In the world of outdoor machinery, having a clear comprehension of each element is essential for effective maintenance and troubleshooting. This knowledge empowers users to enhance the longevity and performance of their tools.

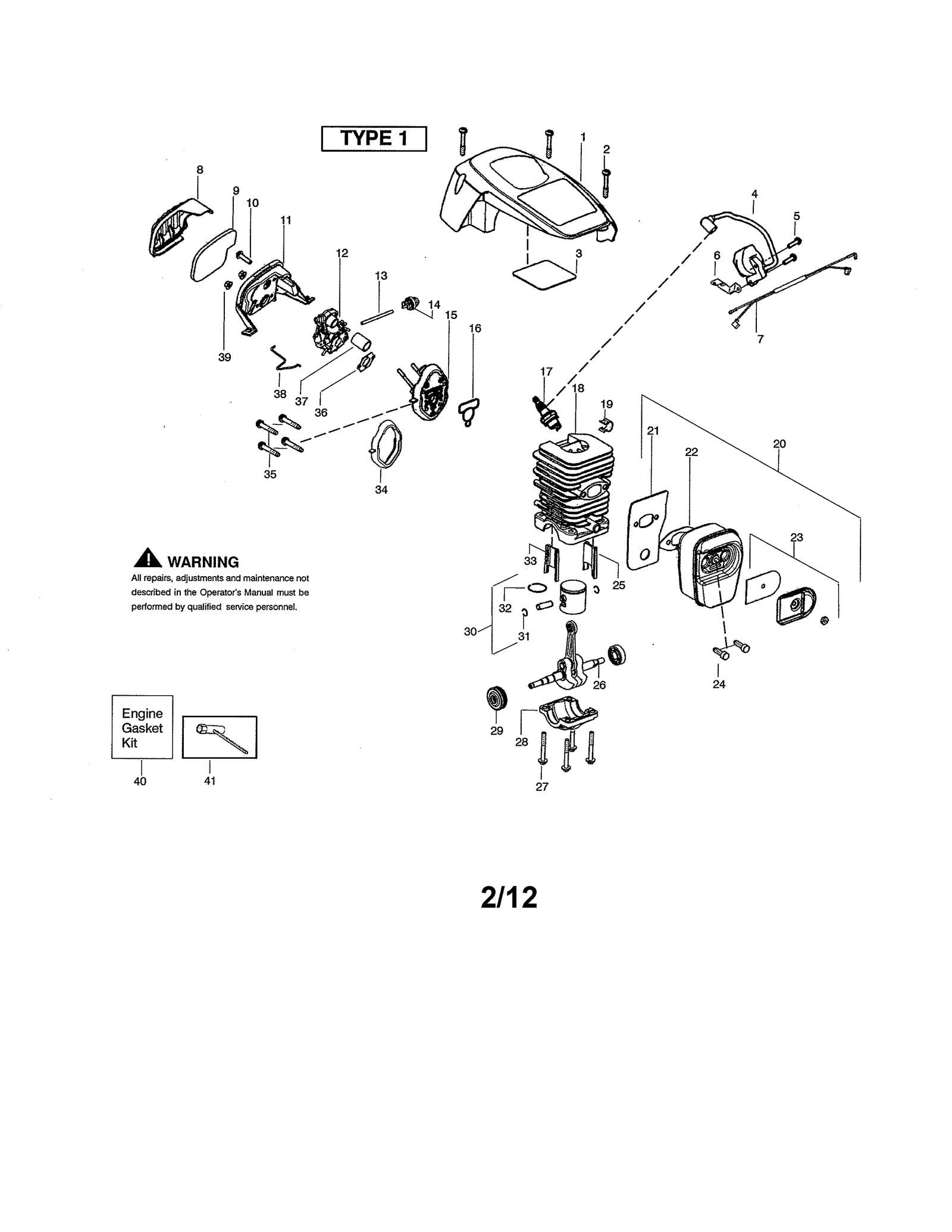

When it comes to understanding how your device operates, a visual representation can be invaluable. Such illustrations help identify individual components, making it easier to locate issues and determine necessary replacements.

Furthermore, grasping the arrangement of these elements not only simplifies repairs but also optimizes your equipment’s efficiency. By delving into the specifics, you can ensure your machinery remains in peak condition for all your outdoor tasks.

Poulan Pro PR4218 Overview

This section provides a comprehensive look at a powerful outdoor tool designed for cutting and trimming tasks. Known for its efficiency and reliability, this equipment caters to both amateur and professional users alike, making it a popular choice in the market.

Key Features

Equipped with a robust engine, this machine offers exceptional performance and durability. Its lightweight design enhances maneuverability, while the ergonomic handle ensures comfort during extended use. The combination of a high-quality chain and bar allows for precise cutting, making it ideal for various landscaping projects.

