The intricate world of marine propulsion systems offers a fascinating look into how power is harnessed for aquatic adventures. For enthusiasts and professionals alike, grasping the layout and functionality of each component is crucial for effective maintenance and repair. Whether navigating serene lakes or tackling challenging waters, having a solid understanding of these mechanisms can enhance both performance and safety.

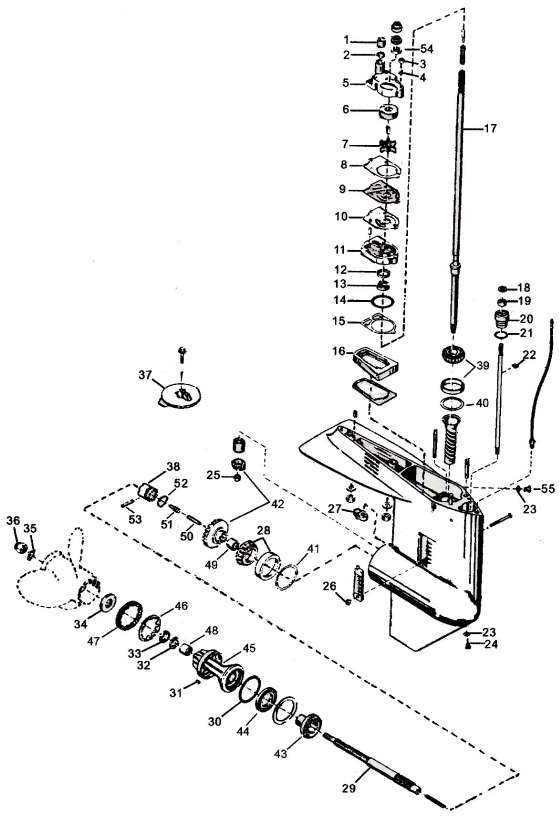

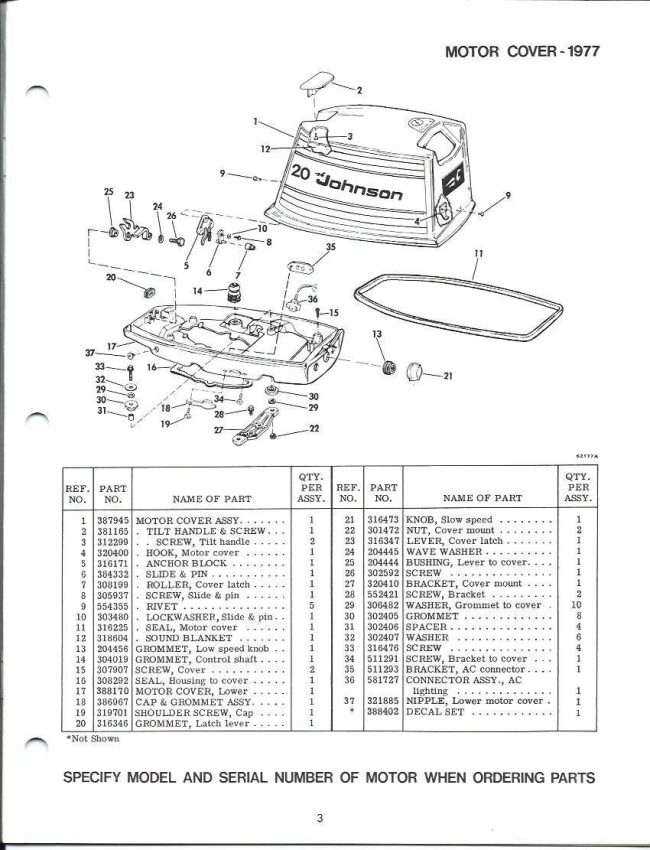

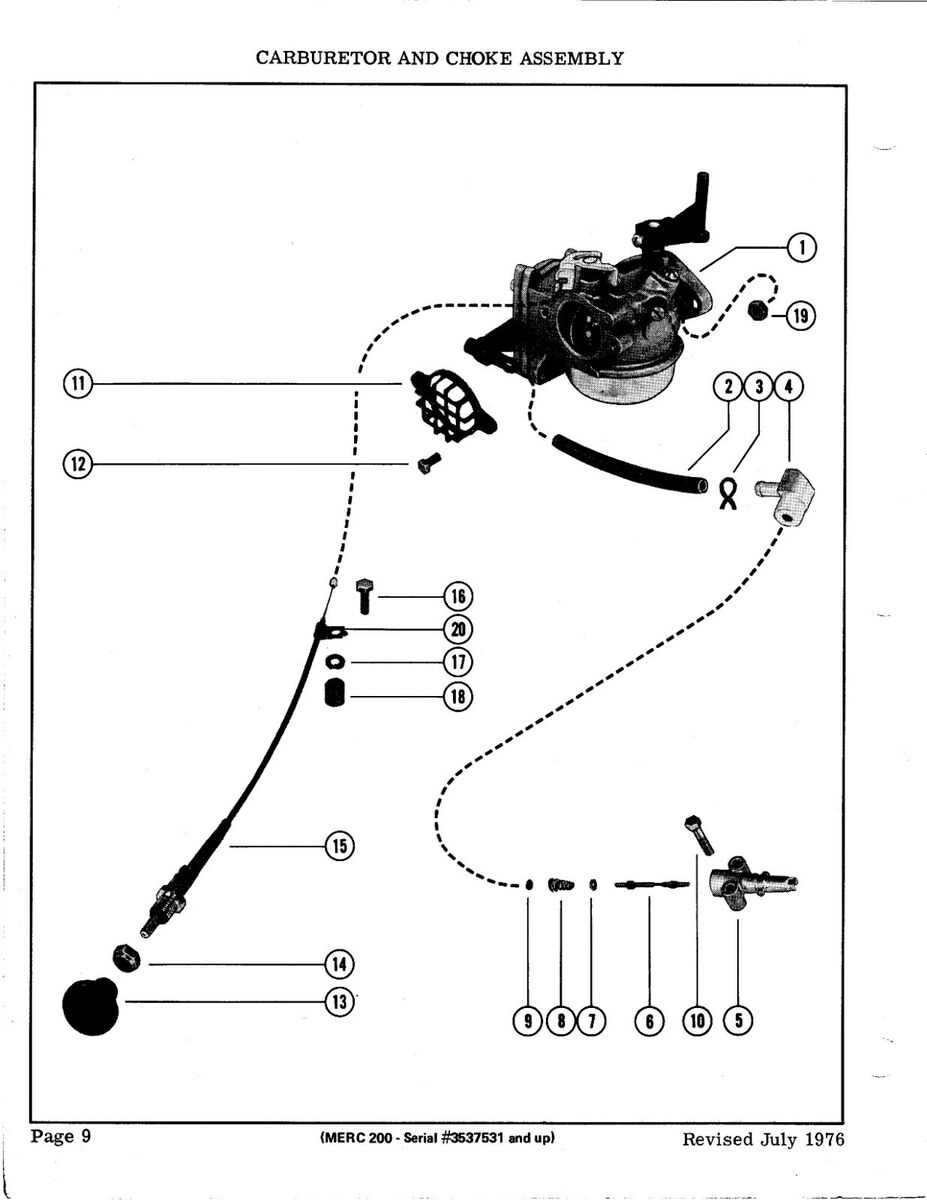

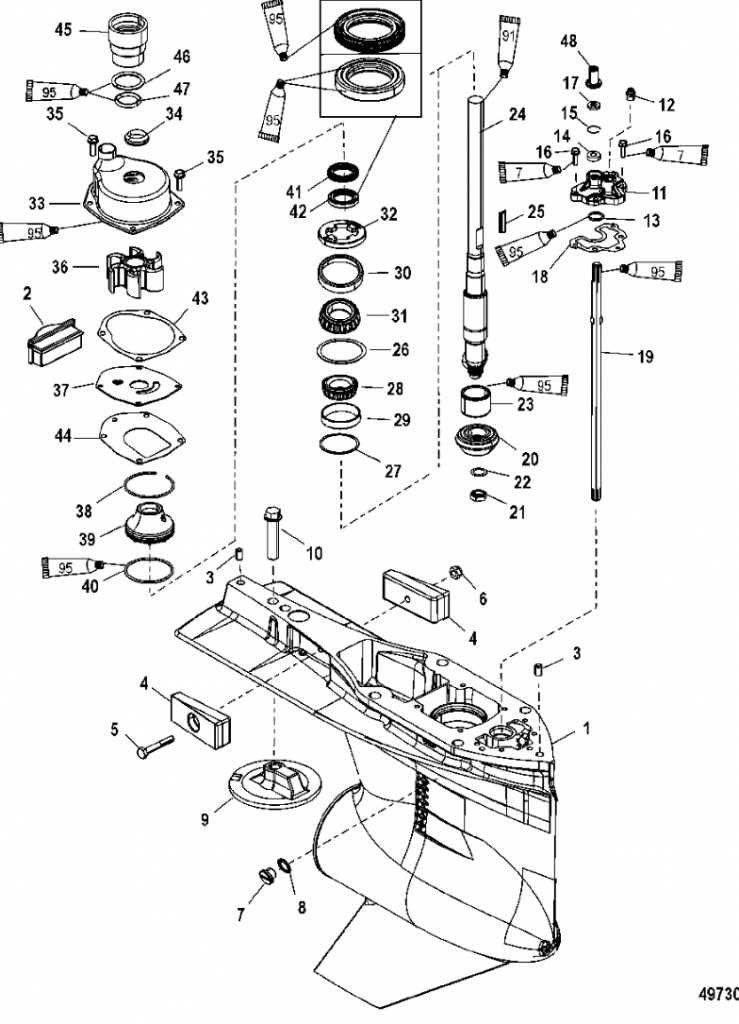

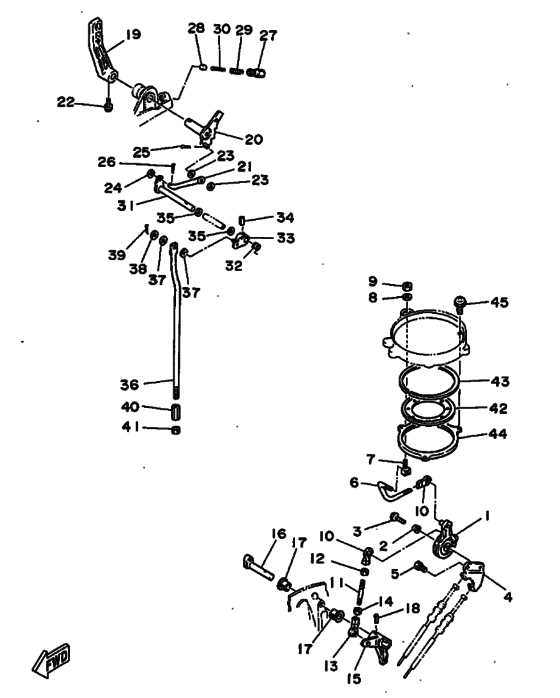

Visual representations serve as invaluable resources, providing clarity on how various elements interact within the engine. Such illustrations not only aid in identifying specific pieces but also facilitate a deeper comprehension of their roles in the overall system. This knowledge is essential for anyone looking to optimize their vessel’s efficiency and longevity.

As we delve into the specifics of these marine engines, we will explore the critical components that contribute to their reliable operation. By familiarizing ourselves with the arrangement and function of each part, we can better prepare for any troubleshooting or upgrades needed to ensure a smooth and enjoyable journey on the water.

Understanding Mercury 20 HP Outboard

This section delves into the essential aspects of a popular small-engine watercraft propulsion system. Designed for versatility and efficiency, it plays a crucial role in recreational and professional maritime activities. Understanding its components and functionality can enhance performance and maintenance, ensuring a smooth experience on the water.

Performance and Efficiency

The design focuses on delivering reliable power while maintaining fuel efficiency. Users often appreciate the balance between output and consumption, which makes it suitable for various aquatic environments. Recognizing the key elements that contribute to this efficiency can aid in optimizing operation and prolonging lifespan.

