In the realm of agricultural equipment, the intricate workings of machinery play a crucial role in optimizing farming practices. Understanding the various elements that contribute to the functionality of these machines is essential for effective maintenance and operation. By examining the assembly of key components, operators can ensure their equipment performs at its best.

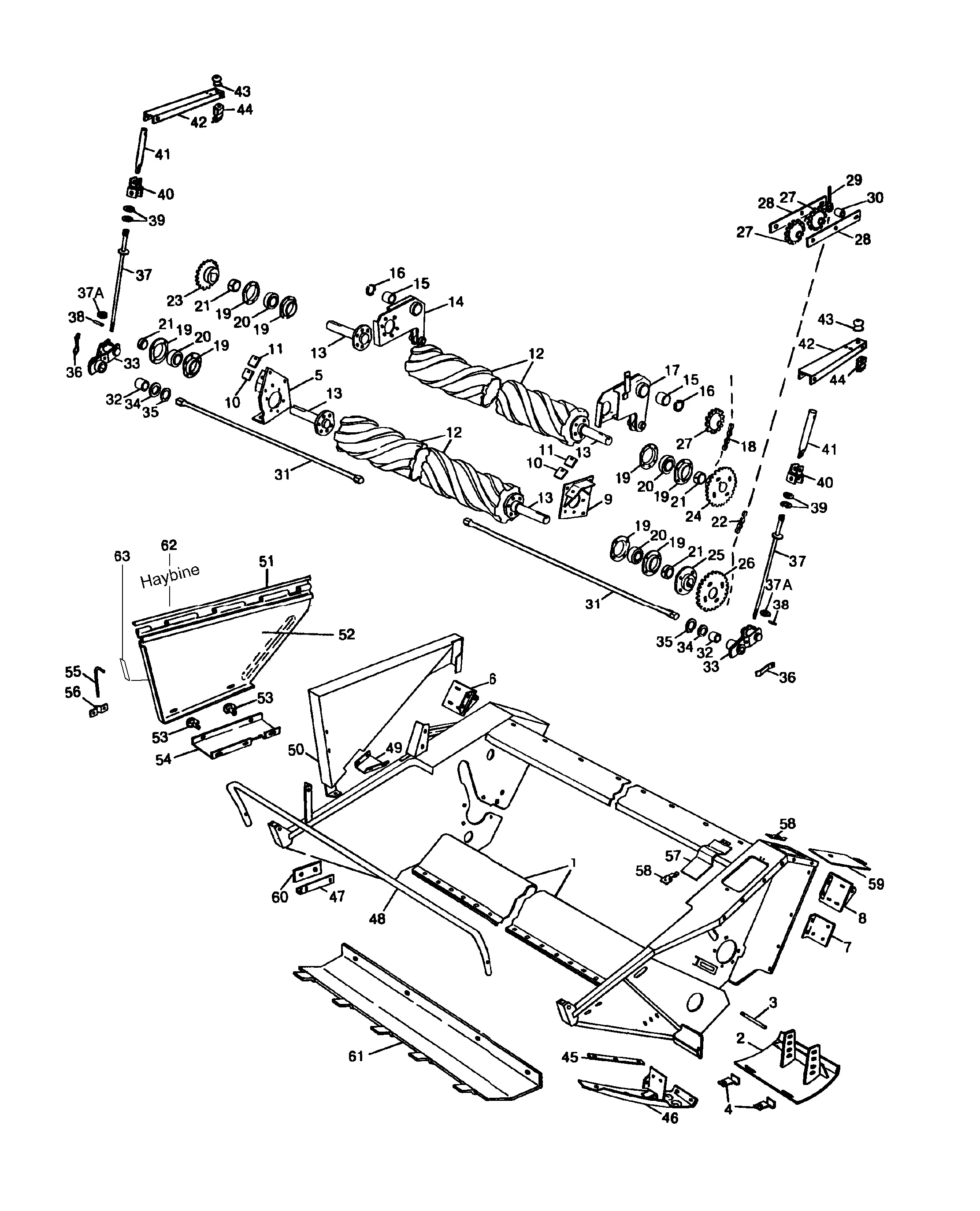

Each machine consists of numerous sections that work in harmony to achieve the desired results. Familiarity with these components not only aids in troubleshooting but also enhances overall productivity on the field. A clear visual representation of these parts can serve as a valuable resource for both seasoned professionals and newcomers alike.

