In the world of agricultural machinery, the effectiveness of harvesting operations greatly relies on the intricate design and functionality of various attachments. This section delves into the essential elements that contribute to the optimal performance of these specialized tools. By familiarizing oneself with these components, operators can enhance their productivity and ensure smoother harvesting processes.

Identifying crucial elements within these mechanisms is vital for maintaining equipment efficiency. Each piece plays a distinct role, working in harmony to achieve desired results. By examining the layout and arrangement of these parts, users can better understand how to troubleshoot issues and perform necessary maintenance tasks.

Additionally, visual representations of these components serve as valuable resources for both seasoned operators and newcomers alike. With a comprehensive understanding of the structure and function of these attachments, users are empowered to make informed decisions, leading to improved outcomes during the critical harvest season.

Overview of New Holland 824 Corn Head

This section provides a comprehensive look at a specialized harvesting attachment designed for efficient crop collection. Its robust engineering and innovative features enhance performance in various agricultural settings, making it a vital component for modern farming operations.

Equipped with advanced technology, this apparatus maximizes yield and minimizes loss during the harvesting process. Its design facilitates smooth operation, ensuring that the machinery can adapt to diverse field conditions while maintaining productivity.

Key attributes include durability, ease of maintenance, and compatibility with a range of harvesting equipment. These characteristics contribute to reduced downtime and improved efficiency, allowing farmers to optimize their harvesting efforts.

In summary, this harvesting tool exemplifies the blend of innovation and functionality, providing users with the reliability and performance necessary for successful agricultural practices.

Key Components of Corn Heads

The efficiency of harvesting is largely determined by the critical elements that constitute the gathering machinery. Understanding these components is essential for optimizing performance and ensuring durability in the field.

| Component | Description |

|---|---|

| Gathering Chains | Facilitate the movement of crop material toward the center for processing. |

