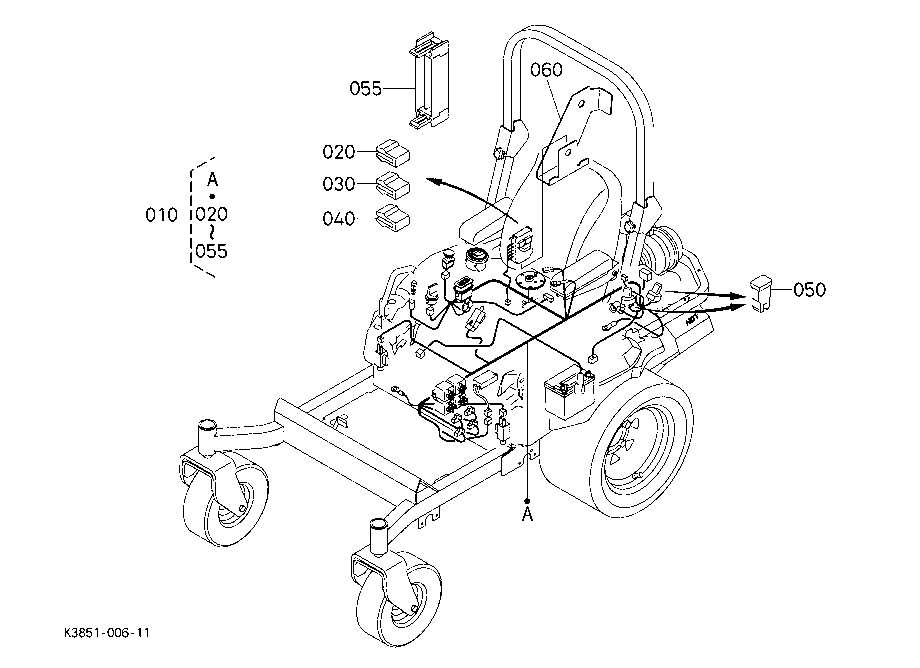

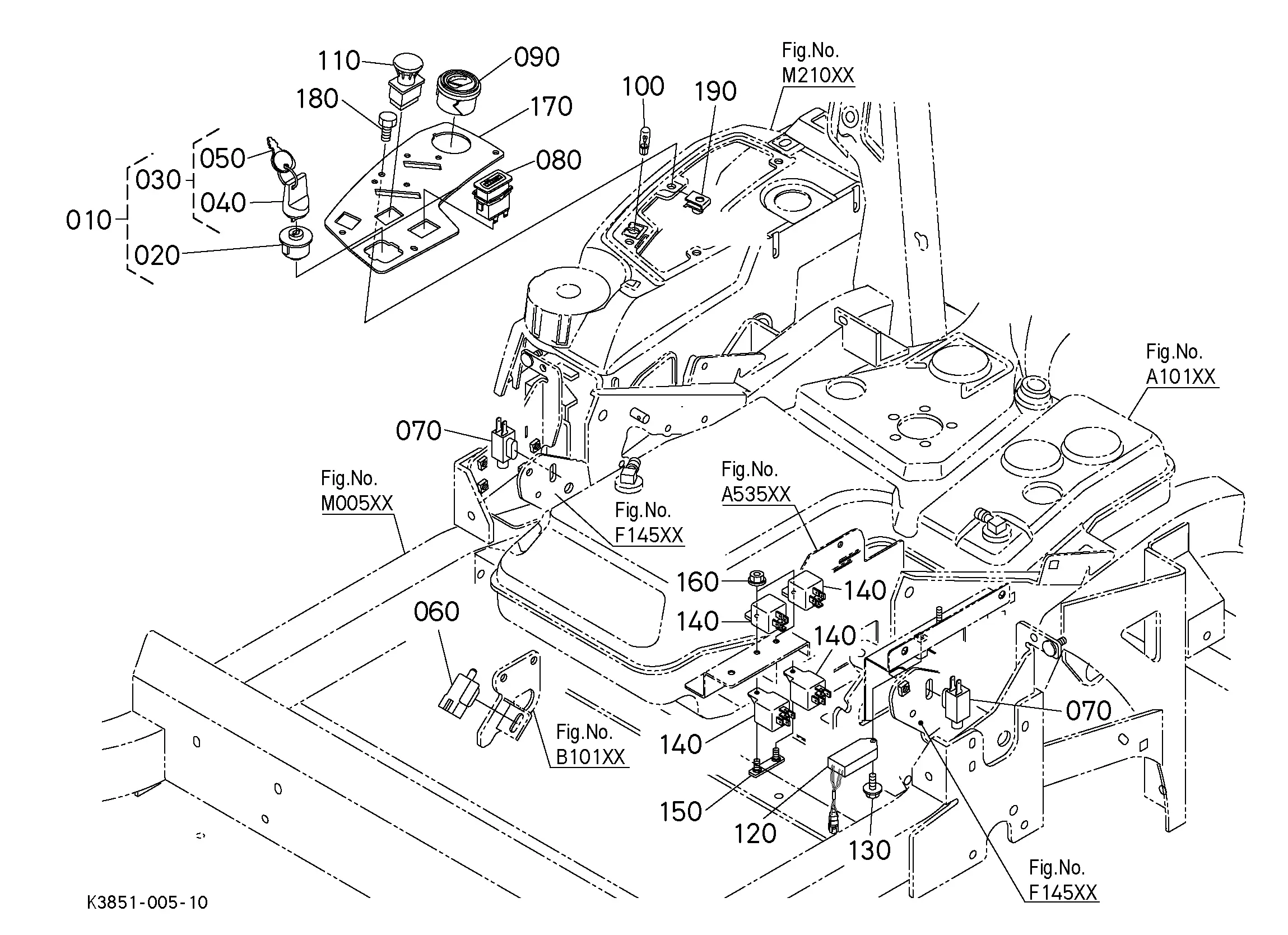

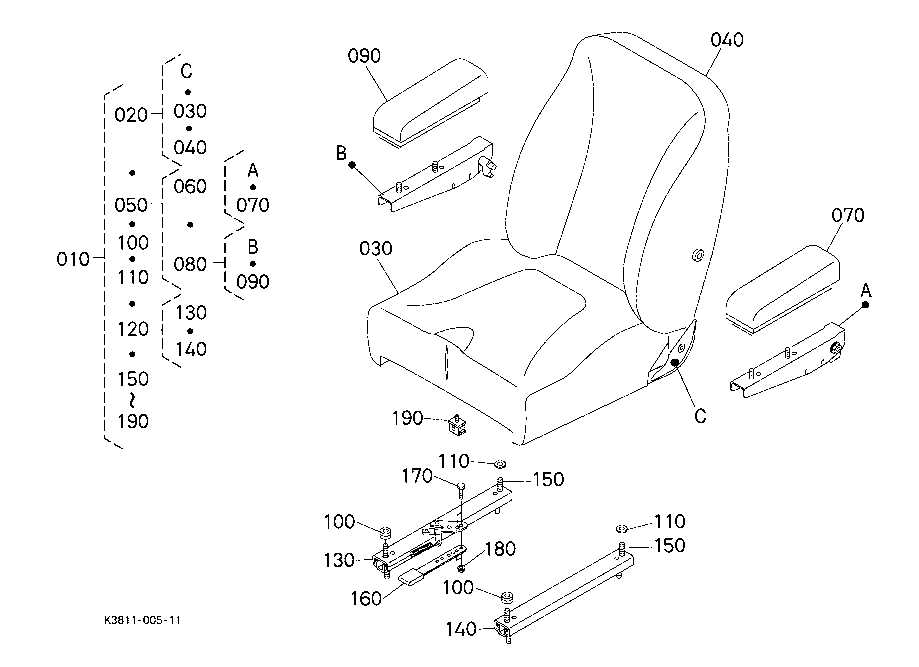

The complexity of machinery often necessitates a comprehensive understanding of their assembly. By examining the various elements that contribute to the overall functionality, operators can better maintain and troubleshoot their equipment. This section focuses on breaking down the intricate interconnections and relationships between different components.

Visual representations serve as invaluable tools for anyone involved in the upkeep of mechanical systems. These illustrations facilitate a clearer understanding of how each part interacts within the whole, ensuring that maintenance tasks can be performed with precision. Being familiar with the layout not only enhances repair efficiency but also promotes a deeper appreciation for the design and engineering behind the machinery.

