In the realm of machinery and tools, comprehending the intricate details of each element is essential for optimal performance and maintenance. The various constituents play a crucial role in ensuring that everything functions smoothly and efficiently. This section aims to illuminate the intricate relationships and functionalities that these individual pieces bring to the whole system.

By exploring the layout and interconnections among the components, users can gain valuable insights into their equipment’s operation. Whether you’re troubleshooting an issue or simply seeking to deepen your knowledge, familiarizing yourself with these elements can enhance your understanding and proficiency. Furthermore, a clear grasp of the assembly can aid in identifying potential improvements and upgrades.

Equipped with this knowledge, you’ll be better prepared to navigate the complexities of your machinery. Emphasizing the significance of each part not only promotes better care but also fosters a more efficient working environment. As you delve into the specifics, you’ll discover the benefits of recognizing how each piece contributes to the overall functionality of your tools.

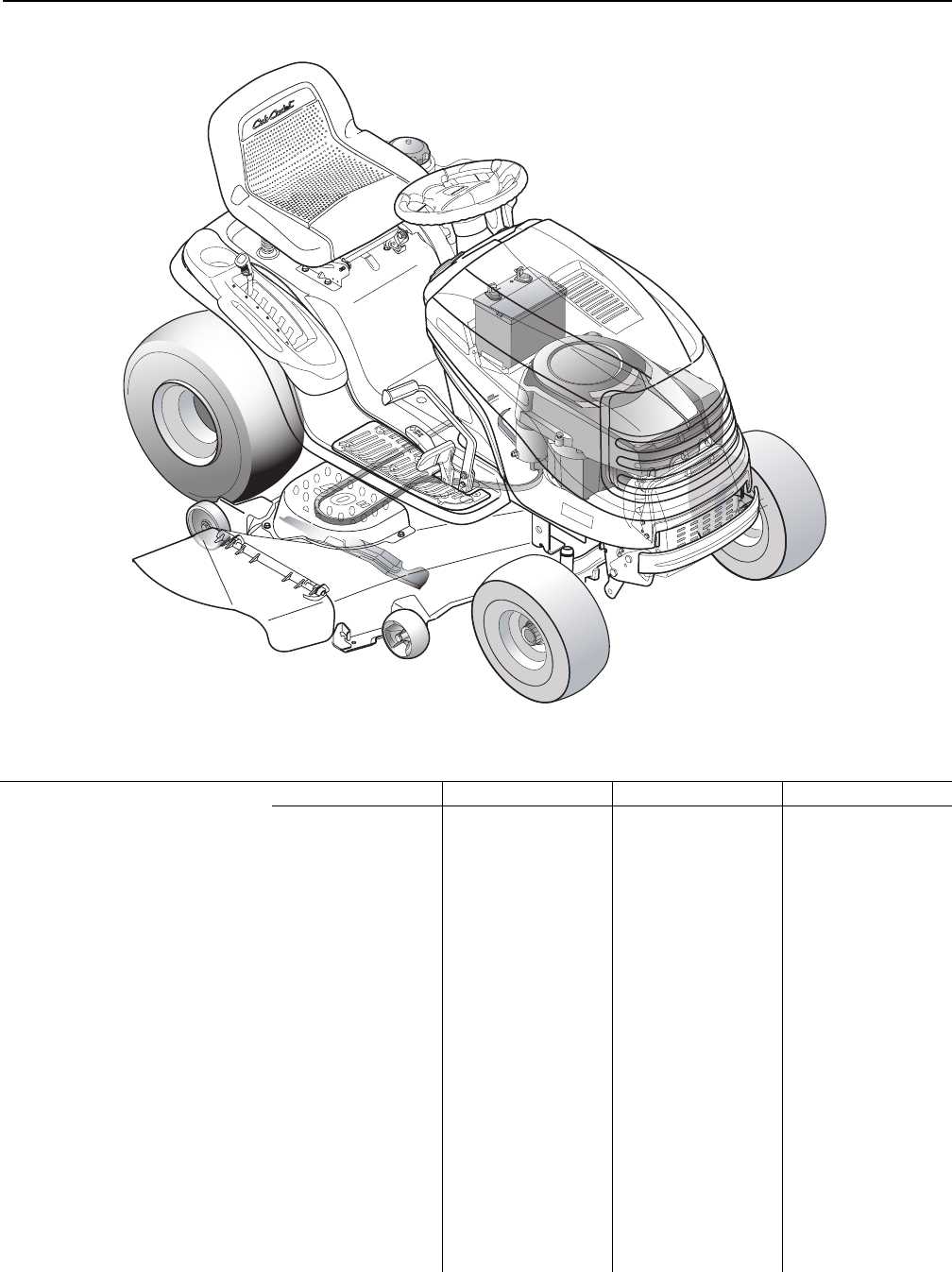

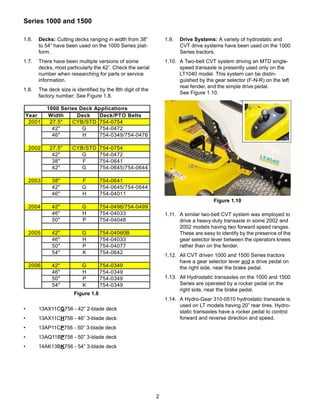

Understanding the Lt1045 Parts Diagram

Comprehending the components of machinery is crucial for effective maintenance and repair. A visual representation that outlines each element plays a vital role in facilitating a deeper understanding of how these parts work together. This section will explore the significance of such illustrations, highlighting their benefits and usage.

The Importance of Visual Representations

Visual aids serve as essential tools for technicians and enthusiasts alike. They provide clarity and enhance the efficiency of troubleshooting processes. Key advantages include:

- Improved Identification: Clear images help in recognizing individual elements quickly.

- Enhanced Communication: Standardized visuals make it easier for teams to discuss specific components.

- Streamlined Repairs: Understanding the arrangement aids in efficient disassembly and reassembly.

How to Utilize These Illustrations Effectively

To make the most of these visual guides, consider the following steps:

- Study the Overview: Begin with the complete view to get an understanding of the assembly.

- Focus on Details: Examine specific sections for a closer look at each part.

- Refer Back During Maintenance: Keep the representation handy while performing repairs to ensure accuracy.

By integrating these practices, users can enhance their proficiency in managing machinery and ensure optimal performance over time.

