The efficiency of any farming implement heavily relies on its individual components working in harmony. Proper knowledge of these elements can significantly enhance the performance of your machinery, ensuring optimal results in your agricultural endeavors. This section aims to provide clarity on the essential pieces that contribute to the functionality of your tool.

Each element plays a vital role in the overall operation, influencing both effectiveness and durability. From the smallest fittings to larger assemblies, comprehending their arrangement and interaction can lead to better maintenance practices. This insight helps in identifying potential issues before they escalate, thereby prolonging the lifespan of your equipment.

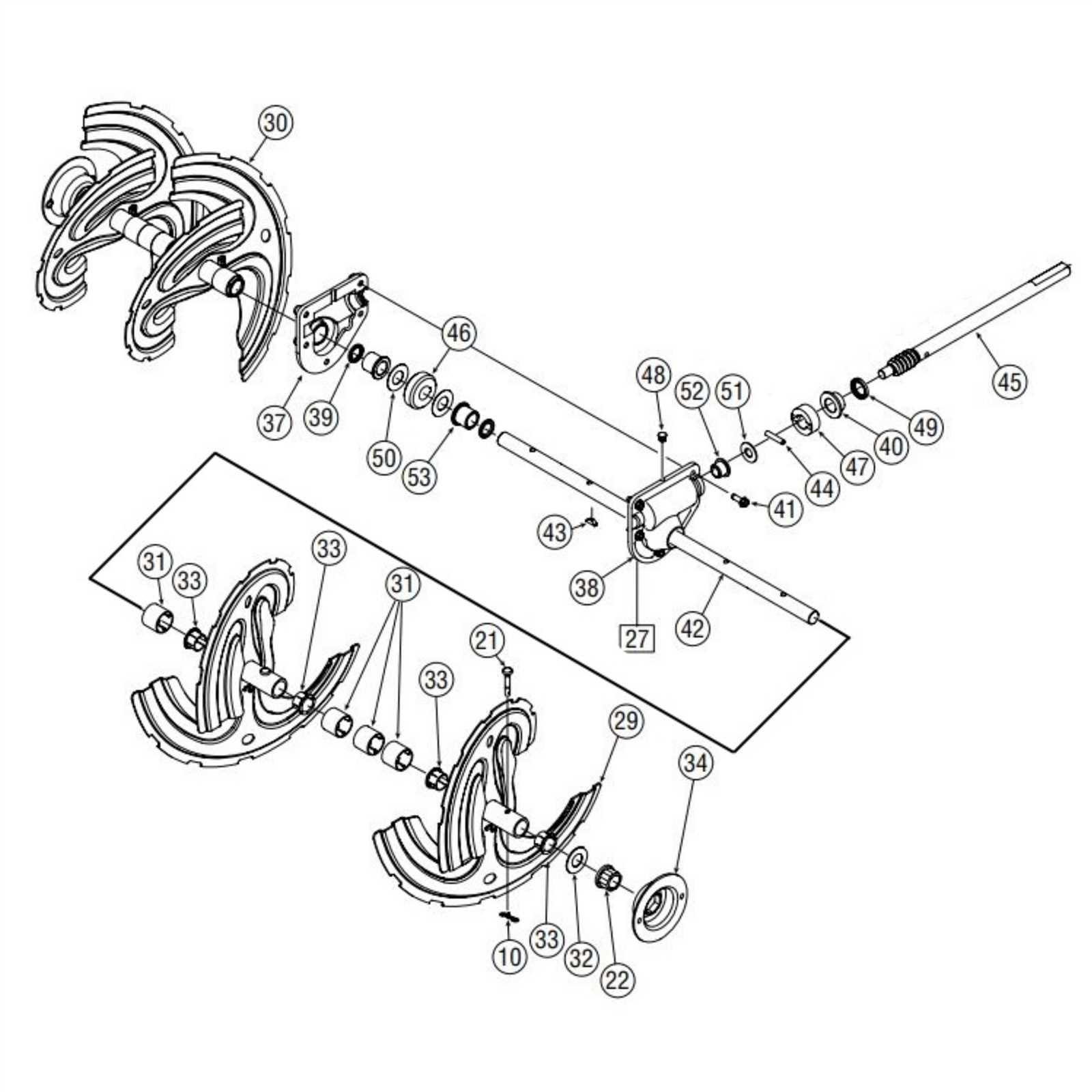

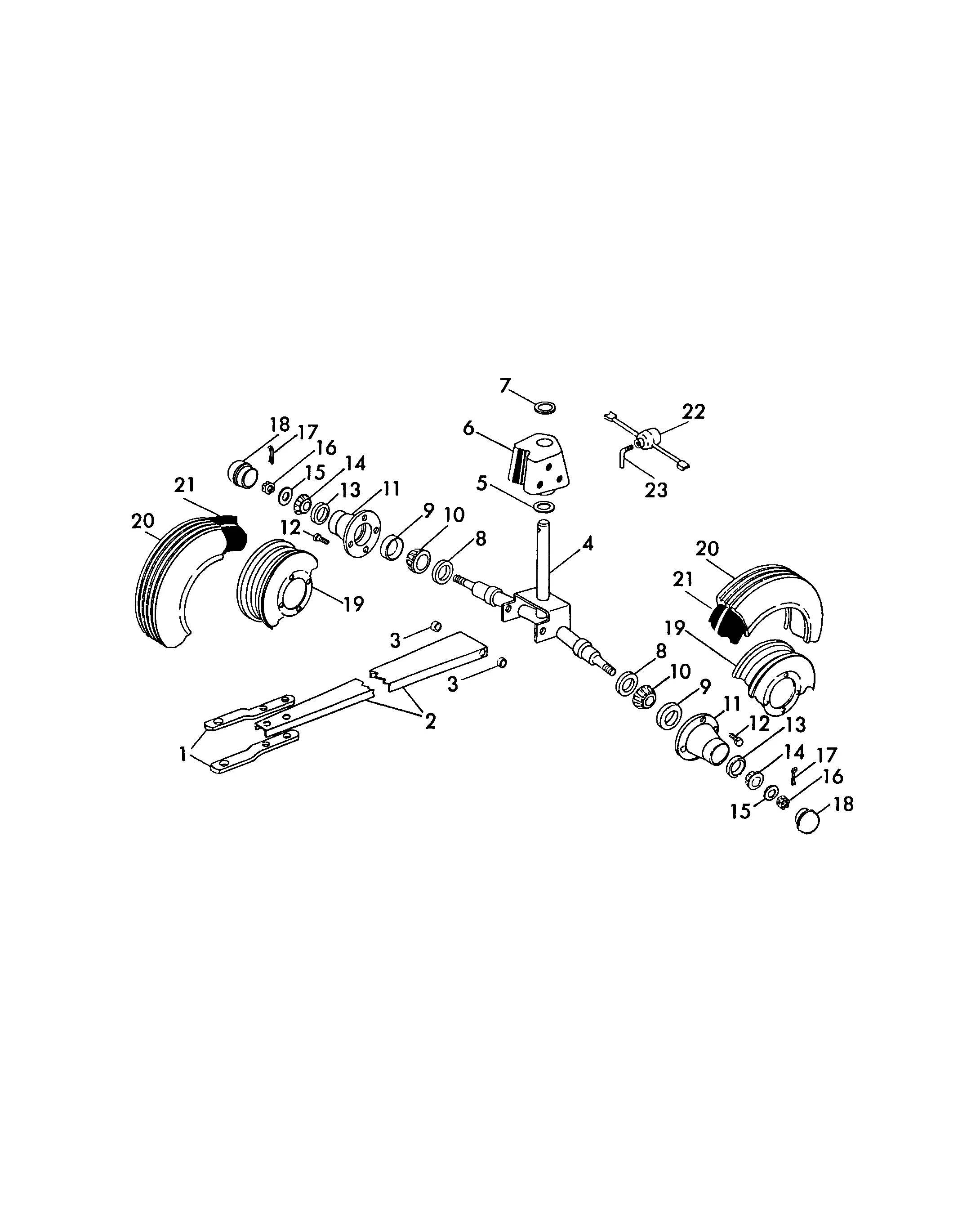

In the following sections, we will explore the various elements in detail, offering a visual representation to aid your understanding. By familiarizing yourself with these components, you will be better equipped to make informed decisions regarding repairs and enhancements, ultimately optimizing your agricultural productivity.

