The efficient functioning of any circulation system relies on the intricate interplay of its various components. Each element plays a crucial role in maintaining optimal performance, ensuring smooth operation and longevity. Familiarity with these individual pieces is essential for effective maintenance and troubleshooting.

In this section, we will explore the essential elements that comprise these systems, shedding light on their specific functions and interconnections. By understanding how each part contributes to the overall efficiency, you can make informed decisions regarding upkeep and repairs.

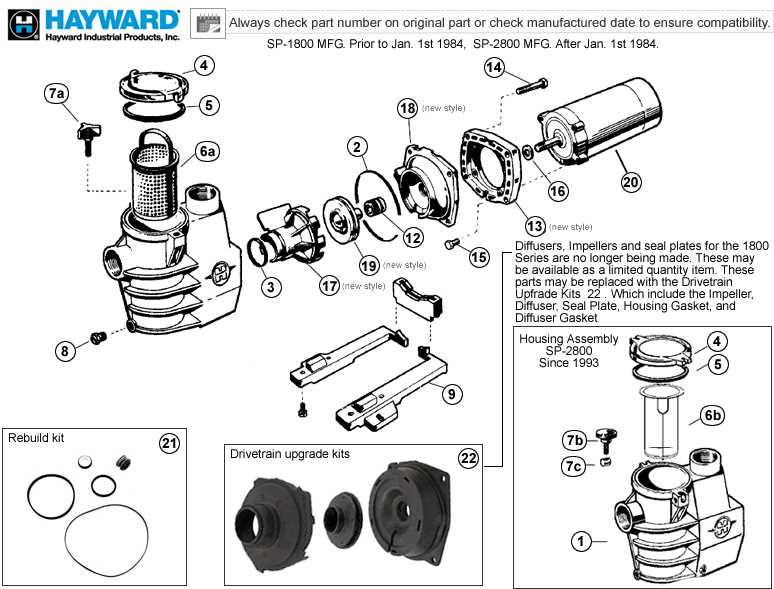

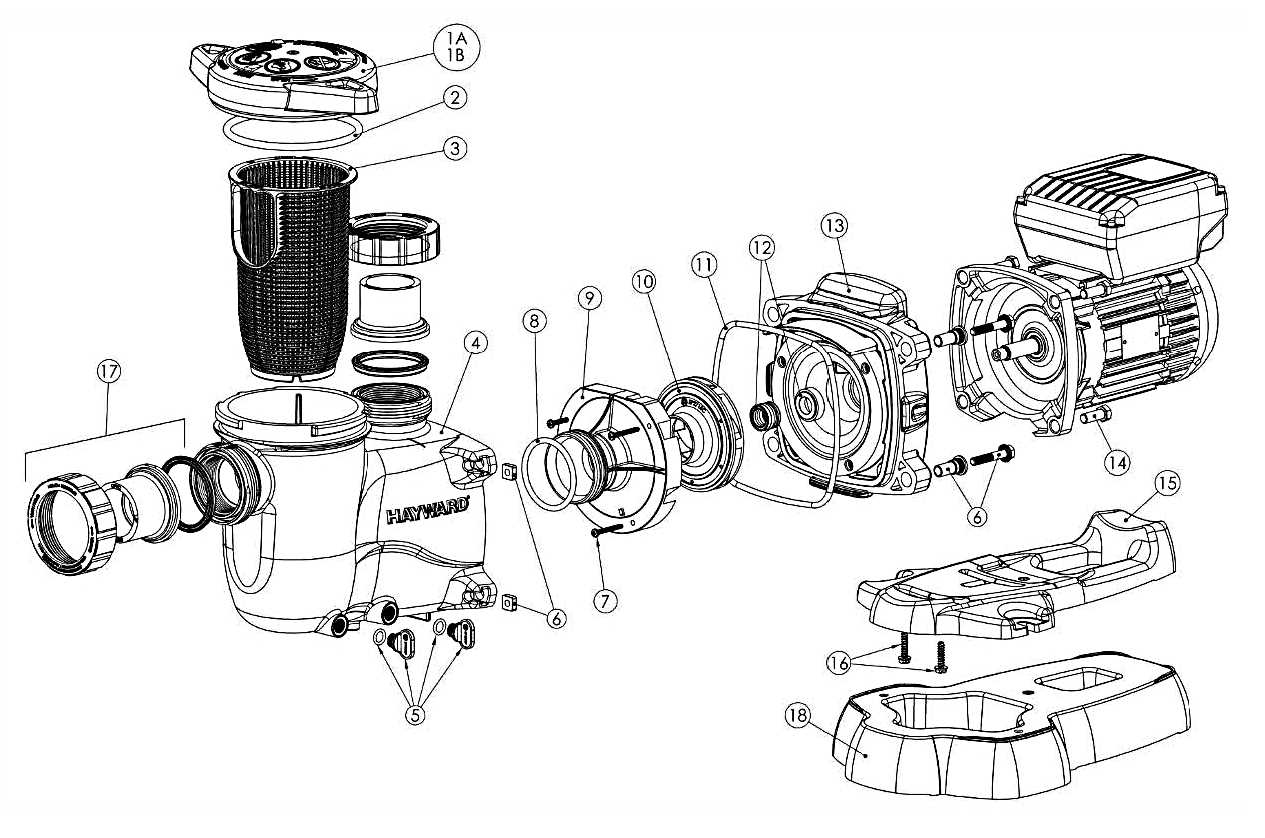

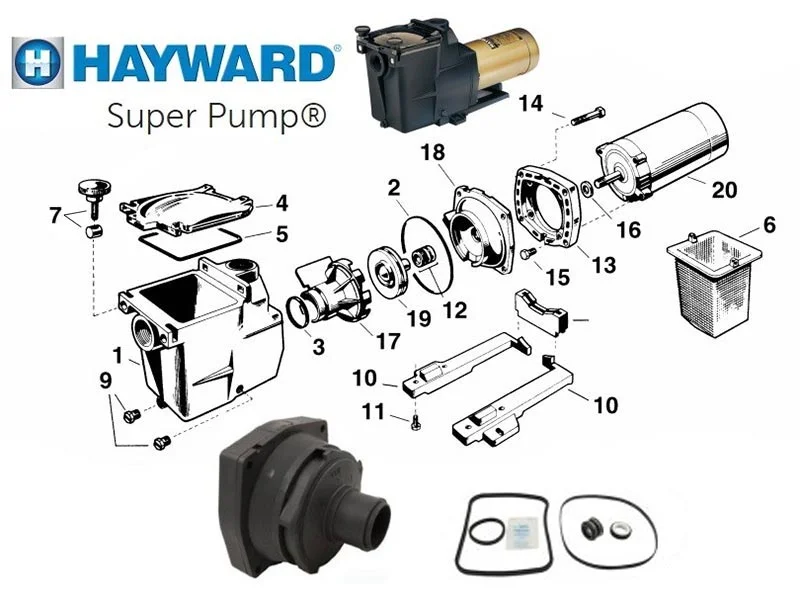

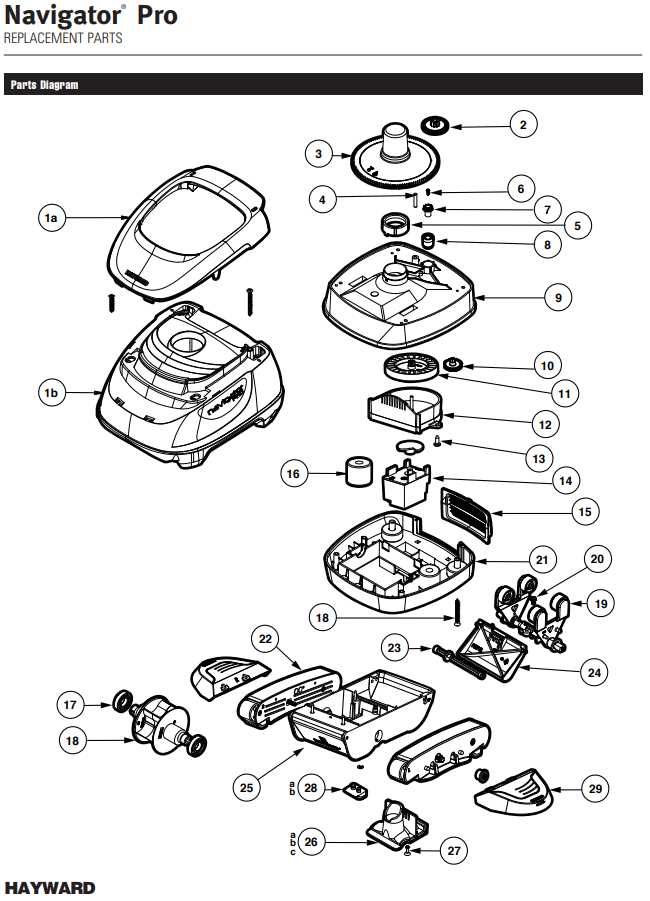

Additionally, a visual representation of these components can significantly enhance your comprehension, providing clarity on how they fit together within the broader framework. This insight not only aids in identifying potential issues but also empowers you to take proactive measures in ensuring the reliability of your system.

Understanding Hayward Pool Pump Components

Grasping the essential elements of a circulation system is crucial for maintaining optimal performance and longevity. Each component plays a significant role in ensuring the effective movement of water, contributing to a clean and healthy environment. Familiarity with these parts can aid in troubleshooting and enhance the overall experience.

- Housing: This outer shell protects the internal mechanisms while providing structural integrity.

- Impeller: This rotating element is vital for creating the flow of liquid, driving it through the system.

