In the realm of agricultural equipment, comprehending the intricate network of components is essential for optimal performance and maintenance. Each element plays a pivotal role in ensuring that the machinery operates smoothly and efficiently, contributing to overall productivity. This section delves into the various segments that make up these essential machines, providing insights into their functions and interrelationships.

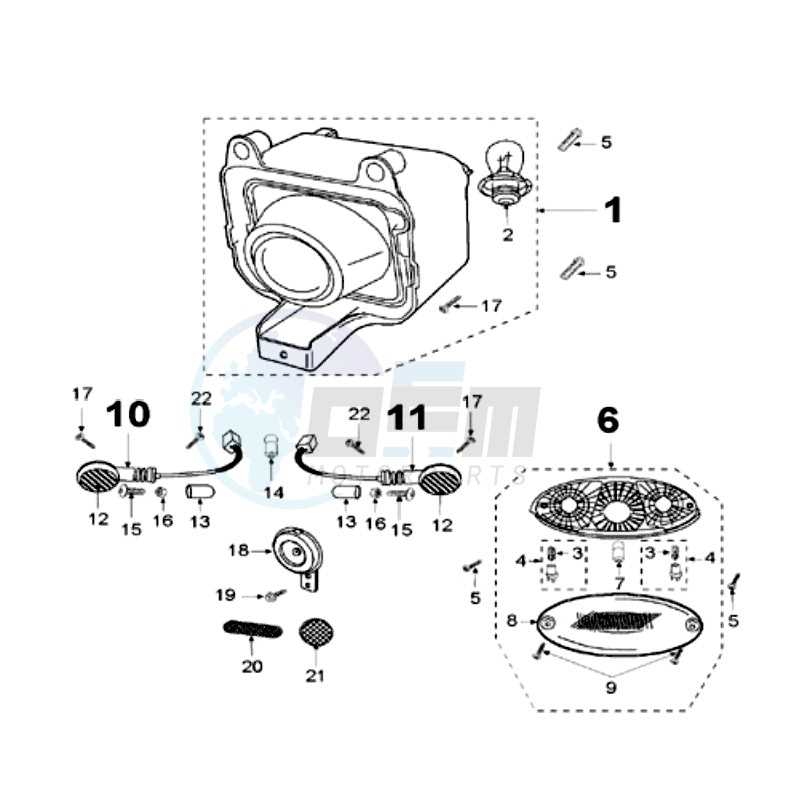

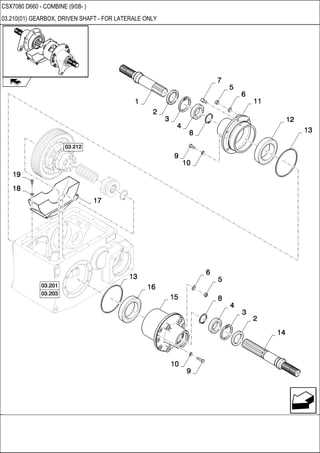

