In the realm of farming equipment, the efficiency and longevity of machinery heavily depend on the quality and maintenance of its individual elements. Each component plays a crucial role in the overall functionality, ensuring that operations run smoothly during peak seasons. A detailed examination of these elements can significantly enhance the performance of the equipment, ultimately leading to better yields and less downtime.

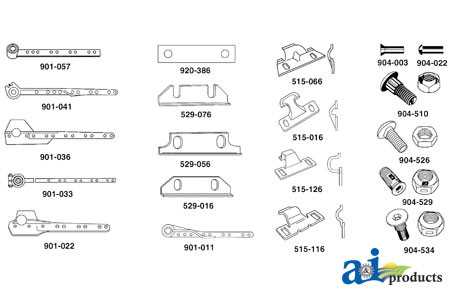

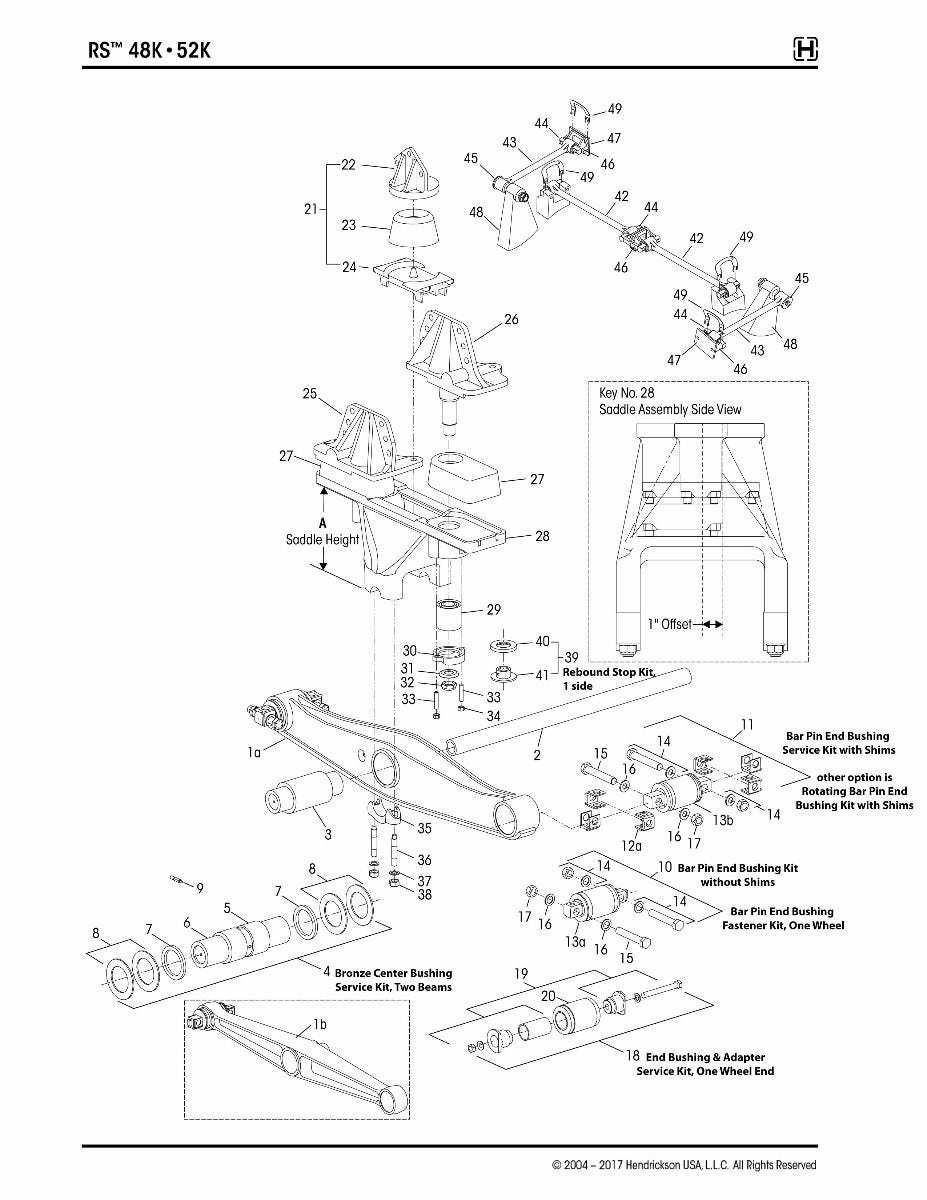

Visual aids can be invaluable in grasping the intricate relationships between various components. By studying comprehensive layouts, operators and technicians can identify specific parts that may require attention or replacement. This understanding not only simplifies maintenance tasks but also empowers users to make informed decisions regarding repairs and upgrades.