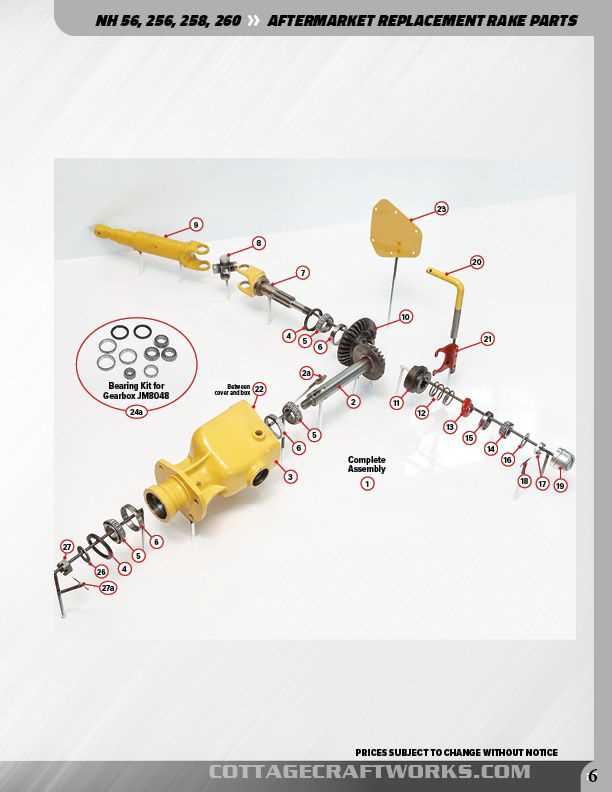

Understanding the New Holland 56 Rake

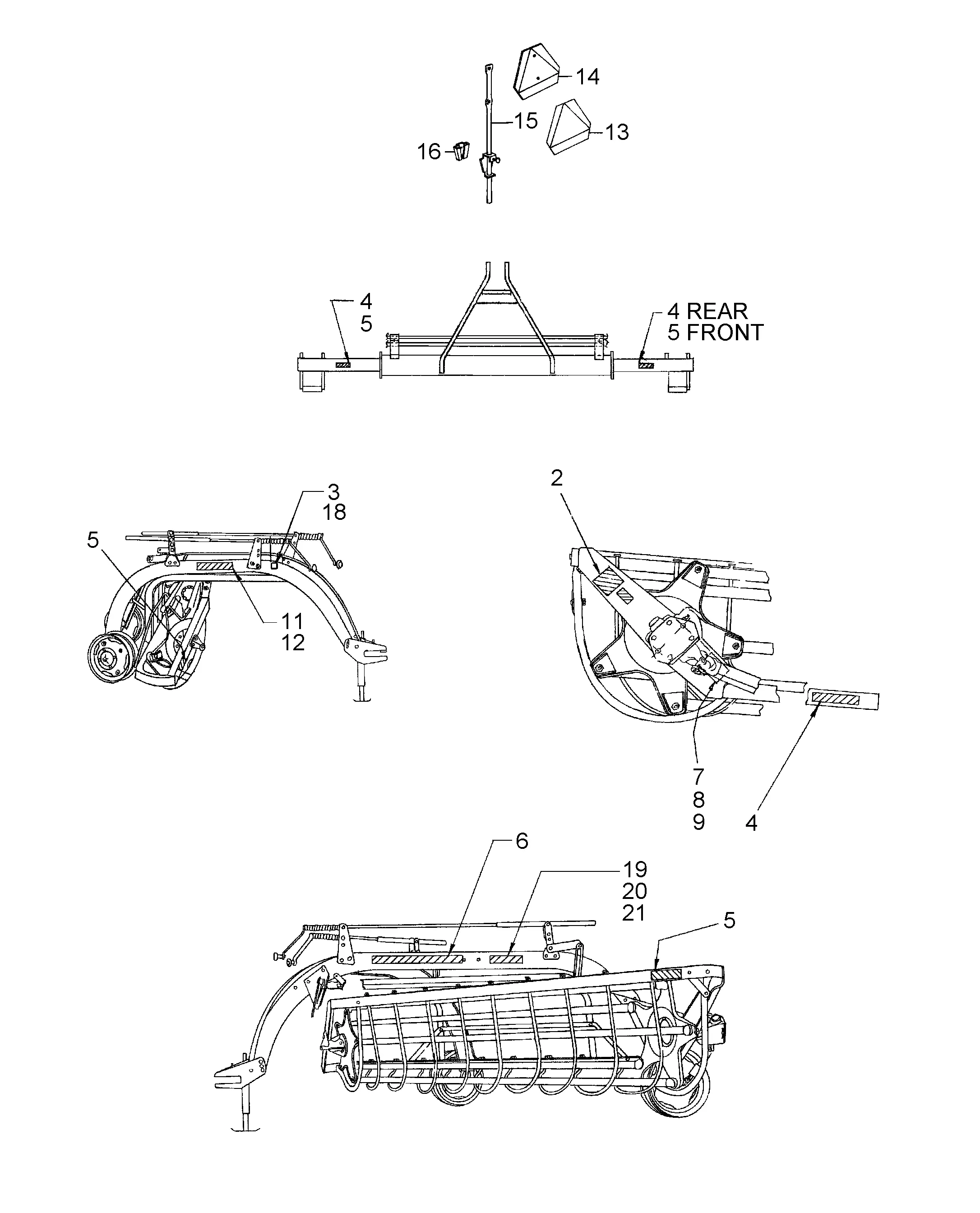

The machine in question is widely recognized for its effectiveness in managing hay during the harvesting process. It has been designed to optimize the gathering and aligning of crop materials, ensuring efficiency in the field. This equipment has become a reliable choice for those needing a tool to streamline their farming operations.

