The intricate design of small-scale equipment plays a crucial role in enhancing operational efficiency. A comprehensive examination of these machines reveals the interconnectedness of various components, each contributing to overall functionality. Recognizing how these elements interact can significantly aid in maintenance and troubleshooting efforts.

When delving into the structural layout of such machinery, one uncovers a wealth of information regarding its configuration. An organized visual representation can serve as a valuable reference for anyone seeking to understand the relationships between different parts. This understanding is essential for both novice operators and seasoned technicians alike.

Moreover, familiarity with the specific arrangement of each element allows for more effective repairs and upgrades. By comprehending the layout, users can ensure that their equipment remains in optimal working condition, thus maximizing productivity and minimizing downtime. Ultimately, a clear visualization of the assembly empowers individuals to take charge of their machinery with confidence.

Understanding the Kubota Z121S

This section aims to provide a comprehensive overview of a popular compact machine designed for various tasks in landscaping and agriculture. Known for its reliability and efficiency, this model is favored by both professionals and homeowners for its robust features and user-friendly design.

Key Features

One of the standout characteristics of this model is its powerful engine, which ensures consistent performance across diverse terrains. The ergonomic controls allow for easy operation, making it accessible for users of all skill levels. Additionally, its compact size enables maneuverability in tight spaces, enhancing productivity during work.

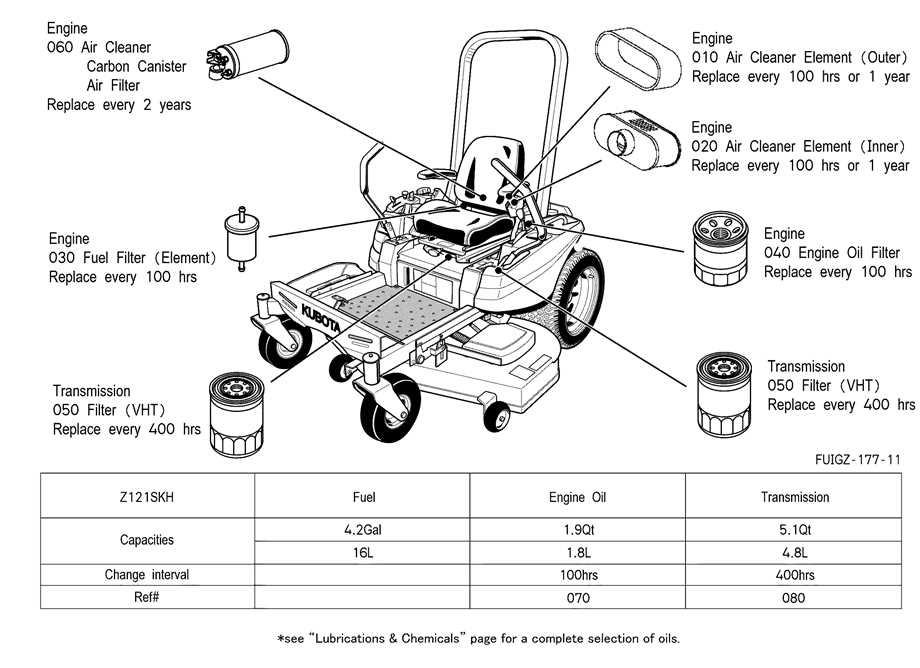

Maintenance and Care

Regular upkeep is essential to prolong the life of this equipment. Routine checks on fluid levels, filters, and belts can prevent major issues and ensure optimal functioning. Utilizing high-quality components during repairs can significantly enhance durability and performance. Understanding the layout and function of various components can aid in effective maintenance.

