In the realm of gardening and landscaping, the effectiveness of your tools greatly influences the outcome of your efforts. An essential aspect of maintaining your outdoor space is ensuring that your equipment operates smoothly and efficiently. Familiarity with the components and their functionalities can significantly enhance your experience and results.

Proper maintenance is crucial for achieving optimal performance from your equipment. By understanding how each element contributes to the overall operation, you can diagnose issues and make informed decisions about repairs and replacements. This knowledge not only saves time but also minimizes frustration during critical tasks.

Additionally, having a clear visual representation of the various components can aid in identifying what you need for maintenance or enhancement. Whether you’re a seasoned professional or a gardening enthusiast, mastering the intricacies of your tools empowers you to achieve a flourishing and vibrant landscape.

Understanding Earthway Spreaders

The equipment designed for the even distribution of materials is essential for achieving optimal results in lawn care and gardening. These devices come in various forms, tailored to specific tasks, ensuring that seeds, fertilizers, and other substances are applied uniformly. By grasping the mechanics and components involved, users can enhance their efficiency and effectiveness in outdoor maintenance.

Familiarity with the key components of these devices allows for better maintenance and troubleshooting. Understanding how each part functions contributes to the longevity of the equipment and improves performance. Regular inspection and proper adjustments are vital to achieving the best results during application.

Moreover, choosing the right type for your specific needs is crucial. Different models cater to various terrains and materials, influencing the overall outcome of your gardening efforts. Investing time in learning about these options will ultimately lead to a more fruitful gardening experience.