Equipped with this knowledge, users can confidently approach their maintenance duties, ensuring longevity and optimal performance of their equipment. Whether you’re an experienced technician or a new operator, familiarizing yourself with these schematics is crucial for effective problem-solving and effective operational practices.

Understanding Kubota Z726XKW Components

Exploring the essential elements of a specific outdoor machinery model provides insight into its overall functionality and efficiency. Each component plays a crucial role in ensuring optimal performance and reliability, making it vital for users to familiarize themselves with these integral parts.

Key Features of the Equipment

The following aspects highlight the significance of understanding the main features of the equipment:

- Durability: Components are designed to withstand various environmental conditions, ensuring longevity.

- Efficiency: Each part contributes to the machine’s effectiveness, optimizing fuel consumption and output.

- Maintenance: Familiarity with each element simplifies routine checks and servicing, enhancing operational lifespan.

Common Components and Their Functions

Familiarity with specific parts and their roles enhances the user experience and operational knowledge:

- Engine: Provides power to the entire system, affecting overall performance.

- Transmission: Transmits power from the engine to the wheels, influencing speed and torque.

- Hydraulic System: Enables various functions such as lifting and steering, essential for maneuverability.

- Electrical System: Powers the ignition and controls, ensuring reliable operation.

- Frame: Supports all components, providing structural integrity and stability during operation.

