The efficiency of any internal combustion engine greatly relies on its fuel management system, which plays a crucial role in the overall performance and functionality of the vehicle. A comprehensive understanding of the various elements involved in this system allows for better troubleshooting, maintenance, and upgrades. By examining these components, enthusiasts and mechanics alike can gain valuable insights into optimizing fuel flow and enhancing engine efficiency.

Within this intricate network, each component has a specific function, contributing to the seamless operation of the engine. Recognizing how these elements interact and their roles in regulating fuel and air mixture is vital for effective repairs and modifications. A visual representation can aid in identifying and understanding these crucial components, facilitating easier maintenance and modifications.

As one delves into the anatomy of this essential system, the intricate design and functionality of each part become more apparent. This exploration highlights the importance of precision in design and the impact of each component on the overall system’s performance. By grasping these concepts, individuals can ensure their vehicle runs smoothly and efficiently.

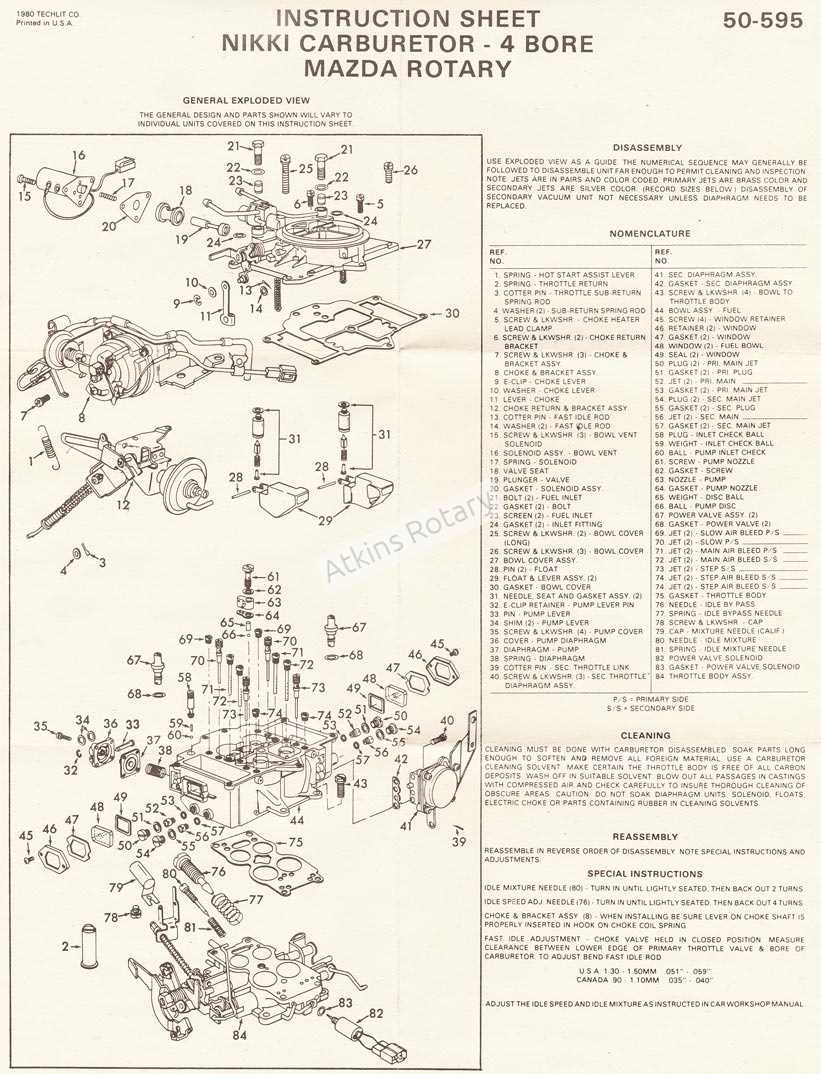

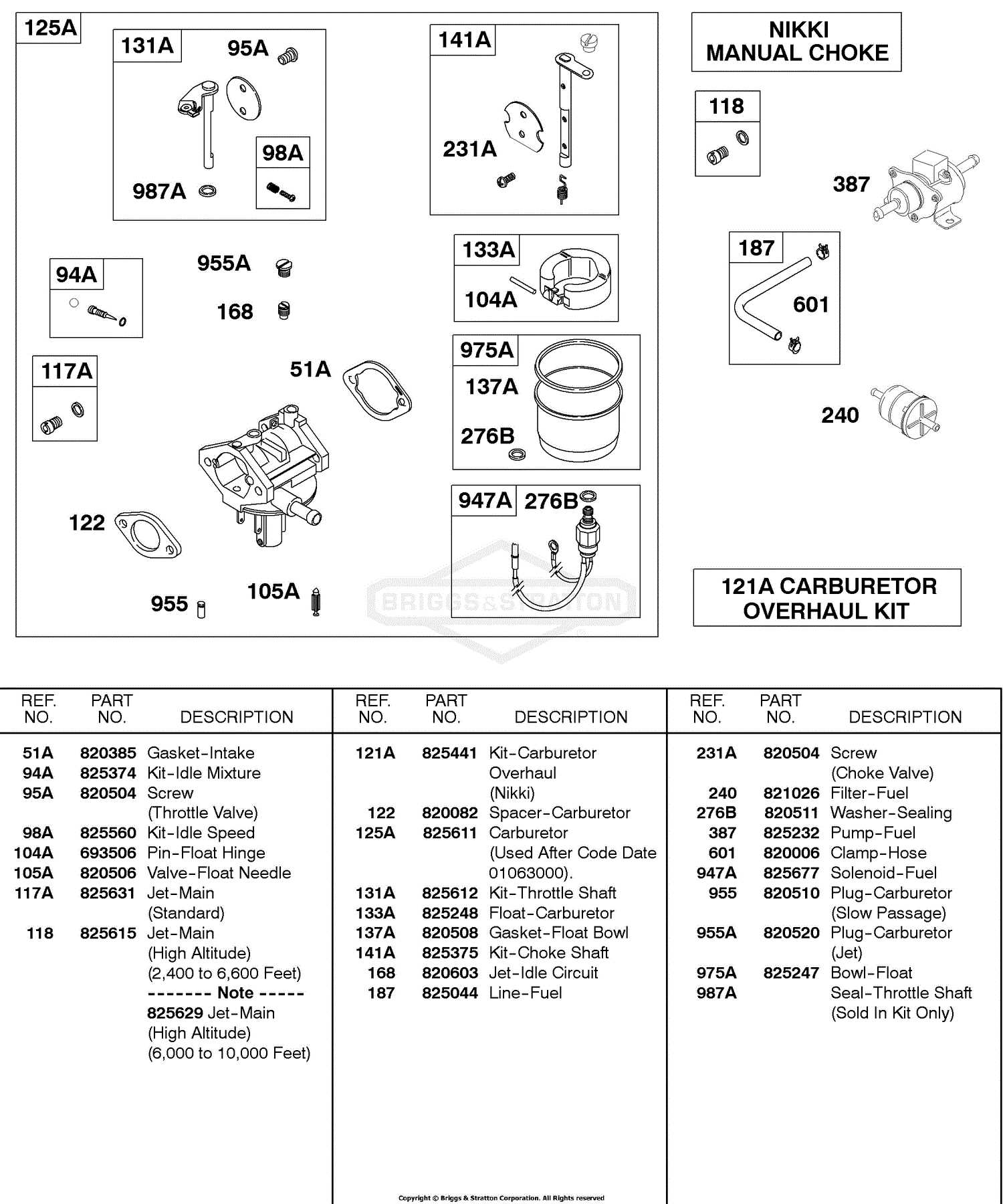

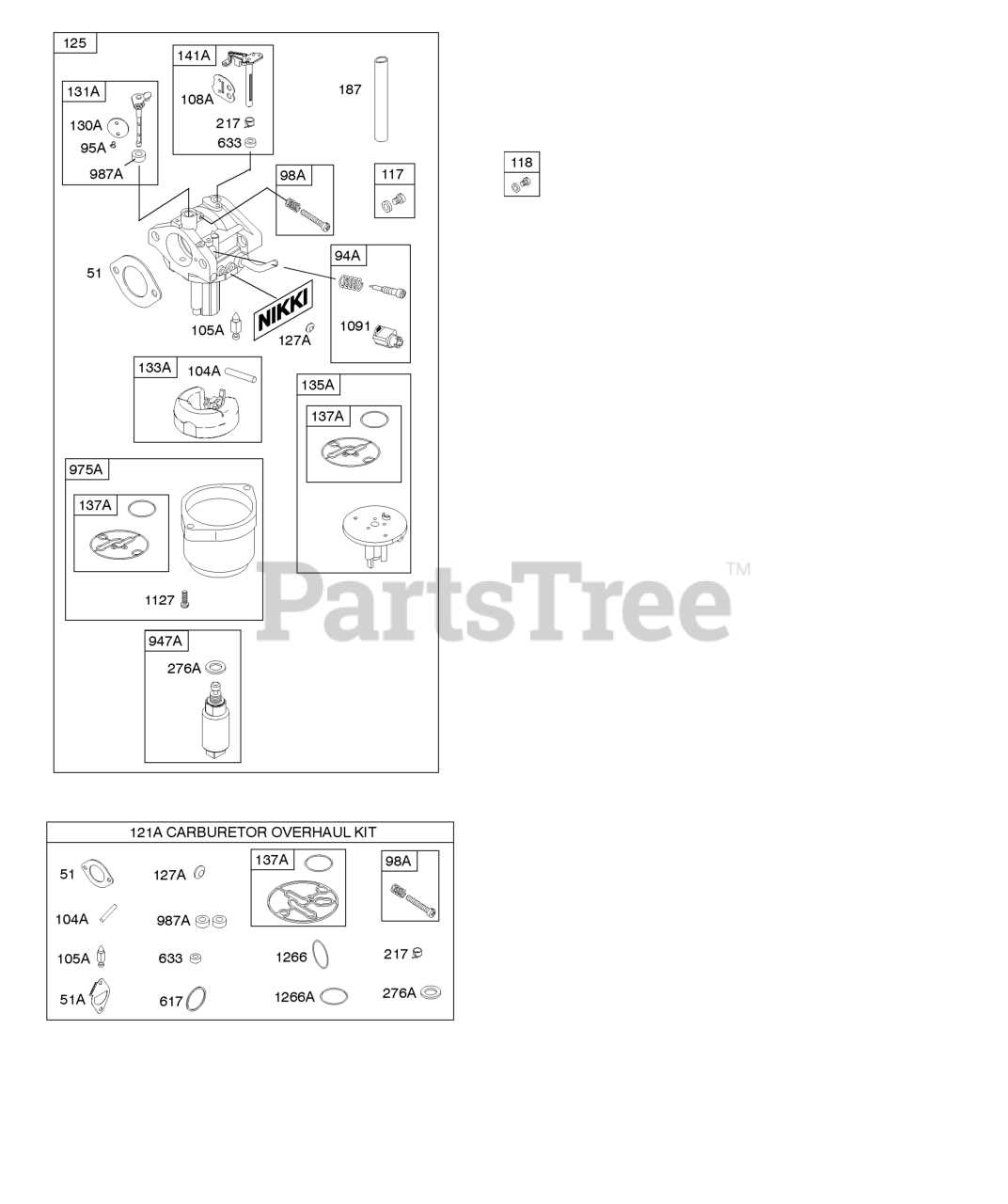

Nikki Carb Parts Overview

This section provides an insight into the essential components of a specific fuel delivery system commonly utilized in various small engines. Understanding these elements is crucial for effective maintenance and performance optimization.

Key Components

- Float Chamber: Regulates the fuel level, ensuring consistent supply to the mixing chamber.

- Throttle Valve: Controls the airflow, adjusting the engine’s power output.

- Jet Nozzles: Facilitate the precise delivery of fuel into the airflow for optimal combustion.

- Venturi: Creates a low-pressure area that draws fuel into the airflow, essential for proper mixing.

- Choke: Restricts airflow to enrich the fuel mixture during startup.

Maintenance Considerations

- Regular Cleaning: Keeping the system free from debris ensures efficient operation.

- Inspection: Periodically check for wear and damage to components for better longevity.

- Adjustment: Fine-tuning fuel delivery and airflow can significantly enhance performance.

- Replacement: Knowing when to replace worn components is essential for maintaining efficiency.

Understanding Carburetor Functionality

The essential role of a fuel delivery system is to mix air and fuel in precise proportions, ensuring optimal combustion within the engine. This intricate process involves various components working in unison to regulate the mixture, adapting to different operating conditions. A thorough comprehension of this system’s functionality reveals how it contributes to efficient engine performance and responsiveness.

