When it comes to maintaining and optimizing the functionality of your equipment, having a clear visual reference is invaluable. This section aims to provide insights into the intricate components that make up your machinery, highlighting their arrangement and interconnections. By familiarizing yourself with these elements, you can enhance your repair and maintenance skills.

Within this guide, you’ll discover a comprehensive overview that illustrates the various sections and features of the system. Each part plays a crucial role in ensuring smooth operation, and recognizing their specific functions can significantly aid in troubleshooting and efficiency improvements. The clarity offered here will empower you to take informed actions during maintenance tasks.

As you explore this resource, you’ll gain a deeper appreciation for the engineering behind your equipment. Whether you’re a seasoned technician or a novice user, understanding the layout and relationships between different elements will enable you to tackle challenges with confidence. Prepare to delve into the details that will elevate your knowledge and skills in machine management.

Understanding the La115 Parts Diagram

Comprehending the components of machinery is essential for effective maintenance and repair. A detailed visual representation can serve as a crucial guide, allowing users to identify each element and its function within the overall system. By analyzing such illustrations, individuals can enhance their troubleshooting skills and ensure optimal performance.

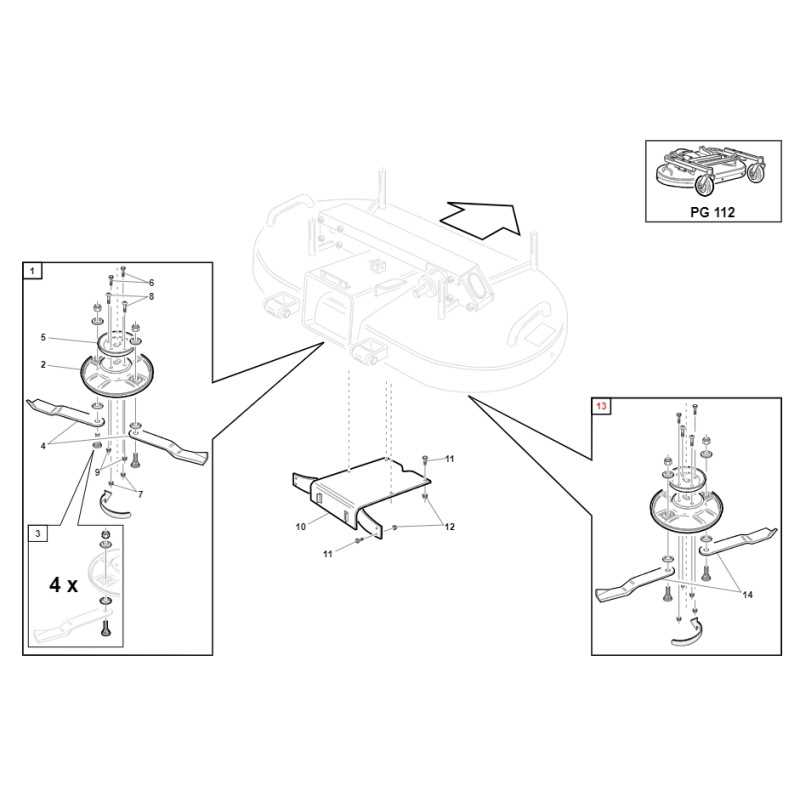

Key Components Overview

Each segment within the visual representation plays a vital role. Understanding these individual parts helps in recognizing how they interact with one another. For example, some elements may be responsible for movement, while others provide structural support or house essential systems. Familiarity with these functions can significantly streamline the repair process.

Benefits of Familiarization

Becoming well-acquainted with these visuals offers several advantages. First, it enhances communication between technicians and operators, as both parties can refer to specific features without ambiguity. Additionally, this knowledge empowers users to perform preventive maintenance, reducing the likelihood of unexpected breakdowns. Ultimately, a thorough understanding fosters confidence and competence in handling machinery.

Overview of La115 Components

This section provides a comprehensive look at the various elements that contribute to the functionality and performance of a specific model. Understanding these components is essential for maintenance, repair, and enhancement of the overall system. Each element plays a vital role in ensuring optimal operation and longevity.

Main Elements

The core structure includes essential components that facilitate movement and power transfer. These elements are designed for durability and efficiency, ensuring that the system operates smoothly under various conditions. Regular inspection and replacement of worn parts can significantly enhance performance.

In addition to the main components, there are several supporting features that improve user experience and operational reliability. These enhancements often include safety mechanisms and controls that provide additional convenience and protection during use. Understanding how these features interact with the core elements can lead to better overall management of the system.

Importance of Accurate Diagrams

Clear representations are vital for understanding complex systems. They serve as visual guides that enhance communication and facilitate comprehension among users, engineers, and technicians alike. Precision in these illustrations minimizes confusion, ensuring that everyone interprets the information consistently.

