When it comes to maintaining your gardening machinery, a comprehensive understanding of its various elements is essential. Each component plays a critical role in ensuring optimal performance and efficiency. By familiarizing yourself with the intricate workings of your device, you can enhance its longevity and reliability.

In this guide, we will explore the essential segments of your equipment, breaking down their functions and interconnections. This knowledge not only empowers you to tackle repairs and replacements with confidence but also aids in the overall management of your gardening tasks.

Whether you’re a seasoned gardener or just beginning your journey, grasping the layout and specifics of your machine’s structure will provide you with valuable insights. A thorough examination of each segment enables you to make informed decisions, ensuring your gardening experience remains both productive and enjoyable.

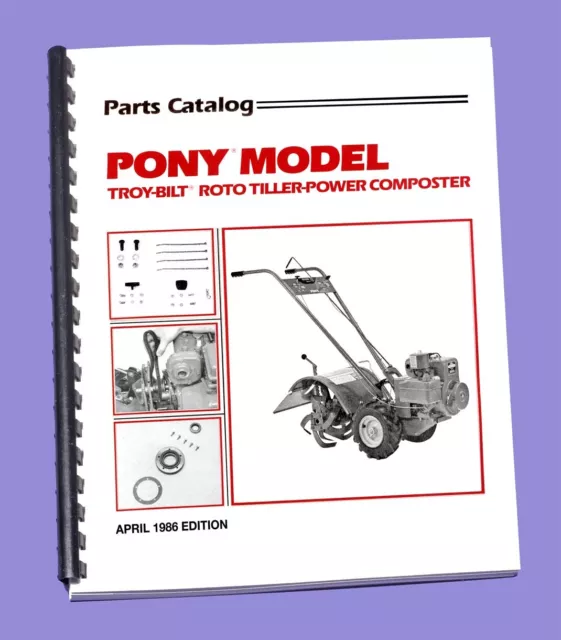

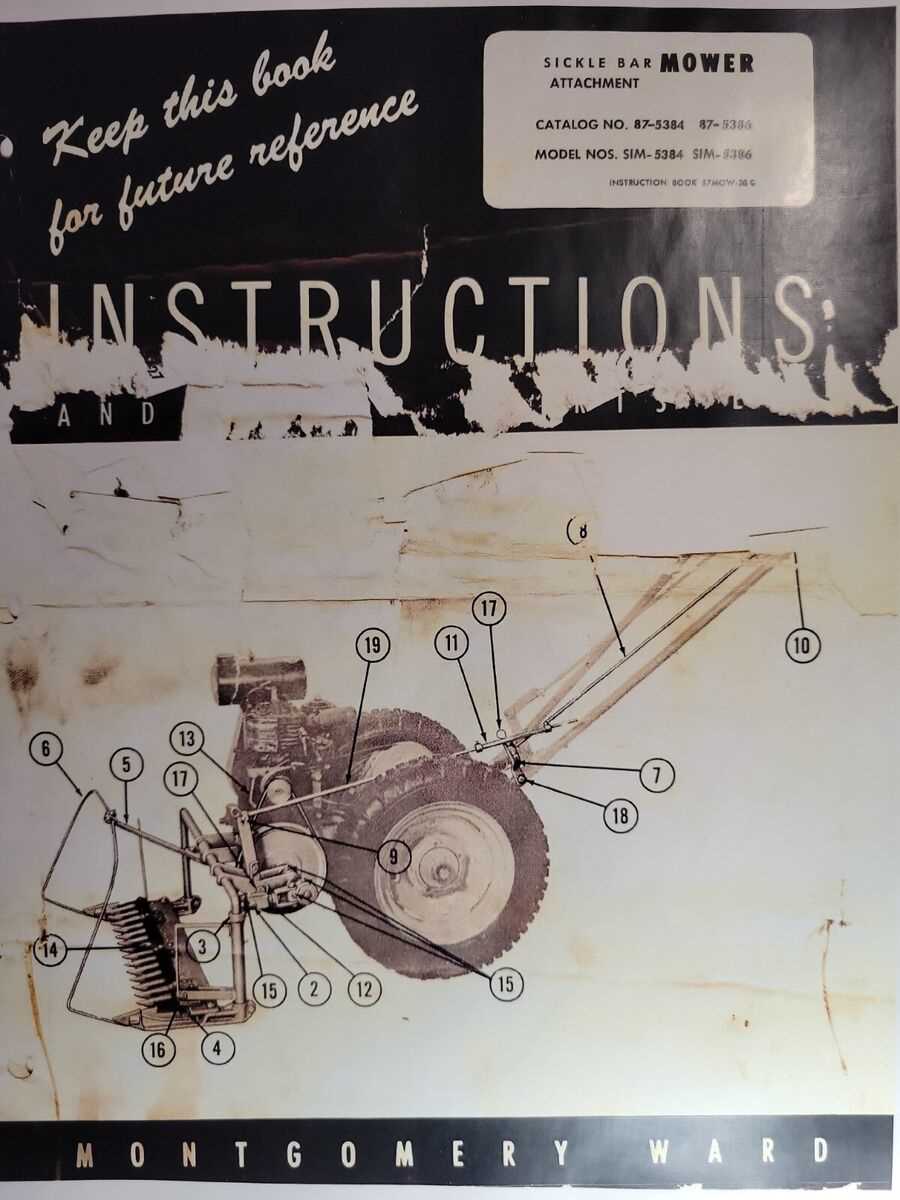

Understanding Montgomery Ward Tiller Models

When exploring the various types of garden cultivation machines, it’s essential to grasp the distinctions between different models available on the market. Each design caters to specific user needs, whether for home gardens or larger agricultural applications. Familiarity with these machines can enhance their operation and maintenance, leading to better performance and longevity.