- Seal: Prevents leaks, ensuring that the system operates efficiently without loss of fluid.

- Capacitor: A component that provides the necessary electrical energy to start the motor, facilitating smooth operation.

- Base: The foundation that supports all other components, ensuring stability and reducing vibrations.

Understanding these key elements enables users to effectively manage their systems, ensuring they operate at peak efficiency. Proper maintenance and timely replacements can significantly extend the lifespan of these systems.

Function of Each Motor Part

This section explores the essential roles of various components within a mechanical assembly. Understanding how each element contributes to overall performance is vital for effective maintenance and troubleshooting.

Key Components

Each unit consists of elements such as the stator and rotor, which work in tandem to create rotational motion. The stator generates a magnetic field, while the rotor turns within it, converting electrical energy into mechanical energy.

Supportive Elements

Additionally, components like bearings and capacitors play crucial roles. Bearings reduce friction, allowing for smooth operation, while capacitors provide the necessary electrical boost for starting and running the assembly efficiently.

Common Issues with Pump Motors

Understanding the frequent challenges faced by these essential devices can greatly enhance their longevity and efficiency. Various factors can lead to malfunctions, impacting performance and leading to costly repairs.

Overheating

Excessive heat is a primary concern, often caused by overloading, inadequate ventilation, or lack of lubrication. Ensuring proper airflow and regular maintenance can mitigate this risk.

