In the realm of recreational games, the intricate workings of a specific table system play a crucial role in delivering an exceptional experience. Each element within this assembly is designed to contribute to the overall functionality, ensuring that every game is both enjoyable and efficient. By delving into the structure of these mechanisms, enthusiasts can gain insights into the craftsmanship behind them.

The various components, from the primary framework to the finer details, serve distinct purposes. Recognizing how these elements interact can enhance gameplay and facilitate maintenance. A thorough exploration of these individual sections provides a roadmap for both novice players and seasoned experts alike, fostering a deeper appreciation for the game.

Understanding the layout of these crucial elements not only aids in troubleshooting potential issues but also empowers users to make informed decisions regarding upgrades or repairs. As one navigates through this exploration, the knowledge gained will undoubtedly enrich the overall experience, making each session more rewarding.

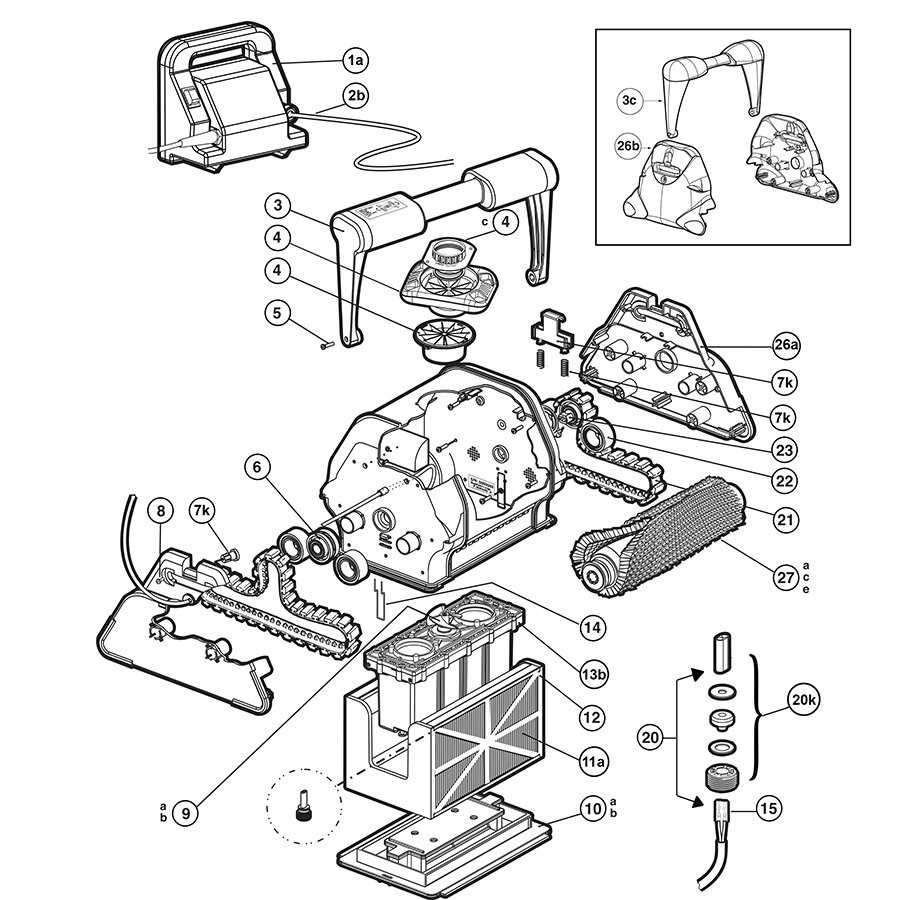

Understanding Lane Shark Components

The intricate design of aquatic machinery involves numerous essential elements that work harmoniously to ensure optimal performance. Each component plays a vital role, contributing to the overall efficiency and functionality of the equipment. By exploring these integral pieces, one can gain insights into their purpose and interrelationships.

Structural Framework: The backbone of the system, providing stability and support, is crucial for handling various operational demands. Its robustness ensures longevity and reliability under varying conditions.

