When it comes to mastering the art of precision cutting, familiarity with the various elements of your tool is essential. Each component plays a crucial role in enhancing performance and ensuring safety during operation. A well-rounded understanding not only improves your skills but also prolongs the lifespan of your equipment.

Identifying the key features of your cutting apparatus can significantly enhance your craftsmanship. Each section serves a specific function, contributing to the overall efficiency and effectiveness of your projects. Knowledge of these components allows users to troubleshoot issues, perform maintenance, and make informed upgrades.

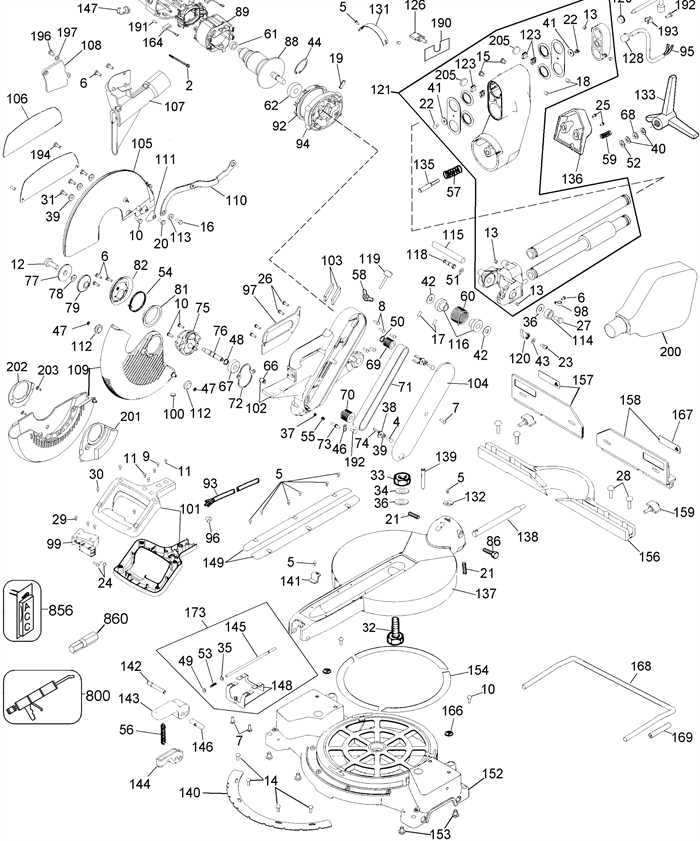

Moreover, visual representations of these elements provide invaluable insights into their arrangement and interaction. Recognizing how these individual parts work together empowers users to optimize their tools for various tasks. Whether you are a seasoned professional or a hobbyist, grasping the anatomy of your cutting tool is fundamental for achieving exceptional results.

Miter Saw Overview and Functionality

This tool is an essential instrument in woodworking, known for its precision and versatility. It enables users to make angled cuts with ease, which is crucial for creating joints, frames, and other intricate designs. Understanding its components and how they work together enhances the user experience and ensures high-quality results.

Key Features

Among the notable attributes are its ability to pivot and tilt, allowing for various cutting angles. The base offers stability, while the blade’s sharpness is vital for achieving clean cuts. Additionally, the integrated fence assists in guiding the material accurately, minimizing errors during the process.

Operational Mechanics

The functionality of this tool relies on a motor that drives the blade at high speeds. Users can adjust the settings based on their specific needs, whether for crosscuts or bevel cuts. Proper handling and maintenance are crucial for prolonging the lifespan of the equipment and ensuring safety during use.

Key Components of a Miter Saw

The functionality of a cutting tool relies heavily on its essential elements, which work in harmony to achieve precision and efficiency. Understanding these critical components is crucial for anyone looking to utilize this equipment effectively.

Blade: The cutting edge of the tool, designed to slice through various materials with accuracy.

Base: The sturdy foundation that supports the entire apparatus, providing stability during operation.

Fence: An important guide that ensures straight cuts by aligning the workpiece securely against it.

Angle Adjustment Mechanism: This feature allows for precise angle modifications, enabling versatile cutting options.

Motor: The powerhouse that drives the blade, influencing the tool’s overall performance and cutting speed.

Understanding these components will not only enhance your proficiency but also help in maintaining the tool for longevity.

Understanding Miter Saw Diagrams

Interpreting the intricate blueprints of cutting tools is essential for effective usage and maintenance. These schematics provide valuable insights into the various components and their interactions, enabling users to grasp the functionality and assembly of the equipment. A clear understanding of these visual aids enhances both safety and performance.

Each illustration typically highlights specific elements, such as the pivot mechanism, cutting head, and base. Familiarity with these features allows users to identify potential issues and make informed decisions regarding repairs or upgrades. By mastering the layout presented in these visuals, one can significantly improve their craftsmanship.