To better comprehend its components and functions, it’s crucial to look at its various mechanical parts and how they contribute to the overall performance. Below is a simplified breakdown of key sections and their roles.

| Component | Function | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Rotary Mechanism | Responsible for the movement and alignment of harvested materials. | |||||||||

| Frame Assembly | Provides structural support, ensuring stability

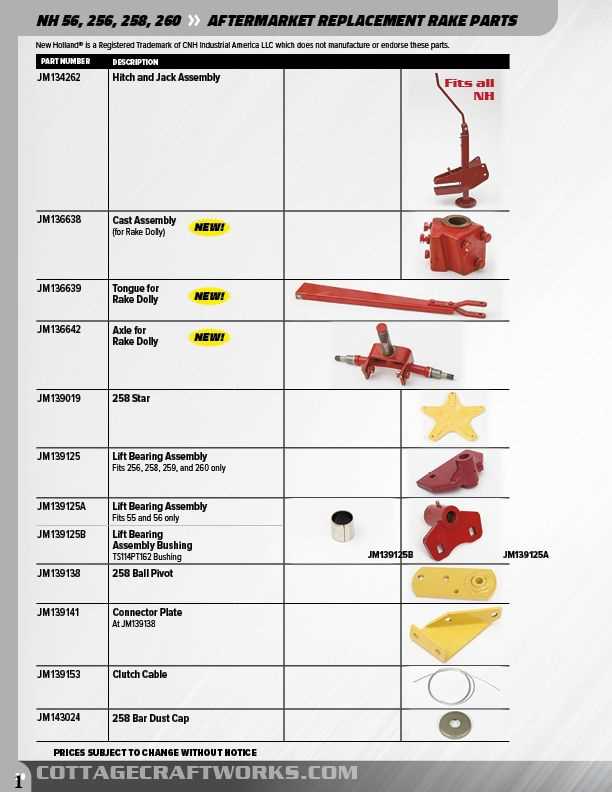

Key Components of the Rake

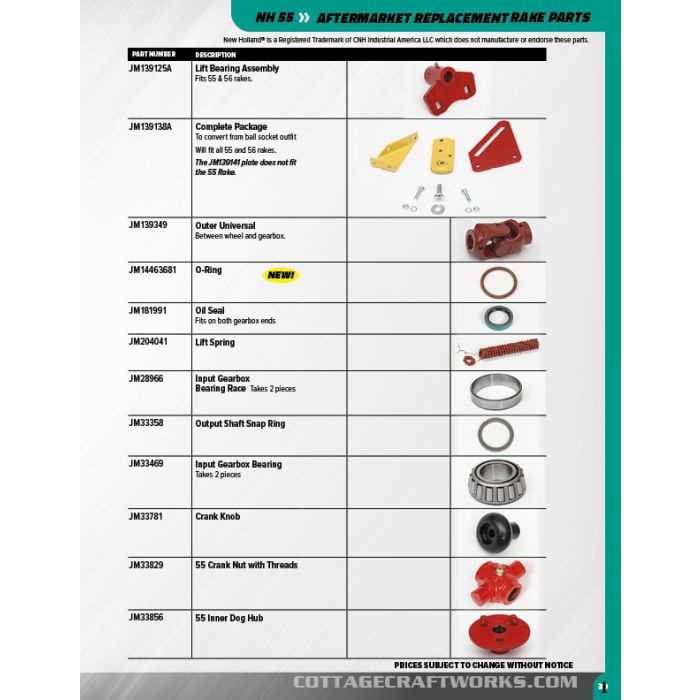

In this section, we will focus on the essential elements that make up the operation and efficiency of the machine. Understanding these parts is crucial for maintaining functionality and ensuring optimal performance during use. Frame Structure: The main framework provides stability and support for the entire mechanism, allowing the various moving parts to work smoothly together. Its design ensures that the tool can handle different types of terrain and workloads. Tine Assembly: This component is responsible for gathering materials efficiently. Each tine is designed to move consistently, adapting to varying conditions on the field to achieve maximum efficiency. Importance of Regular Maintenance