Importance of Parts Diagrams

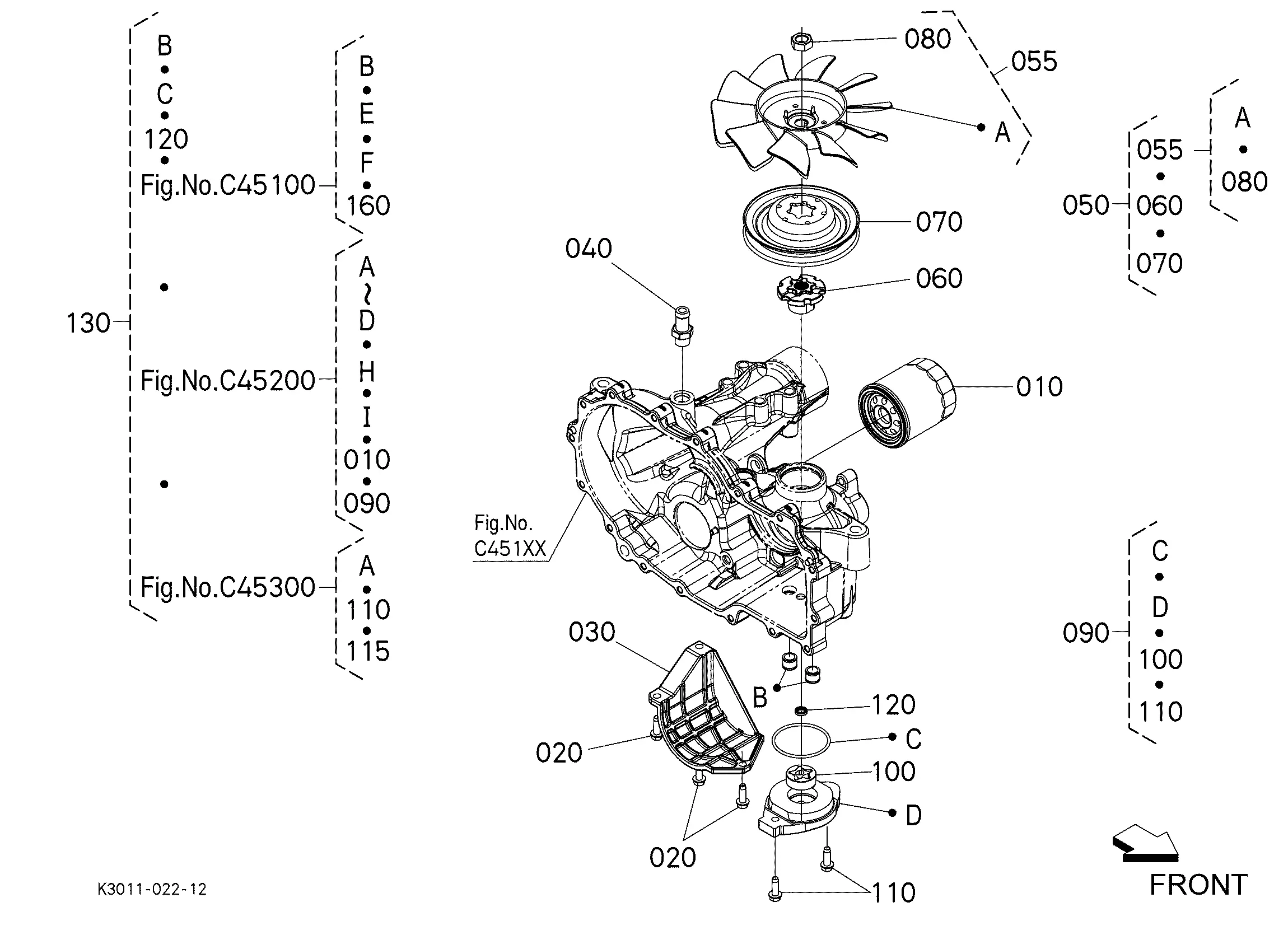

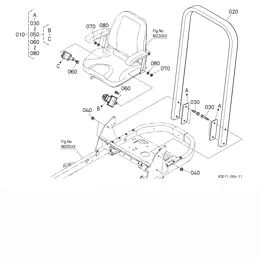

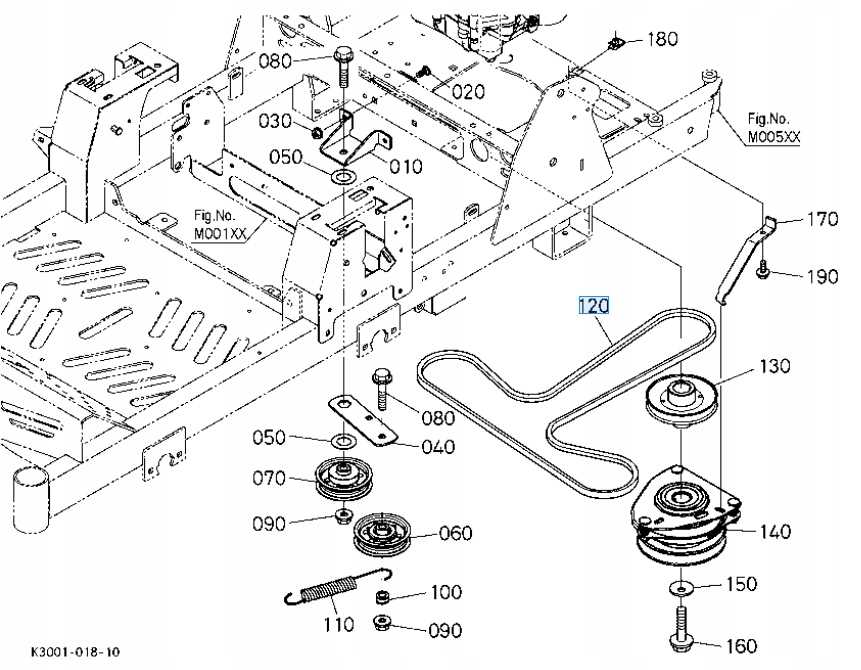

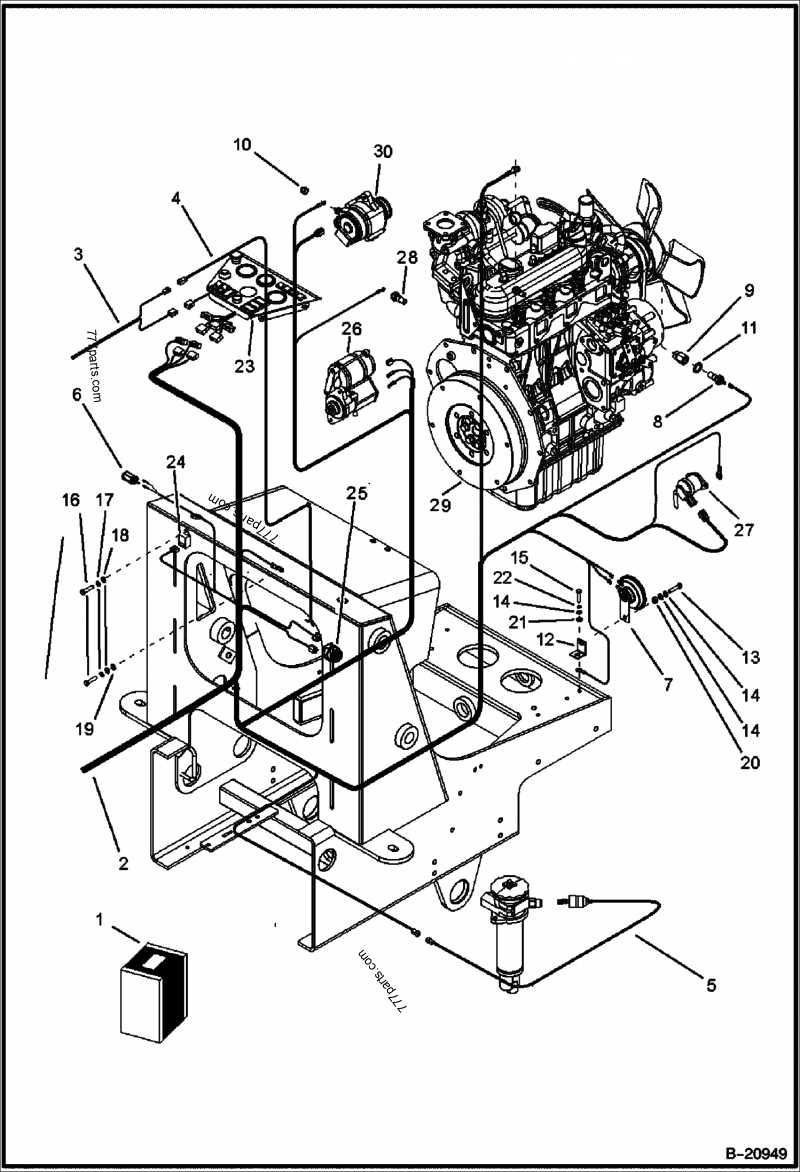

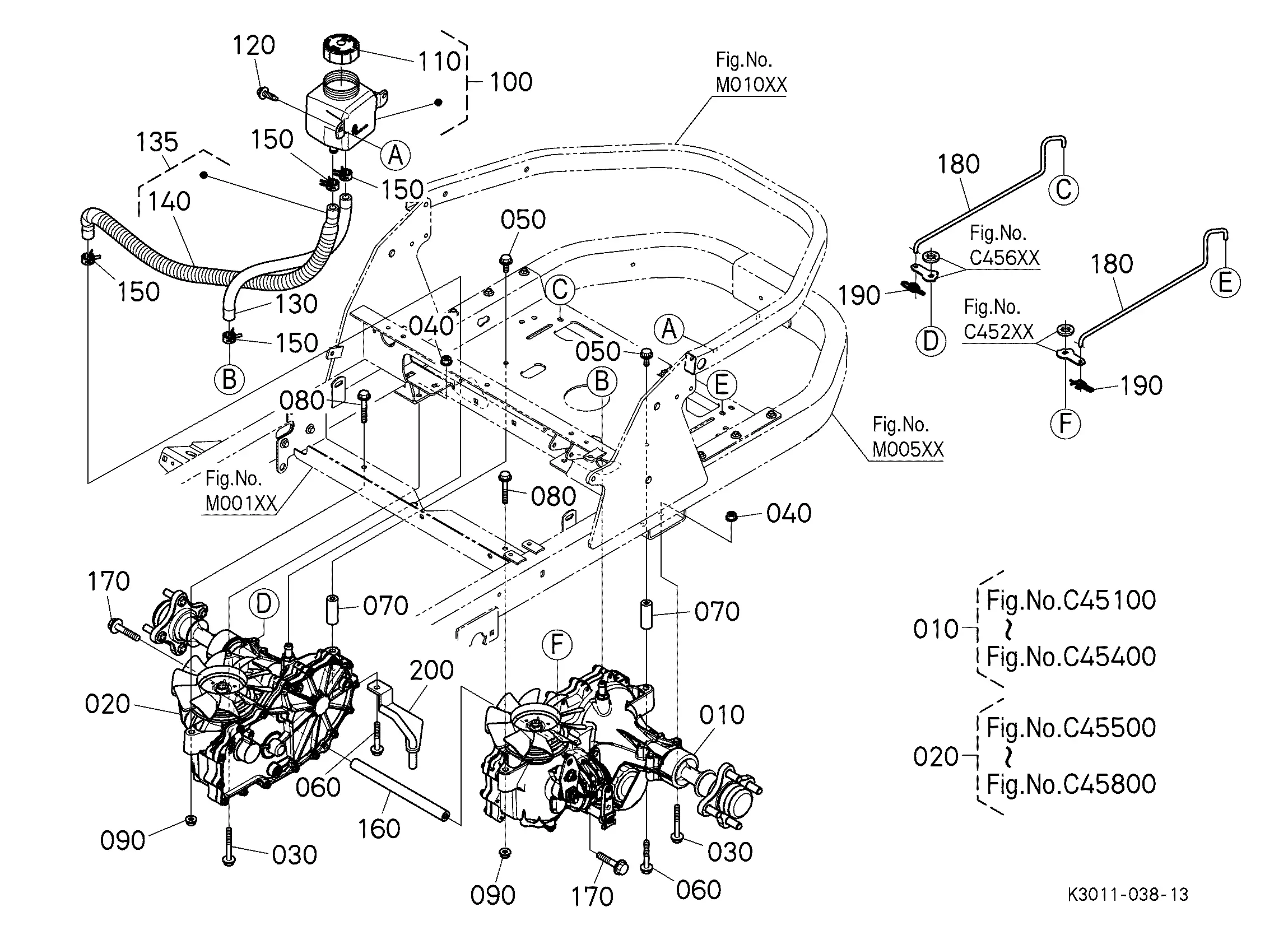

Visual representations of components play a crucial role in understanding machinery. These illustrations provide an accessible way to identify individual elements, facilitating efficient maintenance and repair processes. By breaking down complex systems into understandable segments, users can enhance their knowledge and confidence when working with equipment.

Enhanced Understanding

Utilizing graphical representations aids in grasping how various pieces fit together and function. This clarity can lead to:

- Improved troubleshooting skills

- Better planning for repairs

- Increased efficiency in identifying needed replacements

Streamlined Maintenance Processes

Having access to detailed visuals simplifies regular upkeep and repairs. Key benefits include:

- Faster identification of worn or damaged components