Components and Maintenance

Familiarity with the system’s individual elements is vital for effective upkeep. Regular inspections and timely replacements of critical components prevent malfunctions and enhance reliability. Understanding how each part interacts within the system is essential for troubleshooting and ensuring optimal function during use.

In summary, gaining insights into this engine’s design and operation not only empowers users but also fosters a deeper appreciation for the technology that enables seamless navigation across waterways.

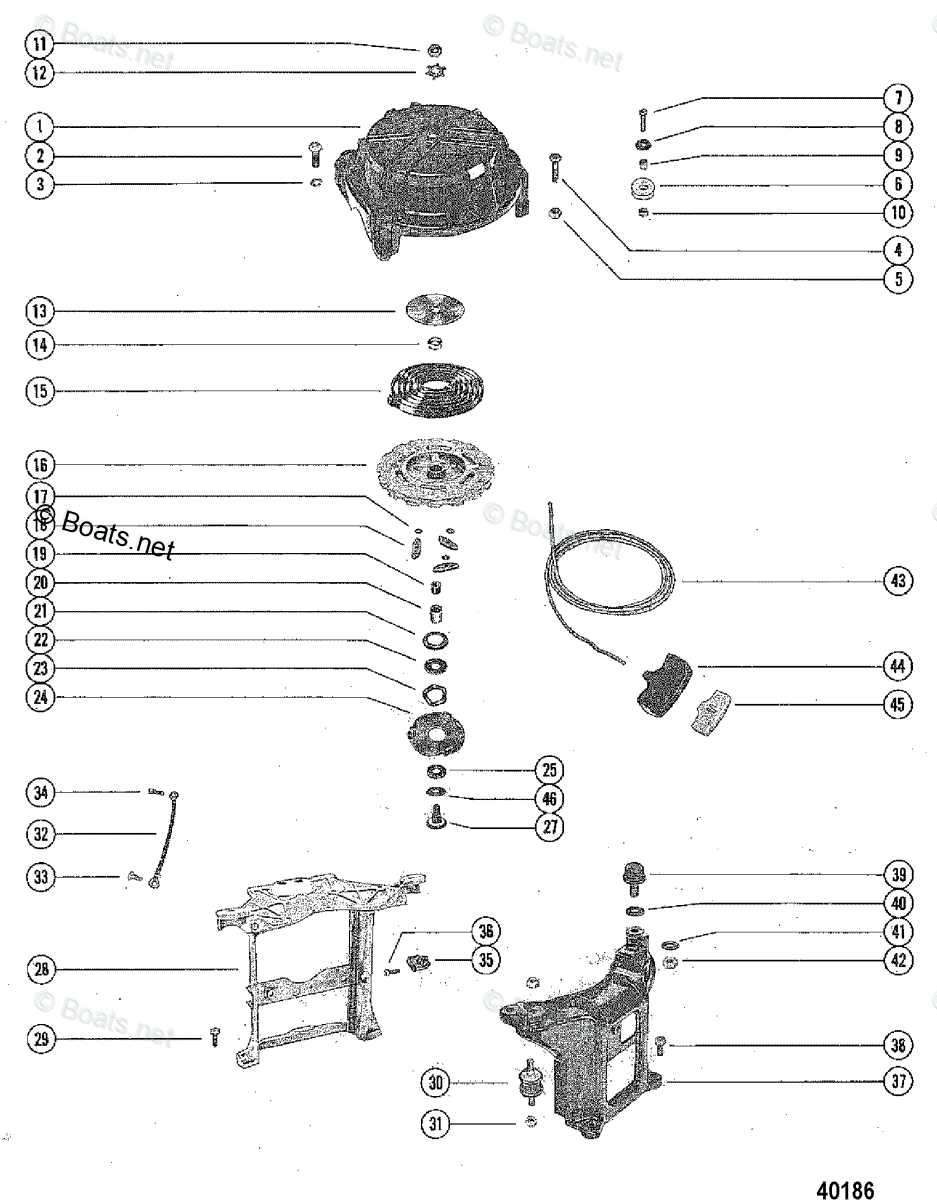

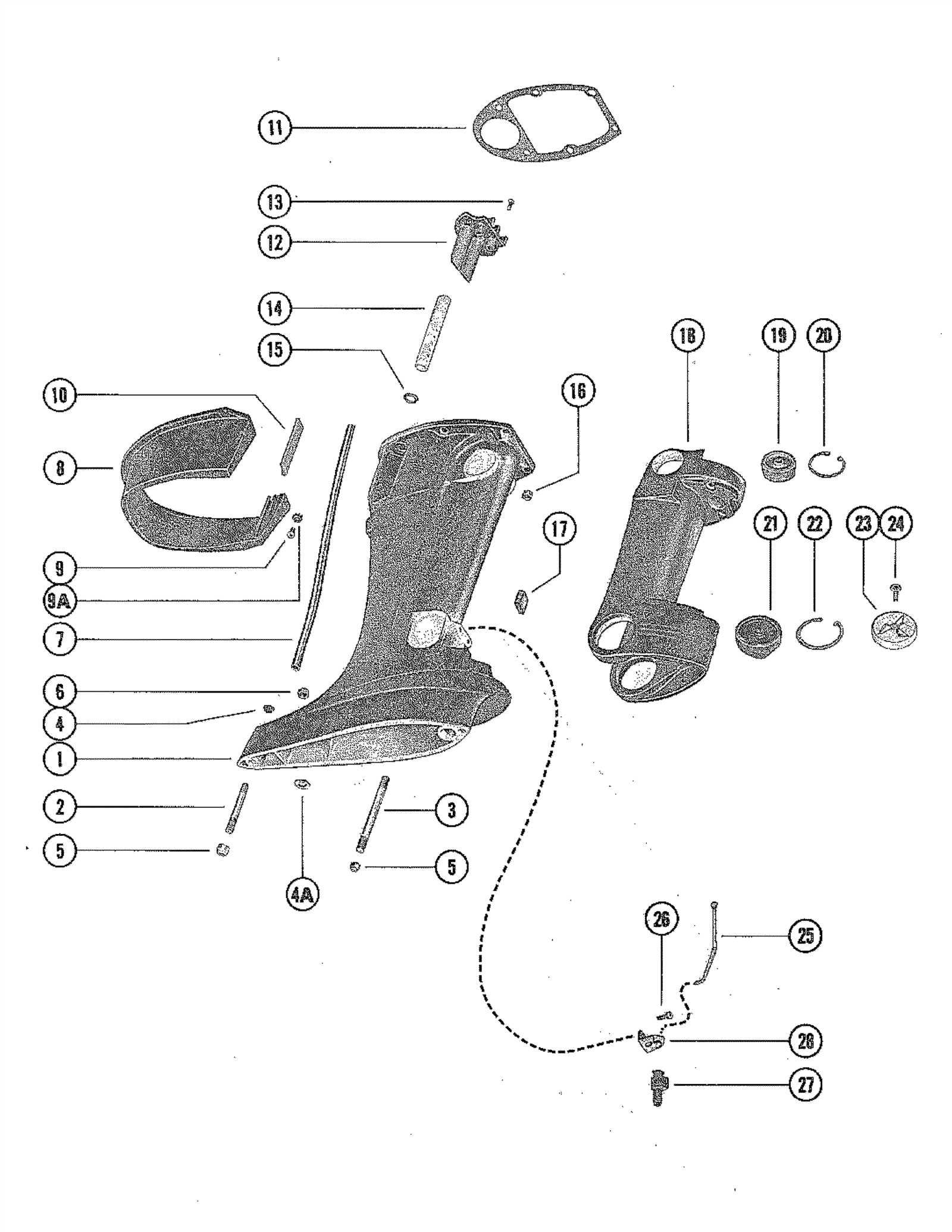

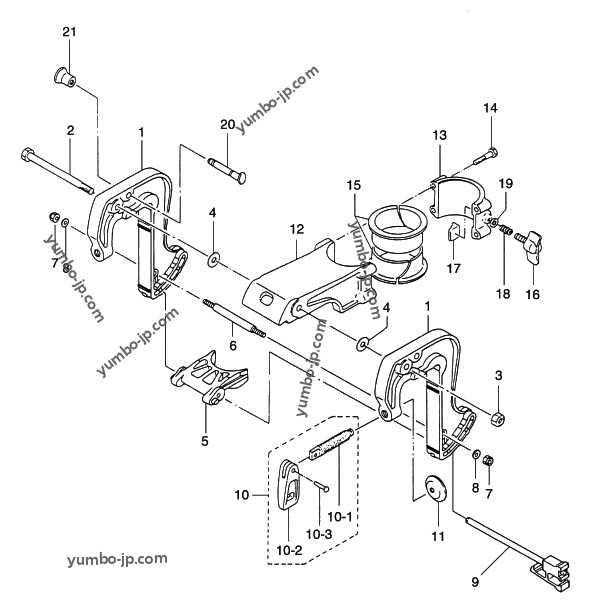

Importance of Parts Diagrams

Visual representations of components are crucial for understanding the structure and functionality of machinery. They serve as a guide, enabling users to identify individual elements and their interconnections, which is essential for maintenance and repair tasks.

Enhanced Understanding

Having a visual reference allows users to:

- Quickly locate specific elements within complex systems.

- Gain insights into the assembly and disassembly processes.

- Improve troubleshooting efficiency by pinpointing potential issues.

Facilitation of Communication

These visuals also play a significant role in collaboration and information sharing. They help to:

- Standardize terminology among technicians and enthusiasts.

- Provide clear instructions for less experienced individuals.

- Enhance the overall learning experience by visually depicting functions.

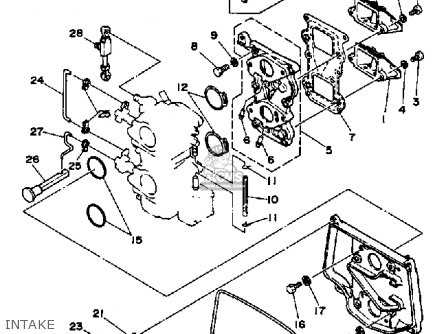