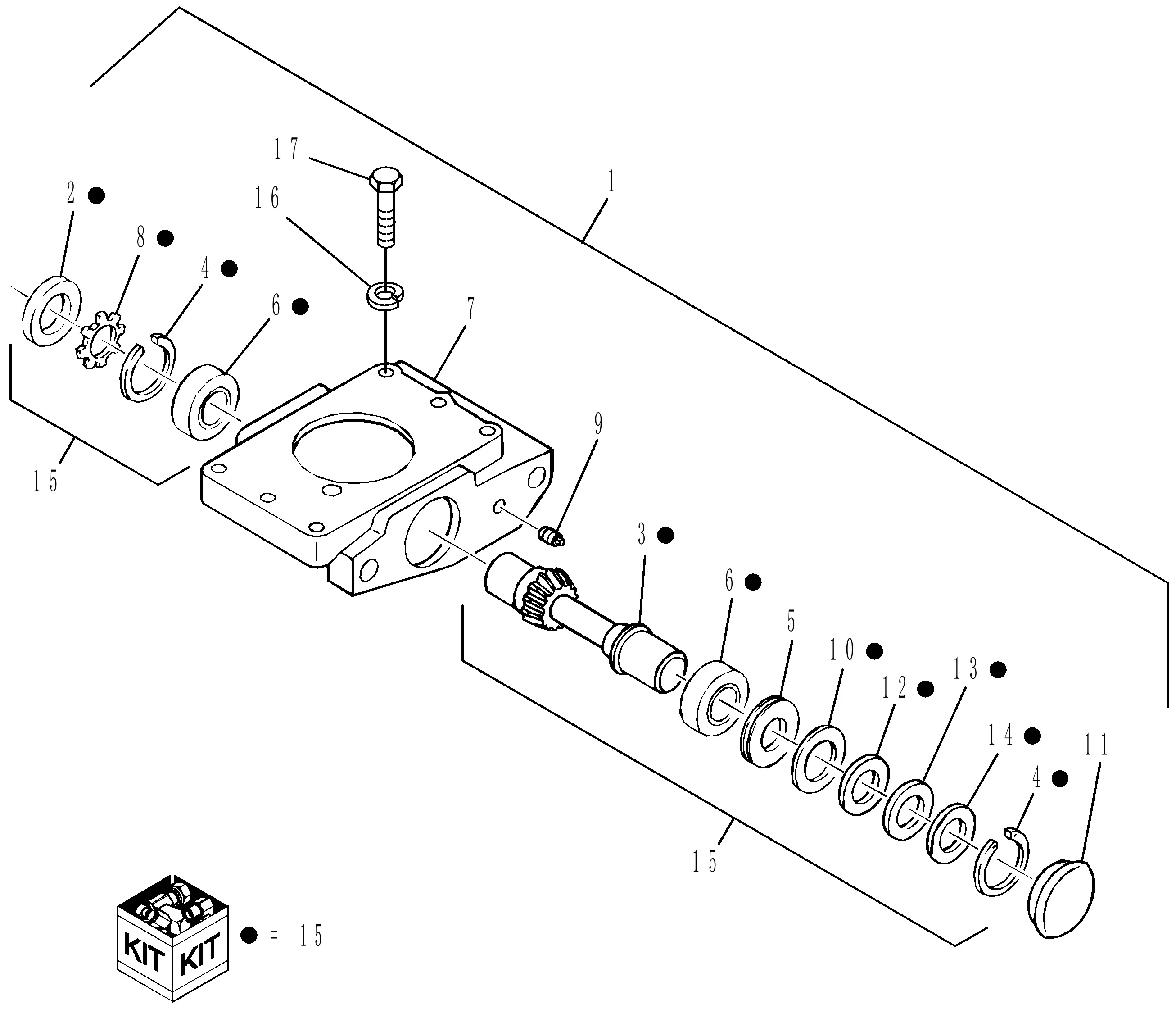

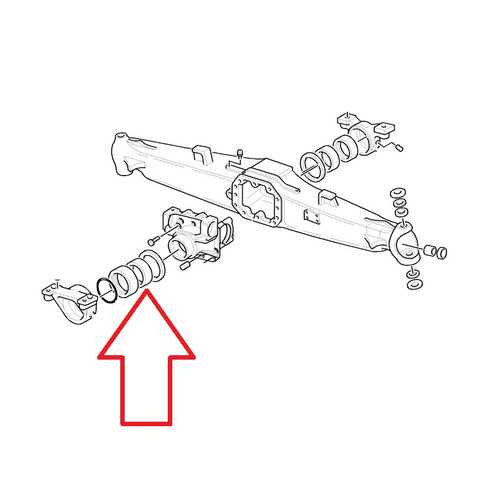

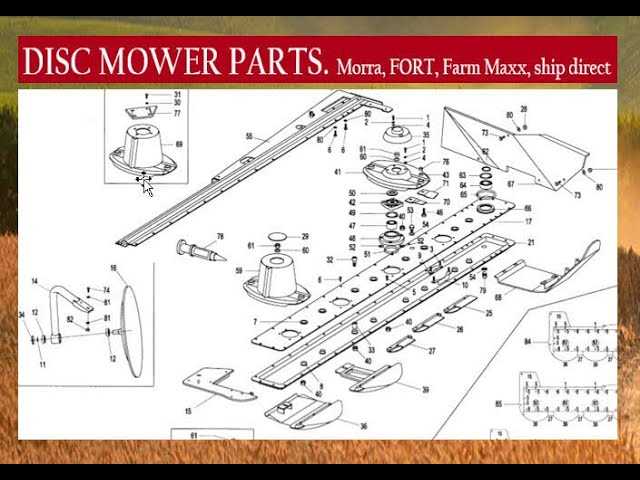

By examining the layout and structure of these components, operators can better identify potential issues and streamline repair processes. A thorough understanding not only enhances troubleshooting capabilities but also aids in the selection of appropriate replacements when necessary. Visual representations of these arrangements serve as invaluable resources, guiding users through the complexities of mechanical systems.

