When it comes to maintaining or repairing a heating system, it’s important to have a clear understanding of how each element works together. Recognizing the role of individual elements can help ensure smooth operation and timely intervention when needed. This guide aims to provide a comprehensive look at the essential components that make up one of the most reliable heating units available.

Each part of the unit plays a critical role in creating an efficient and safe environment. Whether you’re dealing with routine maintenance or troubleshooting specific issues, knowing how these elements interact is key. By familiarizing yourself with the internal structure and the relationships between different mechanisms, you can achieve better control and understanding of the entire system.

In the following sections, we’ll explore the detailed breakdown of this specific heating model, allowing you to

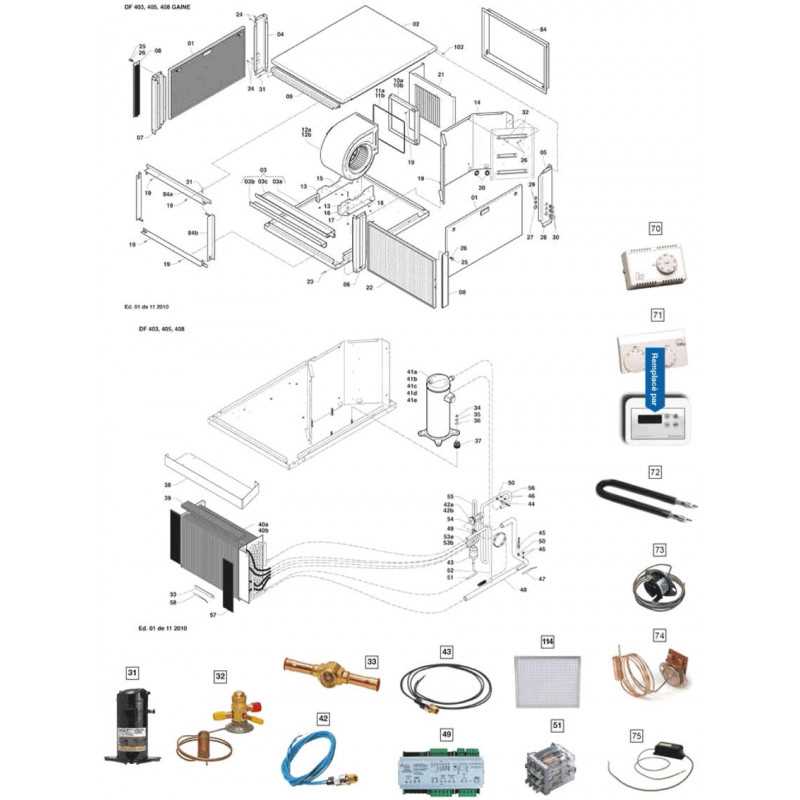

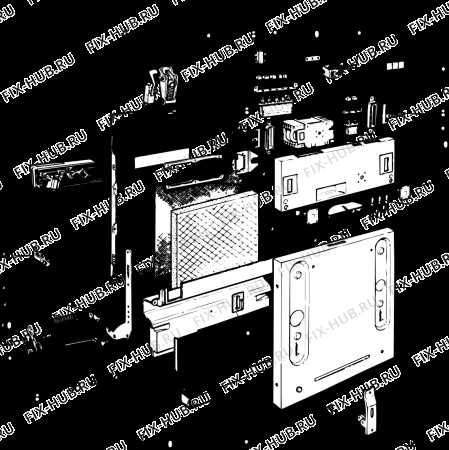

Overview of Mr. Heater Big Maxx Components

The functionality of this heating system relies on the effective operation of its key elements. Understanding the various sections and how they work together is essential for maintaining smooth performance and longevity. Each section serves a specific role in ensuring the overall effectiveness of the equipment, from regulating temperature to maintaining proper airflow.

| Component | Function | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Burner Assembly | Generates the warmth by combining fuel and air, creating an efficient ignition process. | |||||||||

| Fan Motor | Ensures the circulation of warm air throughout the space, aiding in even heat distribution. | |||||||||

| Gas Valve | Regulates the flow of fuel into the system, ensuring safety and control during operation. | |||||||||