- Reduction in errors during reassembly

- Clear guidance for proper installation of new parts

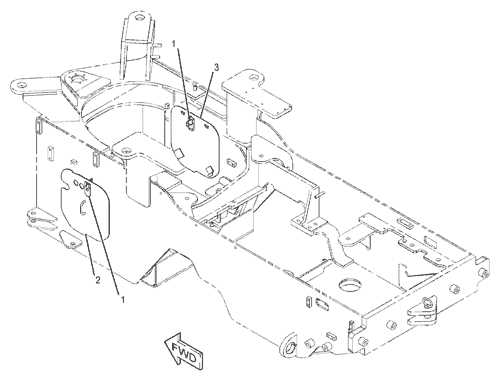

Key Components of Z121S Model

The Z121S model features several vital elements that contribute to its functionality and efficiency. Understanding these components helps users appreciate the design and performance of the machine, ensuring optimal operation and maintenance.

| Component | Description |

|---|---|

| Engine | A powerful unit that provides the necessary horsepower for demanding tasks. |

| Transmission | Facilitates smooth gear shifting, enhancing maneuverability and control. |

| Hydraulic System | Enables efficient operation of attachments and implements through fluid power. |

| Chassis | Robust framework that supports all other components and ensures stability. |

| Wheels | Designed for optimal traction and mobility across various terrains. |

How to Read Parts Diagrams