Whether you are looking to replace worn-out elements or simply wish to deepen your understanding of your machinery, having access to comprehensive schematics can significantly streamline the process. This exploration of component layouts provides insight into how each part contributes to the machine’s efficiency, ultimately leading to better agricultural outcomes.

Understanding the New Holland 488 Haybine

This section explores a specific type of agricultural equipment designed for cutting and conditioning forage. It emphasizes the importance of grasping its functionality and components for effective operation and maintenance.

Key features of this equipment include:

- Efficient cutting mechanism

- Advanced conditioning system

- Durable construction for longevity

To fully appreciate its capabilities, consider the following aspects:

- Operational efficiency and speed

- Maintenance requirements and schedules

- Compatibility with various tractors

Understanding these elements can enhance overall performance and yield in agricultural practices.

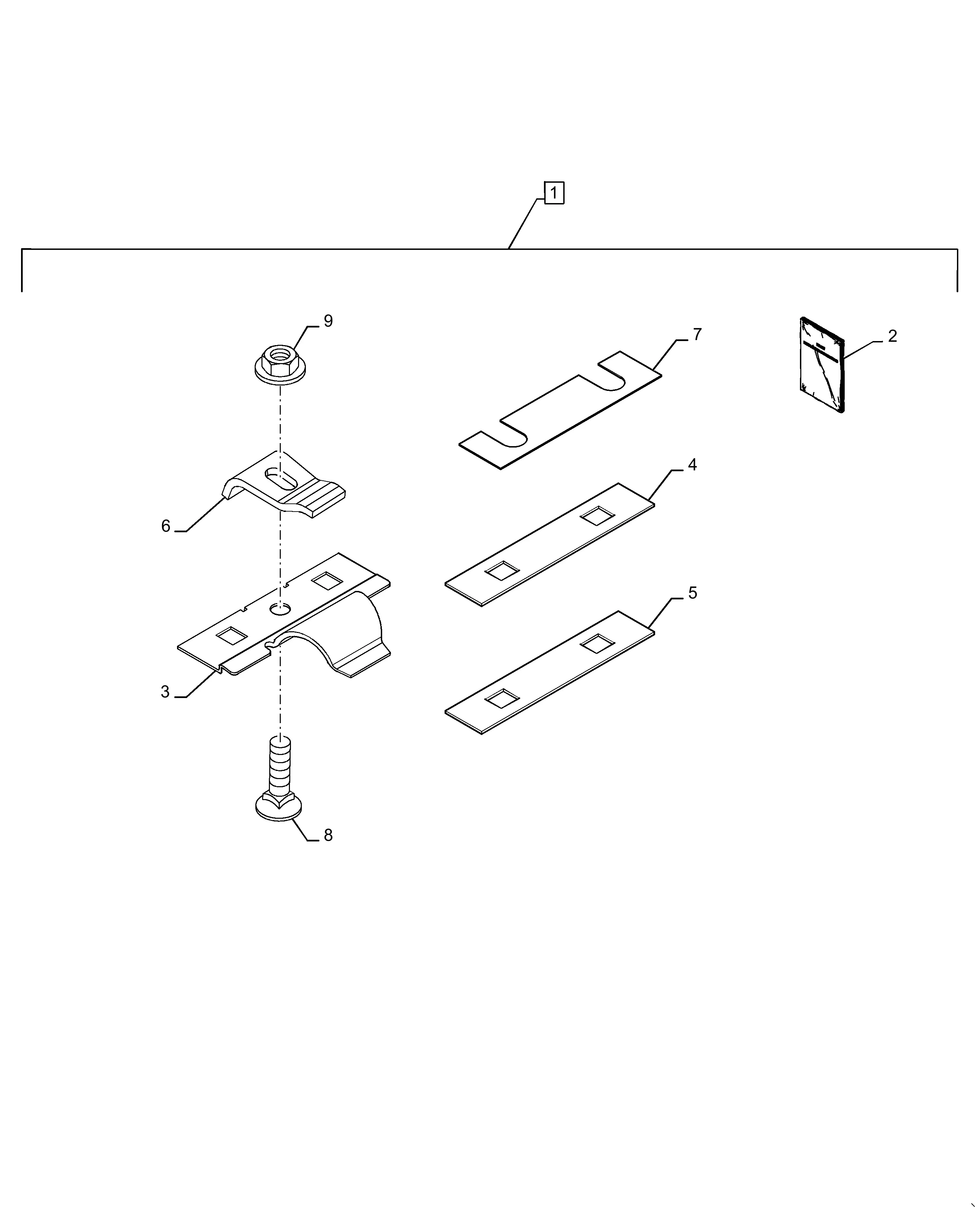

Importance of Parts Diagrams

Understanding the structure and components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools, enabling users to identify individual elements, their functions, and interconnections. This knowledge not only aids in troubleshooting but also enhances the overall efficiency of machinery operations.

Enhancing Maintenance Efficiency

Visual aids streamline the maintenance process by providing a clear overview of all components. Technicians can quickly locate parts that require inspection or replacement, minimizing downtime and ensuring optimal performance.

Facilitating Repairs

When facing malfunctions, having a visual reference can significantly speed up the repair process. Users can easily identify the necessary components and understand how they fit together, reducing the likelihood of errors and ensuring that repairs are carried out accurately.

| Benefit | Description |

|---|---|

| Quick Identification | Allows for immediate recognition of components needing attention. |

| Improved Accuracy | Reduces mistakes during assembly or disassembly. |

| Time Savings | Speeds up both maintenance and repair processes. |

| Better Understanding | Enhances knowledge of machinery operation and design. |

Key Components of the Haybine

The functionality of a cutting machine relies on several crucial elements that work in harmony to ensure efficient operation. Understanding these integral parts allows operators to maintain their equipment effectively and enhance productivity.

| Component | Description |

|---|---|

| Cutter Bar | Responsible for the initial cutting of grass or crops, this part ensures a clean and efficient cut. |

| Auger | This component transports the cut material towards the discharge area, optimizing workflow. |

| Drive System | The mechanism that powers the machine, allowing for smooth and consistent operation. |

| Frame | The structural foundation that supports all other components, ensuring stability during use. |