Understanding the Heating System Layout

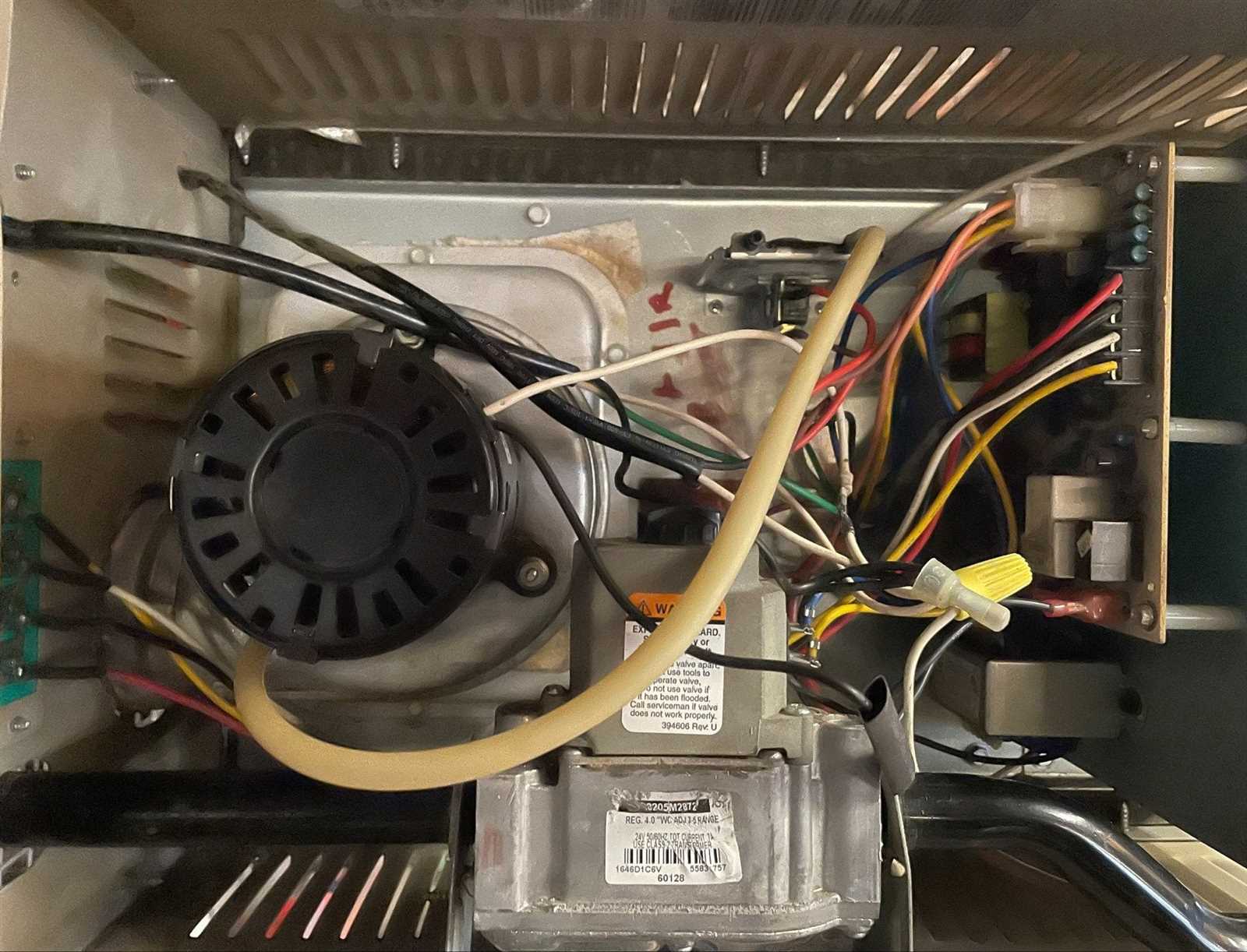

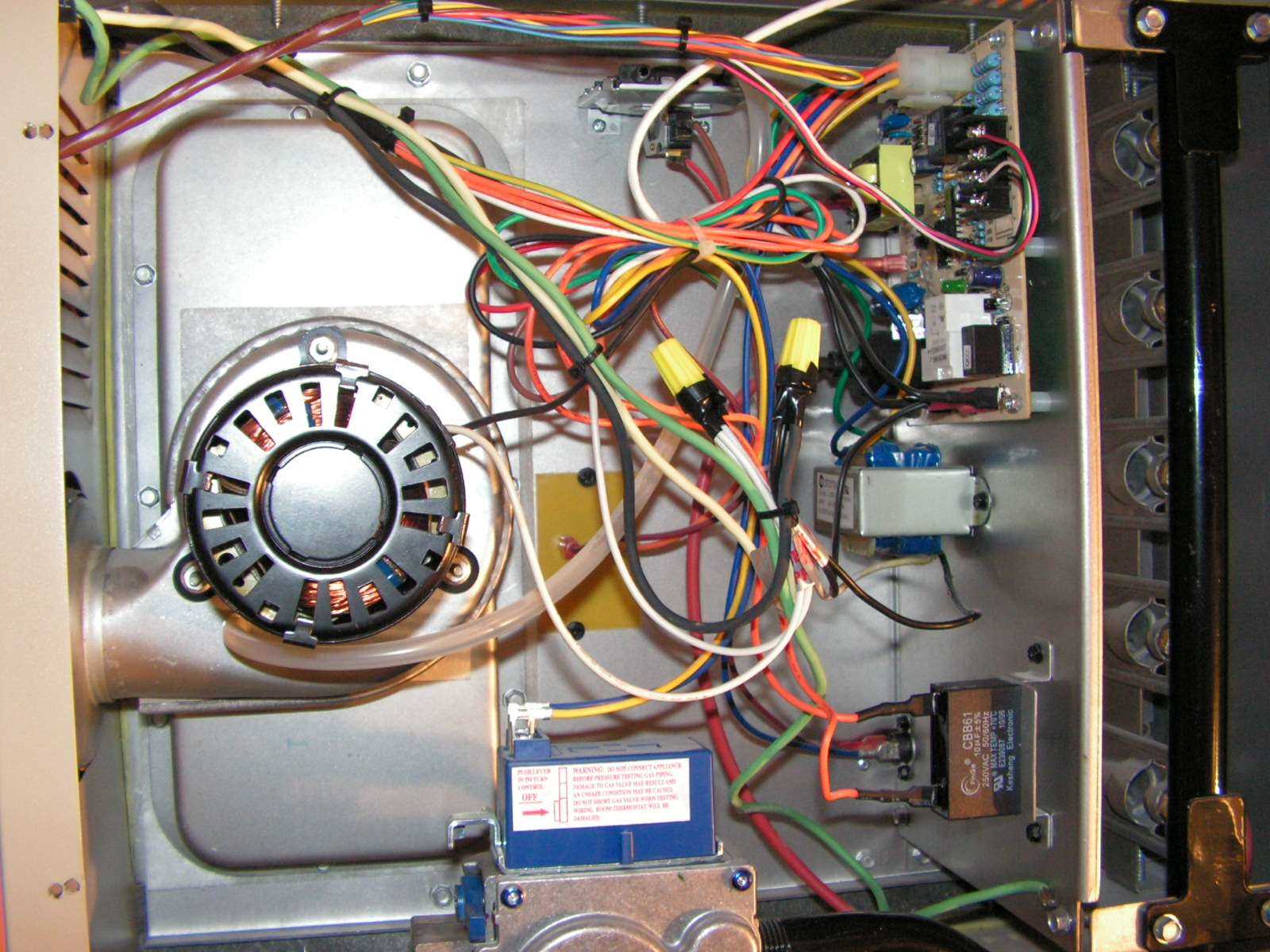

The layout of a typical heating setup is designed to efficiently distribute warmth throughout the space. It is essential to grasp the overall structure, which includes several interconnected components working together to generate and channel thermal energy. These systems are engineered to optimize airflow and heat exchange, ensuring even temperature regulation. Key elements of this design involve a central unit that serves as the core of the operation, ductwork for air distribution, and control mechanisms that regulate the output and flow. Understanding how these pieces fit together helps in maintaining and troubleshooting the system efficiently. Key Parts of the Burner Assembly