Regular upkeep of agricultural machinery ensures long-lasting performance and reduces the likelihood of unexpected breakdowns. By adhering to routine inspections and care schedules, equipment remains in optimal condition, allowing for efficient operation and minimized downtime. Maintenance plays a key role in the longevity and reliability of any machine. Benefits of Routine Checks

Consistent inspections help identify potential issues before they escalate. This proactive approach saves time and costs in the long run, as minor repairs are often less expensive and easier to handle than major malfunctions. Extending Equipment Lifespan

By following a structured maintenance plan, the working life of machinery can be significantly extended. Proper care leads to improved efficiency, reducing the need for frequent replacements and ensuring that the equipment continues to perform at its best. Common Issues and Solutions

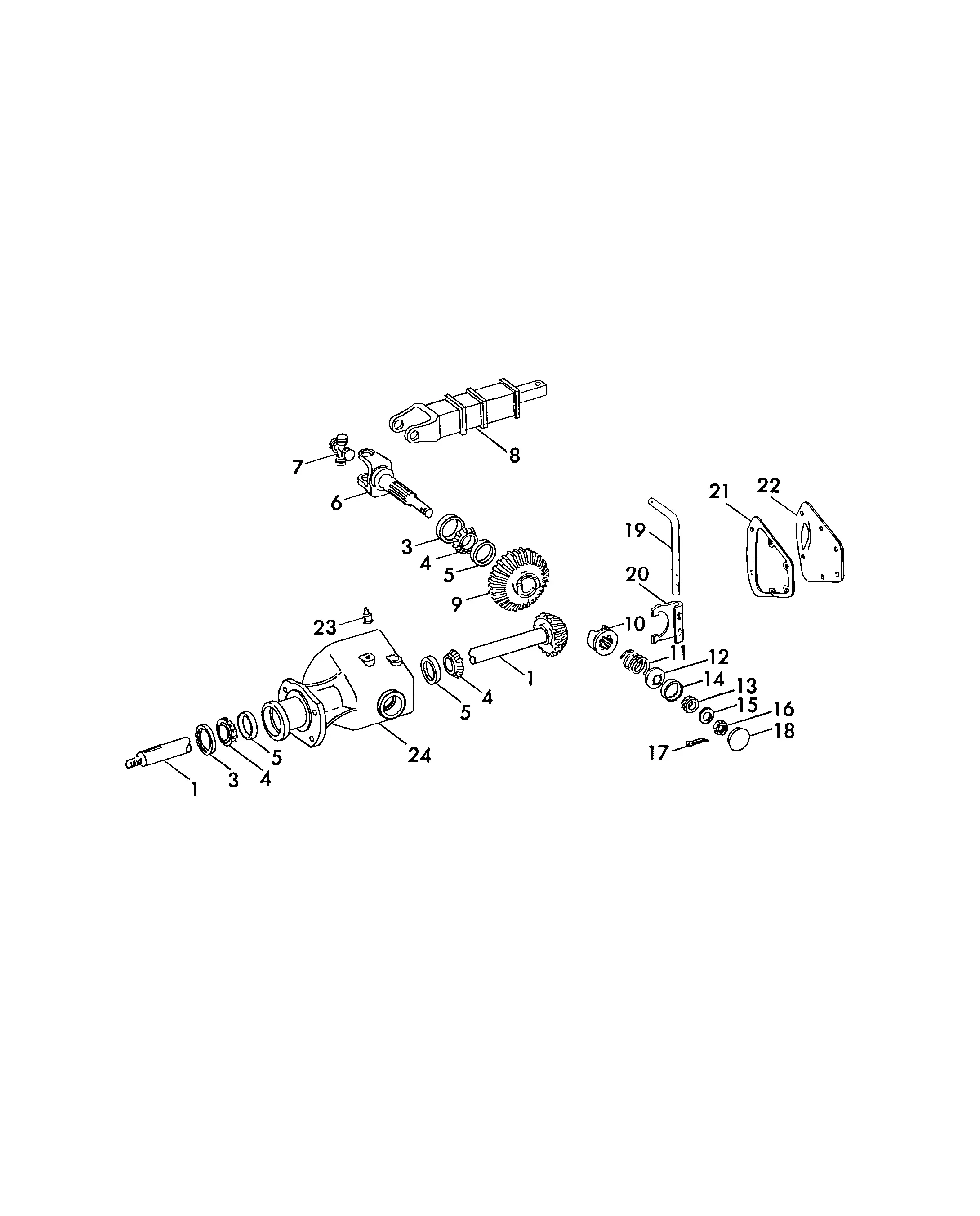

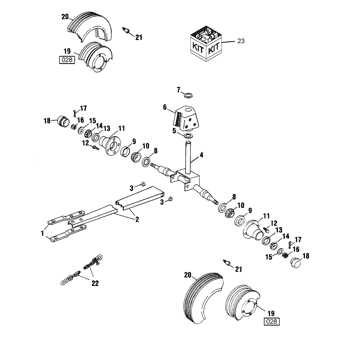

Machinery used in agricultural settings can encounter various operational challenges over time. Regular wear and tear, combined with improper handling or insufficient maintenance, can lead to a range of problems that impact performance and efficiency. Identifying the root cause of these issues is essential for ensuring smooth operation and minimizing downtime. One frequent problem is uneven performance during operation. This can be caused by worn or damaged components, which affect the machine’s ability to function properly. Inspecting and replacing these parts regularly can prevent further damage. Another issue is difficulty in maintaining consistent alignment, which may lead to suboptimal results. Adjusting the alignment settings and ensuring all components are properly secured can help resolve this problem and improve overall accuracy. Lastly, debris buildup can cause blockages and reduced efficiency. Cleaning the equipment thoroughly after each use will help prevent this from occurring and maintain the machine’s functionality. How to Identify Parts on Diagram