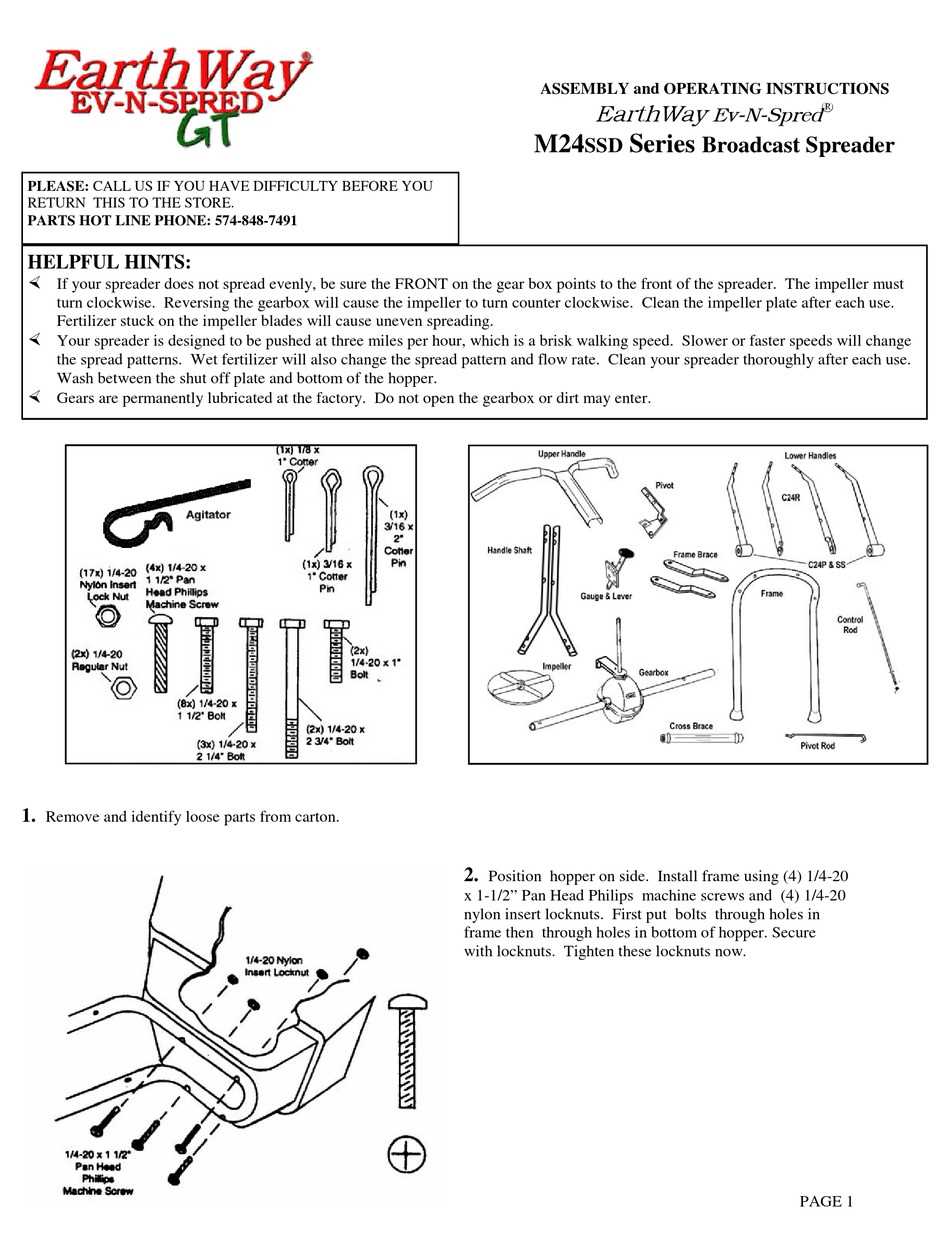

Key Components of Earthway Spreaders

Understanding the essential elements of a distribution tool is crucial for efficient usage and maintenance. Each component plays a vital role in ensuring even application and overall effectiveness. This section delves into the primary features that contribute to the functionality and reliability of these tools.

Frame: The robust structure serves as the backbone, providing stability and support during operation. A well-designed frame can withstand various terrains, ensuring durability over time.

Hopper: This container holds the material being distributed. The design and capacity of the hopper are essential for optimizing load management, allowing for longer periods of use without frequent refilling.

Agitator: This mechanism ensures a consistent flow of the material. An efficient agitator prevents clumping, allowing for smooth and uniform distribution across the desired area.

Wheels: The mobility of the tool heavily relies on its wheels. Their size and tread design are critical for maneuverability and traction, enabling easy navigation over different surfaces.

Controls: Intuitive control systems allow users to adjust the flow rate and distribution pattern effortlessly. Easy-to-use controls enhance the overall user experience, making the application process more efficient.

Calibration Settings: Proper calibration ensures accurate delivery of materials. Adjustable settings help in achieving the desired coverage and prevent wastage, thus maximizing effectiveness.

How to Read Parts Diagrams

Understanding how to interpret visual representations of components is essential for effective maintenance and repair. These illustrations provide a clear view of each element and its connections, enabling users to identify and source necessary items with ease.

Key Elements to Note

When examining these visuals, focus on the following aspects:

| Element | Description |

|---|---|

| Labels | Indicate the name or number of each component. |

| Connections | Show how parts interact or attach to one another. |

| Scale | Gives an idea of the size relative to other elements. |

Steps for Effective Interpretation

To accurately decode these visuals, follow these steps: start by familiarizing yourself with the overall layout, identify and note down any labeled items, and cross-reference these with your service manual for specific information.

Common Issues with Spreaders

When it comes to distributing materials evenly across surfaces, several challenges can arise that hinder performance and efficiency. Understanding these issues is crucial for maintaining optimal functionality and ensuring a smooth operation.

Clogs and Blockages

One of the most frequent problems is the occurrence of clogs, which can disrupt the flow of granules or liquids. This can be caused by damp materials, debris accumulation, or incorrect adjustments, leading to uneven application and wasted resources.

Wear and Tear

Over time, components can degrade due to exposure to the elements and regular use. Signs of wear may include difficulty in operation, uneven distribution patterns, and increased maintenance needs. Regular inspection and timely replacements can help mitigate these issues.

Maintenance Tips for Longevity

To ensure the long-lasting performance of your equipment, regular upkeep is essential. Proper maintenance not only enhances functionality but also prevents costly repairs and extends the lifespan of your tools. By adopting a few simple practices, you can keep your machinery in top condition year after year.

Regular Cleaning

After each use, thoroughly clean the device to remove debris and residue. This prevents corrosion and buildup that can hinder performance. Use a gentle brush or cloth to reach crevices, and avoid harsh chemicals that could damage surfaces.

Inspection and Lubrication

Periodically check all components for wear and tear. Inspect belts, wheels, and any moving parts for signs of damage. Lubricate necessary areas to ensure smooth operation and reduce friction, which can lead to premature wear.

Choosing the Right Replacement Parts

Finding the ideal components for your equipment is crucial for maintaining optimal performance and longevity. Selecting the right pieces not only ensures efficiency but also prevents potential issues down the line. Understanding the specifications and compatibility of each item will help you make informed decisions.

Assessing Compatibility

Before purchasing, evaluate the compatibility of the new components with your existing machinery. Check manufacturer recommendations and compare dimensions and functionalities. This step is essential to avoid frustration and ensure seamless integration.

Quality vs. Cost

While it may be tempting to opt for lower-priced options, investing in high-quality components can save you money in the long run. Durability and performance should be prioritized over initial savings, as cheaper alternatives often lead to more frequent replacements and repairs. Choosing wisely can significantly enhance your overall experience.