Key Features to Consider

Different models come with unique characteristics that impact usability and efficiency. Here are some critical features to evaluate:

| Feature | Description |

|---|---|

| Engine Power | Determines the capability of the machine to handle various soil types and conditions. |

| Working Width | Affects the area covered during each pass, influencing efficiency in larger spaces. |

| Weight | Impacts maneuverability and stability, especially on uneven terrain. |

| Adjustable Depth | Allows users to modify the digging depth, essential for different types of planting. |

Choosing the Right Model

Selecting an appropriate machine requires an assessment of your specific gardening needs. Consider factors such as the size of your garden, soil type, and frequency of use. Researching user reviews and performance ratings can provide valuable insights into which model will best suit your requirements.

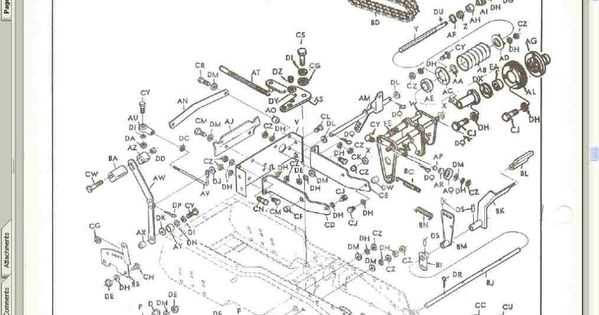

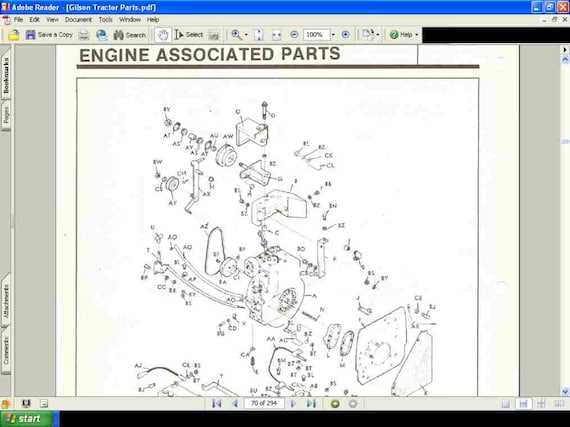

Key Components of Tiller Machines

Understanding the essential elements of soil cultivation machinery is crucial for effective gardening and farming. These machines consist of various critical components that work together to prepare the ground for planting, enhancing both efficiency and productivity.

