In the world of agricultural equipment, grasping the intricacies of various machinery is crucial for optimal performance and maintenance. This section aims to explore a specific model, focusing on its significant elements and their interrelationships. By examining these components, users can enhance their knowledge and ensure the longevity of their equipment.

Visual aids play a vital role in comprehending the structure and function of complex machinery. By providing clear representations, they facilitate a better understanding of how each part contributes to the overall operation. This visual breakdown allows operators to identify issues swiftly and perform necessary repairs with confidence.

As we delve deeper into the specifics of this particular agricultural implement, the ultimate goal is to empower users with the information needed to optimize their machinery’s efficiency. Knowledge of each element not only aids in troubleshooting but also enhances overall productivity in the field.

Understanding Disc Mower Components

In the world of agricultural machinery, grasping the various elements that contribute to operational efficiency is crucial. Each component plays a specific role, ensuring that the overall system functions harmoniously. This knowledge aids in maintenance, troubleshooting, and enhancing performance.

Key Elements of the System

- Cutting Mechanism: The primary apparatus responsible for the actual cutting action. Its design affects both efficiency and quality of work.

- Drive System: This component transfers power from the engine to the cutting mechanism, allowing for smooth operation.

- Support Frame: The structure that houses and secures all other components, providing stability during operation.

- Adjustment Controls: These allow operators to modify cutting height and angle, ensuring optimal results across various terrains.

Importance of Maintenance

Regular upkeep of each element is vital for longevity and effectiveness. Neglecting any part can lead to reduced performance or potential failures. Key maintenance tasks include:

- Inspecting and sharpening the cutting edges.

- Checking for wear and tear on the drive system.

- Ensuring the support frame is free from damage.

- Testing adjustment controls for responsiveness.

By understanding these components and their significance, operators can ensure that their machinery remains in peak condition, ready to tackle the demands of agricultural tasks.

Benefits of Using a Disc Mower

Employing modern cutting equipment offers numerous advantages for agricultural practices. This type of machinery enhances efficiency and effectiveness, streamlining the process of managing grass and crops. Below are some key benefits associated with utilizing such devices in farming operations.

Enhanced Efficiency

- Rapid Cutting Speed: The design allows for quicker cutting, enabling operators to cover large areas in a shorter time frame.

- Uniform Cutting Height: Adjustable settings ensure a consistent length, promoting healthy regrowth and improving forage quality.

- Reduced Labor Costs: Automation and advanced mechanics lessen the need for manual labor, cutting down on expenses.

Improved Performance

- Durability: High-quality materials and robust construction ensure long-lasting performance, even in tough conditions.

- Versatility: Suitable for various types of vegetation, making it a flexible choice for different agricultural needs.

- Minimal Ground Disturbance: The design minimizes soil disruption, promoting healthier soil conditions and better crop yields.

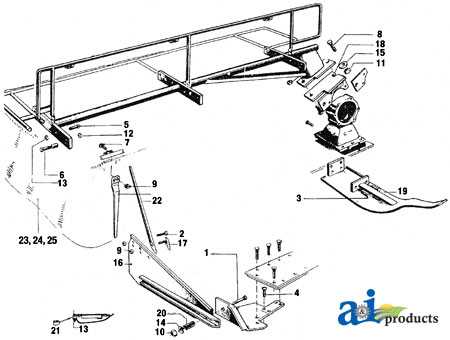

Identifying Parts in New Idea 5407

Understanding the components of agricultural equipment is crucial for efficient operation and maintenance. Each element plays a significant role in the overall functionality, and recognizing these elements can help in troubleshooting and repairs. Familiarity with the assembly can enhance productivity and extend the lifespan of the machinery.

Key Components

Several main elements contribute to the efficient performance of the machine. These include the cutting mechanism, drive system, and safety features. The cutting mechanism is essential for ensuring precise operation, while the drive system delivers power and controls movement. Additionally, various safety features are integrated to protect the operator and prevent accidents.

Maintenance and Inspection

Regular inspection and maintenance of each component are vital for optimal performance. Identifying wear and tear early can prevent costly repairs and downtime. It is important to refer to the manufacturer’s guidelines for specific maintenance practices related to each element, ensuring that the equipment remains in peak condition throughout its service life.

Common Issues with Disc Mowers

Machinery designed for cutting vegetation can face several challenges that hinder their efficiency and performance. Understanding these common problems allows operators to troubleshoot effectively and maintain optimal functionality.

Wear and Tear: Continuous use can lead to degradation of components, affecting cutting performance. Regular inspection and replacement of worn parts are crucial.

Blade Misalignment: Improper positioning of the cutting blades can result in uneven cuts. Ensuring that blades are correctly aligned can enhance the quality of the work.

Clogging: Accumulation of grass and debris can obstruct operation, requiring frequent cleaning to maintain smooth functioning. Keeping the machine clear is essential.