Mechanical Elements: These include gears, motors, and other moving parts that drive the entire mechanism. Their precise engineering allows for seamless movement and adaptability to different tasks.

Control Systems: Advanced technology embedded within these devices facilitates user interaction and enhances operational precision. Through intuitive interfaces, users can manage functions effortlessly, improving overall effectiveness.

Maintenance Features: Designed for ease of upkeep, these aspects allow for quick troubleshooting and repairs, ensuring sustained functionality over time. Regular attention to these elements is vital for optimal performance and longevity.

By delving into each of these components, one can appreciate the complexity and sophistication of aquatic machinery, leading to a deeper understanding of its ultimate purpose and capabilities.

Visual Breakdown of Shark Parts

This section provides an insightful examination of the anatomical features found in these remarkable marine creatures. By exploring their unique structures, we gain a deeper understanding of their adaptations and the roles they play in their ecosystems.

Key Anatomical Features

Each element contributes to the overall functionality and survival of the species. From the streamlined body design to specialized sensory organs, every characteristic serves a purpose.

| Feature | Description | Function |

|---|---|---|

| Fins | Thin, flat appendages located on the sides and top. | Provide stability and propulsion through water. |

| Dermal Denticles | Small, tooth-like structures covering the skin. | Reduce drag and protect against parasites. |

| Spiracles | Small openings located behind the eyes. | Allow for breathing while partially buried in sand. |

| Teeth | Sharp, serrated structures in the jaws. | Essential for catching and consuming prey. |

Understanding Adaptations

The adaptations seen in these animals are a testament to their evolutionary journey. Each feature has been fine-tuned to enhance their hunting capabilities and survival in diverse environments.

Functionality of Each Component

Understanding the role of each element within a mechanical assembly is crucial for optimal performance and maintenance. Each segment contributes uniquely to the overall operation, enhancing efficiency and reliability. This section explores the specific functions of various components, illustrating how they interconnect to achieve desired outcomes.

| Component | Function |

|---|---|

| Motor | Provides the necessary power to drive the system, converting electrical energy into mechanical motion. |

| Gearbox | Regulates the speed and torque of the output, allowing for efficient power transfer and performance adjustments. |

| Drive Belt | Transmits rotational force from the motor to the operational units, ensuring smooth and consistent movement. |

| Control Unit | Acts as the brain of the system, managing operations through sensors and feedback mechanisms for precise control. |

| Frame | Provides structural integrity and support for all components, ensuring stability during operation. |

| Cooling System | Prevents overheating by dissipating excess heat generated during operation, thereby prolonging lifespan and efficiency. |

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires consistent care and attention. By following a few essential practices, you can significantly extend its lifespan and enhance overall performance. Regular maintenance not only prevents issues but also saves time and money in the long run.

Routine Checks

- Inspect components regularly for signs of wear or damage.

- Ensure all moving parts are properly lubricated to reduce friction.

- Check for loose connections and tighten as needed to prevent operational failures.

Cleaning Procedures

- Remove debris and dirt from surfaces to avoid buildup.

- Use appropriate cleaning agents that won’t harm materials.

- Schedule deep cleans periodically to maintain optimal functionality.

Common Issues with Lane Shark

When operating specialized equipment, several frequent challenges can arise that may affect performance and efficiency. Understanding these common pitfalls is essential for maintaining optimal functionality and ensuring a smooth user experience.

Wear and Tear: Over time, components can experience significant deterioration due to constant use. Regular inspections can help identify parts that may require replacement.

Hydraulic Problems: Leaks or pressure drops in the hydraulic system can lead to reduced power and responsiveness. It’s crucial to check hoses and fittings for any signs of damage.

Electrical Issues: Malfunctions in wiring or connectors can disrupt functionality. Ensuring all electrical connections are secure can prevent operational failures.

Alignment and Calibration: Misalignment can result in uneven performance. Regular calibration and adjustments are necessary to maintain precision during operation.