Common Components of Mercury Outboards

Understanding the essential elements of marine engines is crucial for effective maintenance and operation. These vital components work together to ensure optimal performance and reliability on the water. Familiarity with these elements can aid in troubleshooting and enhance overall functionality.

Powerhead serves as the engine’s core, housing critical systems that generate thrust. It includes the cylinder assembly, where combustion occurs, and the crankshaft, which converts linear motion into rotational force.

Gearcase is another key component, located at the lower unit. It contains the gears that transmit power to the propeller, enabling smooth navigation through various water conditions.

Fuel System plays a significant role in engine efficiency. This system includes the fuel pump and carburetor or fuel injection system, responsible for delivering the appropriate air-fuel mixture for combustion.

Ignition System ignites the fuel-air mixture at the correct moment. This system typically includes spark plugs, coils, and various sensors that ensure precise timing for optimal power output.

Cooling System prevents overheating by circulating water through the engine. This mechanism is vital for maintaining safe operating temperatures, especially during prolonged use.

Lastly, Electrical Components power essential functions, including the starter motor and battery. These elements ensure that the engine starts reliably and operates smoothly throughout its use.

How to Read a Parts Diagram

Understanding an assembly representation is essential for anyone looking to maintain or repair equipment. These visual guides provide a comprehensive overview of components, helping users identify each element and its function. Familiarity with this type of illustration can streamline the repair process and ensure that all necessary pieces are accounted for.

To effectively interpret such a representation, consider the following steps:

- Familiarize Yourself with the Layout: Start by observing the overall structure. Typically, components are arranged logically, often in the order of assembly.

- Identify Each Component: Each section will usually include labels or numbers corresponding to specific elements. Take note of these identifiers for easier reference.

- Consult the Legend: Most illustrations feature a legend or key that explains symbols or color codes used. Refer to this to clarify any confusion.

- Understand Relationships: Pay attention to how components connect. Arrows or lines may indicate the assembly sequence or the interaction between parts.

By following these steps, you can enhance your comprehension of assembly representations and improve your repair and maintenance skills.

Identifying Key Replacement Parts

Understanding the essential components of your marine engine is crucial for maintaining its performance and longevity. Recognizing which elements may require replacement can significantly enhance your experience on the water. This section will guide you in identifying the most important items that often need to be replaced, ensuring your engine remains in optimal condition.