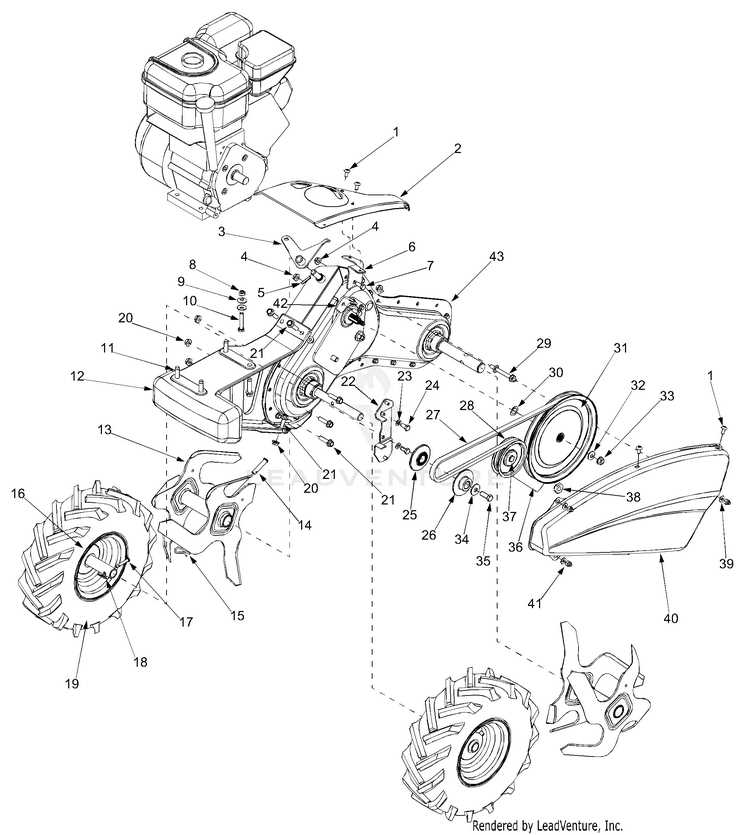

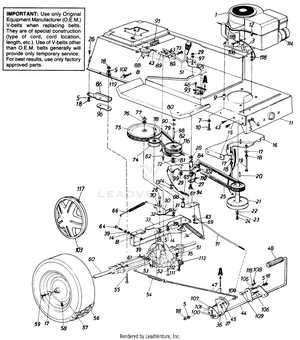

1. Engine: The engine serves as the powerhouse of the machine, providing the necessary energy to drive all other components. Its type and power output significantly influence the overall performance and capability of the equipment.

2. Tines: These are the rotating blades that break up and aerate the soil. The design and arrangement of the tines can vary, impacting their effectiveness in different soil conditions.

3. Chassis: The framework supports all other components and provides stability during operation. A robust chassis ensures durability and helps withstand the rigors of outdoor use.

4. Wheels: Equipped for mobility, wheels allow the machine to traverse various terrains. Some models may feature adjustable wheels for better control and ease of transport.

5. Handles: Ergonomically designed handles enhance user comfort and control during operation. Adjustable heights are often available to accommodate different operators.

