The Mf 35 is a remarkable machine known for its reliability and performance in various agricultural tasks. Understanding its structure and essential elements is crucial for optimal functionality and maintenance. This section will explore the essential components that make up this valuable equipment.

Each element plays a vital role in ensuring smooth operation, and familiarity with these components can significantly enhance the user experience. Whether you are a seasoned operator or a newcomer, grasping the layout and arrangement of these essential features will empower you to make informed decisions regarding upkeep and repairs.

In this discussion, we will delve into the intricate arrangements of the Mf 35, shedding light on the various sections that contribute to its overall efficiency. By the end of this overview, you will have a clearer understanding of the critical elements that drive this machine’s performance.

Mf 35 Parts Overview

This section provides an essential understanding of the components that make up the Mf 35. Each element plays a critical role in the machine’s functionality, ensuring smooth operation and reliability. Familiarity with these elements is crucial for effective maintenance and troubleshooting.

Key Components

- Engine Assembly

- Transmission System

- Chassis and Frame

- Hydraulic System

- Electrical System

- Wheels and Tires

Maintenance Considerations

- Regular inspection of the engine assembly to ensure optimal performance.

- Checking the hydraulic fluid levels to maintain efficiency.

- Monitoring the electrical system for any potential issues.

- Ensuring the chassis remains free from rust and damage.

- Maintaining tire pressure for safety and functionality.