| Snouts | Guide the crop into the machine while minimizing losses. |

| Augers | Assist in transferring harvested material to the combine’s intake. |

| Knives | Cut the stalks efficiently for a clean harvest. |

| Frame | Provides structural support and stability during operation. |

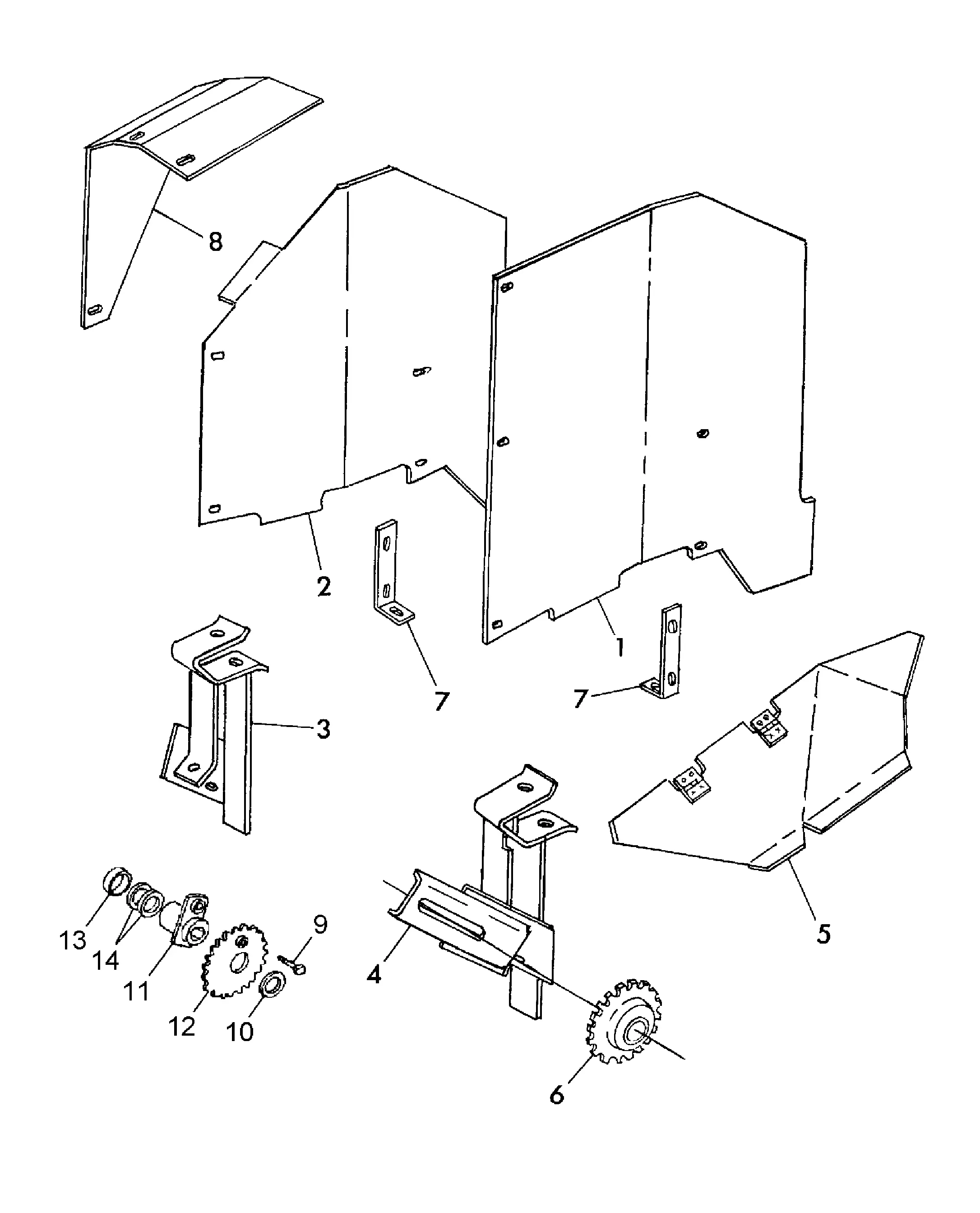

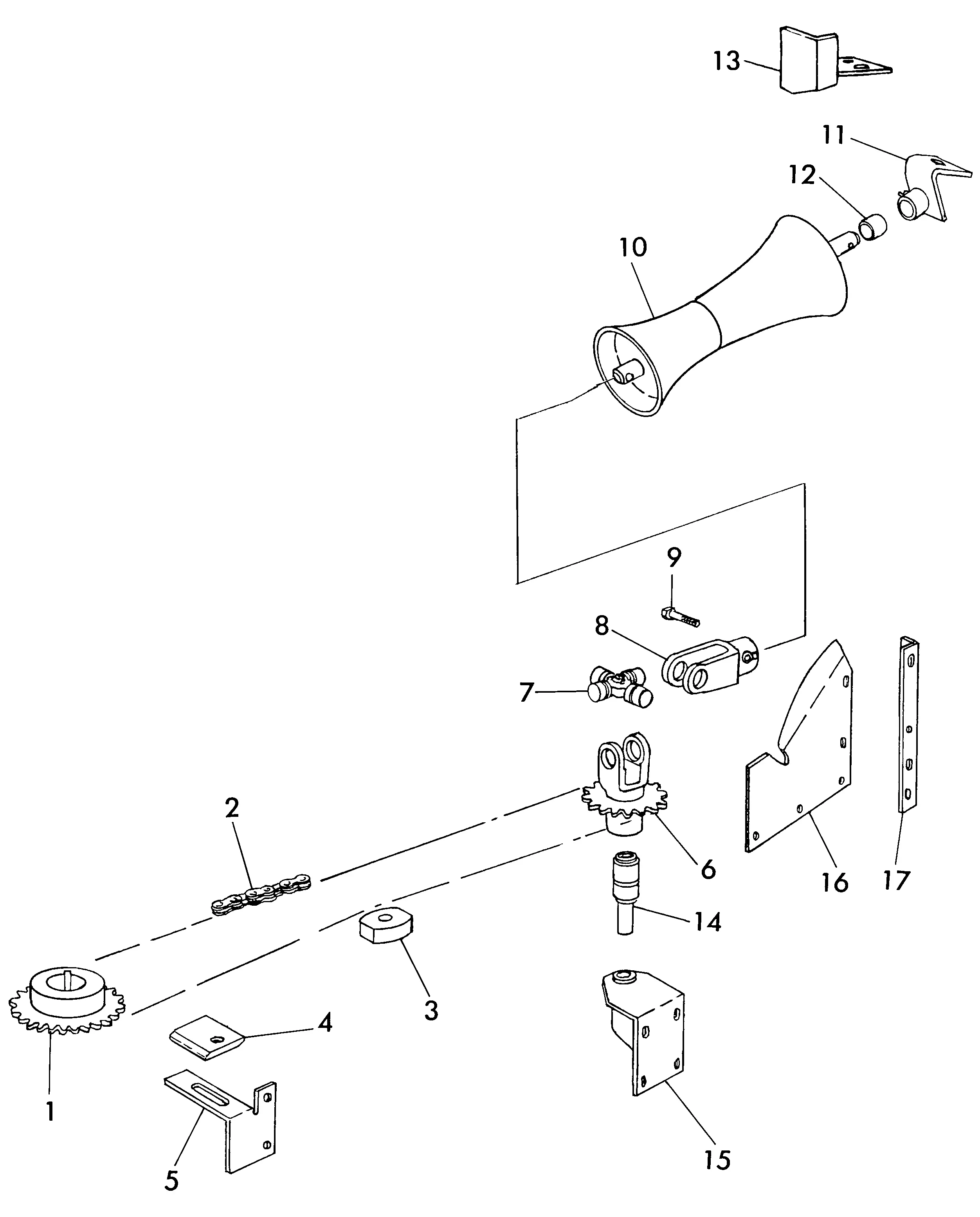

Understanding Parts Diagrams

Deciphering schematics is essential for anyone involved in maintenance or repair of machinery. These illustrations provide a visual representation of components, making it easier to identify and source replacements when needed. A clear understanding of these visuals can significantly enhance efficiency during repairs.

Effective use of these illustrations can prevent costly mistakes and save valuable time. They often highlight the relationship between different elements, ensuring that one can grasp how each part interacts within the whole system. By familiarizing yourself with these visuals, you empower yourself to tackle repairs with confidence.

Ultimately, mastering these visual aids transforms the repair process into a more manageable task, fostering a deeper connection with the machinery in question.

Maintenance Tips for Optimal Performance

Ensuring peak functionality of agricultural machinery requires consistent upkeep and attention to detail. Regular maintenance not only extends the lifespan of equipment but also enhances productivity during operation. Here are essential practices to follow for optimal results.

Regular Inspections

- Conduct frequent visual checks for wear and tear.

- Examine belts and chains for proper tension and alignment.

- Inspect hydraulic systems for leaks and functionality.

Lubrication and Cleaning

- Grease all moving components according to the manufacturer’s recommendations.

- Clean debris and residue from the machinery to prevent clogging and overheating.

- Ensure all filters are replaced regularly to maintain airflow and efficiency.

Following these guidelines will help maintain the machinery’s efficiency and ensure reliable operation during peak seasons.

Common Issues and Troubleshooting

When working with agricultural machinery, it’s essential to be aware of potential challenges that may arise during operation. Understanding common problems and their solutions can significantly enhance efficiency and reduce downtime. This section provides insights into frequent issues and offers practical troubleshooting tips.

Typical Problems

- Uneven Crop Flow: This can lead to clogs and reduced performance.

- Excessive Wear: Components may wear out faster due to improper adjustments.

- Noisy Operation: Unusual sounds can indicate mechanical issues.

- Hydraulic Failures: Leaks or pressure drops can hinder functionality.