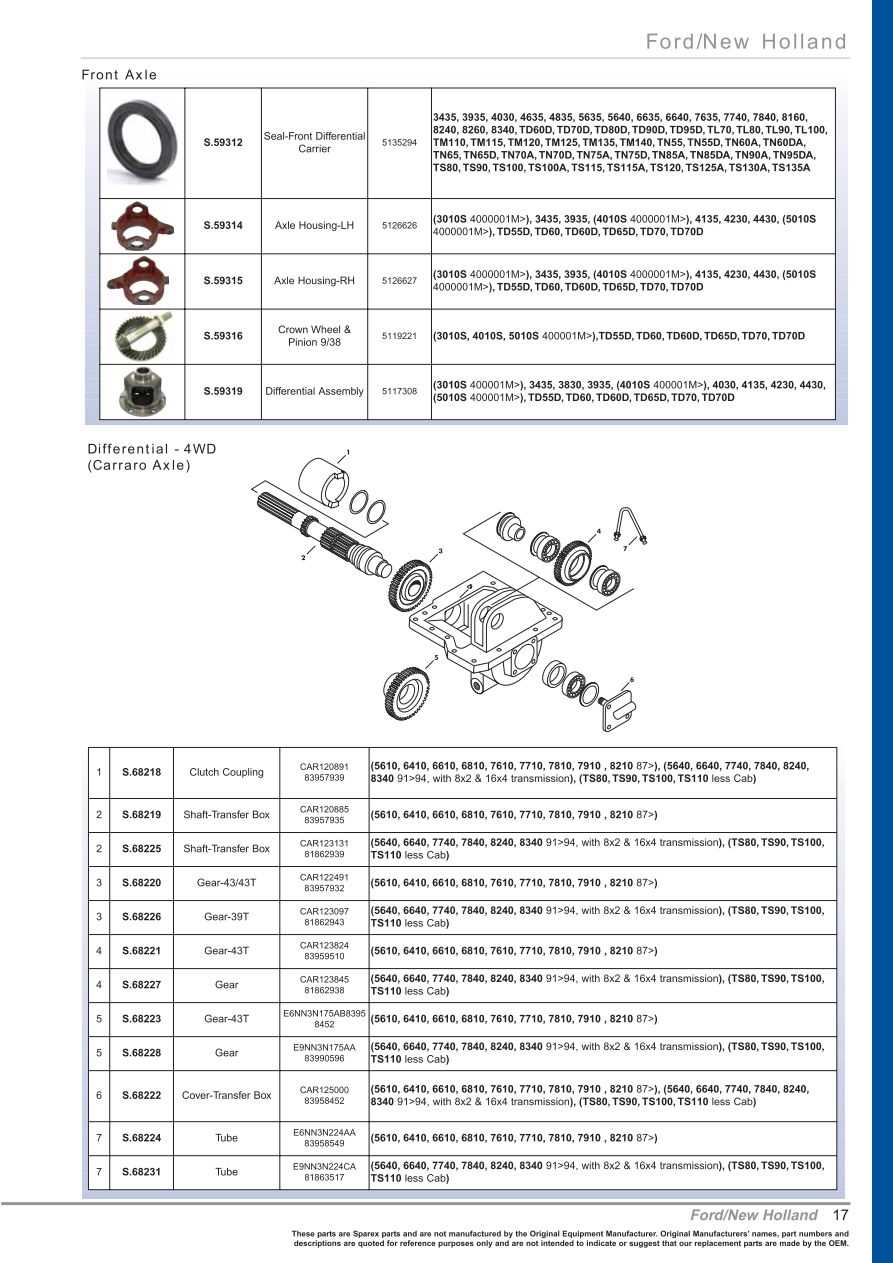

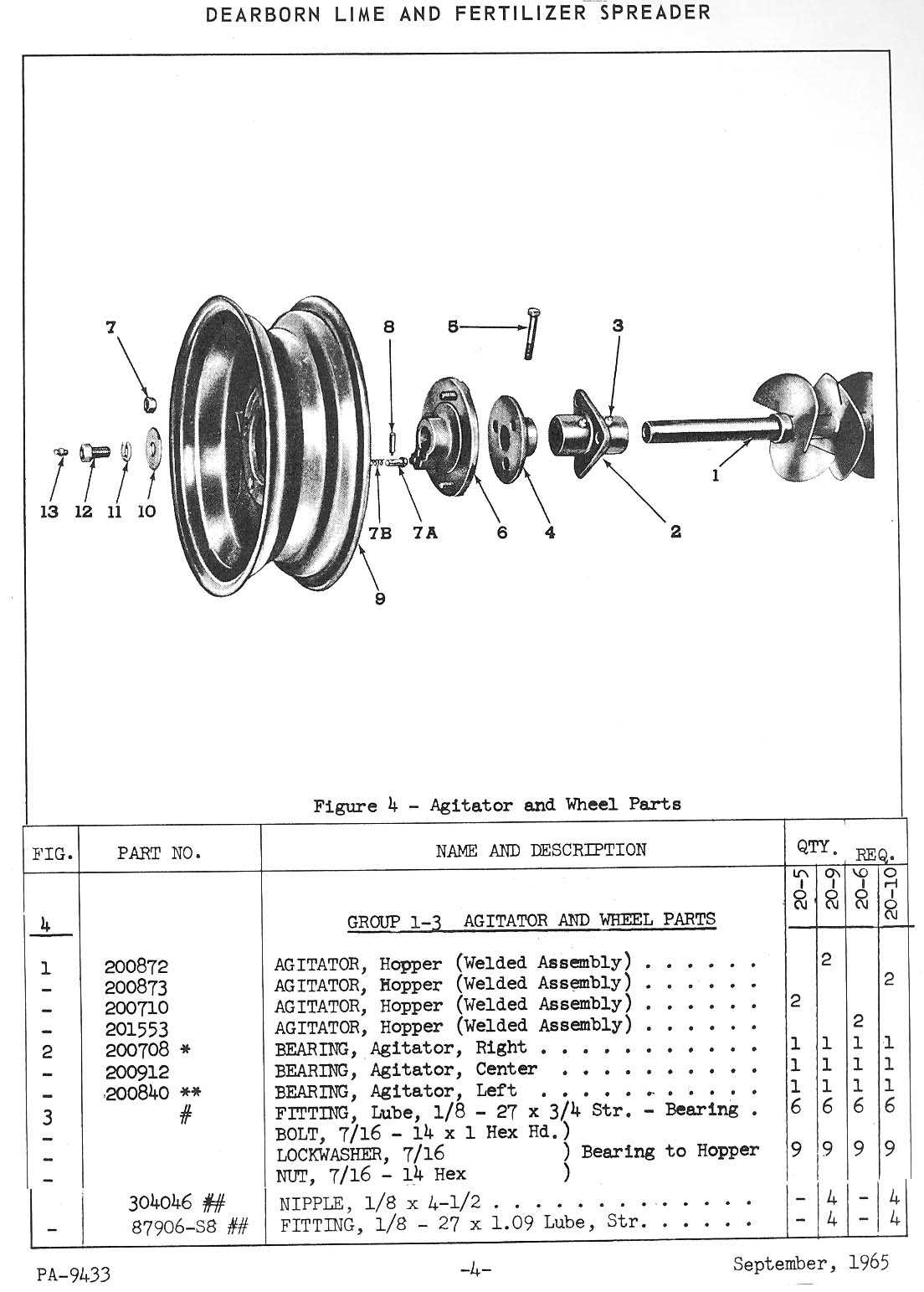

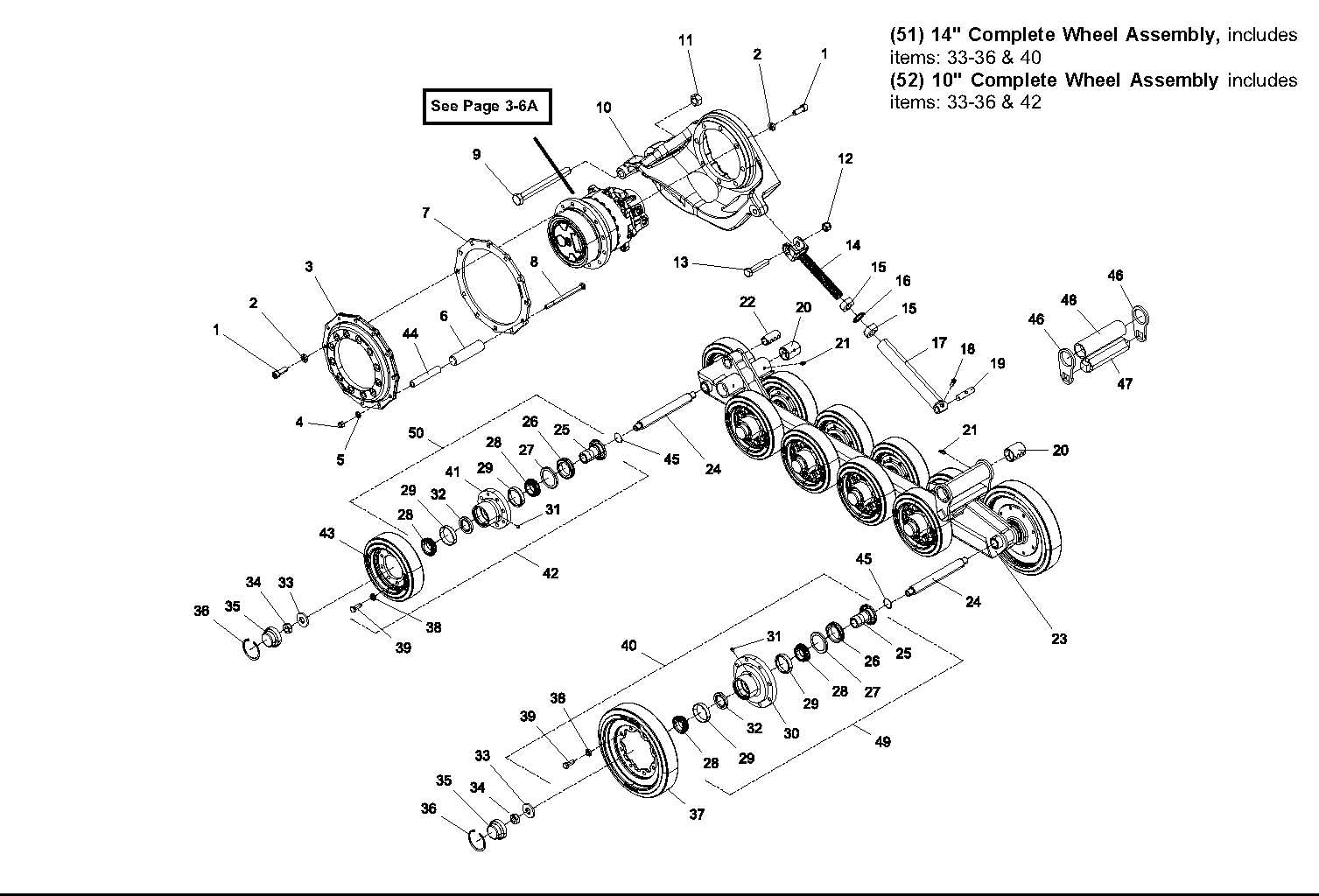

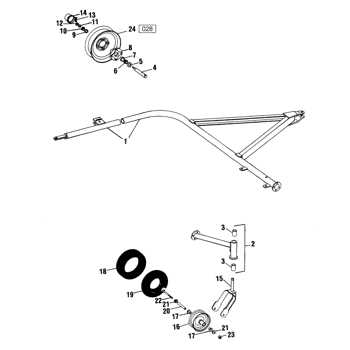

Understanding how to locate and recognize components on a technical illustration is essential for efficient maintenance or repair tasks. By carefully studying the structure and connections between different elements, you can easily determine the specific component you are looking for. Here are some steps to help you navigate the illustration:

|