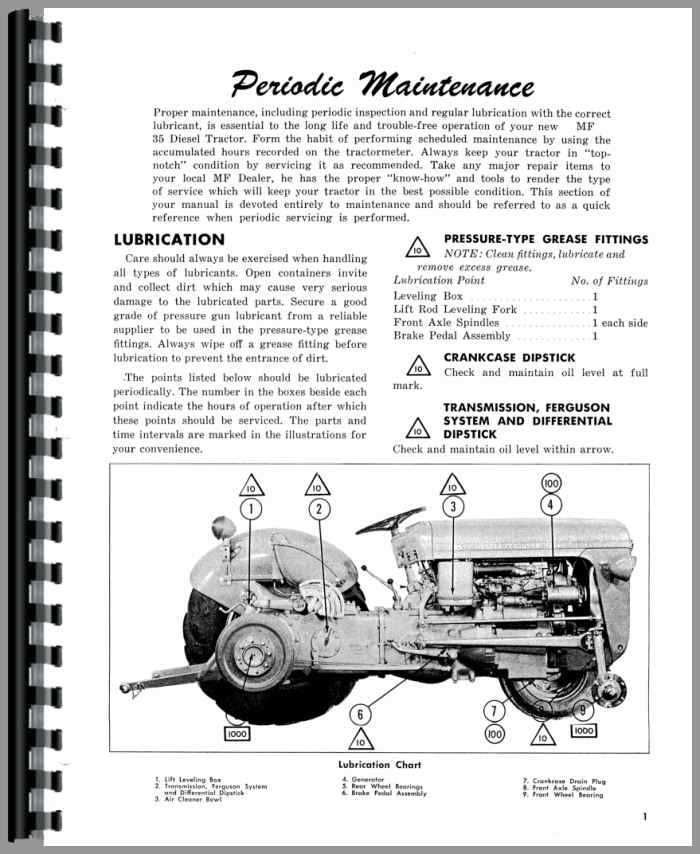

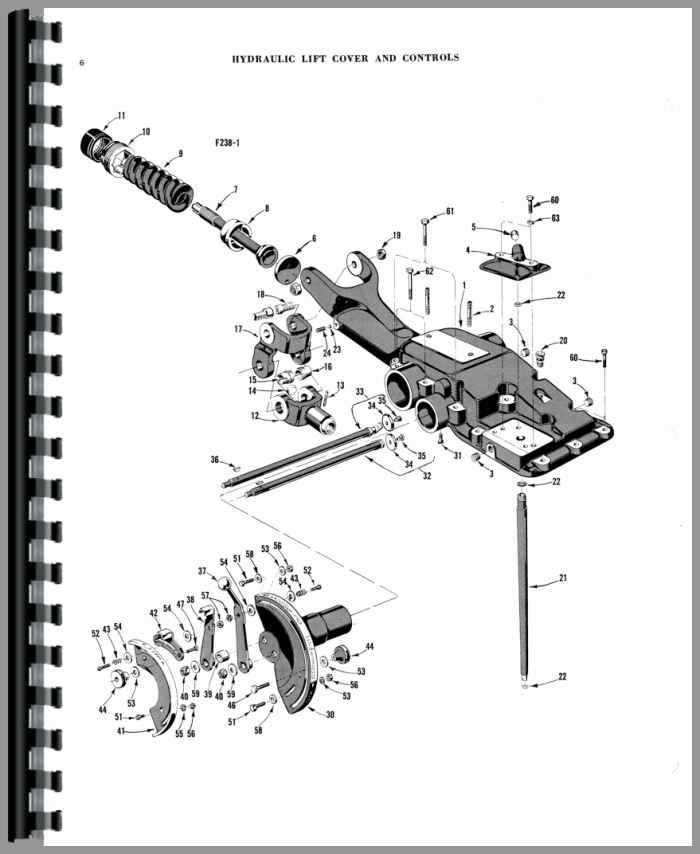

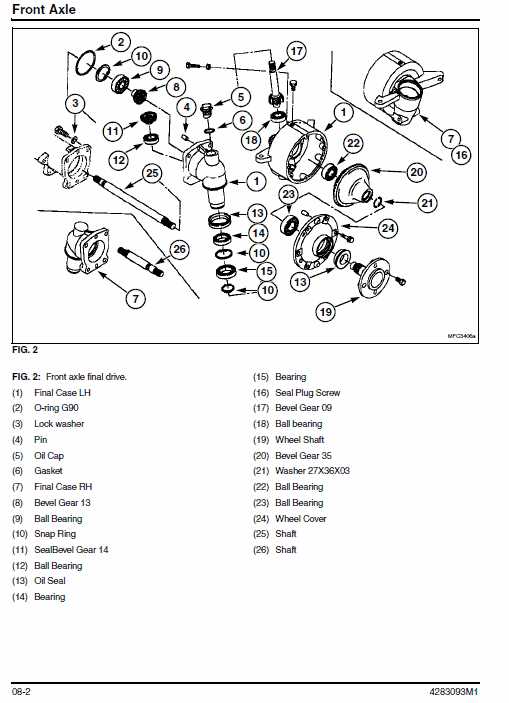

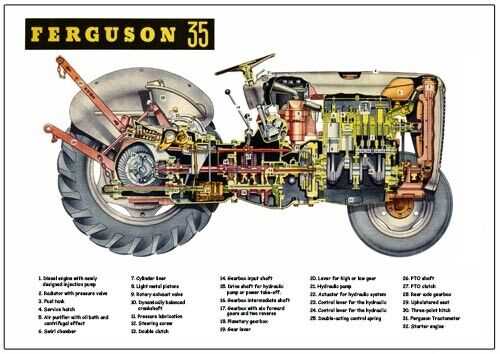

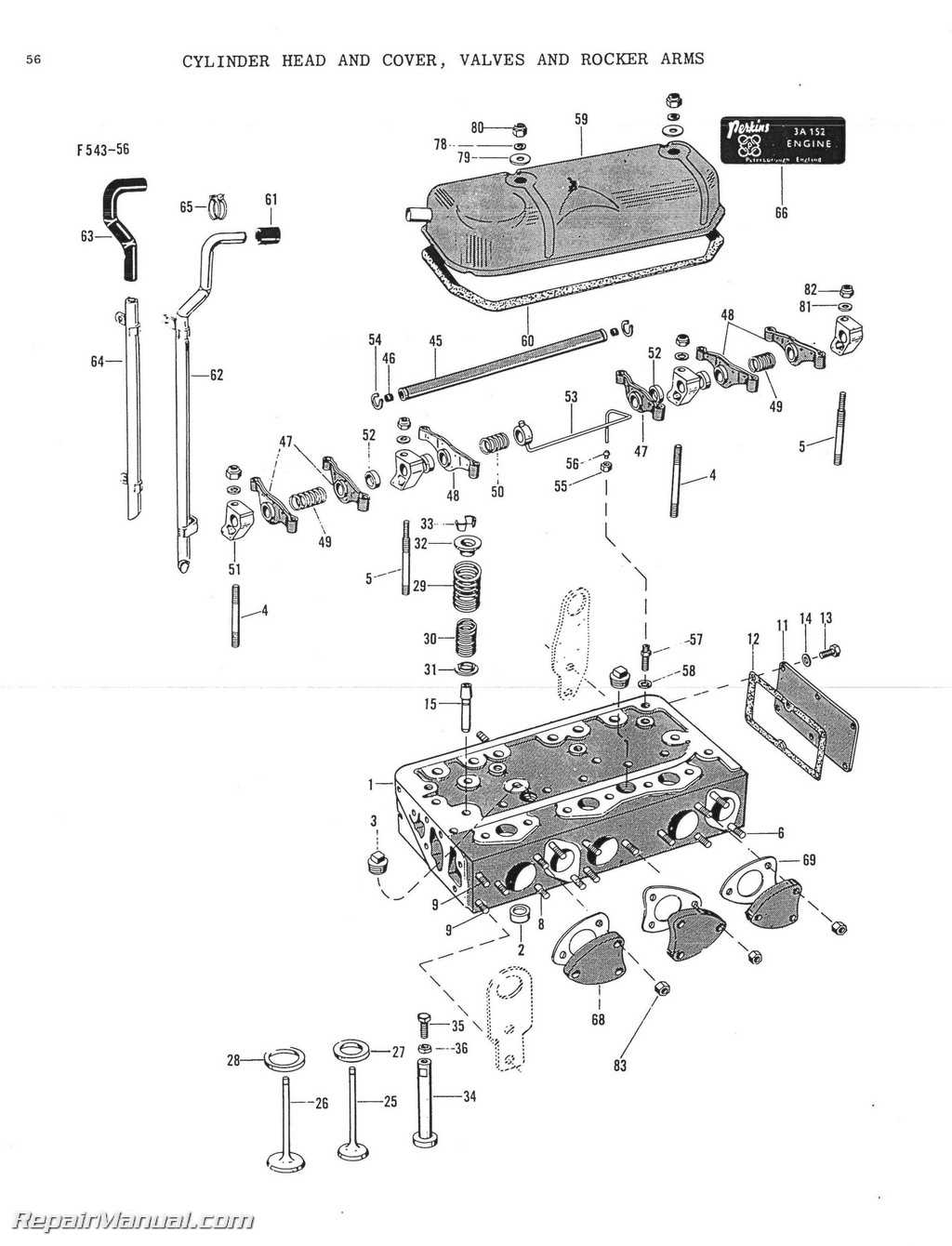

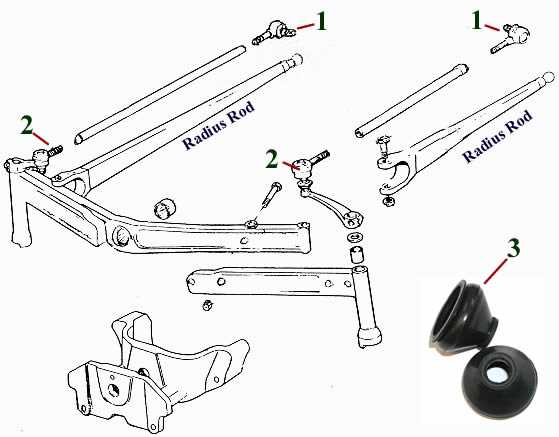

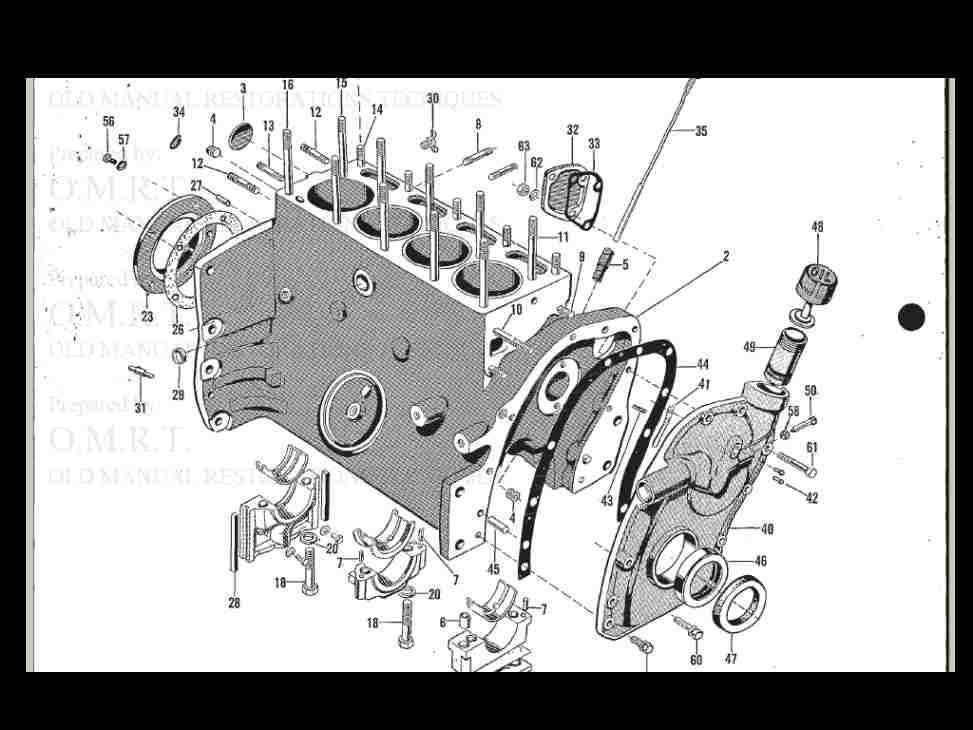

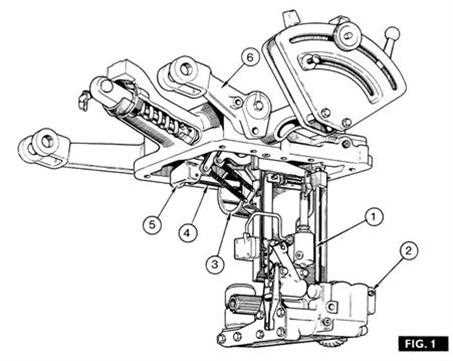

Understanding the Parts Diagram

This section provides a comprehensive overview of the visual representation that illustrates the various components of a machine, highlighting their relationships and functions. By examining this graphical guide, users can gain valuable insights into how different elements interact, aiding in both maintenance and repair tasks.

Interpreting the Visual Representation

Each component is often labeled with specific numbers or letters, allowing for easy identification. These labels correspond to a reference key that provides detailed descriptions of each item, making it easier for individuals to locate and understand the role of each element within the machinery.

Importance of Clarity and Accuracy

Clear visuals are essential for effective troubleshooting and repair. When users can accurately interpret the layout, they are better equipped to address issues, replace components, or perform upgrades. Therefore, familiarity with this graphical representation enhances overall efficiency and effectiveness in managing the equipment.