Moreover, recognizing the significance of each part fosters a deeper appreciation for the technology that drives modern agriculture. As we explore the configurations, users will gain a clearer perspective on how to maintain and optimize their equipment for years to come. This knowledge is crucial for anyone looking to maximize efficiency and longevity in their machinery.

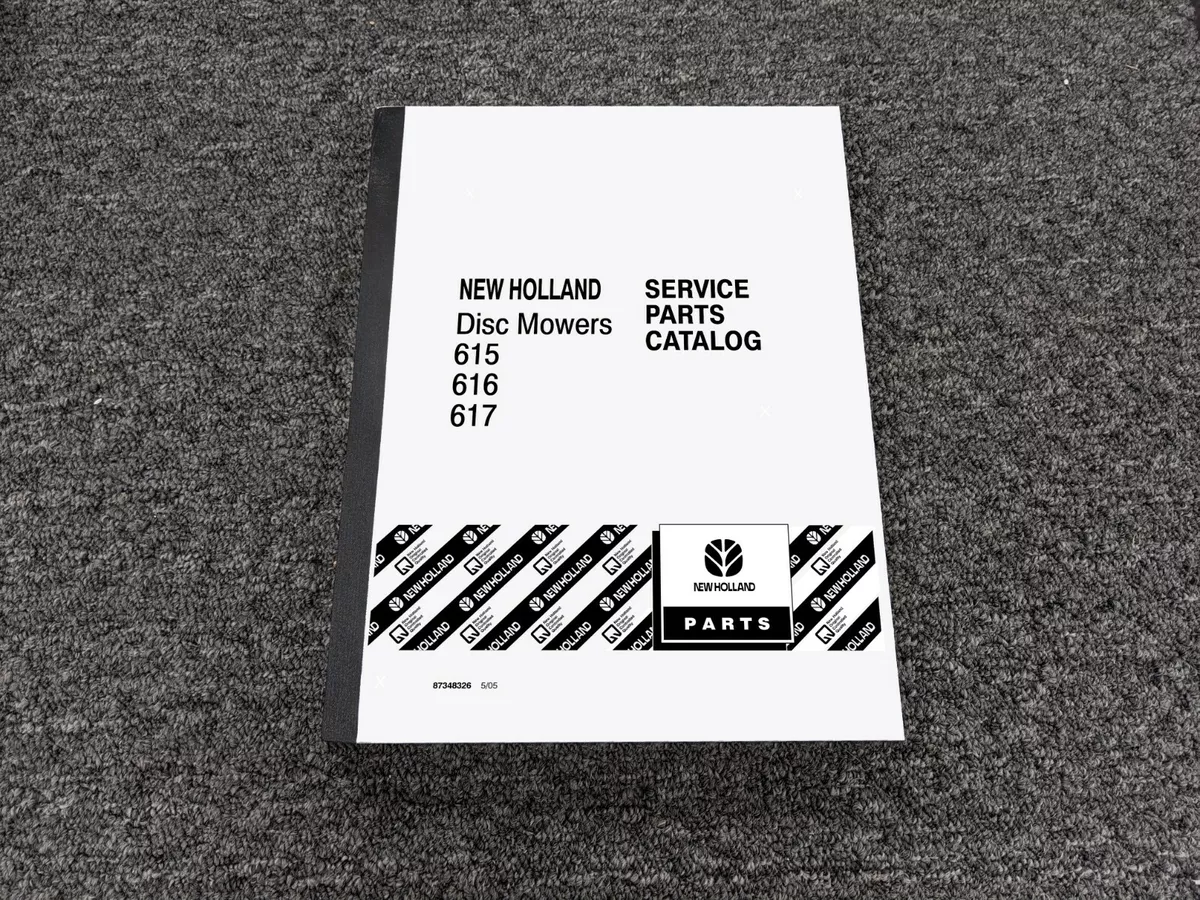

Understanding the New Holland 616

This section aims to provide insights into a specific agricultural machine, highlighting its features and operational principles. By examining its components, users can enhance their familiarity with the equipment and optimize its usage for various farming tasks.