Usage and Maintenance

Proper usage and regular upkeep are essential for maintaining peak performance. Users should follow recommended guidelines for operation and ensure routine inspections. Adhering to maintenance practices, such as chain sharpening and lubrication, will significantly extend the lifespan of this reliable tool.

Key Features of the Chainsaw

Chainsaws are essential tools for various cutting tasks, ranging from tree maintenance to woodworking. Their design and functionality make them highly effective for both professionals and DIY enthusiasts. Understanding the standout characteristics of these machines can help users choose the right one for their needs.

Power and Performance

- Engine Type: Chainsaws are typically powered by either gas or electricity. Gas models offer greater mobility, while electric versions are quieter and more environmentally friendly.

- Bar Length: The length of the cutting bar can significantly influence the saw’s capability. Longer bars are suitable for larger jobs, while shorter ones are ideal for precision work.

- Chain Speed: The speed at which the chain moves impacts cutting efficiency. Higher speeds allow for quicker cuts and reduce the time spent on tasks.

Safety Features

- Chain Brake: This mechanism stops the chain instantly in case of kickback, enhancing user safety.

- Low Kickback Chain: Designed to minimize the risk of kickback, this type of chain helps prevent accidents.

- Safety Switch: A feature that prevents accidental starts, ensuring that the tool only operates when intended.

Choosing a chainsaw with the right combination of features ensures effective and safe operation, making it a valuable addition to any toolkit.

Importance of Understanding Parts Diagram

Comprehending the layout of components within any machinery is essential for effective maintenance and repair. A clear visual representation allows users to identify, replace, and manage individual elements efficiently, reducing downtime and ensuring optimal functionality.

Benefits of Familiarity with Component Layouts

- Enhances troubleshooting capabilities.

- Facilitates easy replacement of faulty elements.

- Promotes better maintenance practices.

- Reduces the likelihood of errors during repairs.

Key Aspects to Consider

- Understanding how each part interacts with others.

- Identifying potential wear points.

- Recognizing compatibility with alternative components.

Identifying Components in the Diagram

Understanding the various elements within a mechanical illustration is essential for effective maintenance and repairs. Each section reveals specific parts that work together to ensure optimal functionality. By recognizing these components, users can better navigate the complexities of assembly and disassembly processes.

Begin by familiarizing yourself with the labels and symbols used in the illustration, as these provide crucial insights into the purpose of each part. Pay attention to the connections between components, as this will help clarify how they interact during operation. Identifying any wear or damage becomes easier when one knows the arrangement and function of each element.

Ultimately, thorough comprehension of the parts illustrated not only facilitates repairs but also enhances the overall longevity of the equipment. Investing time in this understanding leads to more informed decisions and efficient troubleshooting.

Common Issues with Poulan Pro PR4218

Chainsaw users often encounter a variety of challenges that can impact performance and efficiency. Understanding these common problems can help in timely diagnosis and maintenance, ensuring the tool operates smoothly. Addressing issues promptly not only extends the lifespan of the equipment but also enhances user experience.

Engine Troubles

One frequent concern is related to the engine. Users may experience difficulties starting the machine or notice erratic idling. These issues can stem from several factors, including fuel quality, clogged filters, or problems with the ignition system. Regular maintenance, such as replacing spark plugs and cleaning air filters, can mitigate these problems.

Chain and Bar Issues

Another common area of concern involves the cutting mechanism. Users might find the chain becoming dull quickly or jumping off the bar. This can result from improper tensioning, lack of lubrication, or using the wrong chain type. Regularly inspecting the chain and bar for wear and ensuring proper tension can help maintain cutting efficiency and safety.

Where to Find Replacement Parts

When seeking components for your outdoor equipment, it’s essential to know the best sources for quality items. Various retailers, both online and physical stores, offer a range of options to ensure your machinery runs smoothly again. Below are some effective avenues to explore when looking for the necessary replacements.

| Source Type | Description |

|---|---|

| Online Retailers | Websites specializing in outdoor tools often carry a vast selection of components. Look for reputable sites with customer reviews. |

| Local Dealers | Authorized dealers usually provide genuine items and knowledgeable assistance. Visiting them can also support your community. |

| Salvage Yards | These places can be treasure troves for hard-to-find pieces at lower prices. Inspect items carefully for quality. |

| Manufacturer’s Website | The official site of your equipment’s brand often features a section for ordering direct components and offers support. |

| Online Marketplaces | Platforms like eBay or Amazon have numerous sellers offering both new and used components. Be sure to check seller ratings. |

Each of these options has its advantages, making it crucial to consider factors like price, availability, and quality before making a purchase. With the right approach, you can easily find the necessary items to keep your equipment functioning optimally.