Key Components and Their Roles

At the heart of this mechanism are several critical elements that influence how fuel and air are combined. The venturi effect is pivotal; as air flows through a narrow passage, its speed increases while pressure decreases, drawing fuel from the reservoir. This phenomenon is essential for achieving the right mixture ratio, especially during varying throttle positions.

Impact of Adjustments on Performance

Fine-tuning the system can significantly affect performance. Adjustments to the mixture screws and float level directly influence how the fuel is delivered, impacting acceleration, fuel efficiency, and overall engine response. Understanding these adjustments empowers users to optimize their system for better performance and reliability.

Essential Components of Nikki Carbs

Understanding the fundamental elements of fuel delivery systems is crucial for optimizing engine performance. Each component plays a vital role in ensuring proper air and fuel mixing, allowing for efficient combustion and smooth operation. Below are key elements that contribute to the functionality of these systems.

| Component | Function |

|---|---|

| Throttle Body | Controls airflow into the engine, impacting power and responsiveness. |

| Float Chamber | Maintains a consistent fuel level to ensure steady delivery to the mixing area. |

| Jets | Regulate fuel flow, determining the air-fuel mixture ratio for optimal performance. |

| Venturi | Creates a vacuum that draws fuel into the airflow, facilitating mixing. |

| Choke | Richens the mixture during cold starts to aid engine ignition. |

Each of these elements must work harmoniously to achieve the desired engine efficiency and performance. Regular maintenance and understanding their roles can significantly enhance vehicle operation.

Common Issues with Nikki Carb Parts

Understanding the frequent complications associated with fuel delivery systems is essential for maintaining optimal engine performance. These challenges can arise from various components that play a crucial role in ensuring efficient operation. Recognizing these issues early can help prevent significant performance drops and costly repairs.

Fuel Leakage: One prevalent concern is the occurrence of leaks, which can result from worn seals or gaskets. Such leaks not only lead to inefficiencies but also pose safety hazards due to flammable liquids.

Clogged Jets: Another issue is the clogging of jets, often caused by debris or varnish buildup from stale fuel. This blockage restricts the flow of fuel, leading to poor engine performance and rough idling.

Imbalanced Mixture: An imbalanced fuel-air mixture can create a variety of performance problems, including poor acceleration and increased emissions. This imbalance often results from improperly calibrated components or external adjustments.

Throttle Response: Delayed or unresponsive throttle can indicate problems within the linkage or diaphragm. This sluggish response affects overall drivability and may stem from wear or incorrect installation of components.

Maintenance Neglect: Regular maintenance is crucial. Neglecting routine inspections can lead to cumulative issues that may severely impact functionality over time. Regular cleaning and part replacement can mitigate many common problems.

Maintenance Tips for Optimal Performance

To ensure peak efficiency and longevity of your fuel delivery system, regular upkeep is essential. Proper maintenance not only enhances performance but also prevents potential issues that could arise from neglect. This section outlines key practices to maintain your system effectively.

| Tip | Description |

|---|---|

| Regular Cleaning | Periodically clean the internal components to remove buildup that can affect fuel flow and efficiency. |

