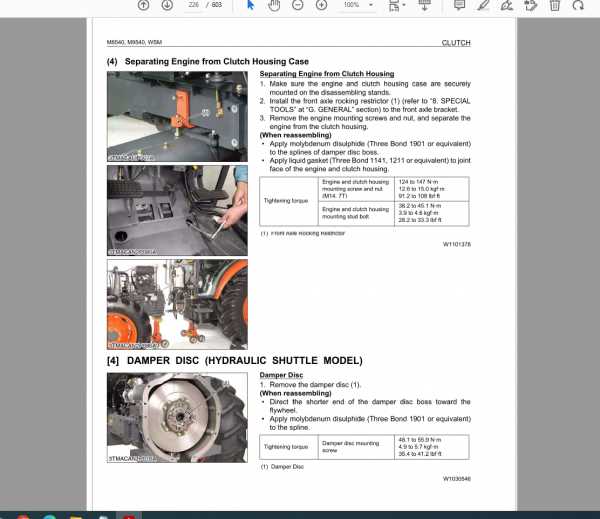

Visual representations of machinery elements serve as valuable tools for understanding how each piece fits into the larger system. By studying these illustrations, one can gain insights into the intricate relationships between different parts, facilitating more informed decision-making during repairs and replacements.

Moreover, a detailed examination of these schematics not only aids in pinpointing specific elements but also enhances overall troubleshooting skills. Familiarity with the structure and functionality of machinery promotes a proactive approach to maintenance, ultimately leading to reduced downtime and improved productivity.

Understanding Kubota Z411 Components

Grasping the intricacies of machinery is essential for effective maintenance and operation. Each element plays a pivotal role in ensuring optimal performance and longevity. A clear understanding of these components allows for better troubleshooting and enhancements.

Main Elements

- Engine: The heart of the machine, responsible for generating power.

- Transmission: Facilitates movement and speed control.

- Hydraulic System: Powers various functions and attachments.

- Chassis: Provides structural integrity and support.

Importance of Familiarity

Acquainting oneself with each part not only aids in timely repairs but also enhances operational efficiency. Knowledge of specific functions allows operators to address issues swiftly and effectively.

Importance of Parts Diagrams

Understanding the intricate components of machinery is crucial for efficient maintenance and repair. Visual representations offer clarity, allowing users to identify elements quickly and accurately.

Key benefits of using visual guides include:

- Enhanced understanding of assembly and disassembly processes.

- Improved accuracy in ordering the correct components.

- Streamlined troubleshooting by highlighting specific areas of concern.

Furthermore, these illustrations serve as valuable references for both novice and experienced technicians. By having a clear layout, one can delve deeper into the workings of equipment, ultimately ensuring optimal performance and longevity.

Key Features of the Z411 Model

This model is renowned for its exceptional engineering and innovative design, making it a standout choice in its category. Users appreciate the combination of durability and performance, which ensures reliability in various applications.

Powerful Engine: The heart of this machine is its robust engine, delivering impressive horsepower for demanding tasks. This strength translates into efficient operation across diverse terrains.

Compact Size: Its compact dimensions allow for maneuverability in tight spaces, making it ideal for urban environments or small job sites.

User-Friendly Controls: The intuitive control layout enhances operator experience, providing easy access to all essential functions, thus minimizing downtime and maximizing productivity.

Versatile Attachments: This model supports a wide range of attachments, enabling users to customize their equipment for specific tasks, whether for landscaping or agricultural needs.

Comfortable Cabin: Designed with operator comfort in mind, the cabin features ergonomic seating and controls, reducing fatigue during extended use and enhancing overall work efficiency.

How to Read a Parts Diagram

Understanding an illustration of components can greatly enhance your ability to identify and replace individual pieces of machinery. This visual representation serves as a crucial tool for maintenance and repair, providing clarity on how different elements interact within a system.