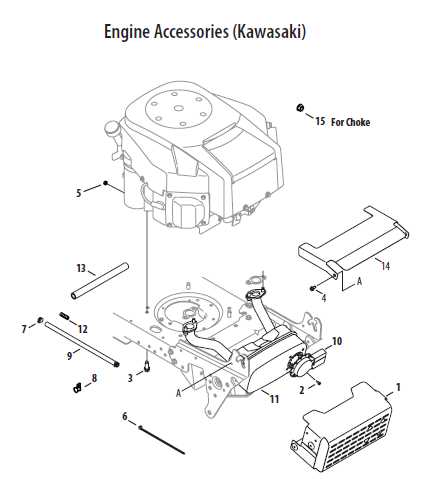

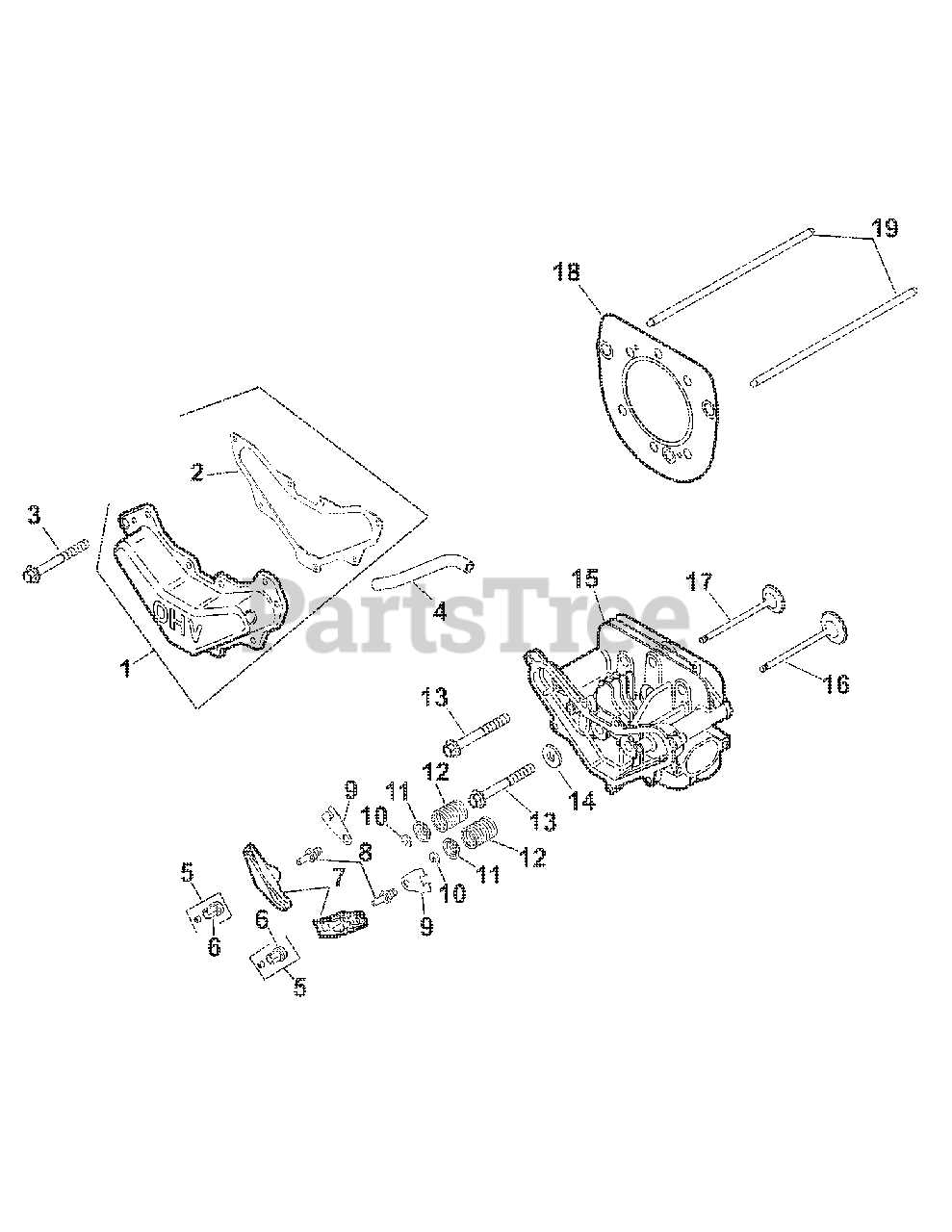

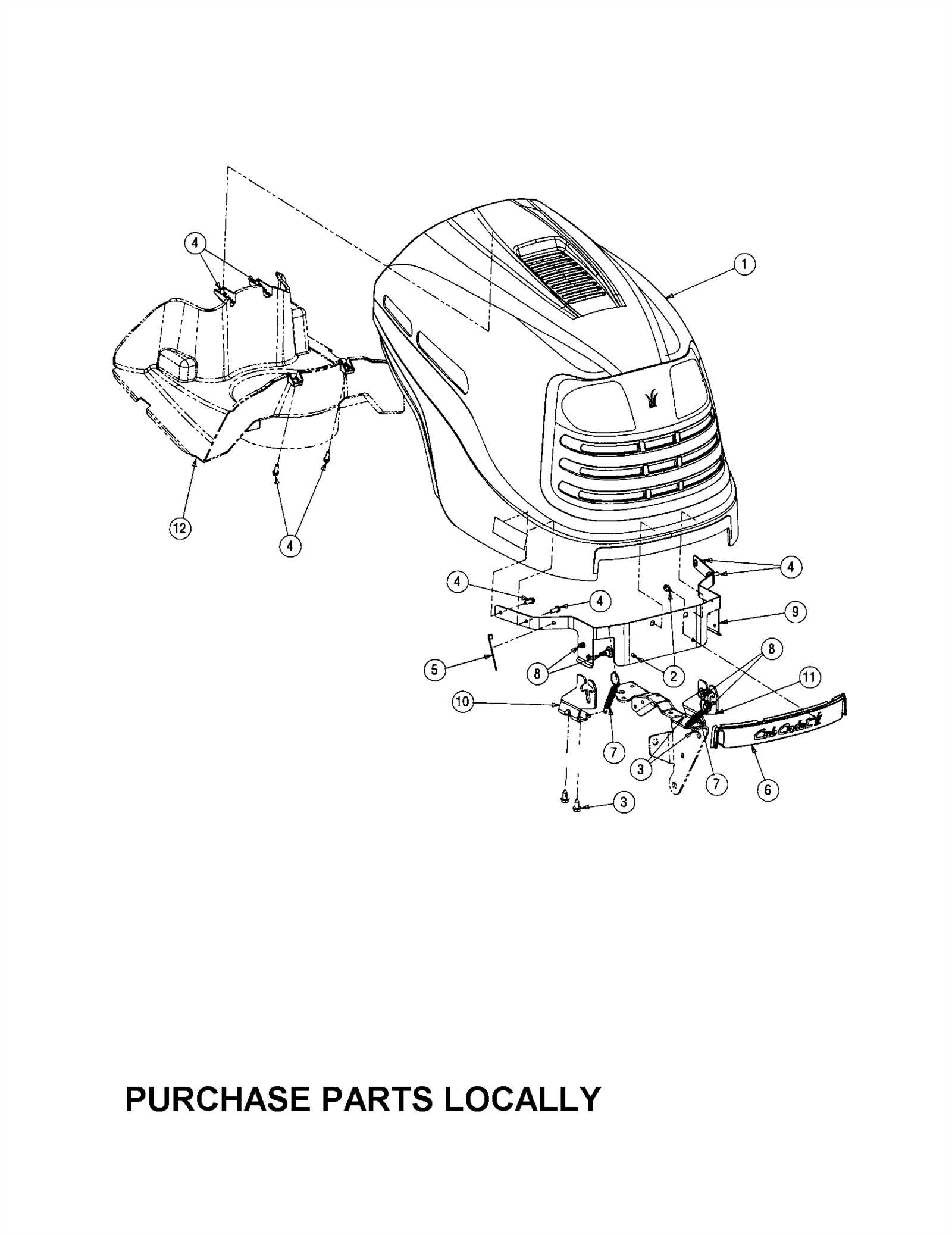

Key Components of the Lt1045

Understanding the essential elements of this machinery is crucial for both maintenance and operation. Each component plays a specific role in ensuring efficiency and effectiveness during use. Below are some of the fundamental parts that contribute to its overall functionality.

- Engine: The powerhouse that drives the entire system, providing the necessary energy for operation.

- Transmission: This element is responsible for transferring power from the engine to the wheels, enabling movement.

- Chassis: The framework that supports various components, ensuring stability and durability under different working conditions.

- Hydraulic System: Critical for lifting and maneuvering, this system utilizes fluid power to perform heavy lifting tasks.

- Control Panel: The interface through which the operator manages the functions and settings of the machine.

Each of these components interacts with others, creating a cohesive unit that can perform complex tasks efficiently. Understanding their roles can enhance both the operational knowledge and maintenance practices for users.

Importance of Accurate Diagrams

Precise visual representations are crucial for understanding complex systems and machinery. They serve as essential tools for both novices and experts, providing clarity and facilitating efficient communication. When these illustrations are meticulously crafted, they can significantly enhance the comprehension of intricate components and their interactions.

Accurate representations not only streamline the maintenance and repair processes but also reduce the likelihood of errors. When technicians have access to reliable visuals, they can quickly identify issues, locate specific elements, and execute tasks with confidence. This reduces downtime and promotes overall operational efficiency.