The burner assembly is a crucial element in ensuring efficient operation. Its components work together to facilitate the ignition process and maintain consistent performance. Understanding the essential elements of this system can help with maintenance and troubleshooting, ensuring smooth and effective operation. One important feature is the igniter, which initiates the combustion process by generating a spark. The flame sensor monitors the presence of the flame, ensuring that the combustion continues safely. Meanwhile, the manifold is responsible for directing the flow of fuel to the appropriate area for burning. These components must be kept in good condition, as any malfunction can disrupt the entire system’s operation. Regular inspection of the key elements helps maintain functionality and safety. Air Circulation and Ventilation Components

Proper airflow is essential for maintaining a balanced environment, ensuring that fresh air moves efficiently and stale air is removed. A well-designed system can regulate temperatures, minimize humidity, and enhance overall comfort in a space. Effective air circulation prevents stagnant zones and encourages a more uniform distribution of air throughout the area. The key components involved in this process typically include fans, ducts, and vents. Fans are responsible for driving the air, while ducts serve as channels guiding the flow to different sections. Vents control the intake and release, managing the air exchange between the interior and exterior. Maintaining these elements in good working condition ensures continuous and even ventilation, which is vital for the system’s long-term performance. Clean ducts and properly functioning fans prevent energy loss and reduce wear on other mechanical parts, contributing to a more efficient operation overall. Commonly Replaced Elements in the Unit

The unit, like any complex system, contains a variety of components that may wear out over time. Regular maintenance helps extend the lifespan of these elements, but certain parts may still require replacement due to frequent usage or external factors. Understanding which components are more prone to wear can aid in troubleshooting and preventive care. Ignition System Components

One of the most frequently addressed areas is the ignition system. Elements such as the igniter or flame sensor can accumulate residue, reducing their efficiency. When these parts start to show signs of malfunction, they often need to be cleaned or swapped out to restore proper operation. Control Board and Valves

The control board acts as the brain of the unit, managing various functions. Over time, electrical components on the board may degrade. Similarly, gas valves or Control Board and Wiring ConfigurationThis section delves into the essential elements that ensure proper functionality and connectivity of the system. Understanding the arrangement of components and their interconnections is crucial for effective operation and troubleshooting. A well-structured layout promotes efficiency and minimizes the risk of malfunctions. Overview of the Control Assembly

