The functionality of an electric propulsion system relies heavily on the intricate design and arrangement of its various components. Each element plays a crucial role in ensuring optimal performance, making it essential for users to familiarize themselves with the overall structure and individual parts. Whether you are a seasoned angler or a novice, having a clear grasp of these elements will enhance your boating experience.

In this section, we will delve into the intricate assembly of a particular model, highlighting the significance of each component and its contribution to the system’s efficiency. Understanding how these parts interact and function together can empower users to troubleshoot issues effectively and perform necessary maintenance.

By examining the layout and functionality of the key components, users will gain valuable insights that can lead to improved care and longevity of the propulsion system. Proper knowledge equips boaters with the tools needed to make informed decisions regarding repairs and upgrades, ultimately enhancing their time on the water.

The efficient operation of an electric propulsion system relies on various essential elements that work in harmony. Understanding these components is crucial for users looking to optimize performance and maintain functionality.

Motor and Drive System

The motor serves as the powerhouse, providing the necessary thrust for movement. Coupled with the drive mechanism, it translates electrical energy into kinetic energy, ensuring smooth navigation across water bodies.

Control and Steering Mechanism

The steering apparatus allows for precise directional control, enabling users to maneuver effectively. The interface, often equipped with intuitive controls, enhances user experience by simplifying adjustments during operation.

- Power Supply: A reliable battery source is vital for sustained operation.

- Mounting Bracket: This component ensures secure installation, allowing stability during use.

- Propeller: Optimized for efficiency, the propeller contributes to overall thrust and maneuverability.

By familiarizing oneself with these integral parts, users can ensure that their electric propulsion system performs optimally and remains in top condition.

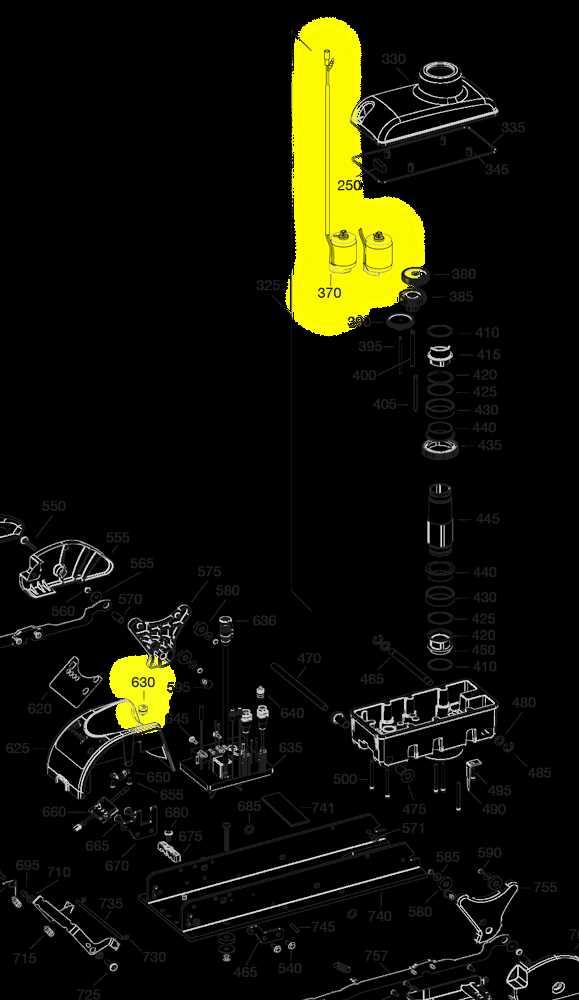

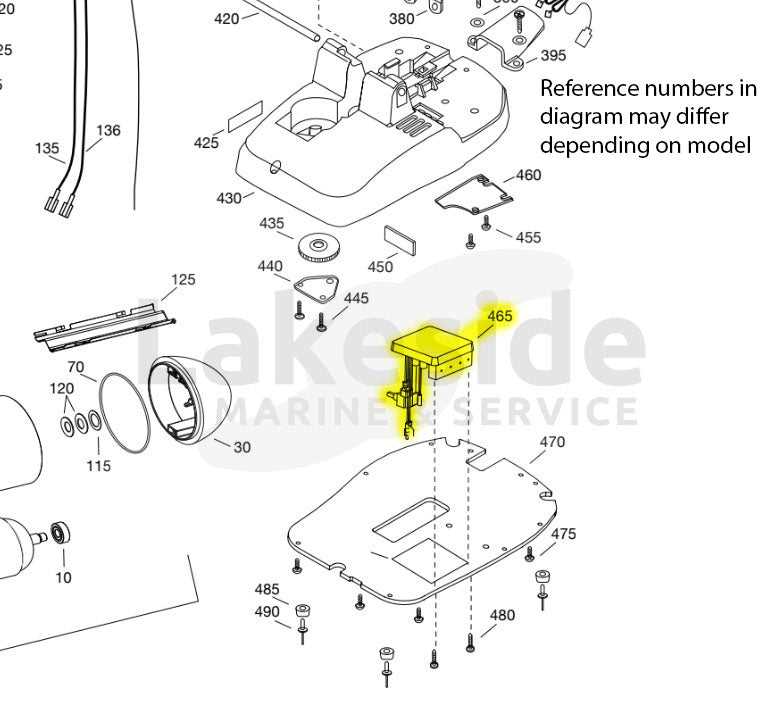

Understanding the Parts Diagram

When examining the layout of any mechanical system, it’s essential to recognize how each individual component contributes to the overall function. Visual breakdowns serve as an effective guide, offering a clear view of the intricate elements that make up the device. By analyzing these visual representations, you can gain a deeper understanding of the relationship between the components, ensuring a smoother troubleshooting or maintenance process.