Efficient functioning relies on an intricate assembly of elements that work in harmony. Each part serves a crucial role in ensuring smooth operations, and understanding these roles is essential for effective maintenance and troubleshooting.

| Component | Function |

|---|---|

| Engine | Powers the machine and drives various functions. |

| Hydraulic System | Facilitates movement and operation of attachments. |

| Chassis | Provides structural support and stability during operation. |

| Transmission | Transfers power from the engine to the wheels or implements. |

| Control System | Allows the operator to manage functions and settings. |

By understanding the structure and function of these key components, users can ensure their machinery remains in optimal condition, improving overall efficiency in agricultural practices.

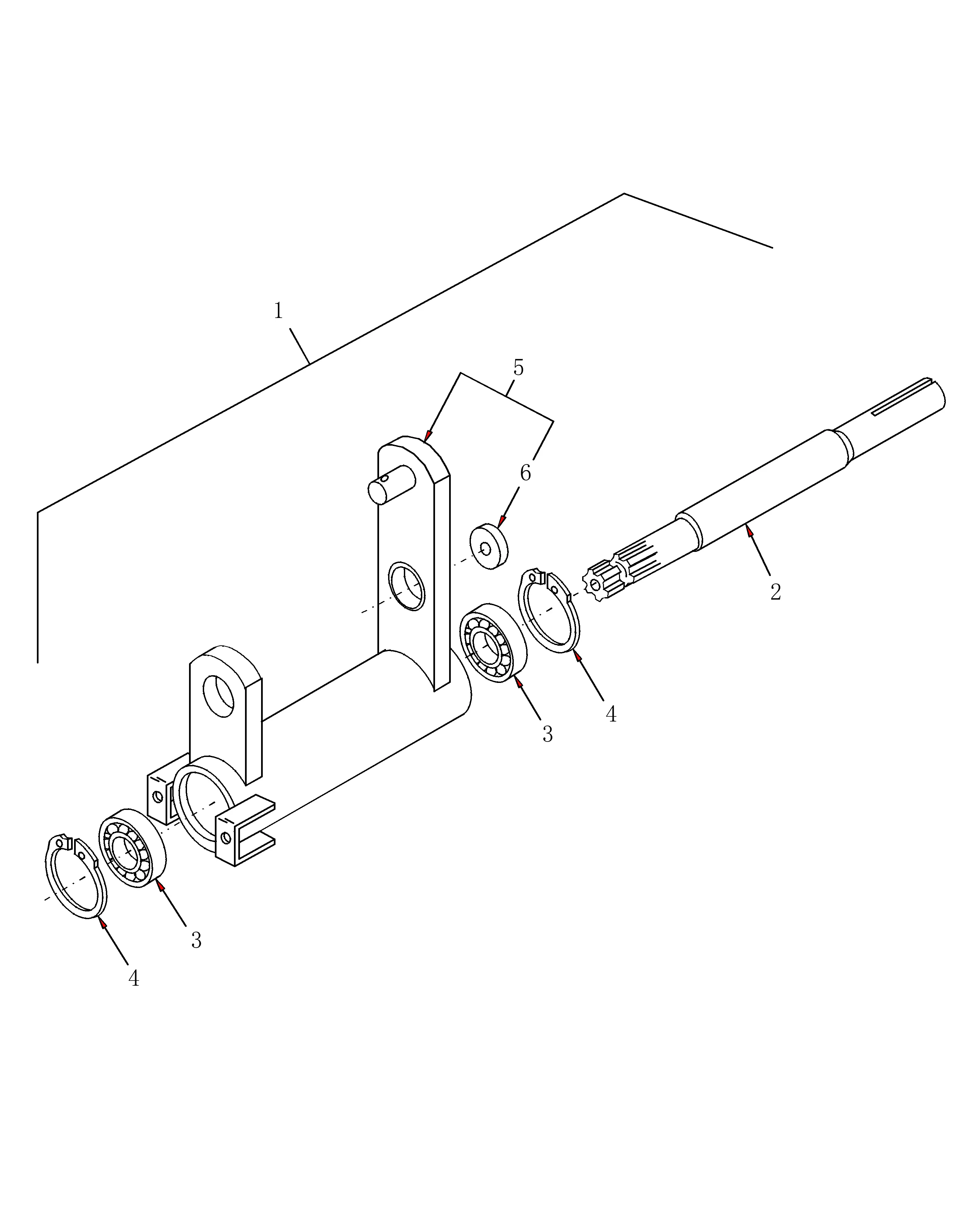

Essential Components of the 616 Model

This section explores the critical elements that constitute the functionality and efficiency of the machinery in question. Understanding these components is vital for maintenance and optimal performance.

Main Elements

The core features of this model include the engine, transmission system, and hydraulic components, each playing a significant role in the overall operation.

Table of Key Components

| Component | Description |

|---|---|

| Engine | Powers the entire system and ensures effective operation. |