To effectively interpret these illustrations, follow these key steps:

| Step | Description |

|---|---|

| 1 | Familiarize yourself with the layout and the overall structure depicted. |

| 2 | Identify numbered or labeled components, which often correspond to a list or key. |

| 3 | Look for connections between parts to understand how they work together. |

| 4 | Refer to accompanying documentation for detailed specifications and installation guidance. |

By mastering these techniques, you will ultimately streamline your repair process and ensure efficient maintenance of your equipment.

Common Issues and Solutions

Every mechanical system may encounter challenges that hinder its performance. Understanding these common problems can help users identify symptoms early and implement effective remedies. Below are some prevalent issues faced by operators and suggested solutions to enhance functionality.

One frequent concern is overheating, which can arise from inadequate coolant levels or a malfunctioning radiator. To address this, regularly check fluid levels and ensure proper airflow around the unit. If problems persist, inspecting the cooling system for blockages or leaks may be necessary.

Another common issue is inconsistent operation, often caused by fuel contamination or air blockages in the lines. To resolve this, routinely inspect and replace fuel filters, and purge any air pockets that may develop. Maintaining clean fuel is essential for smooth functioning.

Lastly, wear and tear on moving components can lead to noise and reduced efficiency. Regular maintenance checks and timely replacement of worn parts can significantly mitigate these concerns. Keeping a maintenance schedule can help prolong the lifespan of the machinery.

Where to Find Replacement Parts

Locating suitable components for machinery can often be a challenging task. However, several reliable sources exist to assist you in acquiring the necessary items to ensure optimal functionality of your equipment.

- Authorized Dealers: Visiting certified retailers guarantees authenticity and quality. They typically maintain a comprehensive inventory of items tailored for specific machinery.

- Online Marketplaces: Websites like eBay, Amazon, and specialized platforms offer a wide selection of components. Always check seller ratings and reviews for reassurance.

- Local Repair Shops: Many repair facilities have access to various components and can order what you need directly from manufacturers.

- Salvage Yards: These locations can provide used components at a lower cost. It’s essential to inspect items for wear and compatibility.

- Manufacturer Websites: Directly visiting the manufacturer’s website often provides options to purchase items online or find local distributors.

By exploring these avenues, you can find the right components that meet your requirements while ensuring the longevity and efficiency of your machinery.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of machinery requires regular attention and care. Implementing a consistent maintenance routine can prevent breakdowns and enhance performance over time.

Regular Inspections

Conduct frequent evaluations to identify wear and tear. Look for any signs of damage or malfunction, as early detection is key to avoiding costly repairs.

Proper Lubrication

Utilize high-quality lubricants to reduce friction and prevent rust. Maintaining optimal levels of oil and grease will help extend the lifespan of moving parts.

Emphasizing preventive care and addressing issues promptly will ultimately lead to more reliable operation and greater efficiency.

Comparative Analysis with Other Models

This section explores the differences and similarities among various equipment types, highlighting their unique features and performance metrics. Understanding these distinctions can aid in making informed decisions regarding machinery selection for specific tasks.

Performance Metrics

- Engine Power: Compare horsepower and torque output.

- Fuel Efficiency: Analyze consumption rates across models.

- Operational Range: Evaluate the capabilities in different terrains.

Durability and Maintenance

- Material Quality: Assess the robustness of components.

- Maintenance Needs: Review frequency and ease of service.

- Warranty Options: Compare coverage and terms offered.

Resources for Further Exploration

For those seeking to enhance their understanding of machinery components and maintenance, a variety of valuable resources are available. These tools can provide insights, diagrams, and detailed information that will aid in effective repairs and upgrades.

- Manufacturer Websites: Explore official sites for technical documents and user manuals.

- Online Forums: Engage with communities where enthusiasts share knowledge and experiences.

- YouTube Channels: Watch instructional videos that demonstrate repair techniques and component identification.

- Industry Publications: Read articles and guides from experts that delve into best practices and innovations.

- Parts Retailers: Visit online shops that often provide diagrams and compatibility information for various models.

Utilizing these resources will empower users to gain the ultimate knowledge necessary for maintaining their equipment efficiently.