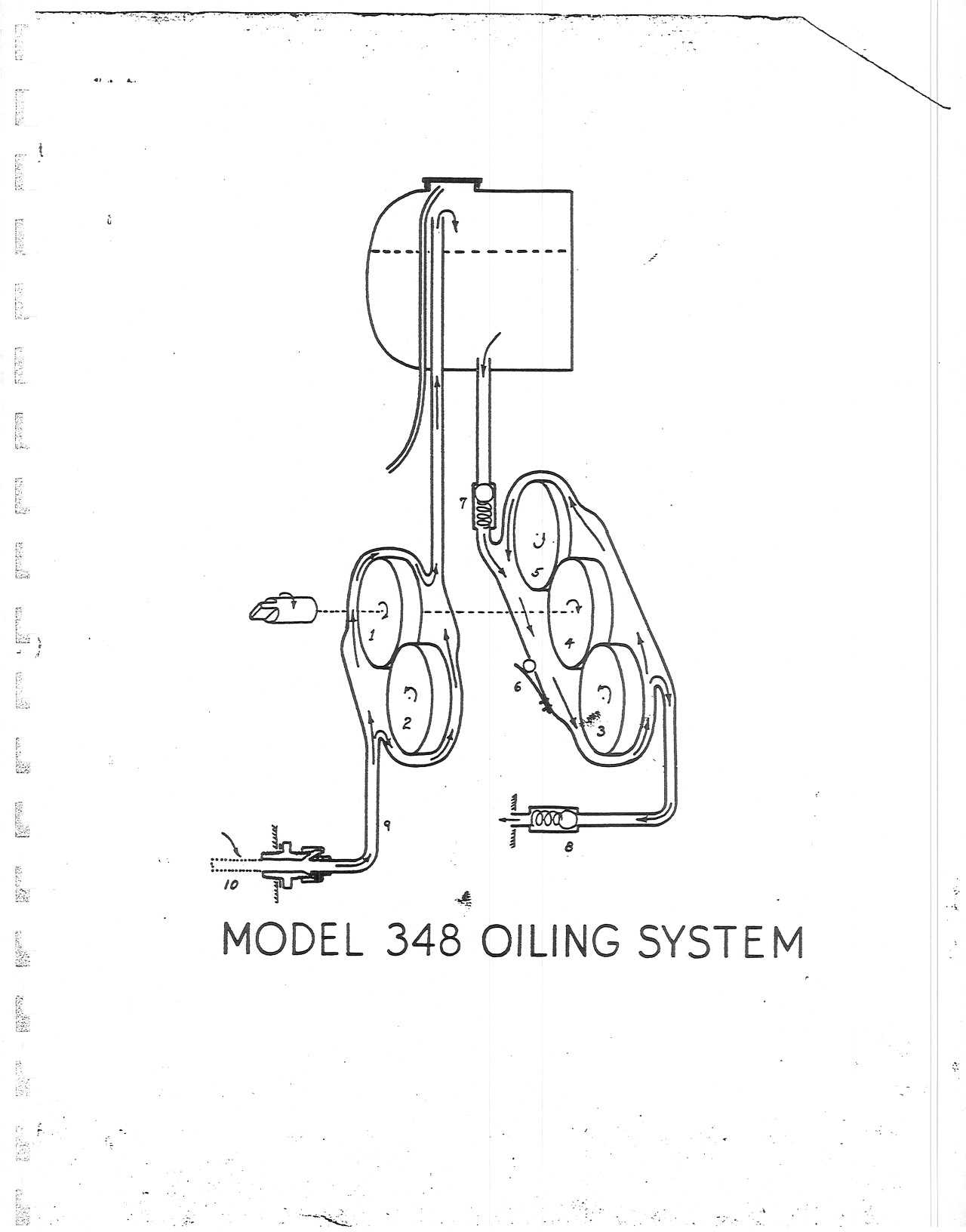

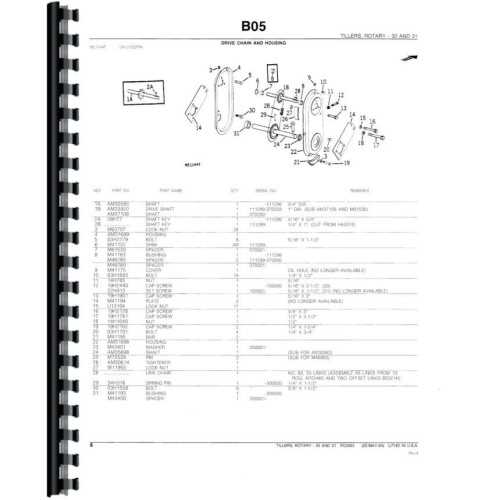

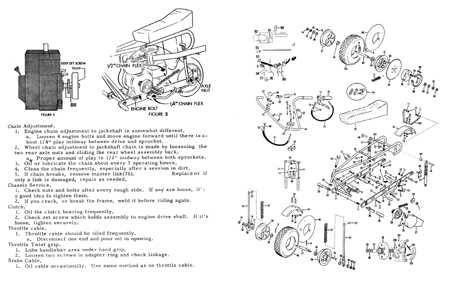

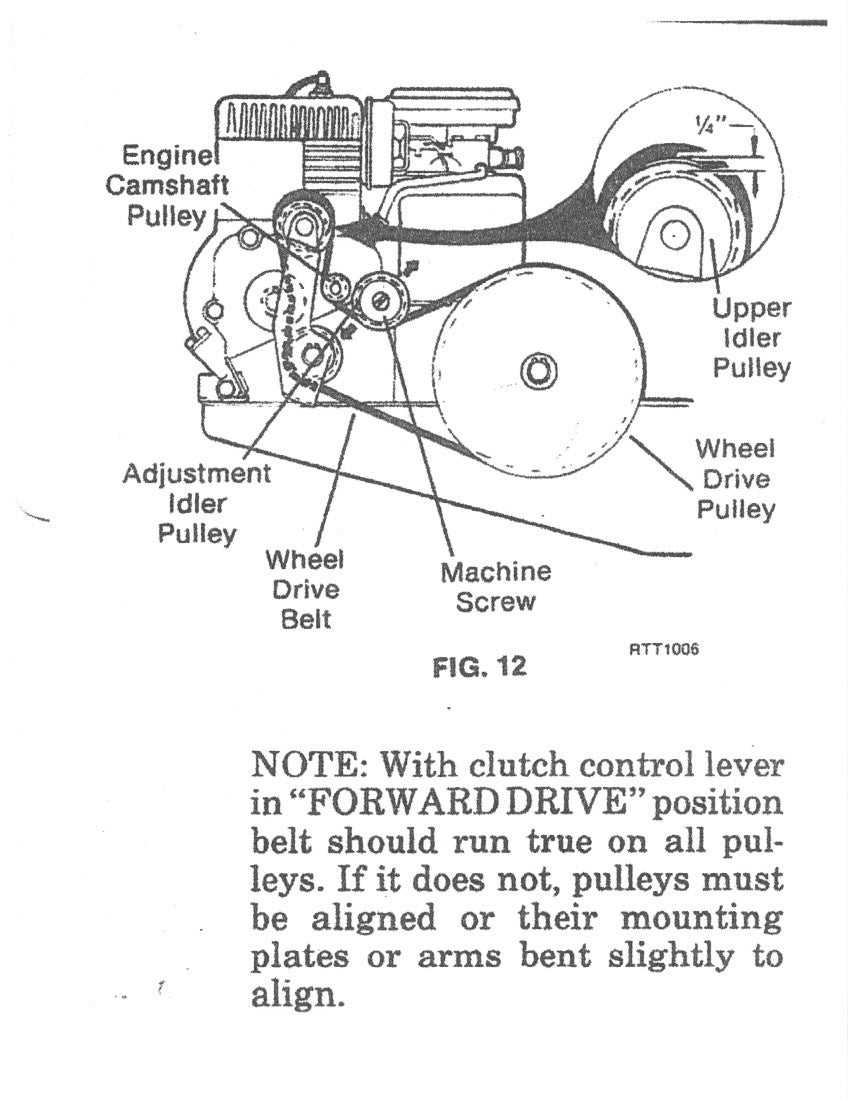

6. Drive System: This includes gears and belts that transfer power from the engine to the tines and wheels. An efficient drive system is essential for optimal performance and longevity.

Each of these components plays a vital role in the functionality of soil cultivation machinery, making it essential to understand their characteristics and maintenance needs for successful gardening endeavors.

Importance of Replacement Parts

Maintaining the functionality of any machinery is crucial for optimal performance and longevity. Over time, components may wear out or become damaged, leading to reduced efficiency and potential operational failures. Understanding the significance of timely replacements ensures that equipment continues to operate smoothly and effectively, minimizing downtime and repair costs.

Enhanced Performance

Replacing worn or faulty components can dramatically improve the overall performance of equipment. When essential elements are functioning correctly, machines operate at their best, providing better results in various tasks. Regular updates help in maintaining peak productivity and achieving desired outcomes.

Cost-Effectiveness

Investing in new components can ultimately save money. By addressing issues promptly, operators can prevent more extensive damage that would require expensive repairs or even complete replacements. Proactive maintenance through timely replacements ensures that investments in machinery are protected and extends the lifespan of the equipment.

Finding Accurate Parts Diagrams

Locating precise schematics for machinery components is crucial for effective maintenance and repair. These illustrations not only facilitate the identification of necessary elements but also ensure that replacements fit correctly. A comprehensive understanding of the layout can significantly enhance the efficiency of any restoration project.

