In the world of agricultural machinery, efficiency and precision are paramount. The successful operation of a specific device designed for collecting forage relies heavily on its various integral elements. Each section plays a crucial role in ensuring optimal performance and productivity during use.

To fully appreciate the functionality of this tool, it is essential to explore the intricate arrangement and design of its components. By examining how these elements interact, farmers can enhance their knowledge and skills, leading to better maintenance and improved yield outcomes.

Moreover, a clear visualization of the device’s structure serves as an invaluable resource. It allows users to identify potential areas for repair or upgrades, ultimately contributing to the longevity and efficiency of the machinery in the field.

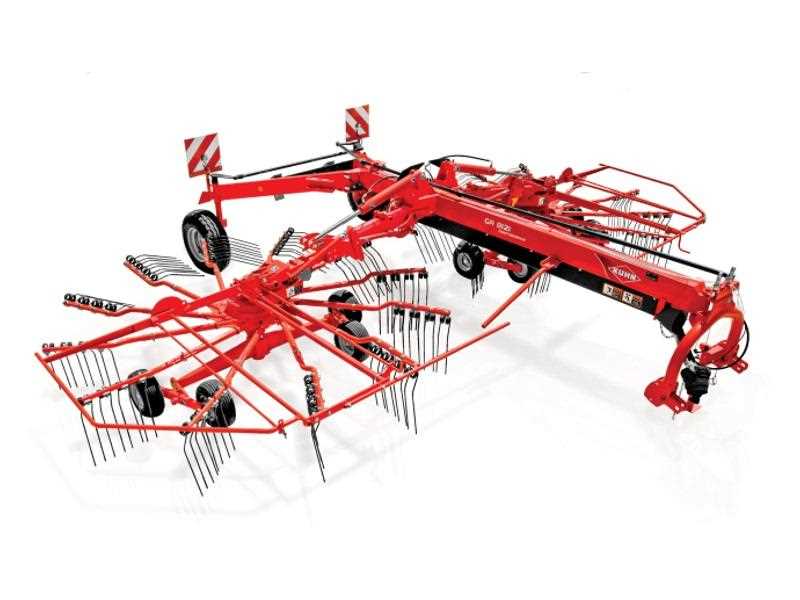

Kuhn Rotary Rake Overview

This section provides an insightful look into a specific type of agricultural equipment designed for efficient grass management. These implements play a crucial role in collecting and preparing forage for drying and baling, ensuring optimal results during the harvesting process.

Key Features

The machinery is equipped with several distinctive elements that enhance its performance. Features such as adjustable working widths allow operators to customize the tool according to field conditions. Additionally, the innovative design ensures even distribution of collected materials, promoting uniform drying and improving forage quality.

Benefits of Usage

Employing this equipment can lead to significant time savings and increased productivity on the farm. Its ability to operate efficiently in various terrains makes it a versatile choice for farmers. Furthermore, the reduction in material damage during collection contributes to better yields, highlighting the importance of this tool in modern agricultural practices.

Understanding Rake Functionality

In the realm of agricultural machinery, efficient collection and arrangement of materials are vital for optimizing productivity. A specific implement designed for this purpose employs rotating mechanisms that enhance the gathering of organic matter, ensuring even distribution and preparation for further processing.

| Component | Function |

|---|---|

| Rotating Arms | Lift and move material from the ground to a desired location. |

| Pivot Mechanism | Allows for flexibility and adaptability to varying terrains. |

| Tines | Engage with the material for efficient gathering and separation. |

| Frame | Provides structural support and stability during operation. |

Understanding the operation of these components helps in maintaining the implement, ensuring optimal performance and longevity in the field.

Main Components of the Rake

Understanding the essential elements of this agricultural implement is crucial for optimal performance and maintenance. Each component plays a significant role in the functionality and efficiency of the machine, contributing to the overall process of collecting and arranging materials effectively.

Frame and Structure

The frame serves as the backbone, providing stability and support. It is designed to withstand various field conditions while ensuring that other elements operate smoothly. A robust structure is vital for durability and longevity.

Gathering Mechanism

This mechanism is responsible for the collection of materials, utilizing rotating arms or similar systems. Efficiency in this area enhances the speed and thoroughness of the gathering process, making it an ultimate component in achieving productivity.

Benefits of Using Kuhn Equipment

Investing in high-quality agricultural machinery can significantly enhance efficiency and productivity on the farm. Superior equipment not only streamlines operations but also ensures reliability and durability, which are essential for successful farming. The advantages of using reputable brands in the industry cannot be overstated.