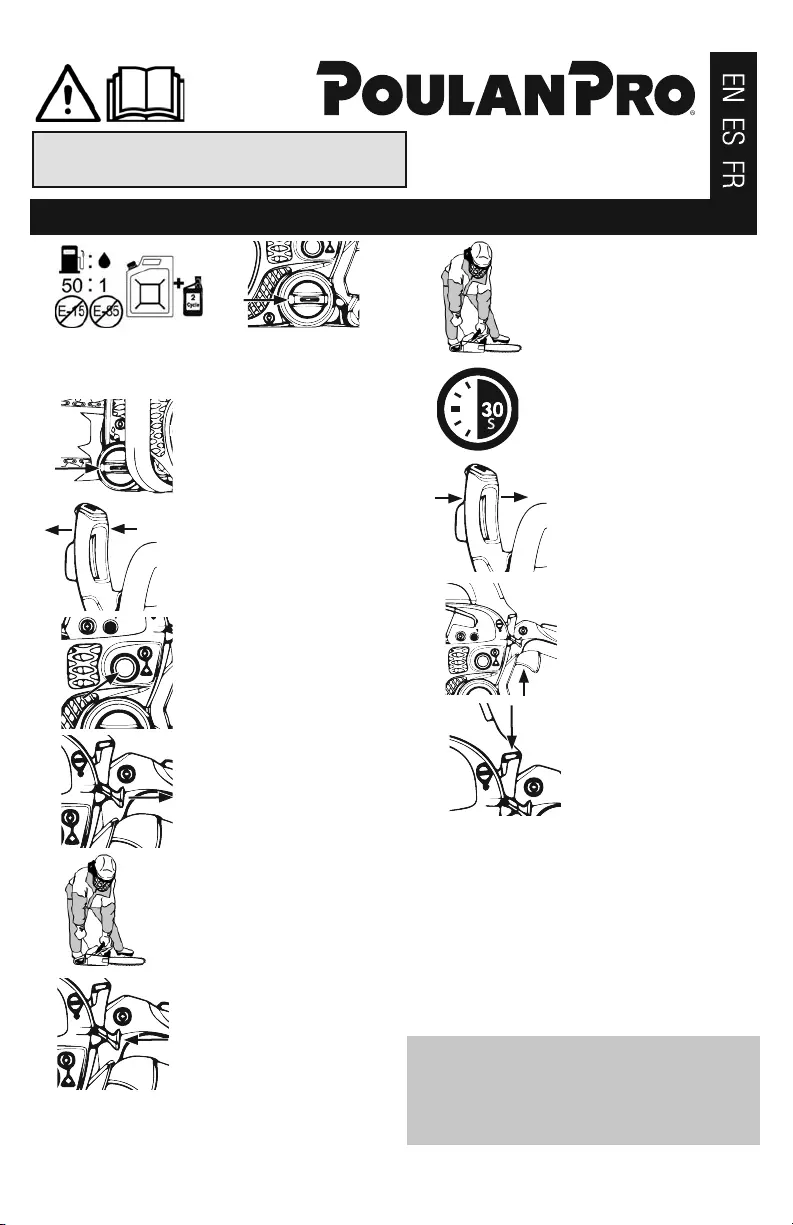

Step-by-Step Repair Guide

This guide provides a comprehensive approach to fixing common issues with your chainsaw. By following these detailed steps, you can ensure a smooth repair process and enhance the longevity of your equipment.

- Gather Necessary Tools:

- Screwdrivers (flathead and Phillips)

- Wrenches

- Replacement components

- Safety gear (gloves, goggles)

- Assess the Problem:

Identify the specific issue, whether it’s related to the engine, chain, or other parts.

- Disassemble the Equipment:

Carefully take apart the unit, noting the placement of each component for reassembly.

- Replace Damaged Parts:

Swap out any broken or worn-out components with new ones, ensuring compatibility.

- Reassemble:

Put the equipment back together, following the notes made during disassembly.

- Test Functionality:

Run the chainsaw to confirm that all repairs were successful and everything operates smoothly.

By adhering to this structured approach, you can effectively restore your tool to optimal performance.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular upkeep and attention to detail. Implementing a routine maintenance schedule not only enhances efficiency but also extends the lifespan of your machine, allowing it to operate at its best for years to come.

Regular Cleaning

Keeping your equipment clean is essential. After each use, remove debris and dirt, particularly from the air filter and cutting components. This prevents clogs and maintains airflow, leading to improved performance.

Inspection and Replacement

Conduct regular inspections to identify any worn or damaged parts. Timely replacement of these components is crucial; this proactive approach minimizes the risk of breakdowns and ensures smooth operation during use.