Moreover, knowing how each section works together ensures smoother operation and greater precision during tasks. A thorough comprehension of the entire assembly encourages a more efficient workflow, reducing frustration and errors. Ultimately, becoming adept at reading these illustrations contributes to overall success in woodworking endeavors.

Importance of Each Component in the Miter Saw Mechanism

In understanding the intricacies of a miter saw, it becomes evident that each element within its assembly plays a crucial role in ensuring both precision and safety during operation. This breakdown serves to illuminate the significance of every constituent part, underscoring their collective contribution to the tool’s functionality.

1. Blade Assembly

- The blade, being the primary cutting implement, dictates the accuracy and quality of the cut. Its sharpness and diameter determine the type and depth of cuts achievable.

- The blade guard, an integral safety feature, shields users from accidental contact with the blade during operation, ensuring workplace safety.

2. Motor and Drive Mechanism

- The motor, acting as the powerhouse of the miter saw, provides the necessary torque and speed to rotate the blade efficiently through various materials.

- The drive belt or gear system transfers the motor’s rotational energy to the blade, maintaining precise control over cutting speed and power.

Each of these components, from the blade assembly to the motor and its drive mechanism, collaborates seamlessly within the miter saw’s framework. This synergy allows for the execution of intricate cuts with utmost accuracy and safety, making the tool indispensable in woodworking and construction settings.

Common Miter Saw Models Explained

In the world of precision cutting tools, various models cater to different needs and preferences. Understanding the features and functionalities of these options can significantly enhance your woodworking or construction projects. Each variant offers unique advantages, making it essential to select the right tool for specific tasks.

Sliding Models

Sliding options are particularly popular for their ability to extend the cutting capacity. These tools feature a sliding mechanism that allows the blade to move forward and backward, which increases the width of cuts possible. Ideal for wider materials, they provide versatility and are often favored for trim work and larger projects.

Compound Variants

Compound designs offer the added benefit of tilting the blade to make beveled cuts. This functionality allows for angled cuts in both horizontal and vertical orientations. They are perfect for intricate designs and joinery, making them a staple for those who seek both precision and creativity in their craftsmanship.

How to Identify Miter Saw Issues

Recognizing problems with cutting tools is essential for maintaining their performance and ensuring safety during use. By observing specific signs, users can quickly address potential failures before they escalate into serious complications. This section outlines key indicators that suggest a tool may be malfunctioning.

Common Signs of Malfunction

- Inconsistent Cuts: If the cuts appear uneven or imprecise, it may indicate misalignment or dull blades.

- Unusual Noises: Grinding, rattling, or buzzing sounds can point to internal issues or worn components.

- Excessive Vibration: Noticeable shaking during operation could signal a loose assembly or imbalance.

- Overheating: If the tool becomes excessively hot, it may be due to friction from a dull blade or overuse.

Steps to Diagnose Problems

- Inspect the blade for wear and tear; replace it if necessary.

- Check for alignment issues by ensuring the tool is set up correctly and securely.

- Examine all moving parts for damage or looseness.

- Listen carefully while operating to identify any irregular sounds.

By following these guidelines, users can effectively troubleshoot issues and keep their cutting tools in optimal condition.

Maintenance Tips for Miter Saws

Regular upkeep is essential for ensuring optimal performance and longevity of your cutting tool. Proper care not only enhances accuracy but also minimizes the risk of accidents. By following a few straightforward practices, you can keep your equipment in top condition.

Routine Cleaning

- Wipe down the surface after each use to remove dust and debris.

- Inspect the blade for any build-up of pitch or resin and clean it with appropriate solvents.

- Ensure the base and sliding rails are free from obstructions to allow smooth operation.

Periodic Inspection

- Check the alignment of the blade regularly to ensure it cuts accurately.

- Examine all screws and bolts for tightness to prevent any loose components during operation.

- Inspect the electrical cord and plug for any signs of wear or damage.

Implementing these maintenance practices will help extend the life of your equipment and improve its efficiency, ensuring that it remains a reliable tool in your workshop.

Safety Features in Miter Saws

When operating power tools, prioritizing safety is essential to prevent accidents and ensure a secure working environment. Various innovative mechanisms are incorporated to protect users from potential hazards, enhancing the overall experience while working with these machines.

Blade Guards are a fundamental safety element, designed to cover the cutting edge when not in use. This feature minimizes the risk of accidental contact, promoting safer handling.

Electric Brakes are another critical component. They allow the blade to stop quickly after use, reducing the time it takes to cease operation and preventing unintended injuries.

Laser Guides serve to improve precision, aiding in aligning cuts accurately and reducing the need for unnecessary adjustments that could lead to mishaps.

Additionally, dust collection systems enhance visibility and maintain a clean workspace, mitigating the risk of slips and falls due to debris.

In conclusion, understanding and utilizing the safety features available in power tools is the ultimate way to create a secure and efficient workspace.