Key Components of Mf 35

The Mf 35 showcases a variety of essential elements that contribute to its functionality and efficiency. Understanding these key components is crucial for anyone looking to enhance their knowledge of this remarkable machine. Each element plays a specific role, ensuring optimal performance in various agricultural tasks.

One of the most significant features is the engine, which serves as the heart of the machine, providing the necessary power to perform demanding tasks. The transmission system is another vital component, allowing smooth gear shifts and effective control over speed and torque.

The hydraulic system is designed to facilitate lifting and maneuvering implements, enhancing the machine’s versatility. Additionally, the braking system ensures safety and stability during operation, while the chassis supports all components, providing a robust framework.

Each of these elements works in harmony, ensuring that the Mf 35 remains a reliable tool for agricultural operations, reflecting the craftsmanship and engineering that have gone into its design.

Assembly Process Explained

The assembly procedure for the Mf 35 involves a series of coordinated steps to ensure each component is correctly positioned and securely fitted. Understanding this process is crucial for achieving optimal functionality and longevity of the machine.

To begin the assembly, follow these key stages:

- Preparation of Components

- Gather all necessary items needed for the assembly.

- Inspect each element for any defects or damages.

- Initial Fitting

- Position the main structure on a stable surface.

- Carefully attach the foundational elements.

- Securing Connections

- Use appropriate fasteners to connect parts.

- Ensure all connections are tightened to specified torque levels.

- Final Adjustments

- Check for proper alignment of all components.

- Make necessary adjustments to ensure smooth operation.

By meticulously following each step in the assembly process, users can ensure their machine operates efficiently and reliably.

Maintenance Tips for Longevity

Ensuring the extended life and optimal performance of your machinery requires a proactive approach to upkeep. Regular attention and care can significantly reduce the risk of breakdowns and enhance overall efficiency. Implementing a few simple practices can go a long way in preserving functionality and reliability over time.

To maintain your equipment effectively, consider the following guidelines:

| Tip | Description |

|---|---|

| Regular Inspection | Perform frequent checks to identify any signs of wear or potential issues early. |

| Cleaning | Keep surfaces clean from dirt and debris to prevent corrosion and blockages. |

| Lubrication | Apply suitable lubricants to moving components to minimize friction and wear. |

| Follow Manufacturer Guidelines | Adhere to recommended schedules and procedures for maintenance provided by the manufacturer. |

| Store Properly | Ensure that equipment is stored in a dry, safe environment to prevent damage. |

By integrating these practices into your routine, you can significantly enhance the lifespan and performance of your machinery, ensuring that it operates smoothly for years to come.

Troubleshooting Common Issues

When working with machinery, encountering problems is not uncommon. Understanding how to identify and resolve these challenges can significantly enhance performance and prolong the lifespan of the equipment. This section provides insights into typical difficulties users may face, along with practical solutions to address them.

Identifying Common Problems

- Inconsistent operation

- Unusual noises during use

- Difficulty starting the engine

- Unexpected vibrations

Each of these issues can arise from various underlying causes. Careful observation and systematic investigation are key to diagnosing the problem effectively.

Steps to Resolve Issues

- Check fluid levels and ensure they are within the recommended range.

- Inspect connections and ensure they are secure and free from corrosion.

- Look for visible signs of wear or damage on components.

- Test the functionality of electrical systems to ensure proper operation.

- Consult the user manual for specific troubleshooting guidelines.

By following these steps, users can often identify the source of the issue and implement the necessary fixes. Regular maintenance and timely attention to problems can help avoid more significant complications in the future.