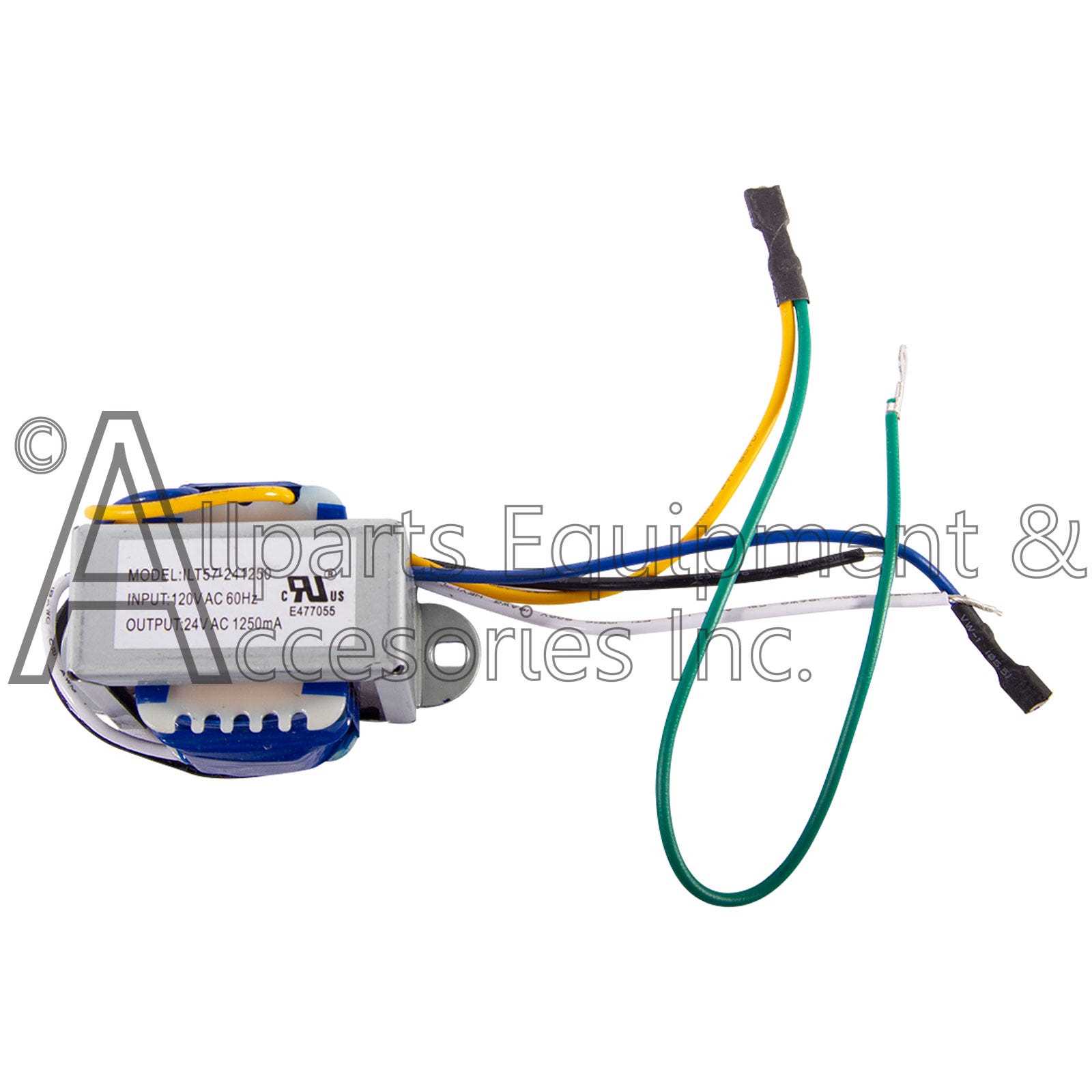

The control assembly serves as the brain of the system, managing various functions and ensuring smooth operation. It processes signals and commands to maintain optimal performance. The integration of multiple components within the assembly allows for enhanced control and monitoring capabilities. Wiring SetupEstablishing the correct wiring setup is vital for reliable performance. Proper connections facilitate the flow of electricity and enable communication between components. Below is a table outlining the key connections typically found within the assembly:

How the Gas Valve Operates

The functioning of a gas control mechanism is crucial in regulating fuel flow within various heating appliances. This component plays a pivotal role in ensuring the safe and efficient delivery of gas to the combustion chamber, allowing for the proper operation of the unit. Understanding its operation can provide insights into the overall efficiency and safety of the system. Principle of Operation

At its core, the gas control mechanism utilizes a series of internal components to manage the flow of gas. When activated, the valve opens, allowing gas to enter the system. This process is typically controlled by a thermostat, which detects the temperature and adjusts the gas flow accordingly. A precise balance is essential; too much gas can lead to unsafe conditions, while too little can hinder performance. Safety FeaturesModern gas valves incorporate various safety features to prevent malfunctions. These include thermal protection, which shuts off the gas flow if the temperature exceeds safe limits, and pressure regulators, which maintain consistent gas pressure throughout the system. Additionally, some units are equipped with electronic ignition systems that enhance safety by reducing the risk of gas buildup. Thermostat and Temperature Control MechanismThe mechanism responsible for regulating warmth plays a crucial role in maintaining comfort within a space. This system monitors the ambient environment and makes necessary adjustments to ensure a stable and desirable temperature. Understanding its components and functionality is essential for effective operation. At the heart of this regulation lies a sensor that detects fluctuations in temperature. Once a variation is noted, the system activates or deactivates the appropriate heating elements. This responsiveness ensures that the environment remains within a set range, optimizing energy efficiency while enhancing user comfort. Additionally, the integration of user interfaces allows individuals to set their preferred levels of warmth easily. Modern advancements in technology have introduced programmable options, enabling tailored heating schedules that align with personal routines. This combination of automation and manual control empowers users to manage their environment effectively. Troubleshooting Tips for Common Issues

When encountering difficulties with your heating system, it’s essential to identify the root of the problem effectively. This guide provides practical suggestions to help you diagnose and resolve typical complications that may arise, ensuring a comfortable environment in your space. Identifying Common Problems

Basic Troubleshooting Steps

|