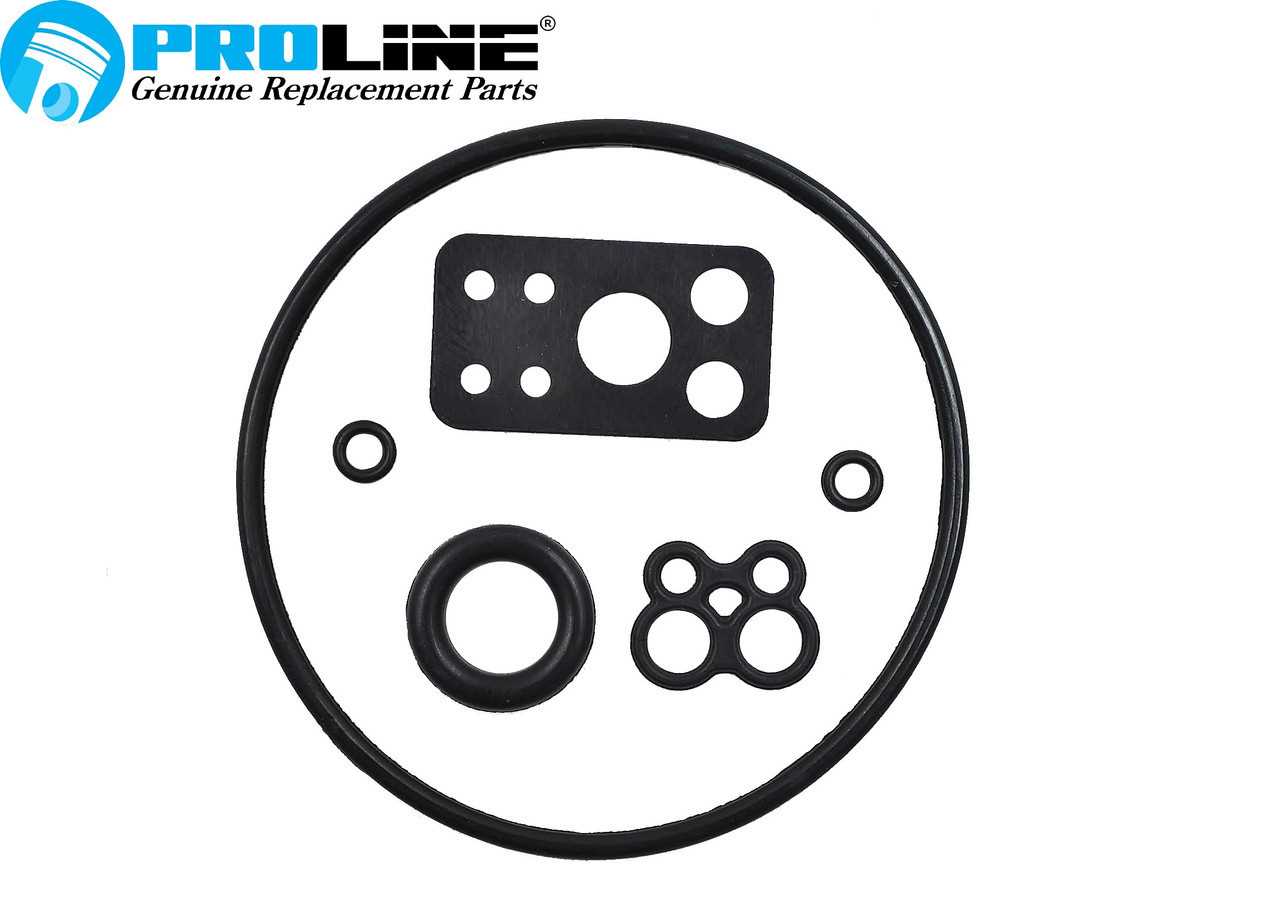

| Inspect Seals and Gaskets | Check for wear and tear in seals and gaskets to prevent leaks and maintain proper pressure. |

| Check Fuel Quality | Use high-quality fuel to minimize deposits and ensure efficient combustion within the system. |

| Adjust Settings | Regularly check and adjust the air-fuel mixture to optimize performance based on operating conditions. |

| Monitor Performance | Keep an eye on performance metrics and be alert to any changes that may indicate underlying issues. |