For those engaged in agricultural activities, having access to accurate and detailed representations of machinery can streamline operations and enhance productivity. By familiarizing themselves with the inner workings of their tools, users can ensure that their equipment remains in optimal condition, ready to tackle the demands of the farming season.

Understanding New Holland Haybine Mechanics

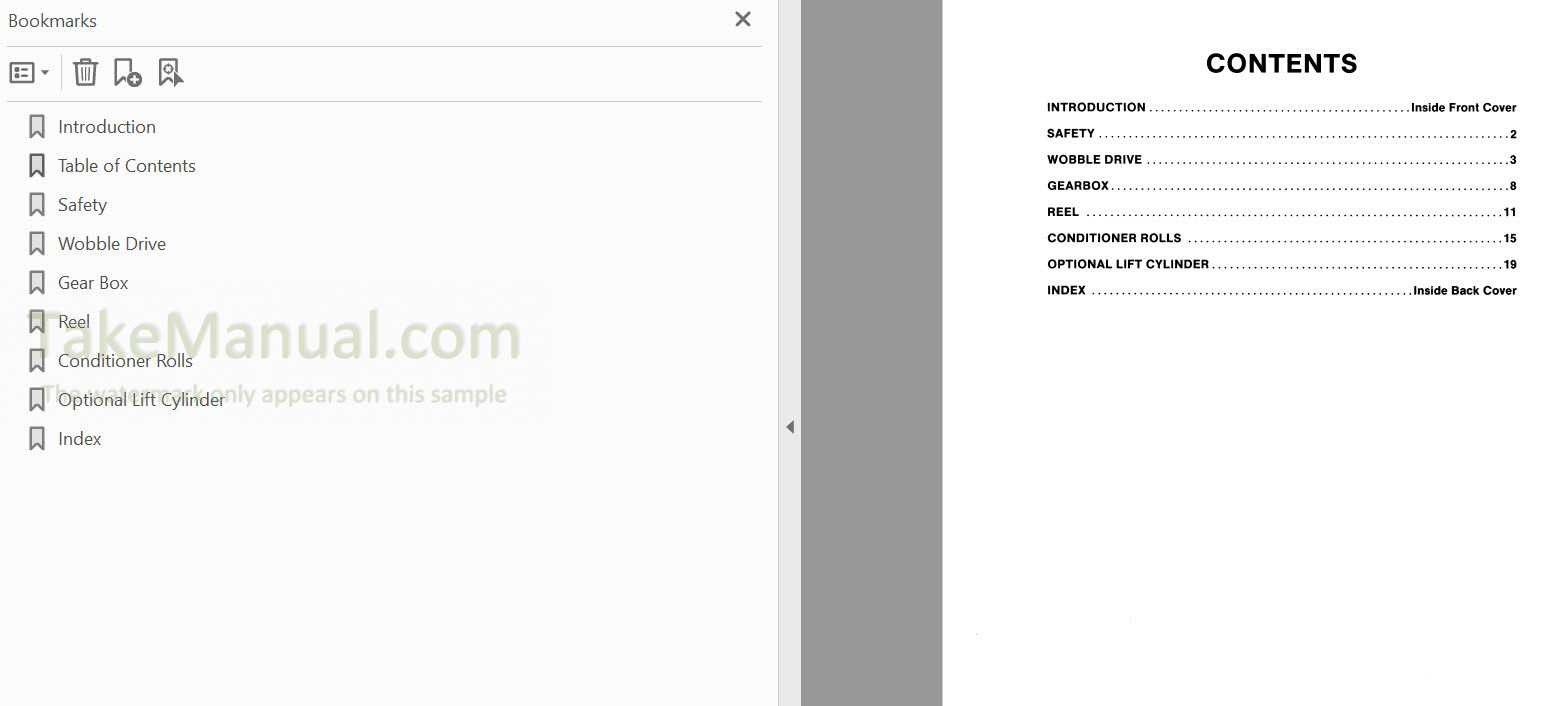

The inner workings of agricultural cutting equipment play a crucial role in enhancing efficiency and productivity. Grasping the mechanics behind these machines enables operators to maintain their functionality and ensure optimal performance in the field. This section delves into the fundamental components and their interactions, providing insights into how these systems work together to facilitate seamless operation.