Importance of Quality Resources

Utilizing reliable sources is essential when searching for technical visuals. Many online platforms offer detailed representations, but verifying their accuracy is paramount. Official manufacturer websites, reputable forums, and specialized retailers often provide the most trustworthy information.

How to Interpret Schematic Illustrations

Understanding the various symbols and notations used in these visuals is vital. Familiarizing yourself with common designations will enable you to navigate through the information effectively, making your repair or replacement process much smoother.

| Resource Type | Description | Advantages |

|---|---|---|

| Manufacturer Website | Official source for component illustrations | High accuracy and reliability |

| Online Forums | Community-shared visuals and insights | Diverse experiences and tips |

| Retailer Sites | Commercial platforms with product listings | Easy access to purchasing options |

Common Issues with Tiller Parts

Garden cultivators, while essential for maintaining healthy soil, can encounter a range of challenges. Understanding these common problems can help users troubleshoot effectively and maintain optimal performance.

- Engine Difficulties:

- Starting issues often arise due to fuel problems or ignition failure.

- Inconsistent operation may be linked to dirty air filters or carburetor issues.

- Transmission Problems:

- Slipping gears can indicate low fluid levels or worn components.

- Stalling during use often points to issues with belts or cables.

- Blade Wear:

- Blades can become dull over time, reducing efficiency.

- Damage or bending may occur from hitting rocks or hard soil.

- Frame Integrity:

- Rust or corrosion can weaken the structure, leading to instability.

- Loose bolts and fasteners can cause misalignment and increased wear.

Regular maintenance and timely repairs can significantly extend the lifespan of these garden machines, ensuring they remain reliable and effective tools for any gardener.

How to Maintain Your Tiller

Proper upkeep of your gardening machinery is essential for ensuring its longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents costly repairs in the future. By following a few straightforward steps, you can keep your equipment in excellent working condition throughout the seasons.

1. Regular Cleaning: After each use, remove dirt, debris, and any clippings that may have accumulated. A clean machine reduces wear and helps identify potential issues early.