Troubleshooting Tips

- Regularly inspect components for signs of wear and tear.

- Ensure proper alignment and adjustment of parts to maintain even crop flow.

- Check hydraulic systems for leaks and ensure optimal fluid levels.

- Listen for abnormal noises and investigate the source promptly.

By addressing these common issues with systematic troubleshooting, operators can enhance the longevity and performance of their machinery.

Aftermarket Parts vs. OEM Options

In the world of agricultural machinery, the choice between alternative components and original manufacturer offerings is a crucial consideration for operators. Each option presents its own set of advantages and disadvantages that can significantly impact performance, longevity, and maintenance costs.

Alternative components often attract buyers due to their lower price points and availability, making them an appealing choice for those looking to save on expenses. Conversely, original manufacturer offerings are typically associated with guaranteed compatibility and reliability, ensuring that the equipment operates as intended.

| Factor | Aftermarket Components | OEM Offerings |

|---|---|---|

| Cost | Generally lower | Typically higher |

| Compatibility | Varies by manufacturer | Guaranteed fit |

| Quality | Inconsistent | Consistent and reliable |

| Availability | Widely available | Limited to specific dealers |

| Warranty | Varies | Often includes a warranty |

Ultimately, the decision hinges on individual needs and priorities, weighing factors such as cost, quality, and the specific requirements of the machinery in question.

Installation Guide for Key Parts

This section provides essential instructions for the correct assembly and setup of critical components in agricultural machinery. Proper installation is vital for ensuring optimal performance and longevity. Following the guidelines will facilitate a seamless integration of the elements, enhancing operational efficiency.

Before beginning the installation process, ensure that you have all necessary tools and components at hand. Start by reviewing the specifications of each item, verifying compatibility, and preparing the workspace to allow easy access and movement.

To install the main structure, align it carefully with the mounting brackets. Utilize the appropriate fasteners, ensuring they are tightened to the manufacturer’s recommended torque specifications. This will prevent any looseness during operation.

Next, attach the auxiliary elements in the order specified in the manual. Pay attention to any alignment marks or guides, as these will assist in achieving proper placement. It is crucial to secure all connections firmly to avoid malfunctions.

Once everything is assembled, conduct a thorough inspection to confirm that all components are correctly installed and secured. A test run should be performed to identify any potential issues before full-scale operation. This proactive approach will help maintain the machinery’s reliability and efficiency.

Comparative Analysis with Other Models

This section aims to explore the differences and similarities among various harvesting attachments, highlighting their functionalities, efficiencies, and unique features. Understanding these distinctions can aid users in making informed choices based on their specific agricultural needs.

Design and Efficiency

When analyzing design aspects, some models prioritize aerodynamics and reduced drag, while others focus on durability and maintenance ease. Efficiency in crop collection and processing varies, influencing overall performance during the harvest season.

Compatibility and Versatility

Compatibility with different machinery is crucial for seamless operation. Certain attachments offer broader adaptability across various tractors, enhancing versatility in diverse farming conditions compared to their counterparts, which may be limited in this regard.

Resources for Parts and Support

Accessing reliable resources for maintenance and assistance is crucial for optimal equipment performance. Whether you are looking for specific components or require expert advice, various avenues can provide the necessary support.

- Manufacturer Websites: Official websites often feature extensive catalogs, manuals, and contact information for customer service.

- Authorized Dealers: Local dealers can provide both genuine components and personalized assistance, ensuring you receive the correct items for your machinery.

- Online Marketplaces: Platforms like eBay or specialized agricultural websites may offer a wide range of components, both new and used, at competitive prices.

- Forums and Community Groups: Engaging with online communities can yield valuable insights, recommendations, and even second-hand items from fellow users.

- Service Manuals: Obtaining a detailed service manual can help troubleshoot issues and understand the assembly of various components.

Utilizing these resources can enhance your ability to maintain and repair your equipment efficiently.