Accurate visuals not only aid in assembly and maintenance but also reduce errors, saving time and resources. When stakeholders have reliable references, they can make informed decisions swiftly, ultimately leading to improved outcomes in projects.

| Benefits | Description |

|---|---|

| Enhanced Clarity | Helps users grasp complex information easily. |

| Error Reduction | Minimizes mistakes during assembly or repair. |

| Informed Decisions | Facilitates quick and effective choices in operations. |

| Resource Efficiency | Optimizes time and material usage through accurate guidance. |

Common Issues in La115 Models

Many users encounter specific challenges when dealing with these popular machinery units. Understanding these common problems can help in troubleshooting and maintenance, ensuring optimal performance and longevity.

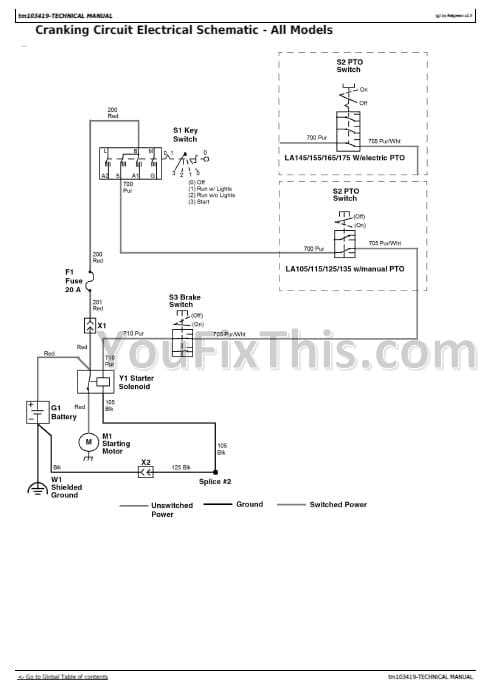

- Electrical Failures:

Issues related to the electrical system can manifest in various ways, such as:

- Battery drainage

- Faulty wiring connections

- Malfunctioning ignition systems

- Engine Performance:

Performance issues often stem from several factors, including:

- Poor fuel quality

- Clogged air filters

- Worn spark plugs

- Transmission Problems:

Users may experience difficulties with the transmission, such as:

- Slipping gears

- Unusual noises during operation

- Fluid leaks

- Mechanical Wear:

Over time, various components may show signs of wear, which can lead to:

- Increased maintenance costs

- Decreased efficiency

- Potential safety hazards

lessCopy code

Addressing these issues promptly can enhance performance and extend the lifespan of the equipment. Regular maintenance and inspections are crucial in preventing many of these common challenges.

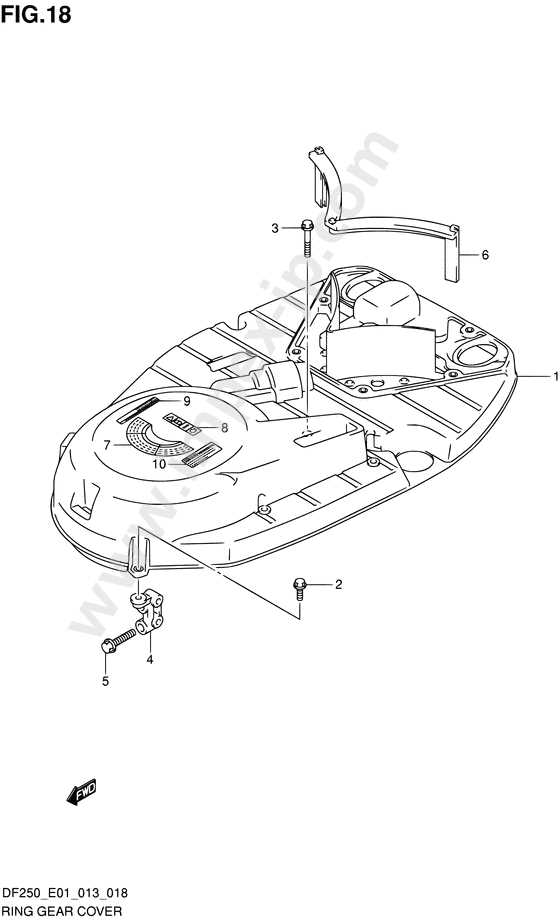

How to Read the Diagram Effectively

Understanding complex illustrations can significantly enhance your ability to assemble, troubleshoot, or maintain machinery. By following a systematic approach, you can decipher the various elements presented, allowing for efficient navigation and comprehension of the visual information provided.