One of the key benefits is the advanced engineering that often leads to improved performance. Users can expect enhanced functionality, resulting in better crop management and higher yields. Furthermore, many top manufacturers offer excellent customer support, providing assistance and resources that are vital for maintenance and operation.

| Benefit | Description |

|---|---|

| Durability | Robust construction ensures long-lasting use, even in challenging conditions. |

| Efficiency | Designed to optimize tasks, reducing time and effort required for farming activities. |

| Technology Integration | Incorporates modern technology for enhanced functionality and precision. |

| Resale Value | High demand for reliable machinery helps maintain value over time. |

| Support Services | Access to comprehensive customer service and maintenance support. |

Ultimately, choosing machinery from well-known manufacturers provides peace of mind, knowing that the equipment is designed to meet the rigorous demands of agricultural work while delivering consistent results year after year.

Common Maintenance Practices

Regular upkeep is essential for ensuring optimal performance and longevity of agricultural machinery. Adopting a systematic approach to maintenance not only enhances efficiency but also reduces the risk of unexpected breakdowns. Understanding key practices can significantly improve the reliability of your equipment.

Regular Inspections

Conducting frequent assessments allows for early detection of wear and tear. Focus on checking critical components such as belts, bearings, and blades. This proactive strategy can prevent costly repairs and downtime.

Lubrication and Cleaning

Maintaining cleanliness and ensuring proper lubrication are crucial. Regularly grease moving parts to minimize friction and extend the lifespan of components. Additionally, remove debris and dirt to prevent build-up that could hinder functionality.