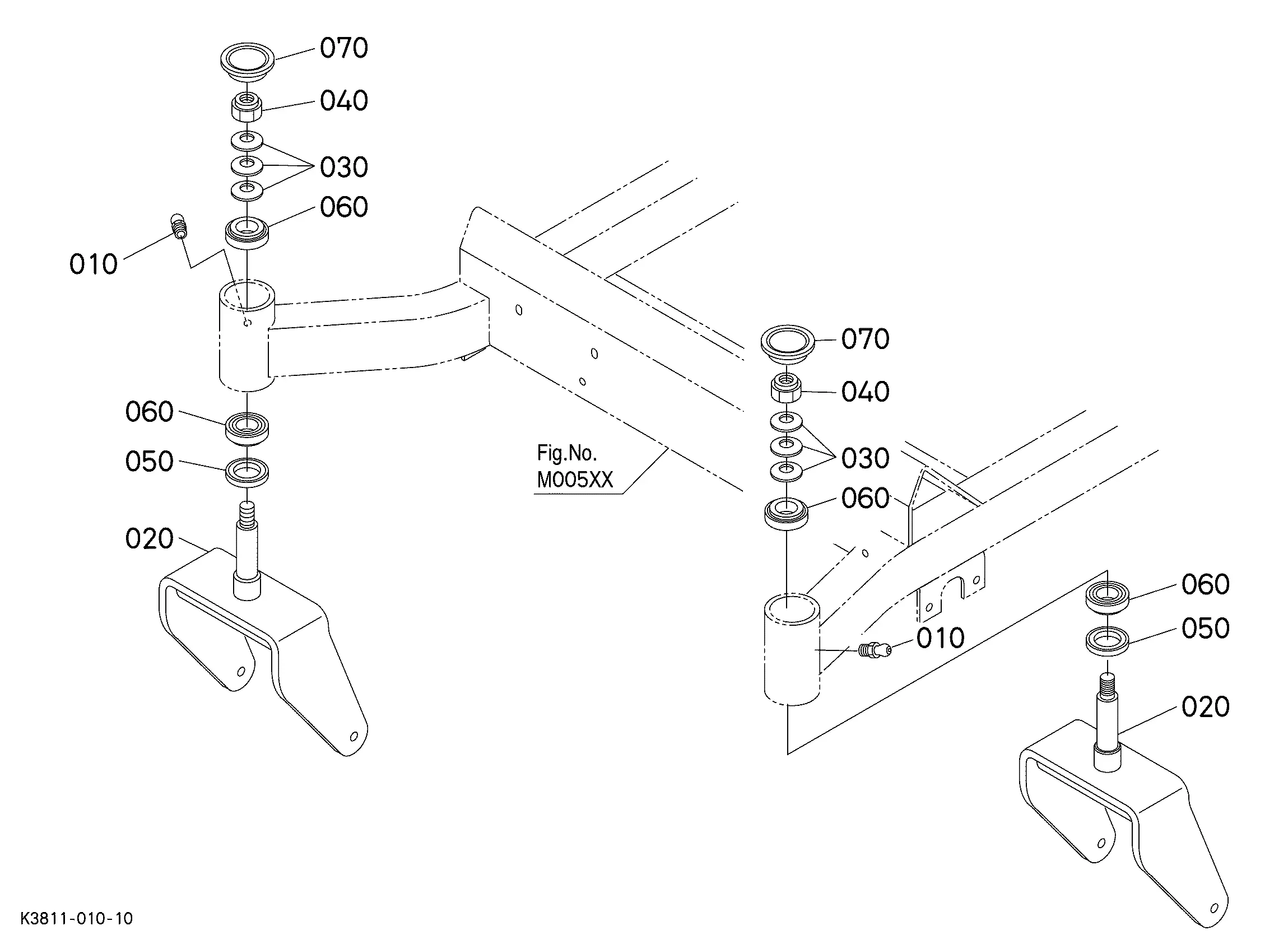

Importance of Parts Diagrams

Understanding the layout and function of various components within machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools that provide insights into the organization and relationships between different elements, making them indispensable for technicians and operators alike.

Enhanced Troubleshooting

Visual guides significantly aid in diagnosing issues. When faced with a malfunction, having a reference that outlines the arrangement of components can streamline the process of identifying the source of the problem. This leads to quicker resolutions and reduced downtime.

Efficient Maintenance Practices

- Facilitates routine checks by providing clear information on each component’s location and function.

- Assists in organizing maintenance schedules by highlighting critical parts that require regular attention.

- Promotes better understanding among team members, fostering collaboration during repairs.

Utilizing visual guides not only simplifies complex tasks but also enhances the overall efficiency of maintenance operations, ensuring machinery remains in optimal condition.

Key Features of Z726XKW Parts

This section highlights the essential attributes and functionalities of the components associated with the model. Understanding these characteristics is crucial for ensuring optimal performance and longevity of the equipment.

Durability and Reliability

One of the primary aspects of these components is their robust construction, which ensures they can withstand rigorous operational conditions. This durability is often enhanced by:

- High-quality materials that resist wear and tear

- Advanced manufacturing techniques that maintain structural integrity

- Extensive testing procedures to verify reliability under various circumstances

Efficiency and Performance

The efficiency of each component plays a significant role in the overall functionality of the machinery. Key performance benefits include:

- Optimized designs that promote seamless integration with other system parts

- Enhanced energy conservation, leading to reduced operational costs

- Improved output and effectiveness in various applications

Identifying Replacement Components

Understanding how to locate suitable substitutes for worn or damaged elements is essential for maintaining the efficiency of your machinery. Proper identification of these components ensures that the equipment operates at its optimal performance, minimizing downtime and enhancing productivity.

To successfully identify replacement components, consider the following steps:

- Consult the manufacturer’s manual to find specific details about each component’s specifications.

- Examine existing elements for part numbers, which can often be found on the surface or attached labels.

- Utilize online resources and forums where fellow users share their experiences and insights regarding compatible components.

- Contact local dealers or authorized service centers for expert advice on suitable replacements.

Additionally, being aware of the functionality and compatibility of each component is crucial. The following aspects can aid in selecting the correct items:

- Material composition: Ensure that the replacement is made of similar or superior materials to guarantee longevity.

- Size and dimensions: Accurate measurements will prevent installation issues.

- Compatibility: Verify that the alternative part is designed to work seamlessly with the existing system.

By following these guidelines, you can efficiently identify and procure the necessary components to keep your equipment running smoothly.

Common Issues and Solutions

Maintaining machinery often involves encountering various challenges that can hinder performance and efficiency. Understanding these common problems and their solutions can significantly enhance operational longevity and reliability. This section provides insights into frequent malfunctions and effective remedies to keep your equipment running smoothly.