Core Components and Their Functions

Each element of the machinery serves a distinct purpose, contributing to the overall efficiency. Below is a table that highlights essential components and their roles:

| Component | Function |

|---|---|

| Cutting Bar | Responsible for slicing through vegetation, ensuring clean cuts. |

| Drive System | Transfers power from the engine to various components, enabling movement. |

| Auger | Assists in directing cut materials towards the center for efficient handling. |

| Rollers | Facilitate smooth movement over the ground, reducing soil disturbance. |

Maintenance Tips for Longevity

Regular upkeep is vital for sustaining performance and extending the life of the equipment. Key maintenance practices include routine inspections, lubrication of moving parts, and timely replacement of worn components. By adhering to these guidelines, operators can prevent breakdowns and ensure their machinery operates at peak efficiency.

Key Components of the 477 Haybine

This section explores the essential elements that contribute to the functionality and efficiency of the cutting machine. Understanding these components is crucial for optimal performance and maintenance.

- Cutter Bar: This is the primary cutting mechanism, designed to efficiently slice through grass and crops.

- Roller System: These rollers help to condition the cut material, ensuring it dries evenly and quickly.

- Drive System: Comprising gears and belts, this system transmits power from the engine to the working parts.

- Header: The front attachment that guides the material into the cutter bar, optimizing cutting efficiency.

- Frame: The sturdy structure that supports all components, providing stability during operation.

Regular inspection and maintenance of these key parts can significantly enhance the longevity and effectiveness of the machine.

Importance of Regular Maintenance

Consistent upkeep is crucial for the longevity and efficiency of agricultural machinery. Neglecting routine care can lead to decreased performance, increased wear, and unexpected breakdowns. By prioritizing maintenance, operators ensure that their equipment operates at peak performance, ultimately saving time and money.

Timely inspections help identify potential issues before they escalate, allowing for more manageable repairs. Furthermore, regular servicing enhances safety and reliability, minimizing the risk of accidents during operation. Investing in maintenance not only prolongs the lifespan of the machinery but also improves overall productivity on the farm.

How to Identify Wear and Tear

Recognizing signs of deterioration in agricultural machinery is crucial for maintaining optimal performance and extending the lifespan of the equipment. Regular inspections can help identify issues before they escalate, ensuring efficient operation and reducing repair costs.

Visual Inspections

Start by examining the machinery for visible signs of damage or excessive wear. Look for cracks, rust, or deformation in metal components. Check for frayed belts or hoses, as these can significantly impact functionality. Regularly cleaning the machine can also help reveal hidden wear.

Performance Indicators

Monitor the performance of the equipment during use. Notice any unusual noises, vibrations, or changes in efficiency, such as decreased cutting effectiveness or difficulty in movement. These indicators can suggest underlying problems that require further investigation.

Common Repairs for Haybine Parts

Maintaining equipment in optimal working condition is essential for efficient agricultural operations. Regular inspections and timely repairs can significantly extend the lifespan of machinery and enhance performance. Below are some frequent maintenance tasks and repairs that are commonly performed on these implements.

- Blade Replacement: Dull or damaged blades can hinder cutting efficiency. Regularly checking and replacing them ensures clean cuts.

- Drive Belt Inspection: Worn or frayed belts can lead to power loss. Inspecting and replacing them as needed prevents further damage to the machinery.

- Gearbox Maintenance: Gearboxes may require lubrication or replacement of worn gears. Keeping them in good condition is vital for smooth operation.

- Hydraulic System Checks: Leaks or low fluid levels can affect performance. Regularly inspecting hydraulic components helps maintain functionality.

Performing these repairs not only enhances the efficiency of agricultural tasks but also minimizes downtime and repair costs. Keeping a maintenance schedule can lead to a more productive and reliable farming operation.