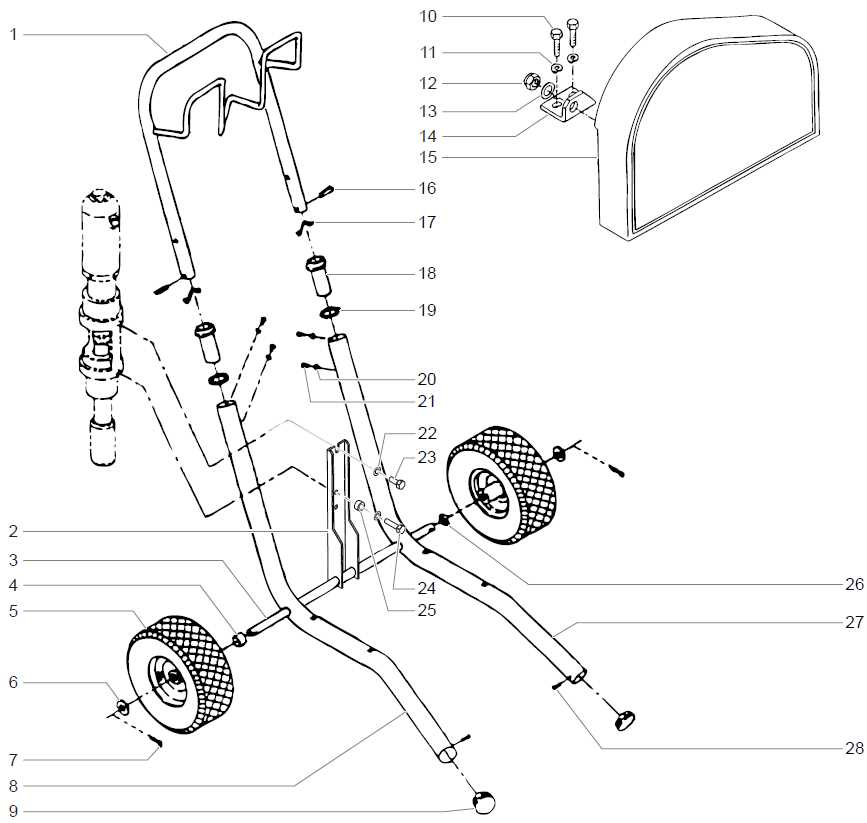

Installation Guide for New Components

In this section, we will explore the steps necessary for integrating new elements into your equipment. Proper installation ensures optimal performance and longevity, making it essential to follow guidelines meticulously. Each component has specific requirements, and understanding these will facilitate a smooth installation process.

Preparation Steps

Before beginning the installation, gather all necessary tools and materials. Make sure to review the accompanying instructions for each component. It’s advisable to clean the work area and the equipment itself to prevent contamination and ensure that all connections are secure. Checking for any existing wear or damage is also crucial to avoid complications during the installation.

Installation Process

Start by carefully removing any outdated or broken components. Follow the manufacturer’s instructions to attach the new elements, ensuring each is fitted correctly. Use appropriate fasteners and avoid overtightening, as this may cause damage. Once all parts are in place, conduct a thorough inspection to verify that everything is secure and aligned.

Finally, perform a test run to confirm that the installation was successful. Monitor the equipment closely during initial use, checking for any unusual sounds or behaviors. Adjust as needed to ensure peak functionality.

Upgrading Your Spreader for Efficiency

Enhancing your equipment for optimal performance can significantly boost productivity and ensure a more effective application of materials. By focusing on specific upgrades, you can streamline operations, reduce waste, and achieve better results in your gardening or landscaping tasks.

Key Areas for Improvement

- Calibration: Ensure that your device is properly calibrated to deliver precise amounts of material. Regular checks can prevent over-application and save resources.

- Maintenance: Keep all moving parts well-lubricated and free of debris to promote smooth operation and extend the lifespan of your equipment.

- Replacement of Worn Components: Identify and replace any damaged or worn components that may hinder efficiency. This includes tires, gears, and the distribution mechanism.

Investing in Technology

- Upgraded Control Systems: Consider investing in modern control systems that allow for variable rate applications, ensuring materials are distributed evenly based on specific needs.

- Smart Features: Incorporating smart technology can offer real-time monitoring and adjustments, leading to improved precision and efficiency.

By focusing on these upgrades, you can enhance the effectiveness of your equipment, ultimately leading to a more efficient workflow and better outcomes in your projects.

Where to Buy Quality Parts

Finding reliable components for your gardening tools is essential for maintaining their performance and longevity. A well-sourced item not only enhances functionality but also ensures safety during use. Here are some recommended avenues for acquiring high-quality replacements.

| Source | Description | Advantages |

|---|---|---|

| Online Retailers | Websites specializing in gardening equipment often have a wide selection. | Convenience, variety, and often competitive pricing. |

| Local Garden Centers | Brick-and-mortar stores that focus on gardening supplies. | Personalized assistance and the ability to inspect items before purchasing. |

| Manufacturer’s Website | Official sites provide original components directly from the source. | Assurance of quality and compatibility with your equipment. |

| Second-Hand Market | Platforms where users sell pre-owned items. | Potential for lower prices, but requires careful inspection for quality. |

By exploring these options, you can ensure that you acquire components that meet your needs and maintain the efficiency of your gardening equipment.