Main Components Overview

The core structure of such systems often includes several critical elements designed to work in harmony. Each piece has a distinct role, contributing to the operation and efficiency of the machine. Recognizing these primary elements not only helps in repairs but also improves overall system knowledge, empowering you to identify potential issues quickly.

Detailed View of Internal Mechanisms

Breaking down the internal mechanisms allows for a closer look at the smaller, more intricate parts that are often less visible. Understanding how these hidden elements interact ensures that you can approach maintenance tasks with precision and confidence, leading to more effective outcomes when addressing mechanical problems.

Motor and Drive Assembly Details

The motor and drive assembly is a crucial component in ensuring the effective operation of a propulsion system. This assembly typically comprises various elements that work in harmony to convert electrical energy into mechanical power, enabling movement and control. Understanding the intricacies of this assembly can help in maintenance, troubleshooting, and performance optimization.

Key components of this assembly include the motor itself, the drive shaft, and the gearbox. Each element plays a specific role in the overall functionality, contributing to the smooth operation and efficiency of the system.

| Component | Description |

|---|---|

| Motor | The primary device that converts electrical energy into mechanical energy, driving the propeller. |

| Drive Shaft | A long rod that transmits power from the motor to the propeller, facilitating movement. |

| Gearbox | A mechanism that adjusts the speed and torque generated by the motor, optimizing performance. |

| Propeller | The component that interacts with the water to create thrust, propelling the vessel forward. |

Maintaining these components in optimal condition is essential for reliable performance. Regular inspections and servicing can prevent common issues, ensuring the propulsion system operates smoothly and efficiently.

Control System Components Explained

The control system consists of various interconnected elements that work together to ensure smooth and precise operation. Each component plays a crucial role in maintaining efficient functionality and enhancing overall performance. Understanding the different parts that make up the control system is essential for optimizing its use and troubleshooting potential issues.

Main Control Unit

The main control unit serves as the brain of the system, processing input commands and sending signals to other components. It coordinates the movement and ensures all elements respond accurately to the user’s actions.

Actuators and Sensors

Actuators are responsible for converting electrical signals into mechanical movements, allowing the system to carry out tasks such as steering and speed adjustments. Sensors, on the other hand, provide real-time data, helping the control unit make informed decisions.

- Steering actuator: Adjusts the direction according to user input.

- Speed control sensor: Monitors velocity and adjusts accordingly.

- Power Supply and Wiring Insights

The electrical system plays a pivotal role in ensuring the efficiency and reliability of any motorized equipment. Understanding the fundamentals of how power flows through the system, alongside the proper connections and setup, is essential for smooth operation and longevity. This section delves into the essentials of power distribution and wiring, providing key information to optimize performance.

Voltage and Current Considerations

One of the primary aspects to consider is the voltage requirement. Using the correct voltage ensures that the system operates without strain, reducing the risk of overheating or malfunction. Additionally, ensuring proper current flow through well-chosen cables minimizes energy loss and enhances overall efficiency.

- Always verify the voltage compatibility of your equipment.

- Use wiring that matches the current demand to avoid damage.

- Ensure all connections are secure and corrosion-free.

Wiring Setup for Optimal Performance

The layout and quality of wiring directly affect the equipment’s performance. High-quality materials and proper routing help reduce resistance and interference, leading to more reliable results. Attention to detail during the installation process can prevent future issues and extend the system’s lifespan.

- Plan the wiring route to

Maintenance Tips for Longevity

Regular care is essential to ensure that your equipment operates smoothly and remains reliable over time. By following a few simple steps, you can significantly extend its lifespan and reduce the likelihood of unexpected malfunctions. Proper attention to both mechanical and electrical components will help keep your device in optimal condition, even in challenging environments.

Task Frequency Inspect all wiring and connections Monthly Clean moving parts and lubricate where necessary Every 6 months Check for corrosion or wear on metallic components Annually Test the system in dry conditions before use Before each use Implementing these steps consistently will ensure your device stays in top shape, enhancing its efficiency and performance over time. Routine inspections and timely adjustments will help prevent costly repairs, keeping your investment running smoothly for years to come.

Common Issues and Troubleshooting

When dealing with frequent technical malfunctions, it’s important to understand how to recognize typical problems and resolve them efficiently. This section offers guidance on identifying common difficulties and how to approach their correction.

Power Connectivity Problems

A common challenge involves issues related to power supply. Check connections thoroughly, ensuring all cables are properly linked and free from corrosion. If power interruptions persist, verify the condition of fuses and replace any damaged ones. This can prevent many recurring problems.

Control Malfunctions

If you experience erratic control or response issues, recalibration might be necessary. Verify that settings are configured correctly and reset the system if required. Regular maintenance of control units can prevent these types of errors from becoming frequent.