Furthermore, detailed illustrations contribute to better training and education. Newcomers can benefit from clear depictions that demystify complex concepts, allowing for a smoother learning curve. In addition, having high-quality visuals fosters a deeper understanding of the system, enabling individuals to become more proficient in their roles.

In conclusion, the significance of accurate visual guides cannot be overstated. They play a vital role in enhancing safety, efficiency, and knowledge retention in any technical field. Investing time in creating and maintaining these essential tools is an investment in success.

Common Issues with Lt1045 Parts

When working with machinery components, various challenges may arise, impacting performance and functionality. Identifying these common problems is crucial for maintenance and efficient operation, ensuring longevity and reliability in your equipment.

Frequent Problems Encountered

Users often face issues such as wear and tear, misalignment, and insufficient lubrication. Understanding these can help in early detection and resolution.

Preventative Measures

Regular inspections, proper storage, and adhering to maintenance schedules can significantly mitigate these issues. It is advisable to keep a close eye on component condition to prevent breakdowns.

| Issue | Impact | Solution |

|---|---|---|

| Wear and Tear | Decreased efficiency | Regular replacement |

| Misalignment | Increased strain | Realignment procedures |

| Insufficient Lubrication | Overheating | Routine lubrication |

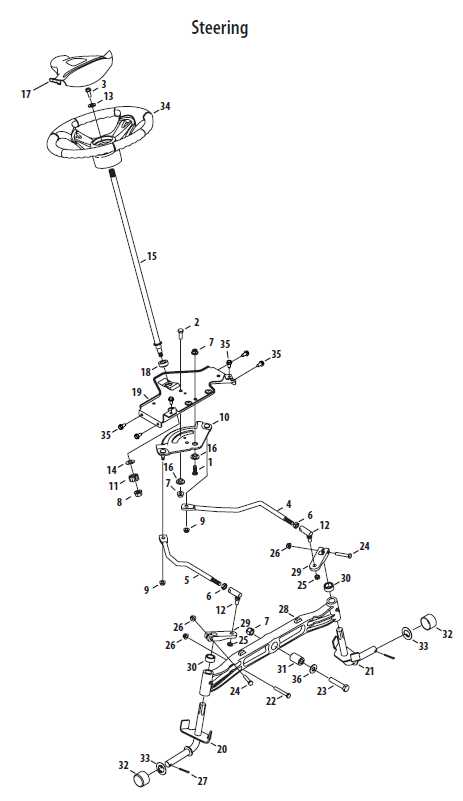

How to Read the Diagram Effectively

Understanding a schematic representation can greatly enhance your ability to troubleshoot and maintain your machinery. By mastering a few key strategies, you can interpret the visual layout more efficiently and quickly locate the components you need to work with.

Here are some essential tips to help you navigate the illustration:

- Familiarize Yourself with Symbols: Take the time to learn the various symbols and notations used in the representation. Each symbol has a specific meaning, and knowing them will facilitate quicker understanding.

- Identify Key Sections: Break down the layout into manageable sections. Recognizing major areas can help you focus on specific parts without feeling overwhelmed.

- Follow the Flow: Observe how the elements are connected. Understanding the flow can provide insights into how different components interact with each other.

- Use a Reference Guide: Keep a reference guide handy that explains the symbols and their functions. This will serve as a valuable tool when you encounter unfamiliar representations.

- Take Notes: While reviewing, jot down important notes or observations. This practice can aid in retaining information and serve as a quick reference for future work.

By applying these strategies, you will enhance your ability to interpret technical illustrations, making maintenance and repairs more straightforward and efficient.

Maintenance Tips for Lt1045 Owners

Proper upkeep is essential for ensuring the longevity and efficient operation of your machinery. Regular maintenance not only enhances performance but also prevents costly repairs in the long run. Following a systematic approach can help keep your equipment in optimal condition.

1. Regular Inspections: Conduct frequent examinations of all components. Look for signs of wear, leaks, or corrosion. Early detection of issues can save time and resources.