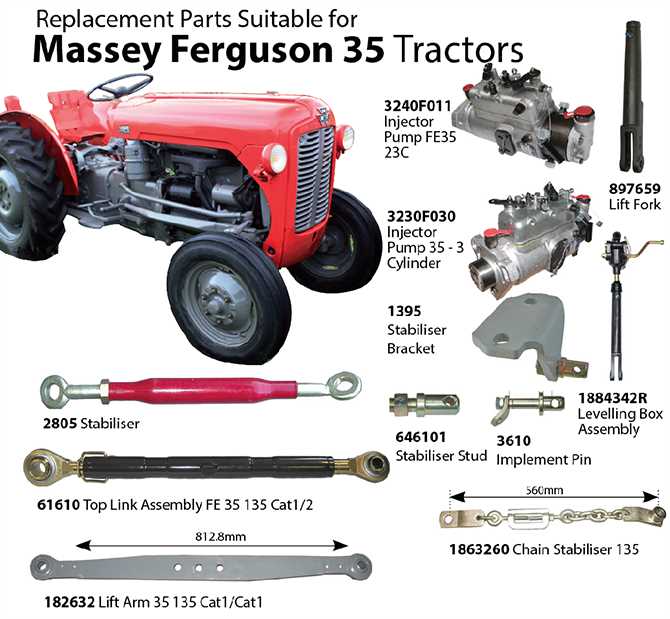

Replacement Parts Availability

Access to components for the MF 35 is crucial for maintaining optimal performance and ensuring the longevity of the machinery. Availability can vary based on several factors, including demand, location, and the age of the equipment. Understanding where to source these elements can significantly ease the repair process.

Sources for Components

- Authorized dealerships: These offer original equipment and can provide expert advice on compatibility.

- Online retailers: Many websites specialize in agricultural machinery and often have a wide range of options.

- Local suppliers: Visiting nearby stores can yield quick results, especially for commonly needed items.

- Second-hand markets: Auctions and online classifieds may have used items in good condition at lower prices.

Considerations When Sourcing

- Compatibility: Ensure that the replacement item matches the specifications of your equipment.

- Quality: Opt for reputable brands or suppliers to avoid issues with substandard replacements.

- Warranty: Check if the component comes with a guarantee to protect your investment.

- Pricing: Compare costs among different sources to find the best deal.

Improving Performance with Upgrades

Enhancing the efficiency and functionality of machinery can be achieved through various improvements. By implementing strategic modifications, operators can significantly boost the performance and longevity of their equipment. Upgrades not only optimize existing features but also introduce new capabilities, allowing for smoother operations and increased productivity.

Benefits of Upgrading Components

Investing in advanced components can lead to remarkable enhancements in overall performance. Upgraded elements often come with improved technology, which can result in better efficiency, lower fuel consumption, and reduced wear and tear. These benefits ultimately contribute to a more reliable and robust machine, capable of handling demanding tasks with ease.

Choosing the Right Enhancements

When selecting modifications, it’s essential to consider compatibility and functionality. Conducting thorough research can help identify the most suitable upgrades for specific needs. Whether focusing on enhancing power output or improving operational stability, making informed choices can lead to substantial advancements in performance, ensuring that the equipment remains competitive in any environment.

Resources for Further Learning

Expanding your understanding of machinery and its components can greatly enhance your operational skills and maintenance knowledge. Whether you are a novice or an experienced operator, various resources are available to deepen your expertise in this area.

Books and Manuals: Numerous publications provide detailed insights into machinery functioning, maintenance techniques, and troubleshooting methods. Seek out manuals specifically designed for the model you are working with, as they often include valuable tips and guidance.

Online Courses: Many educational platforms offer courses focusing on machinery operation and maintenance. These courses can provide interactive learning experiences and may include video tutorials, quizzes, and expert-led sessions.

Forums and Communities: Engaging with fellow enthusiasts and professionals through online forums can be an excellent way to share knowledge and seek advice. Many communities are dedicated to specific machinery, allowing you to connect with others who share your interests.

YouTube Channels: There are numerous channels dedicated to machinery education, featuring instructional videos, maintenance demonstrations, and user experiences. These visual resources can enhance your understanding through practical examples.

Manufacturer Websites: Visit the official websites of manufacturers for technical support, FAQs, and downloadable resources. These platforms often provide the most accurate and up-to-date information about their products.