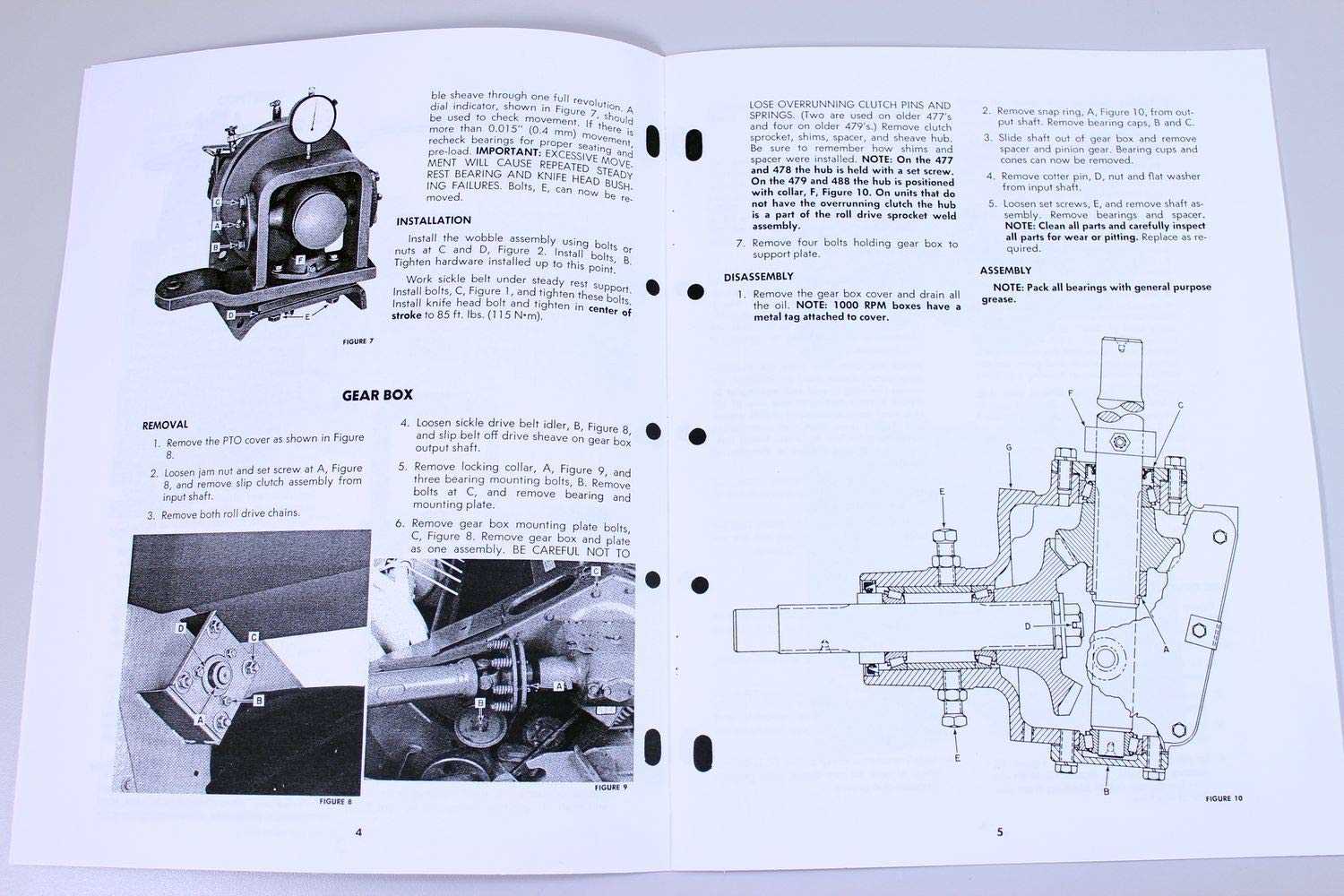

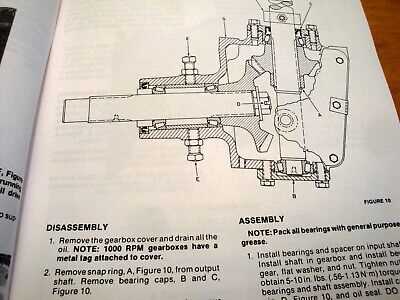

| Gearbox | This part regulates the speed and torque, crucial for adapting to different operating conditions. |

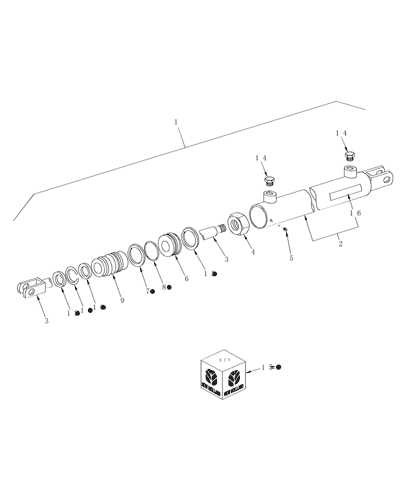

How to Read the Diagram

Understanding technical illustrations is essential for effective maintenance and repairs of agricultural machinery. These visual guides provide an overview of components, their arrangements, and interactions. Familiarity with these visuals can greatly enhance your troubleshooting capabilities.

To interpret these visuals accurately, follow these steps:

| Step | Description |

|---|---|

| 1 | Identify the key elements and symbols used in the illustration. |

| 2 | Locate the reference numbers that correspond to individual components. |

| 3 | Examine the layout to understand the relationships and connections between parts. |

| 4 | Consult the accompanying legend or key for clarification of any unclear symbols. |

By mastering these techniques, you can confidently navigate the intricacies of your machinery’s layout, ensuring optimal performance and longevity.

Common Issues and Solutions

When operating agricultural machinery, several frequent challenges may arise that can impact efficiency and performance. Understanding these common problems and their remedies is essential for maintaining optimal functionality.

1. Uneven Cutting: This issue often stems from dull blades or misalignment. Regularly inspect and sharpen the blades, and ensure all components are properly aligned to achieve a consistent cut.

2. Clogging: Material buildup can obstruct operation. To resolve this, periodically clean the machinery and adjust the settings to accommodate varying crop conditions, preventing accumulation.

3. Hydraulic Failures: Hydraulic system malfunctions can lead to inadequate power. Check fluid levels and inspect hoses for leaks. Replacing worn components will restore functionality.