| Transmission | Facilitates the transfer of power and controls speed. |

| Hydraulic System | Drives various functions and enhances maneuverability. |

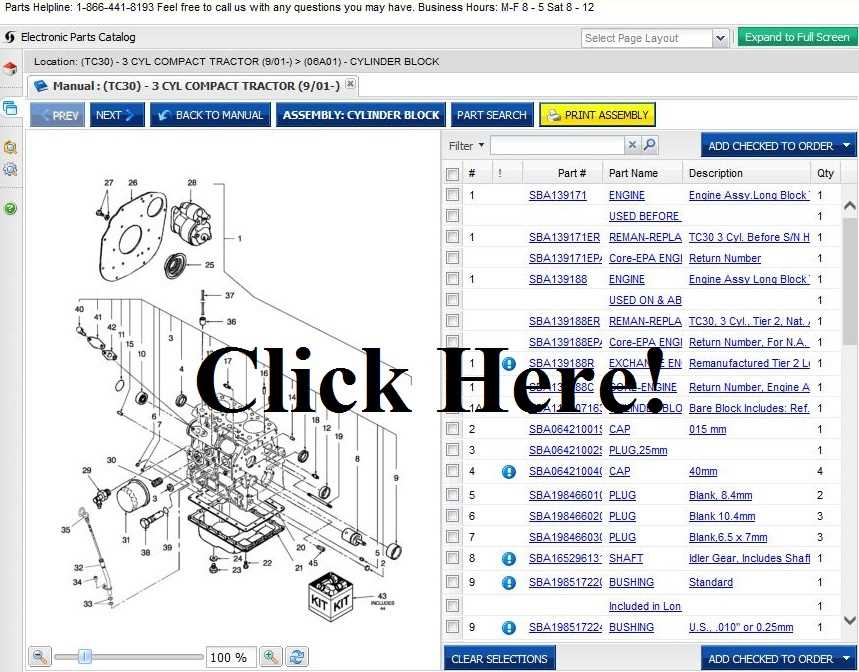

How to Access Parts Diagrams

Finding visual guides for components can greatly enhance your understanding and maintenance of machinery. These resources provide essential insights into the layout and function of each piece, ensuring that repairs or upgrades can be carried out effectively.

Online Resources: Numerous websites specialize in offering comprehensive visuals and specifications. A simple search can lead you to manufacturer sites or dedicated forums where enthusiasts share valuable information.

Manuals and Catalogs: Printed or digital manuals often contain detailed illustrations. Accessing these can provide a reliable reference for assembly and disassembly processes.

Community Support: Engaging with online communities can be beneficial. Many users are willing to share their expertise, including direct links to resources and personal experiences related to specific components.

Ultimately, leveraging these methods will facilitate a deeper understanding of machinery assembly and maintenance.

Common Repairs for New Holland 616

Regular maintenance and timely fixes are essential for ensuring optimal performance of agricultural machinery. Familiarity with frequent issues allows operators to proactively address them, minimizing downtime and enhancing productivity.