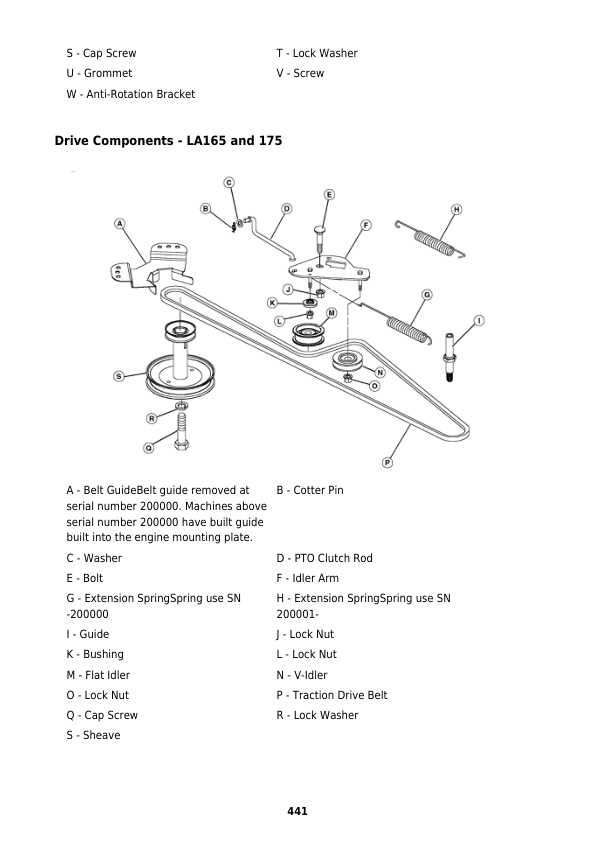

Breaking Down the Components

To begin, familiarize yourself with the key sections of the visual representation. Each area typically contains distinct symbols and labels that correspond to specific features. Recognizing these will help you identify parts quickly and understand their functions.

| Symbol/Label | Description |

|---|---|

| A | Power Supply Unit |

| B | Control Module |

| C | Motor Assembly |

Utilizing Reference Keys

Most illustrations include a reference key that explains the meaning of each symbol. Always refer to this guide when you encounter unfamiliar markings. It provides context and enhances your understanding of how each element interacts within the system.

Identifying Replacement Parts Quickly

Efficient identification of components is crucial for maintaining functionality and performance. Understanding how to swiftly recognize the right substitutes can save time and resources during repairs or upgrades. This process involves not only knowledge of the items themselves but also familiarity with their configurations and specifications.

Utilizing Reference Materials

Access to comprehensive reference resources is essential. Manuals, catalogs, and online databases provide valuable insights, allowing users to pinpoint the exact components they require. Visual aids play a significant role, as they enable quick comparisons and facilitate decision-making.

Leveraging Technology

Modern technology enhances the identification process. Applications and software designed for tracking and managing components streamline the search. Digital tools can help users cross-reference and quickly locate the needed items, ensuring that replacements are both accurate and timely.

Tools Needed for La115 Maintenance

Proper upkeep of your equipment requires specific implements to ensure optimal performance and longevity. Having the right tools not only simplifies the maintenance process but also enhances efficiency, allowing for effective troubleshooting and repairs.

Basic Hand Tools: Essential items include wrenches, screwdrivers, and pliers, which are fundamental for any maintenance task. These tools facilitate adjustments and replacements with ease.

Diagnostic Equipment: A multimeter and pressure gauge are vital for diagnosing issues. These devices help pinpoint problems, ensuring precise repairs.

Safety Gear: Donning gloves, goggles, and protective clothing is crucial for safety during maintenance. These items protect against potential hazards, making the process safer and more efficient.

Lubricants and Cleaners: Quality oils and cleaning solutions are necessary for maintaining optimal functioning. Regular application ensures parts remain in good condition and free from debris.

By utilizing the appropriate tools and equipment, you can delve into maintenance tasks with confidence, achieving ultimate performance and reliability from your machinery.

Tips for Assembling La115 Parts

When working on a mechanical assembly, careful preparation and attention to detail are crucial for a successful outcome. Understanding the components and their arrangement can significantly ease the process, ensuring everything fits together seamlessly.

Begin by organizing your components; group similar items to prevent confusion. This will save time and reduce errors during assembly. Having a clear workspace will also help you focus and locate parts more efficiently.

Refer to any available reference materials, as they can provide valuable insights into the assembly sequence and highlight potential challenges. Familiarize yourself with the unique features of each component, which can aid in their proper installation.

Utilize the right tools for the job to avoid damage and ensure precision. A well-equipped toolkit will make the assembly process smoother and more enjoyable.

Finally, take your time. Rushing can lead to mistakes that may require disassembly and rework. By being patient and methodical, you’ll achieve the best results in your project.

Resources for Further Information

Exploring additional materials can significantly enhance your understanding of complex machinery and their components. Various sources provide in-depth insights, technical specifications, and practical applications that can prove invaluable for enthusiasts and professionals alike.

Online Forums and Communities: Engaging with online platforms dedicated to machinery and equipment can offer a wealth of knowledge. These communities often feature discussions, troubleshooting tips, and personal experiences that can guide your learning process.

Manufacturer Websites: Official sites of equipment producers typically contain manuals, guides, and resource links. These documents can provide comprehensive details about specific models, maintenance procedures, and compatibility with other tools.

Technical Publications: Numerous books and journals focus on machinery operation and repair. These resources often include diagrams, explanations, and case studies that can deepen your comprehension and provide practical examples.

Educational Videos: Video tutorials available on various platforms can be highly effective for visual learners. These resources often break down complex processes into manageable steps, making it easier to grasp technical concepts.

Workshops and Training Sessions: Participating in hands-on workshops or training courses can offer practical experience. Learning from experts in the field can clarify doubts and reinforce theoretical knowledge with real-world applications.