4. Belt Slippage: Slipping belts can reduce efficiency. Ensure proper tension is maintained and replace any worn belts to ensure smooth operation.

5. Electrical Issues: Faulty wiring or connections can disrupt operation. Regularly inspect and secure electrical connections, and replace damaged wires to maintain reliable performance.

Maintenance Tips for Longevity

Ensuring the durability of your machinery requires consistent care and attention. By implementing effective maintenance practices, you can enhance performance and extend the lifespan of your equipment.

Regular Inspections: Conduct routine checks to identify wear and tear early. Pay special attention to critical components and make necessary adjustments promptly.

Proper Lubrication: Keep moving parts well-lubricated to reduce friction and prevent overheating. Use the recommended lubricants for optimal results.

Cleanliness: Maintain a clean environment by removing debris and dirt from the machine. This prevents blockages and promotes efficient operation.

Storage Conditions: Store equipment in a sheltered area to protect it from harsh weather conditions. This minimizes the risk of rust and other environmental damage.

Follow Manufacturer Guidelines: Adhere to the maintenance schedule and recommendations provided by the manufacturer to ensure proper upkeep and performance.

Where to Find Replacement Parts

Locating suitable components for your agricultural machinery can significantly enhance its performance and longevity. Ensuring that you source high-quality items is essential for maintaining efficiency and minimizing downtime. Fortunately, there are several reliable avenues available to assist you in your search.

Online Retailers are an excellent starting point. Many websites specialize in agricultural equipment, offering a wide range of components that can be shipped directly to your location. Take advantage of user reviews and detailed product descriptions to make informed choices.

Local Dealers often carry a selection of essential items and can provide personalized service. They may also offer expert advice on compatibility and installation, ensuring that you choose the right products for your machinery.

Salvage Yards can be a treasure trove for those seeking economical alternatives. Often, you can find gently used components that are still in excellent condition, allowing you to save money while still getting quality items.

Finally, consider reaching out to Manufacturer Support. Many companies offer catalogs and customer service that can guide you to the right solutions. This can be particularly beneficial for hard-to-find components.

By exploring these options, you can successfully locate the necessary replacements to keep your equipment running smoothly.

Upgrades for Improved Performance

Enhancing the efficiency and productivity of agricultural machinery can significantly impact overall farming operations. By implementing targeted modifications, operators can optimize performance, extend equipment lifespan, and ultimately achieve better yields. Various upgrades are available that focus on key components, ensuring that machines operate at their best under varying conditions.

One effective approach is to enhance the cutting system. Upgrading blades or incorporating high-quality knife sections can lead to cleaner cuts and reduced wear. This improvement not only enhances the quality of the crop but also minimizes downtime for maintenance.

Another vital area is the drive mechanism. Upgrading to more efficient belts or gears can improve power transfer and reduce energy loss. This change results in smoother operation and better fuel efficiency, allowing for longer working hours without frequent refueling.

Investing in control technology is also beneficial. Advanced monitoring systems provide real-time data, enabling operators to make informed decisions. By utilizing precision farming techniques, users can maximize productivity while minimizing resource waste.

Finally, improving tire performance can enhance traction and stability on various terrains. Selecting tires designed for specific conditions can lead to better maneuverability and less soil compaction, contributing to healthier fields.

In summary, thoughtful enhancements in key areas can lead to substantial gains in machinery performance. By focusing on cutting, drive systems, technology integration, and tire quality, operators can ensure their equipment meets the demands of modern agriculture.

Comparing Models: 488 vs Others

When evaluating different agricultural implements, it’s essential to understand the distinctions among various models. Each machine brings unique features and specifications that cater to specific farming needs. By examining these differences, farmers can make informed choices that enhance their productivity and efficiency.

In this comparison, we will focus on a well-regarded model and explore how it stands against its peers. Key aspects such as cutting width, operating speed, and maintenance requirements are crucial when assessing performance. Additionally, the durability and ease of use can significantly impact a farmer’s overall experience with the equipment.

While some models may excel in maneuverability, others might offer superior power and cutting capacity. It’s also worth noting that technological advancements in newer variants can provide added benefits such as improved fuel efficiency and enhanced operator comfort. Ultimately, understanding these factors will aid in selecting the best implement to suit specific agricultural tasks.