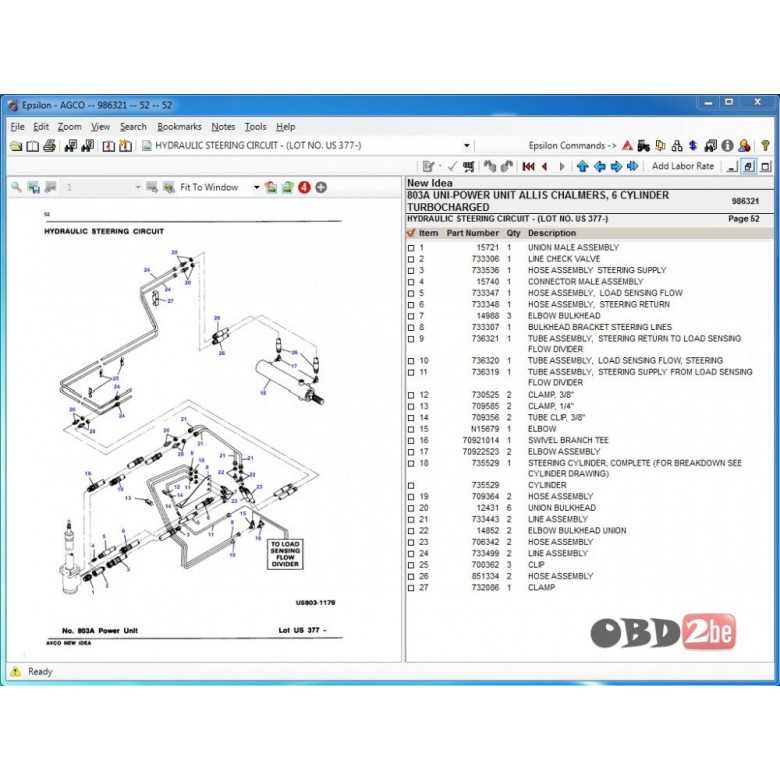

Hydraulic Issues: Hydraulic systems may develop leaks or pressure problems, impacting the overall performance. Routine checks can prevent major breakdowns.

Noise and Vibration: Unusual sounds or vibrations can indicate underlying mechanical problems. Addressing these issues promptly can prevent further damage and enhance longevity.

Maintenance Tips for Mower Parts

Ensuring the longevity and efficiency of your cutting equipment requires regular care and attention. By following a few essential guidelines, you can keep all components in top shape, thereby enhancing performance and reducing the risk of breakdowns.

Regular Inspection

Routine checks are vital for identifying wear and tear before it becomes a significant issue. Consider the following:

- Examine blades for sharpness and damage.

- Check belts for signs of fraying or cracks.

- Inspect bearings and pulleys for proper function.

- Look for leaks in hydraulic systems if applicable.

Cleaning and Lubrication

Keeping components clean and well-lubricated will prolong their lifespan. Follow these practices:

- Remove debris after each use to prevent buildup.

- Use a suitable lubricant on moving parts to reduce friction.

- Ensure all grease fittings are filled as per the manufacturer’s guidelines.

- Wipe down surfaces to prevent rust and corrosion.

Replacement Parts Availability and Sources

Ensuring the functionality of agricultural equipment often relies on the accessibility of high-quality components. Operators can minimize downtime and enhance performance by sourcing reliable replacements from trusted suppliers. Identifying these resources is crucial for maintaining efficiency and prolonging the lifespan of the machinery.

Authorized Dealers and Retailers

One of the most reliable avenues for acquiring essential components is through authorized dealers. These vendors typically provide genuine replacements that match the original specifications, ensuring compatibility and durability. Additionally, many retailers offer online platforms, making it convenient for customers to browse available items and place orders directly from their homes.

Aftermarket Options

For those seeking cost-effective alternatives, aftermarket suppliers present a viable solution. These options often feature competitive pricing and a wide selection of compatible components. However, it is vital to verify the quality and reputation of the suppliers to avoid potential issues with performance or longevity. Researching reviews and comparing products can lead to informed decisions and satisfactory results.

Assembly and Disassembly Procedures

This section outlines the essential steps for assembling and disassembling components effectively. Proper techniques ensure safety and functionality, leading to enhanced performance of the equipment.

Before starting the process, gather all necessary tools and equipment. Familiarize yourself with the layout and functionality of each element to facilitate a smooth workflow.

| Step | Action |

|---|---|

| 1 | Disconnect power sources to prevent accidental activation. |

| 2 | Remove any protective covers to gain access to the components. |

| 3 | Carefully detach the components by loosening bolts and fasteners. |

| 4 | Store all removed parts in a designated area to avoid loss. |

| 5 | Inspect each part for wear or damage before reassembly. |

| 6 | Align and secure the components according to the manufacturer’s specifications during reassembly. |

| 7 | Reconnect power sources and test the system for proper operation. |

Following these systematic procedures helps maintain the integrity of the equipment and ensures efficient operation over time.

Comparative Analysis of Mower Models

This section explores the differences among various cutting equipment models available in the market. By examining key features, performance metrics, and overall user satisfaction, we aim to provide a comprehensive understanding that can guide potential buyers in their decision-making process.

Key Features Comparison

| Model | Cutting Width | Horsepower | Weight | Price Range |

|---|---|---|---|---|

| Model A | 6 ft | 50 HP | 1200 lbs | $4,000 – $5,000 |

| Model B | 5.5 ft | 45 HP | 1100 lbs | $3,500 – $4,500 |

| Model C | 7 ft | 60 HP | 1300 lbs | $5,500 – $6,500 |

Performance Metrics

In assessing the efficiency of each model, factors such as cutting speed, fuel consumption, and maintenance requirements are crucial. Model A demonstrates superior fuel efficiency, making it ideal for larger operations. In contrast, Model B offers a more lightweight option, which can be beneficial for smaller properties. Model C, while heavier, excels in speed and can handle more challenging terrains effectively.