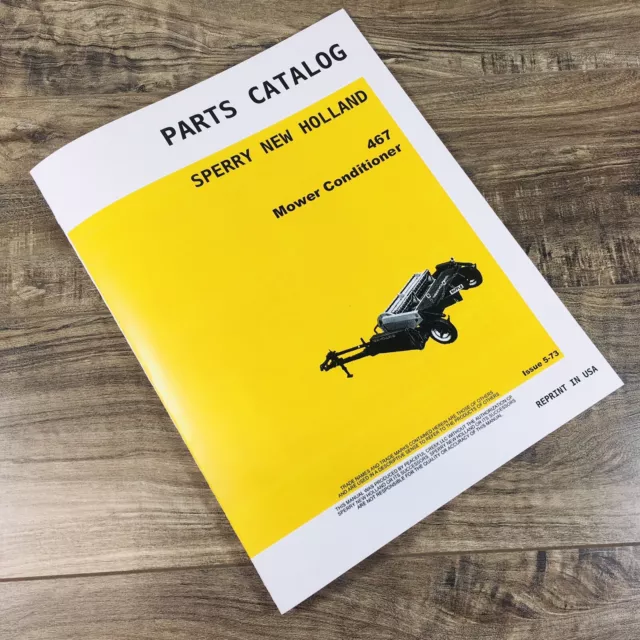

Where to Find Replacement Parts

Finding quality components for your agricultural machinery can significantly enhance its performance and longevity. Several avenues exist for sourcing these essential items, each offering unique benefits that cater to various needs and preferences.

Online Retailers

One of the most convenient methods is through online retailers. Numerous websites specialize in agricultural equipment, providing an extensive inventory that allows you to compare prices and specifications easily.

| Website | Description |

|---|---|

| Tractor Supply Co. | Offers a wide range of equipment accessories and components for various machinery. |

| Agri Supply | Specializes in farm equipment and provides a comprehensive selection of parts. |

| eBay | A platform for new and used items where you can often find hard-to-find components. |

Local Dealerships

Local dealerships often carry specific items suited to the machinery they sell. Building a relationship with these suppliers can lead to personalized service and expert advice tailored to your equipment.

Understanding Parts Diagrams and Labels

Interpreting visual representations of machinery components is crucial for effective maintenance and repair. These illustrations serve as a guide, allowing users to identify various elements and their respective functions. Clear labeling helps streamline the troubleshooting process and ensures that necessary replacements or adjustments are made with precision.

Importance of Clarity

Well-structured visuals enhance comprehension, making it easier for operators to locate specific items. Accurate labels eliminate confusion, particularly for those who may not be familiar with the equipment. A detailed illustration empowers users to communicate more effectively about repairs and maintenance needs.

Navigating the Visuals

Familiarity with the layout and labeling conventions used in these visuals can significantly improve efficiency. By understanding how components are organized, users can quickly pinpoint areas that require attention. This knowledge not only saves time but also minimizes the risk of errors during servicing.

Troubleshooting Common Haybine Issues

Maintaining optimal performance in your cutting equipment requires an understanding of potential problems that may arise. By identifying common malfunctions, you can ensure smooth operation and extend the lifespan of your machinery.

Here are some typical issues and their solutions:

- Uneven Cutting:

- Check for dull blades.

- Inspect the cutting height settings.

- Examine the overall balance of the machine.

- Excessive Vibration:

- Verify that all components are securely fastened.

- Look for bent or damaged parts.

- Ensure proper lubrication is applied.

- Clogging Issues:

- Clear any debris from the intake area.

- Check for any blockages in the feed system.

- Adjust the feed rate as necessary.

By addressing these challenges promptly, you can maintain efficiency and achieve the ultimate results in your agricultural tasks.

Best Practices for Operating Haybines

Efficient management of cutting equipment is essential for maximizing productivity and ensuring optimal performance. Understanding key techniques and maintenance tips can significantly enhance the lifespan of machinery while improving the quality of the harvested crop.

Regularly inspect and maintain blades to ensure sharpness and proper alignment, which is crucial for clean cutting. Monitor the machine’s settings to adjust for varying field conditions, ensuring adaptability to different types of forage.

When operating, maintain a steady speed to reduce wear and ensure even cutting. It’s also important to keep the equipment clean to prevent buildup that can affect performance and lead to costly repairs.

Lastly, ensure all safety protocols are followed to protect both the operator and those nearby. By adopting these practices, operators can achieve the ultimate efficiency in their operations.