Noise and Vibration

Unusual sounds and vibrations may indicate misalignment, wear, or debris buildup. Regular inspections and timely repairs can prevent further damage and ensure smooth operation.

Importance of Regular Maintenance

Consistent upkeep is crucial for ensuring the longevity and efficiency of mechanical systems. Neglecting routine care can lead to decreased performance, increased energy consumption, and costly repairs. By prioritizing maintenance, users can enhance the reliability of their equipment and prevent unforeseen breakdowns.

Regular checks not only identify potential issues before they escalate but also optimize functionality. This proactive approach contributes to a safer environment and ensures that all components work harmoniously.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Inspect Components | Monthly | Identifies wear and tear |

| Clean Filters | Bi-Monthly | Improves efficiency |

| Lubricate Moving Parts | Quarterly | Reduces friction |

| Check Electrical Connections | Annually | Ensures safety |

| Replace Worn Parts | As Needed | Prevents failure |

Identifying Replacement Parts Needed

Understanding the components of your equipment is essential for effective maintenance and repair. When issues arise, recognizing which elements require replacement can significantly improve functionality and extend the lifespan of your unit. This section will guide you in identifying necessary components and ensuring optimal performance.

To accurately determine which elements need replacement, consider the following steps:

- Observe Symptoms: Begin by monitoring the performance of your system. Look for signs such as unusual noises, reduced efficiency, or leaks.