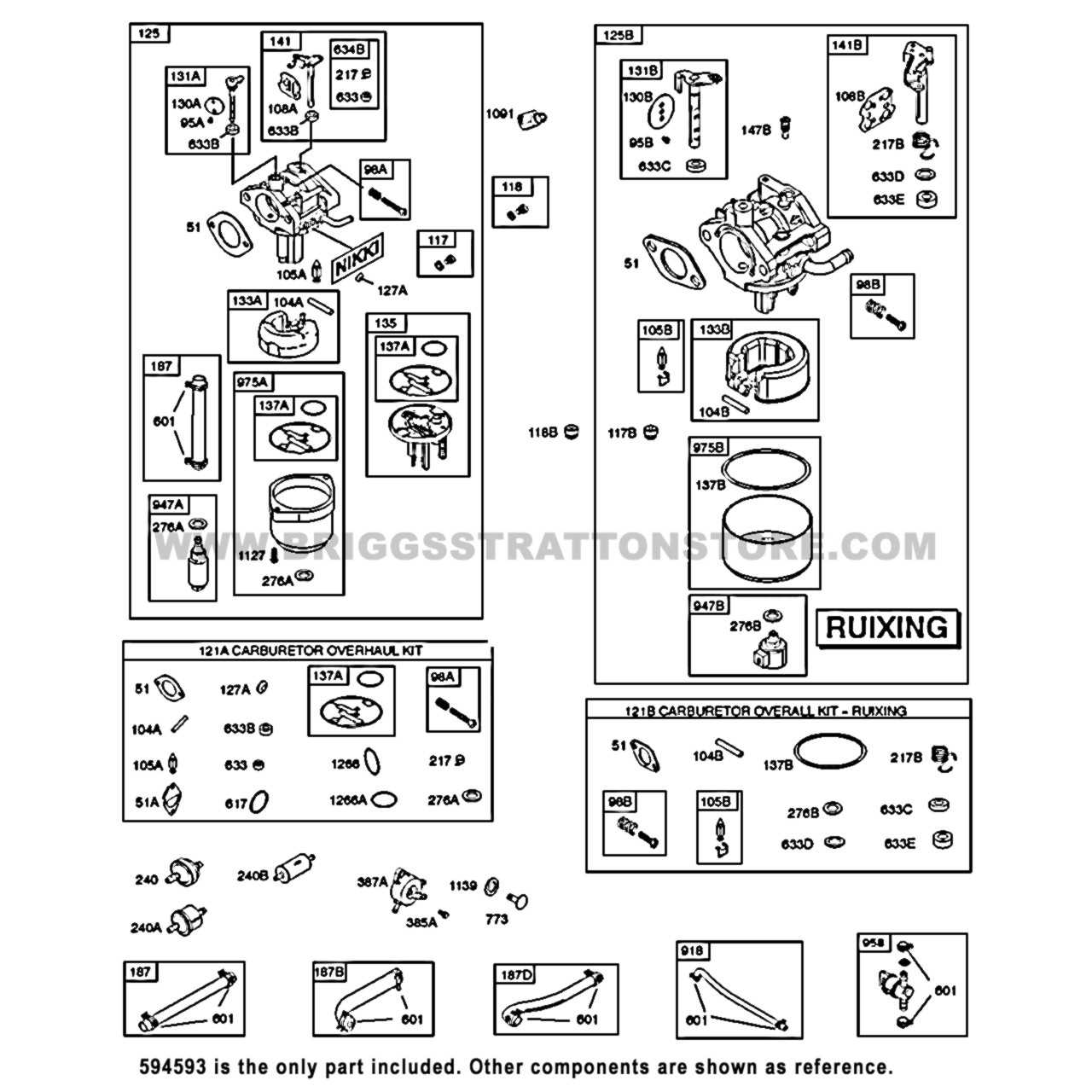

Identifying Parts by Model Number

Understanding how to distinguish components through their identification numbers is crucial for efficient repairs and replacements. Each number serves as a unique identifier that simplifies the process of locating the appropriate items needed for various mechanical systems. With a systematic approach, you can streamline your search and ensure compatibility with existing setups.

Understanding Model Numbers

Model numbers are typically composed of letters and digits, each conveying specific information about the component’s design and specifications. Familiarizing yourself with these sequences will help you interpret their meanings and connect them to the right replacements.

Finding Replacement Components

When seeking substitutes, refer to the manufacturer’s catalog or online resources where you can input the model number to find a list of corresponding items. This method not only saves time but also reduces the risk of acquiring incorrect components.