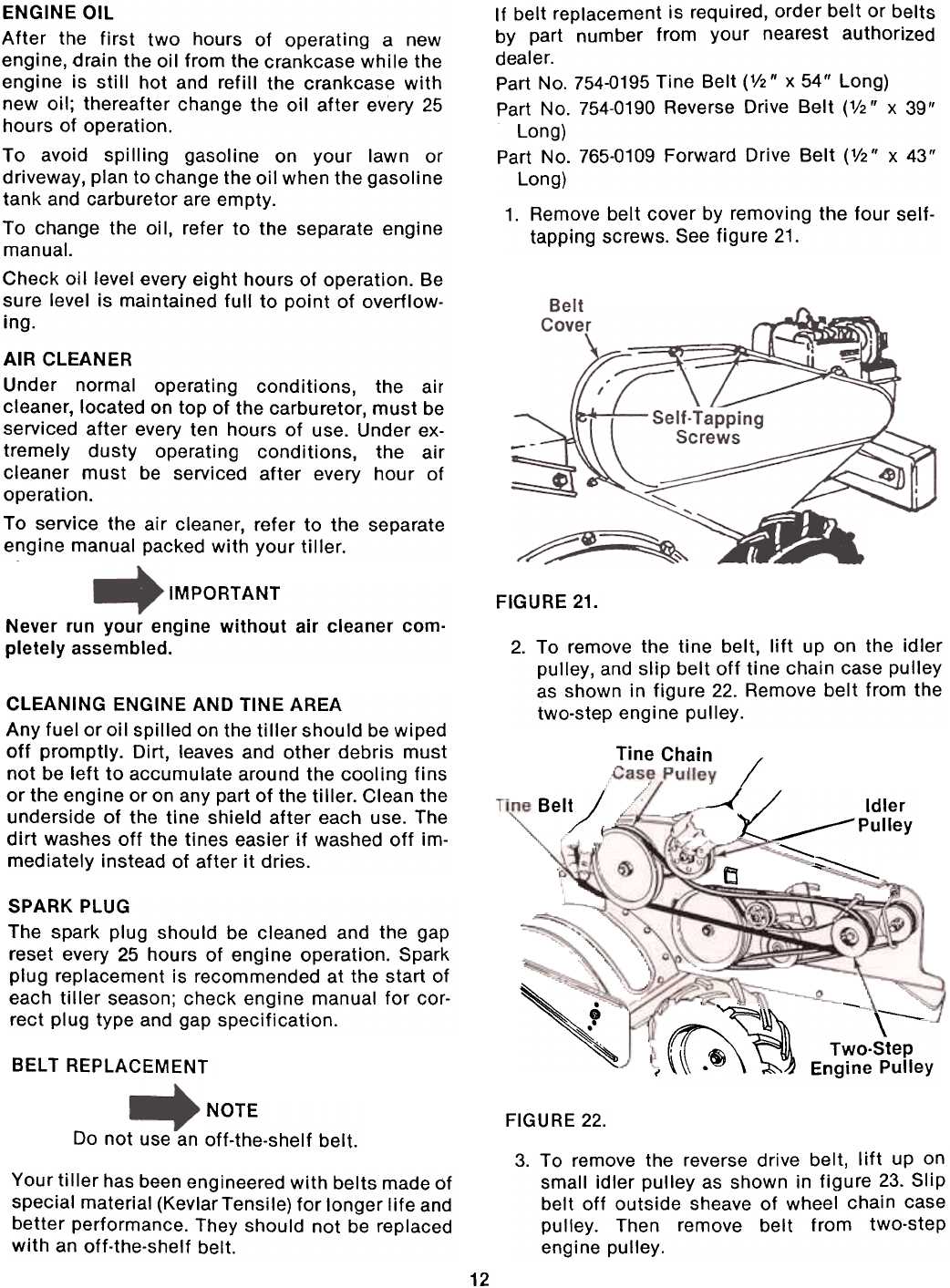

2. Check and Change Fluids: Ensure that all fluids, such as oil and fuel, are at the appropriate levels. Changing the oil regularly keeps the engine running smoothly and prolongs its lifespan.

3. Inspect the Blades: Examine the cutting tools for any signs of damage or dullness. Sharpening or replacing them as needed will improve performance and efficiency.

4. Tighten Loose Components: Periodically check all bolts and screws to ensure they are secure. Loose parts can lead to malfunction or further damage during operation.

5. Store Properly: When not in use, keep your equipment in a dry, sheltered area to protect it from the elements. Proper storage prevents rust and deterioration, ensuring it’s ready for the next season.

By following these guidelines, you can ensure that your gardening equipment remains reliable and effective, helping you achieve a flourishing garden.

Where to Buy Tiller Parts

When it comes to maintaining your gardening equipment, finding the right components is essential for optimal performance. Whether you need replacements or upgrades, knowing where to look can save you time and effort. This guide will help you navigate various options available for sourcing these essential items.

Online Retailers

One of the most convenient ways to purchase components is through online platforms. A variety of websites offer an extensive selection, often with user-friendly search features to help you locate specific items quickly.

Local Hardware Stores

Visiting a nearby hardware store can also yield valuable finds. Many local shops carry a range of equipment accessories and can provide personalized assistance to ensure you choose the right item.

| Source | Advantages | Considerations |

|---|---|---|

| Online Retailers | Wide selection, often competitive pricing | Shipping time may vary |

| Local Hardware Stores | Immediate availability, expert advice | Limited selection compared to online |

| Specialty Shops | Expert staff, specific items | Prices may be higher |

| Second-Hand Market | Potentially lower prices | Quality and condition vary |

DIY Repair Tips for Gardeners

Maintaining your gardening equipment can save you time and money while ensuring your tools operate at peak efficiency. Whether you’re dealing with a malfunctioning cultivator or any other gardening apparatus, simple repair techniques can help restore functionality. Understanding how to troubleshoot and fix common issues is essential for any gardener who wants to keep their tools in top condition.

Identify Common Problems

Before diving into repairs, it’s crucial to recognize typical issues that can arise with gardening machinery. Look for signs of wear and tear, such as unusual noises, reduced power, or difficulty starting. Regular inspections will help you catch these problems early and address them effectively.

Basic Repair Techniques

Many repairs can be handled with just a few basic tools. Start by consulting the user manual for specific instructions related to your equipment. Cleaning filters, tightening bolts, and replacing worn belts are all straightforward tasks that can significantly improve performance. Remember to wear appropriate safety gear when working on machinery to protect yourself from potential hazards.