Frequent Malfunctions

Several issues can arise during the operation of machinery, leading to decreased functionality. Recognizing these problems early on is crucial for effective troubleshooting. Some prevalent concerns include:

| Issue | Description | Solution |

|---|---|---|

| Engine Overheating | Excessive heat can cause damage to engine components. | Ensure proper coolant levels and check for blockages in the cooling system. |

| Starting Difficulties | Inability to start the engine can stem from battery or fuel issues. | Inspect the battery condition and fuel supply for any obstructions. |

| Unusual Noises | Strange sounds may indicate loose or worn components. | Examine and tighten bolts, and replace any damaged parts as necessary. |

| Poor Performance | Loss of power can be attributed to air or fuel filter issues. | Clean or replace filters to restore optimal engine function. |

Preventive Measures

Implementing regular maintenance practices can help minimize the occurrence of these issues. Routine checks, timely replacements of worn-out components, and keeping detailed records of any repairs or modifications can ensure a smoother operation. Prioritizing preventative care is essential for maximizing the lifespan of your equipment.

Where to Find Genuine Parts

Locating authentic components for your machinery is crucial for ensuring optimal performance and longevity. High-quality replacements not only enhance functionality but also maintain the integrity of the equipment. Here are some reliable sources to consider when searching for these essential items.

- Authorized Dealers: Visiting authorized distributors is one of the best ways to acquire genuine replacements. They typically offer a wide selection of components specifically designed for your equipment.

- Manufacturer’s Website: The official site often features a catalog of available items and may provide an option to order directly online.

- Online Retailers: Several reputable e-commerce platforms specialize in machinery components. Ensure that the seller has a good reputation and positive reviews.

- Local Repair Shops: Many local mechanics or repair shops have access to high-quality components and can often source genuine items for you.

- Trade Shows and Expos: Attending industry events can connect you with suppliers and manufacturers, providing opportunities to purchase authentic items directly.

Using these avenues, you can confidently find genuine components that will meet your equipment’s needs while ensuring reliable performance.

Maintenance Tips for Longevity

To ensure the durability and optimal performance of your equipment, regular upkeep is essential. Implementing a systematic maintenance routine not only enhances efficiency but also prolongs the lifespan of your machinery. Below are key practices to consider for maintaining your machine effectively.

Routine Inspections

- Conduct frequent checks on fluid levels, including oil, coolant, and hydraulic fluids.

- Examine belts and hoses for wear and tear, replacing them as necessary.

- Inspect filters and clean or replace them to maintain proper airflow and fluid flow.

Cleaning and Care

- Keep the exterior clean to prevent rust and corrosion.

- Remove debris and dirt from vents and grilles to ensure adequate cooling.

- Schedule regular washdowns to avoid the buildup of grime and contaminants.

By adhering to these maintenance suggestions, you can significantly enhance the reliability and lifespan of your machinery, ensuring it operates smoothly for years to come.

Upgrading and Modifying Components

Enhancing and adjusting elements of your machinery can significantly improve its performance and longevity. By carefully selecting upgrades and modifications, users can tailor their equipment to meet specific operational needs and preferences. Whether aiming for increased efficiency or enhanced functionality, understanding the available options is essential.

When considering upgrades, it is crucial to evaluate the following aspects:

- Compatibility: Ensure that any new components are compatible with the existing system to avoid issues during installation.

- Performance Improvements: Research modifications that enhance power output, efficiency, or handling.

- Cost vs. Benefit: Analyze the costs associated with upgrades against the potential benefits to determine if the investment is worthwhile.

Common modifications include:

- Engine Enhancements: Upgrading the engine components, such as air filters or exhaust systems, can lead to improved performance and fuel efficiency.

- Hydraulic System Adjustments: Modifying the hydraulic components may enhance lifting capabilities and responsiveness.

- Attachment Options: Adding specialized attachments can broaden the functionality of your equipment for various tasks.

Careful planning and execution of upgrades can result in a more robust and versatile machine, tailored to meet the demands of any project.

Resources for Further Information

For those seeking comprehensive knowledge and support related to machinery components and maintenance, a variety of resources are available. These materials can greatly assist in understanding the intricacies of equipment, ensuring optimal performance and longevity.

Online Forums and Communities

Engaging with online forums dedicated to machinery enthusiasts can provide valuable insights and real-world experiences. Participants often share tips, troubleshooting advice, and recommendations for reliable suppliers, fostering a collaborative environment for knowledge exchange.

Manufacturer Websites and Manuals

Visiting official websites of manufacturers is crucial for obtaining accurate specifications and service manuals. These resources typically include detailed information about assembly, maintenance procedures, and parts lists, serving as essential tools for owners and operators.