Hydraulic System Troubleshooting

One prevalent concern involves the hydraulic system. Operators should check for leaks and ensure all connections are secure. Replacing worn seals and filters can significantly improve performance. Regular fluid checks are crucial to prevent complications.

Engine Maintenance

Engine-related issues often arise, necessitating thorough inspections. Common tasks include changing oil and filters, examining belts for wear, and ensuring the cooling system operates efficiently. Addressing these areas promptly can prolong the lifespan of the equipment.

Importance of Genuine Replacement Parts

Using authentic components in machinery maintenance is crucial for ensuring optimal performance and longevity. Genuine replacements are designed specifically for your equipment, guaranteeing compatibility and reliability that aftermarket alternatives often lack.

Quality Assurance

When opting for original components, you benefit from rigorous testing and quality control, which significantly reduces the risk of failure. This leads to fewer repairs and a smoother operation overall.

Cost-Effectiveness

While initial costs may be higher, utilizing authentic parts can ultimately save money by enhancing durability and reducing the frequency of replacements. Investing in quality translates to fewer disruptions in your workflow.

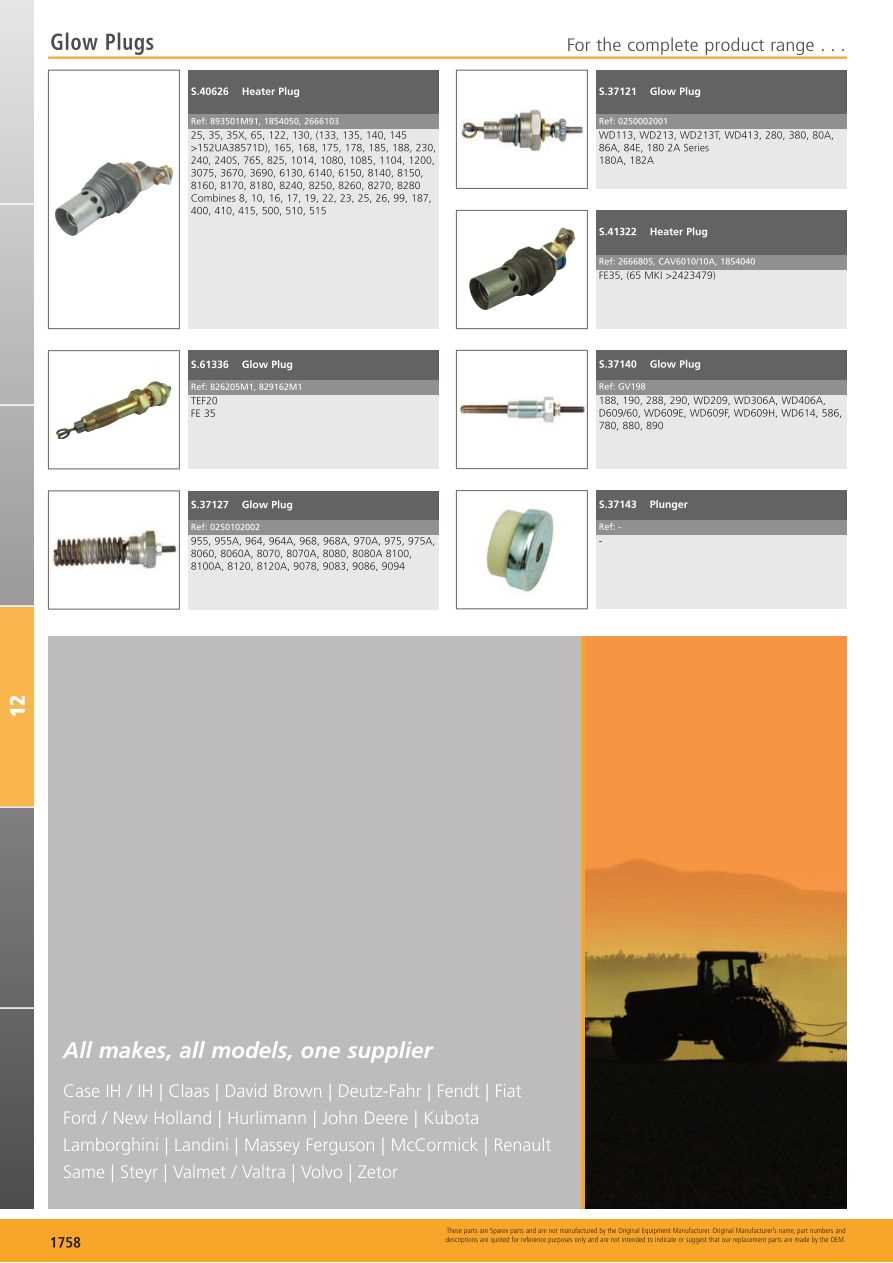

Finding a Reliable Parts Supplier

When it comes to sourcing components for machinery, identifying a trustworthy vendor is crucial. A reliable supplier not only provides quality items but also ensures timely delivery and excellent customer service. This relationship can significantly impact maintenance efficiency and operational success.

Research and Reviews: Start by exploring various suppliers online. Look for reviews and testimonials from other customers to gauge their reliability. Online forums and communities can also offer valuable insights and recommendations.

Quality Assurance: Ensure that the vendor offers products that meet industry standards. Inquire about their quality control processes and certifications, as this can be a strong indicator of their commitment to excellence.

Customer Support: A dependable supplier should provide robust customer support. Verify their responsiveness and willingness to assist with inquiries or issues. This aspect is essential for resolving any potential problems swiftly.

Pricing and Transparency: While cost is a factor, it should not be the only consideration. Look for transparent pricing without hidden fees. A reputable supplier will provide clear and straightforward quotations.

Part Availability: Ensure that the vendor maintains a comprehensive inventory. A supplier with a wide range of components can better serve your needs and reduce downtime when replacements are necessary.

By following these guidelines, you can enhance your chances of finding a supplier that aligns with your requirements, ultimately supporting the longevity and efficiency of your machinery.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of your machinery. By following a structured maintenance routine, you can prevent premature wear and tear, ultimately extending the lifespan of your equipment.