- Consult Documentation: Refer to the user manual or service guide for a breakdown of components and their functions. This will help you pinpoint the source of the problem.

- Visual Inspection: Conduct a thorough examination of the unit. Check for wear, damage, or loose connections that may indicate which elements need attention.

Once you’ve gathered this information, create a list of potential replacements:

- Electrical components, such as capacitors or switches

- Seals and gaskets that may be compromised

- Fan blades or impellers showing signs of damage

- Mounting brackets or housings that are cracked or broken

By systematically identifying and documenting the components that require replacement, you can effectively source the correct items, ensuring your system operates efficiently and reliably.

How to Read Motor Diagrams

Understanding technical illustrations can enhance your ability to troubleshoot and maintain various equipment. Familiarity with these representations allows for a deeper grasp of how components interact within a system.

To effectively interpret these illustrations, consider the following steps:

- Identify Key Symbols: Recognize the standard icons that represent different elements, such as electrical connections and mechanical components.

- Understand Connections: Pay attention to how parts are linked, noting the direction of flow or operation.

- Refer to Annotations: Look for labels and notes that provide additional context or specifications about each component.

- Follow a Legend: Use any provided legends to decode symbols and abbreviations that might not be immediately clear.

By mastering these techniques, you can delve into the complexities of the system and gain a comprehensive understanding of its functioning.

Tools Required for Repair Tasks

Effective maintenance and repair work necessitates a specific set of instruments that ensure efficiency and precision. Utilizing the right tools not only streamlines the process but also enhances the longevity of the equipment. Below are essential tools that every technician should have on hand.

Essential Instruments

| Tool | Purpose |

|---|---|

| Screwdriver Set | For loosening and tightening screws in various assemblies. |

| Wrench | Used for gripping and turning nuts and bolts. |

| Pliers | Ideal for gripping and manipulating small parts. |

| Multimeter | For measuring voltage, current, and resistance. |

| Socket Set | Essential for quickly removing and installing fasteners. |

Additional Tools

In addition to the basic instruments, certain specialized tools may be necessary depending on the complexity of the repair task. Investing in high-quality equipment can significantly improve the repair experience.

Step-by-Step Motor Assembly Guide

This guide provides a comprehensive overview of the assembly process for a specific device, focusing on clarity and precision. By following the outlined steps, you will ensure that each component is correctly positioned and secured, leading to optimal performance and longevity.

Preparation and Tools

Before beginning the assembly, gather all necessary components and tools. Ensure that you have a clean workspace to facilitate organization and minimize the risk of misplacing any elements. Common tools required include a screwdriver, wrench, and torque tool. Familiarize yourself with each component, understanding their functions and how they interconnect.

Assembly Steps

Start by aligning the base with the main housing. Secure it using the appropriate fasteners, ensuring they are tightened to the specified torque to prevent loosening during operation. Next, insert the rotor into the housing, ensuring it spins freely without obstruction. Follow this by attaching the stator and securing it firmly. Finally, connect any electrical wiring, ensuring proper insulation and protection against wear.

Once all components are assembled, perform a thorough inspection to verify the integrity of the assembly. This includes checking for any loose connections and ensuring that all moving parts operate smoothly. By adhering to these steps, you will achieve a reliable and efficient setup.

Choosing the Right Replacement Parts

Selecting appropriate components for your equipment is crucial for ensuring optimal performance and longevity. The right choices not only enhance efficiency but also minimize the risk of future issues. Understanding the specifics of what you need is essential for a successful replacement process.

Factors to Consider

- Compatibility: Ensure that the selected components fit your model perfectly.

- Quality: Opt for high-quality options to guarantee durability and reliability.

- Warranty: Check if the replacements come with a warranty for added peace of mind.

- Reviews: Research customer feedback to assess the performance of various components.

Where to Find Components

- Authorized Dealers: Always a safe bet for genuine replacements.

- Online Retailers: Offer a wide range of options and often competitive pricing.

- Local Hardware Stores: Convenient for immediate needs and local support.

By carefully evaluating these aspects, you can ensure a smooth replacement experience and maintain the efficiency of your equipment.