2. Clean the Machine: Remove dirt and debris from all surfaces. Accumulation of grime can lead to overheating and inefficient operation. Use a soft brush or cloth to clean delicate areas without causing damage.

3. Change Fluids: Ensure that oils and other fluids are changed at recommended intervals. Fresh fluids enhance performance and protect internal parts from wear.

4. Check Belts and Cables: Inspect belts for signs of fraying or stretching. Ensure cables are secure and free from damage. Replacing worn belts and cables prevents unexpected breakdowns.

5. Store Properly: When not in use, store your equipment in a clean, dry location. Protect it from extreme temperatures and moisture, which can lead to deterioration.

6. Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule provided by the manufacturer. Specific guidelines ensure that you perform the necessary tasks at appropriate intervals.

By implementing these maintenance tips, you can extend the lifespan of your machinery and ensure it operates smoothly. Regular attention to these details will pay off in the form of reliable performance and reduced repair costs.

Where to Find Replacement Parts

Locating components for machinery can be a straightforward process if you know where to look. Various resources are available, from online retailers to local suppliers, each offering a range of options for your needs. Understanding the right sources can save time and ensure that you find what you need efficiently.

Online Marketplaces: Websites like eBay and Amazon often feature numerous listings for various items. Searching these platforms allows you to compare prices and read reviews, helping you make informed decisions.

Manufacturer Websites: Many producers have official websites where you can find the exact items required for your equipment. These sites often provide direct purchase options and detailed specifications.

Local Dealers: Visiting nearby retailers can also be beneficial. They may have what you need in stock or can order it for you, allowing for quicker access compared to shipping times from online sources.

Forums and Community Groups: Engaging with online communities or forums dedicated to your equipment can lead to valuable recommendations. Members often share their experiences and suggest reliable sources for specific components.

Exploring these avenues can ultimately enhance your chances of finding the correct replacements, ensuring your machinery operates smoothly and efficiently.

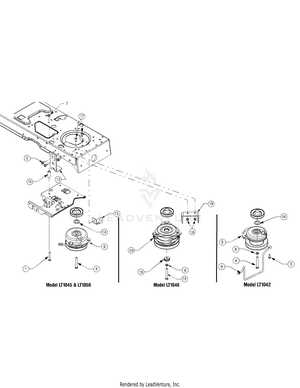

Comparing Lt1045 to Similar Models

When assessing the features and performance of various machinery, it is essential to analyze how specific models stack up against their counterparts in the market. By examining similarities and differences, potential buyers can make informed decisions based on their needs and preferences.

Here are some key aspects to consider when comparing this model to others:

- Performance: Evaluate the engine power, efficiency, and torque delivered by competing machines.

- Build Quality: Consider the materials used in construction, as well as the durability and longevity of the units.

- Features: Compare available functionalities, such as cutting systems, maneuverability, and ease of operation.

- Maintenance: Look into the maintenance requirements and the availability of replacement components for each model.

- Price Point: Analyze the cost relative to features offered, ensuring value for investment.

Furthermore, examining customer reviews and feedback can provide insight into real-world performance and satisfaction. By systematically comparing these aspects, buyers can identify the model that best suits their requirements, ensuring optimal performance and efficiency for their tasks.

FAQs About Lt1045 Parts and Diagrams

This section addresses common inquiries regarding components and their visual representations for a specific model. Understanding these elements can enhance maintenance and troubleshooting efforts.

What is the best way to obtain a visual representation of components? You can often find detailed illustrations in the official manuals or authorized service centers that specialize in this model.

How do I identify the correct components for my equipment? Checking the model number and consulting official resources will provide clarity on the appropriate elements needed for repairs or replacements.

Can I use alternative components? While some alternatives may fit, it is advisable to use manufacturer-recommended elements to ensure optimal performance and safety.

Where can I find installation instructions? Installation guidelines are typically included in user manuals or can be accessed online through reputable forums or manufacturer websites.

What should I do if I can’t find specific elements? If certain components are elusive, consider reaching out to support services or local suppliers who may assist in sourcing them.