Understanding visual representations of components is essential for efficient maintenance and repair. These illustrations serve as a guide, helping you identify each piece and its placement within the assembly. By mastering the interpretation of these images, you can streamline your repair processes and ensure accuracy in ordering replacements.

Familiarizing Yourself with the Layout

Each illustration typically features a systematic arrangement of components, often grouped by functionality. Take note of the key or legend, which explains the symbols and lines used. Familiarizing yourself with this layout is crucial, as it allows you to quickly locate specific elements and understand their relationships to one another.

Identifying Component Numbers and Descriptions

Most visual aids include numbered references that correspond to detailed descriptions in accompanying documentation. Pay close attention to these references, as they provide essential information about specifications, materials, and compatibility. Utilizing both the visual and textual information will enhance your comprehension and enable more effective troubleshooting.

Common Issues with Z121S Parts

When operating machinery, several components may present challenges that can affect overall performance. Understanding these common complications is essential for maintaining efficiency and prolonging the lifespan of the equipment. Recognizing potential failures allows for timely interventions, minimizing downtime and repair costs.

Wear and Tear: Over time, certain elements may experience significant degradation due to regular use. This can lead to reduced functionality, making it vital to regularly inspect these items and replace them as necessary.

Alignment Problems: Misalignment among components can result in uneven wear and increased strain. Ensuring proper alignment during assembly or maintenance can mitigate these issues and enhance operational reliability.

Fluid Leaks: Seals and gaskets may fail, leading to fluid leaks that compromise system efficiency. Regular checks for leaks can prevent major malfunctions and maintain optimal performance.