| Model Number | Description | Compatibility |

|---|---|---|

| 1234AB | Standard flow unit | Compatible with models X1, Y2 |

| 5678CD | High-performance variant | Compatible with models Z3, W4 |

| 91011EF | Heavy-duty version | Compatible with models V5, U6 |

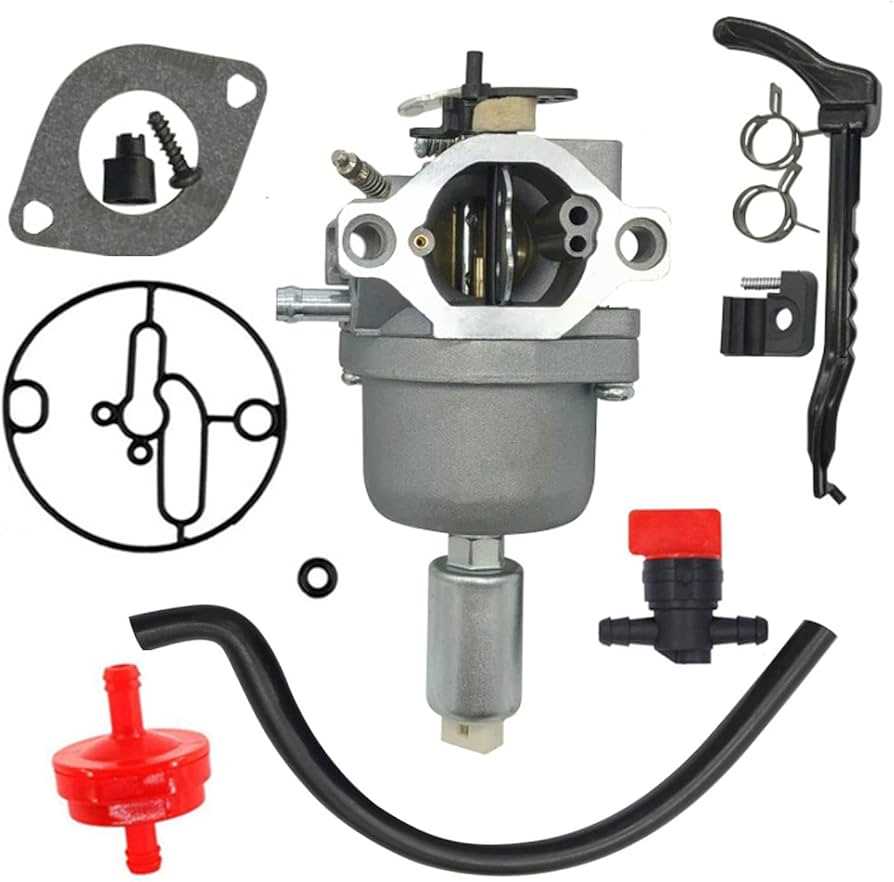

Exploring Aftermarket Replacement Options

When seeking alternatives for essential engine components, enthusiasts often turn to aftermarket solutions that offer both reliability and performance enhancements. These options can provide comparable quality to original equipment while potentially offering improved features or cost savings.

Advantages of selecting aftermarket alternatives include enhanced availability and the possibility of specialized enhancements tailored to specific needs. Many manufacturers produce components that meet or exceed factory specifications, ensuring that your engine operates smoothly and efficiently.

In addition, researching reputable suppliers can reveal innovative designs and materials that improve overall performance. It’s important to consider customer reviews and testimonials to gauge the effectiveness and longevity of the replacements you are considering.

Ultimately, exploring aftermarket alternatives allows for greater flexibility in customizing and optimizing your vehicle’s performance while often providing a budget-friendly solution.

Visual Guide to Nikki Carb Assembly

This section aims to provide a comprehensive overview of the components involved in the assembly process of a specific type of fuel delivery system. Understanding the structure and functionality of these elements is essential for effective maintenance and repair. The visual representation will assist enthusiasts and mechanics in navigating through the assembly with clarity.

Essential Components

- Body Assembly

- Float Chamber

- Throttle Plate

- Jets and Needles

- Air Intake

- Gaskets and Seals

Assembly Process Overview

- Start with the base and ensure a clean surface for optimal sealing.

- Install the float chamber securely, making sure all gaskets are in place.

- Attach the throttle plate, ensuring it operates smoothly.

- Carefully position the jets and needles to achieve the desired fuel flow.

- Complete the assembly by attaching the air intake and ensuring all components are securely fastened.

Following this guide will help in achieving a successful assembly, ensuring reliability and efficiency in performance. Regular inspection and maintenance are recommended to prolong the lifespan of the system.

Resources for Parts and Repairs

For those seeking to maintain or restore their fuel delivery systems, a variety of resources are available to assist in finding components and services. These options cater to different needs, whether you are looking for original equipment or aftermarket alternatives, and they can significantly enhance the efficiency of your vehicle.

Online Retailers and Marketplaces

Numerous online platforms specialize in automotive components, offering a wide range of choices. Websites like eBay and Amazon feature listings from various sellers, making it easy to compare prices and find the right solutions. Additionally, dedicated automotive sites often provide user reviews and ratings, which can guide your selection process.

Local Shops and Salvage Yards

Visiting local repair shops or salvage yards can be beneficial for sourcing rare or discontinued items. These establishments often carry used but functional components at lower prices, contributing to a sustainable approach to vehicle maintenance. Furthermore, knowledgeable staff can provide invaluable advice on installation and compatibility.