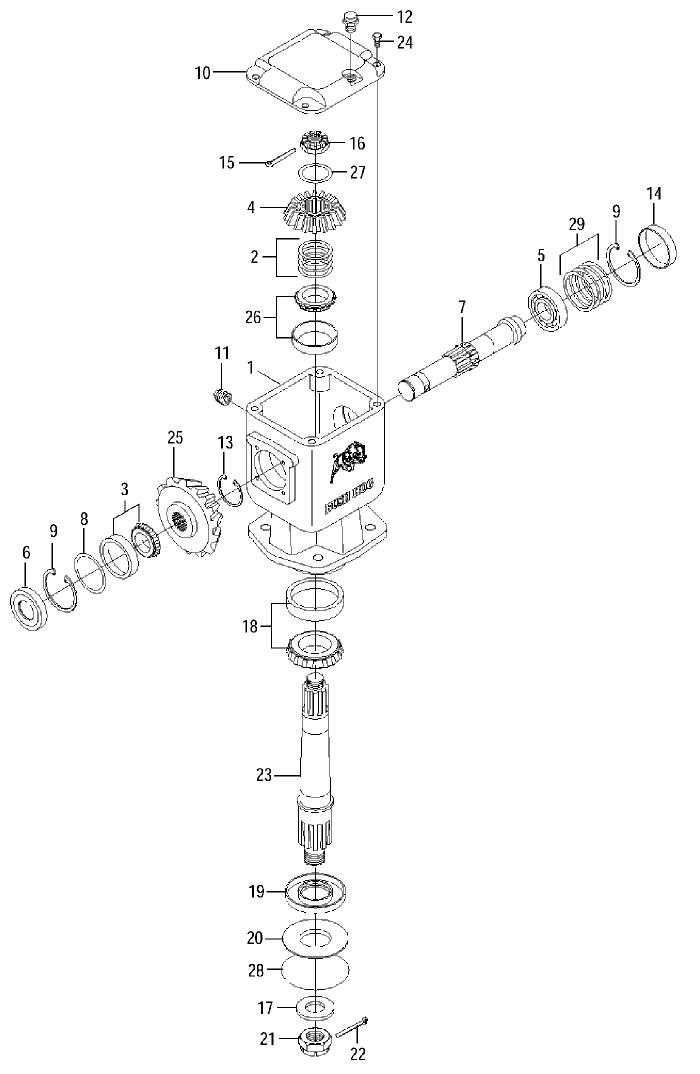

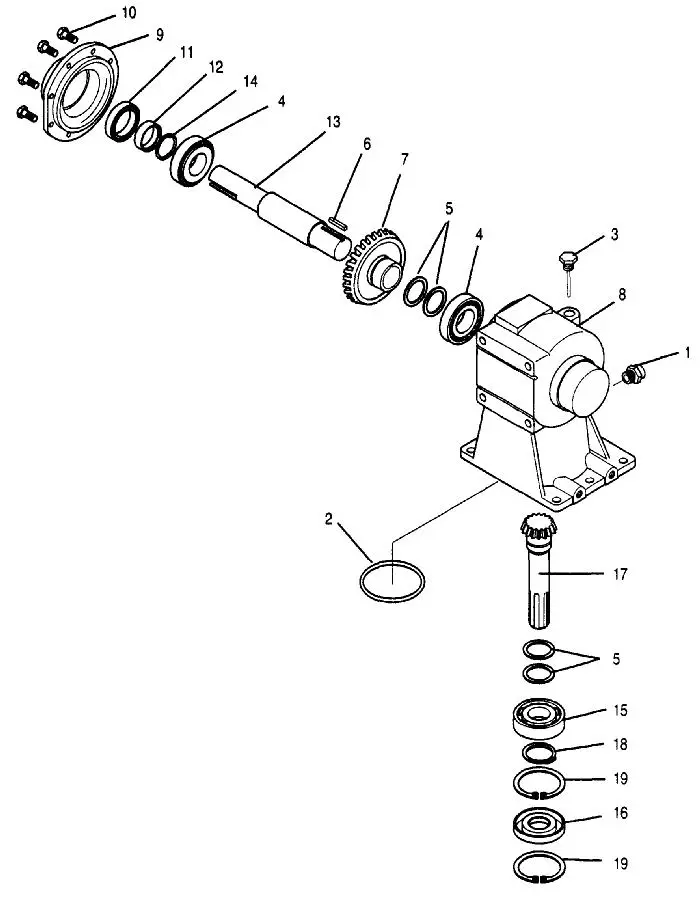

Assembly Instructions for Parts

This section provides essential guidance for the correct assembly of various components in your agricultural machinery. Proper installation ensures optimal performance and longevity of the equipment. Follow these steps carefully to achieve a reliable setup.

Step-by-Step Assembly Process

Begin by organizing all components in a clean, spacious area. Refer to the list of required tools and materials before starting the assembly. Start with the base structure, ensuring all bolts are tightened securely. Gradually add each component, following the recommended sequence to maintain balance and functionality. Regularly check for alignment and adjust as needed.

Final Adjustments and Maintenance

Once all components are assembled, conduct a thorough inspection. Ensure that all moving parts operate smoothly without obstruction. Make any necessary adjustments to achieve the desired performance. Regular maintenance, such as lubrication and tightening of screws, will prolong the lifespan of your equipment and enhance its efficiency.

Identifying Parts in Diagrams

Understanding the components of machinery through visual representations is essential for effective maintenance and operation. Each element within an illustration serves a specific function, contributing to the overall efficiency of the equipment. By recognizing these elements, users can troubleshoot issues and ensure proper assembly.

To accurately identify features, it’s beneficial to familiarize oneself with common terminologies and symbols. Annotations often provide additional context, highlighting the purpose and interconnections of various sections. This knowledge aids in navigating complex schematics and facilitates informed decision-making.

Moreover, taking the time to study these representations can enhance one’s ability to perform repairs and replacements. Clarity in visual aids not only streamlines processes but also minimizes the risk of errors. Ultimately, a comprehensive understanding of these illustrations empowers users to maintain their equipment effectively.

Troubleshooting Common Issues

Addressing typical challenges in agricultural equipment operation can significantly enhance performance and longevity. Identifying symptoms early allows for timely interventions, reducing downtime and ensuring optimal functionality. Here, we explore frequent problems and their potential solutions to streamline maintenance efforts.

One common issue is uneven distribution during operation. This may be caused by improper adjustment of components, leading to inefficiency. Checking and recalibrating settings can restore balance and improve results.

Another frequent concern is unusual noise during use, which often indicates wear or misalignment of parts. Regular inspections and timely replacements can mitigate this problem, preventing further damage.

Lastly, poor soil contact can hinder effectiveness. This may stem from incorrect height settings or blockages. Regular cleaning and height adjustments are essential for maintaining optimal contact with the ground.

Upgrading and Replacing Components

Maintaining optimal performance of agricultural machinery is crucial for efficiency and productivity. Periodically enhancing or substituting specific elements can significantly improve functionality and extend the lifespan of the equipment. This section focuses on key considerations for updating components and ensuring your machinery operates at its best.

When contemplating an upgrade or replacement, it’s essential to assess the wear and tear on individual components. Identifying which parts are underperforming can guide you in making informed decisions. Utilizing high-quality replacements or modernized versions can lead to better operational efficiency and reduced downtime.

| Component | Signs of Wear | Upgrade Options |

|---|---|---|

| Teeth | Cracking, bending, or missing | Enhanced materials for durability |

| Frames | Rust, structural damage | Reinforced designs |

| Wheels | Uneven wear, cracks | Improved tread patterns |

| Drive Mechanism | Noisy operation, slipping | High-efficiency gear replacements |

Regular inspections and timely upgrades not only improve performance but also enhance safety. By investing in quality replacements, operators can achieve a reliable and effective working experience, ultimately maximizing their operational success.