Electrical Failures: Wiring and connectors are susceptible to damage from exposure to harsh conditions. Routine inspections can help identify frayed wires or loose connections, reducing the risk of electrical malfunctions.

Debris Accumulation: Accumulation of dirt and debris can hinder performance and lead to overheating. Keeping the area clean and conducting periodic maintenance can prevent these complications and ensure smooth operation.

By being aware of these common issues, operators can take proactive steps to maintain their equipment, ensuring longevity and reliability in various conditions.

Where to Find Replacement Parts

When it comes to maintaining your machinery, sourcing high-quality components is essential for ensuring optimal performance. Identifying reliable suppliers can save you time and money, and keep your equipment running smoothly. Here are some effective avenues to explore for obtaining the necessary items.

Authorized Dealers

One of the most dependable options is to visit authorized distributors. They provide genuine components that meet the manufacturer’s specifications, ensuring compatibility and durability. Additionally, these dealers often offer valuable insights and support, helping you make informed decisions.

Online Marketplaces

The internet has revolutionized how we shop for replacement components. Various platforms allow users to browse a vast selection of items from multiple sellers. Make sure to check customer reviews and ratings to gauge the reliability of the products and the sellers.

| Source Type | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Genuine quality, expert advice | Potentially higher prices |

| Online Marketplaces | Wide selection, competitive prices | Varied quality, seller reliability |

| Local Retailers | Immediate availability, personal service | Limited selection, variable pricing |

| Second-Hand Options | Cost-effective, unique finds | Quality uncertainty, limited warranties |

Maintenance Tips for Z121S Owners

Proper upkeep is essential for ensuring the longevity and performance of your machine. Regular maintenance can prevent costly repairs and enhance efficiency, allowing you to tackle tasks with confidence.

Routine Inspections

Conduct regular checks on fluid levels, filters, and belts to identify any potential issues early. Maintaining a schedule for these inspections will help keep your equipment in optimal condition.

Cleaning and Care

Regular cleaning is vital. Remove dirt and debris from the exterior and check for clogs in cooling systems. A clean machine not only performs better but also has a longer lifespan.

| Task | Frequency |

|---|---|

| Check Oil Levels | Weekly |

| Inspect Filters | Monthly |

| Clean Cooling System | Every 100 Hours |

| Sharpen Blades | Every Season |

Comparing Z121S with Other Models

When evaluating different compact machinery options, it’s essential to analyze the features and performance of various models within the same category. Each machine offers unique advantages and functionalities that cater to specific tasks and user preferences. By understanding these distinctions, potential buyers can make informed decisions that best suit their needs.

The subject machine stands out with its exceptional maneuverability and efficiency, making it ideal for small to medium-sized properties. However, other comparable models might provide enhanced power or specialized attachments that could appeal to users with different requirements. For instance, some alternatives may prioritize fuel efficiency or have a greater range of implement compatibility, allowing for a wider array of applications.

Moreover, assessing the weight and dimensions can reveal significant differences in handling and transportability. Some models may be more compact, while others offer a larger footprint for stability and traction in various terrains. Understanding these physical characteristics can guide users toward a machine that aligns with their operational environment.

Ultimately, the choice among these machines depends on individual use cases, from residential landscaping to commercial applications. By closely comparing these options, operators can identify which unit will deliver the best performance and value for their specific tasks.

Resources for Technical Support

Accessing reliable resources for assistance is crucial when dealing with machinery and equipment. Various platforms offer detailed information and expert guidance, ensuring users can effectively troubleshoot and maintain their devices. Whether you’re looking for manuals, video tutorials, or forums, having the right resources at your fingertips enhances your understanding and efficiency.

| Resource Type | Description | Link |

|---|---|---|

| Official Manuals | Comprehensive guides for operation and maintenance. | Visit |

| Online Forums | Communities where users share tips and experiences. | Visit |

| Video Tutorials | Step-by-step visual guides for repairs and usage. | Visit |

| Technical Support Contacts | Direct assistance from professionals. | Visit |