Maintenance Neglect: Skipping routine maintenance can lead to more severe issues down the line. Adhering to a consistent maintenance schedule is vital for longevity and reliability.

Upgrades and Customizations Available

Enhancing your vehicle’s performance and aesthetics is an exciting journey that many enthusiasts embark upon. With a wide array of options at your disposal, you can tailor your ride to meet your specific needs and preferences, ensuring a unique experience on the road.

Performance Enhancements

One of the most sought-after upgrades involves improving the engine’s output. By integrating advanced components such as high-performance exhaust systems and tuned engine control units, you can significantly boost horsepower and torque. Additionally, upgrading the suspension system enhances handling and stability, providing a smoother ride even on challenging terrains.

Aesthetic Customizations

Beyond performance, visual enhancements allow you to express your style. Options like custom paint jobs, unique decals, and upgraded lighting systems can transform the appearance of your vehicle. Furthermore, selecting bespoke interior materials and finishes can elevate comfort and luxury, making every journey more enjoyable.

How to Order Replacement Parts

When it comes to maintaining your equipment, acquiring new components is essential for optimal performance. Knowing the right steps to follow can streamline the process, ensuring you receive the correct items without unnecessary delays.

Here are some key steps to effectively place your order:

- Identify the Required Component:

Before placing an order, determine exactly what you need. This may involve:

- Consulting the user manual.

- Reviewing the manufacturer’s website for specifications.

- Checking existing components for model numbers or identifiers.

- Find a Reliable Supplier:

Search for authorized dealers or reputable online retailers. Consider:

- Customer reviews and ratings.

- Return and warranty policies.

- Availability of customer support.

- Gather Necessary Information:

Prepare the details you’ll need to place the order, including:

- Model number of the equipment.

- Specific part number if available.

- Your contact and shipping information.

- Place Your Order:

Follow the supplier’s ordering process, which may include:

- Filling out an online form.

- Contacting customer service via phone or email.

- Confirming the total cost and shipping options.

- Track Your Shipment:

After placing your order, keep an eye on the delivery status to ensure timely arrival. This may involve:

- Using tracking numbers provided by the supplier.

- Checking your email for updates on shipping progress.

lessCopy code

Following these steps will help you successfully acquire the components you need to keep your equipment running smoothly.

Expert Insights on Performance

Achieving optimal functionality in high-performance machinery requires a deep understanding of each component’s role and synergy. Professionals emphasize the significance of precision engineering and regular maintenance to ensure longevity and efficiency. Every element contributes to the overall effectiveness, making it crucial to delve into the intricacies of design and operation.

Key Factors for Enhanced Efficiency

Material Quality: The selection of superior materials is paramount. High-grade substances can significantly elevate durability and performance, ultimately leading to improved results.

Regular Maintenance Practices

Routine check-ups and timely replacements can prevent minor issues from escalating into major failures. Staying proactive is essential for maximizing operational capabilities and ensuring peak performance over time.

Safety Precautions During Repairs

When undertaking maintenance tasks, it is crucial to prioritize safety to prevent accidents and ensure a smooth workflow. Awareness of potential hazards and following best practices can significantly reduce the risk of injury or damage. Taking the time to prepare and adhere to safety measures can enhance both personal protection and the longevity of the equipment being serviced.

Here are some essential safety tips to consider:

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use appropriate safety equipment such as gloves, goggles, and helmets to shield yourself from potential hazards. |

| Ensure Proper Ventilation | Work in a well-ventilated area to avoid inhaling harmful fumes or dust particles during repairs. |

| Disconnect Power Sources | Before beginning any repair work, make sure to disconnect electrical power to prevent accidental shocks. |

| Use Tools Correctly | Familiarize yourself with the tools being used and ensure they are in good condition to avoid mishaps. |

| Keep Work Area Clean | Maintain a tidy workspace to minimize clutter and reduce the risk of slips or falls. |

Implementing these guidelines not only safeguards individuals but also promotes an efficient repair process, allowing for a more effective outcome.