Routine Inspections

Conduct frequent checks on all components to identify any signs of damage or wear. Early detection allows for timely repairs, reducing the risk of more severe issues arising later. Pay attention to fluid levels, belts, and filters.

Proper Lubrication

Ensure that all moving parts are adequately lubricated. Lubrication minimizes friction, preventing overheating and damage. Use high-quality oils and greases recommended by the manufacturer for optimal performance.

Comparing with Other Models

In examining various agricultural machines, it becomes evident that differences in design and functionality can significantly impact performance and efficiency. Each model offers unique features and specifications, which can cater to specific farming needs. By evaluating these differences, operators can make informed choices that best suit their requirements.

When assessing alternatives, it’s crucial to focus on aspects such as engine power, fuel efficiency, and ease of maintenance. Some machines may excel in heavy-duty tasks, while others are tailored for versatility and compactness. For instance, certain models may provide enhanced maneuverability in tight spaces, making them ideal for smaller fields or diverse crops. In contrast, larger counterparts might be better suited for extensive operations, where durability and higher output are prioritized.

Moreover, technological advancements play a significant role in differentiating various options. Modern features, such as advanced GPS systems and automated controls, can elevate productivity levels and simplify operations. Understanding these technological enhancements allows users to select equipment that aligns with contemporary farming practices, ultimately driving greater efficiency and yield.

Upgrades and Modifications Available

Enhancing the performance and functionality of your equipment can significantly improve efficiency and longevity. Various improvements and customizations can be applied to optimize operation and meet specific needs, whether for agricultural use or other applications. These adjustments not only elevate productivity but also adapt the machinery to evolving demands in the field.

Performance Enhancements

Upgrading components such as engines, transmission systems, and hydraulic functionalities can lead to increased power and better handling. Engine tuning and advanced fuel systems can enhance fuel efficiency, while improved transmission can provide smoother operation under heavy loads. Each modification can be tailored to specific requirements, ensuring that the machinery operates at its best.

Comfort and Usability Improvements

Modifications aimed at user comfort can greatly enhance the overall experience. Installing ergonomic seating, upgraded controls, and improved cab insulation can reduce fatigue during long hours of operation. Additional safety features, such as enhanced visibility systems and advanced lighting, further contribute to a more secure working environment.