Common Components to Monitor

Several elements are prone to wear and tear over time. Fuel filters are vital for ensuring that contaminants do not enter the system, while sacrificial anodes protect the engine from corrosion. Regularly checking and replacing these items can prevent larger issues down the line.

When to Consider Replacement

Pay attention to any changes in performance or unusual noises, as these may indicate that certain components are failing. Propellers, for example, can become damaged from impacts with debris, leading to reduced efficiency. Recognizing the signs early can save time and money, helping you maintain smooth operation.

Maintenance Tips for Mercury Motors

Proper upkeep is essential for ensuring the longevity and performance of your marine engine. Regular maintenance not only enhances efficiency but also helps to avoid unexpected breakdowns during your outings on the water. Here are some key practices to keep your engine running smoothly.

- Regular Oil Changes: Change the lubricant according to the manufacturer’s recommendations. Fresh oil helps to reduce wear and tear on internal components.

- Inspect Fuel System: Check for any leaks or clogs in the fuel lines and ensure that the fuel filter is clean.

- Cooling System Maintenance: Ensure the cooling system is functioning correctly by checking the water intake and cleaning any debris that may block it.

In addition to these basic checks, consider the following:

- Battery Care: Regularly inspect battery terminals for corrosion and ensure the battery is charged and securely mounted.

- Propeller Inspection: Examine the propeller for any signs of damage or debris that could hinder performance.

- Winterization: Properly prepare your engine for the off-season by draining fuel, adding stabilizer, and flushing the cooling system.

Following these guidelines will help you maintain your engine in optimal condition, ensuring many enjoyable days on the water.

Finding Genuine Mercury Parts

Locating authentic components for your marine engine is crucial for maintaining optimal performance and longevity. Ensuring you have the right pieces not only enhances functionality but also guarantees safety on the water. Here are some effective strategies to secure genuine replacements.

Research Authorized Dealers

- Visit the official website for a list of certified retailers.

- Contact local marine supply stores for recommendations.

- Check for customer reviews to ensure reliability.

Online Marketplaces

- Utilize reputable e-commerce platforms that specialize in marine equipment.

- Verify seller credentials and return policies before purchasing.

- Be cautious of prices that seem too good to be true; they often indicate counterfeit goods.

Common Issues with 20 HP Models

When dealing with smaller power units, users often encounter a range of challenges that can affect performance and reliability. Understanding these common issues can help in maintenance and troubleshooting, ensuring smoother operation and extended lifespan.

Frequent Problems

- Starting Difficulties: Many operators report challenges when trying to start their engines, which can stem from fuel delivery problems or ignition system malfunctions.

- Overheating: Inadequate cooling can lead to overheating, often caused by clogged water intakes or malfunctioning thermostats.

- Fuel Issues: Contaminated or stale fuel can result in poor performance and engine stalling, necessitating regular fuel checks.

- Propeller Damage: Striking submerged objects can cause damage to the propeller, affecting speed and maneuverability.

Maintenance Tips

- Regularly inspect and clean the fuel system to prevent blockages.

- Check the cooling system frequently, ensuring water intake is clear.

- Monitor the condition of the propeller and replace if necessary.

- Conduct routine checks on the ignition system for optimal performance.

By being aware of these common issues and implementing preventive measures, users can enhance the reliability and efficiency of their equipment.

Resources for Outboard Owners

Maintaining marine engines requires access to reliable information and tools. Various resources can assist enthusiasts in troubleshooting, repairs, and upgrades, ensuring optimal performance.

- Online Forums: Engage with fellow enthusiasts to share experiences and solutions.

- Manufacturer Websites: Official sites often provide manuals, specifications, and maintenance tips.

- Local Dealerships: Seek expert advice and genuine components from trusted dealers.

- YouTube Channels: Visual tutorials can simplify complex tasks and enhance understanding.

- Community Workshops: Participate in hands-on sessions to learn skills and techniques.

By exploring these avenues, owners can ensure their engines run smoothly and efficiently, prolonging their enjoyment on the water.