When working with agricultural machinery, knowing the internal structure and arrangement of its various parts is crucial for efficient maintenance and repair. Detailed illustrations that outline the specific positioning and function of each component can greatly aid in identifying potential issues and making the right fixes. This resource serves as a guide to understanding the complex interplay of mechanical systems, highlighting key areas that need attention for optimal performance.

By exploring a detailed representation of all major sections, users can easily recognize where specific components are located and how they interconnect. Whether you are troubleshooting a mechanical fault or performing routine maintenance, having access to clear, organized layouts can simplify the process. Knowing exactly what each part does and how it fits within the whole structure ensures that any adjustments or replacements can be carried out accurately and efficiently.

Maintaining your machinery’s peak performance involves more than just routine checks. It requires a deep understanding of how each element works in harmony. In the following sections, we’ll break down how to interpret these detailed technical charts, enabling you to gain better insight into the maintenance and repair processes of your equipment.

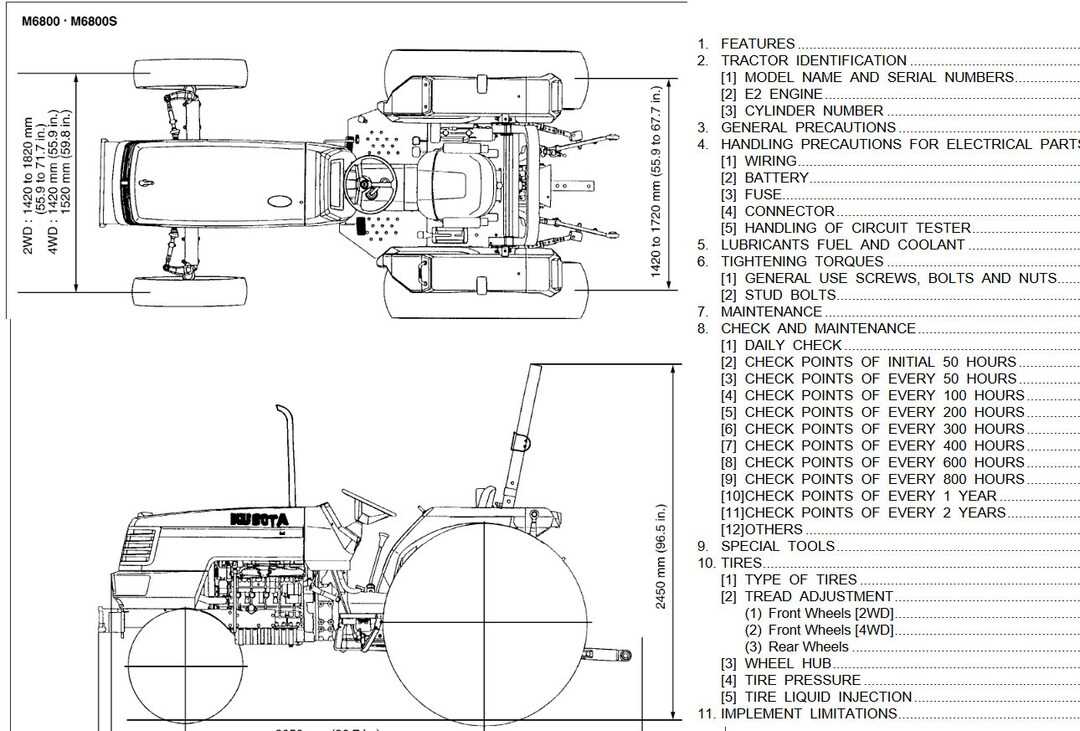

Understanding Kubota M6800 Parts

When maintaining or repairing agricultural machinery, it’s essential to understand the components that make up the equipment. Each piece plays a crucial role in the overall function and performance. Knowing the structure and layout of these elements can simplify troubleshooting and ensure smooth operation for extended periods. Proper identification of every part allows for quicker diagnostics, better maintenance, and less downtime.

The machine consists of various sections, including the engine, transmission, hydraulic system, and electrical components, each requiring different care and attention. Recognizing how these parts interact and contribute to the machine’s efficiency will help operators manage their equipment more effectively. Whether it’s routine servicing or addressing a malfunction, being familiar with the overall construction and specific components is invaluable.

For effective repairs, it’s beneficial to refer to a visual guide that highlights the key elements and their locations. This can provide clarity when sourcing replacements or when performing routine checks. Understanding the layout of your machinery and its interdependent systems can significantly reduce the time spent on repairs and improve the longevity of the equipment.

Importance of Parts Diagrams

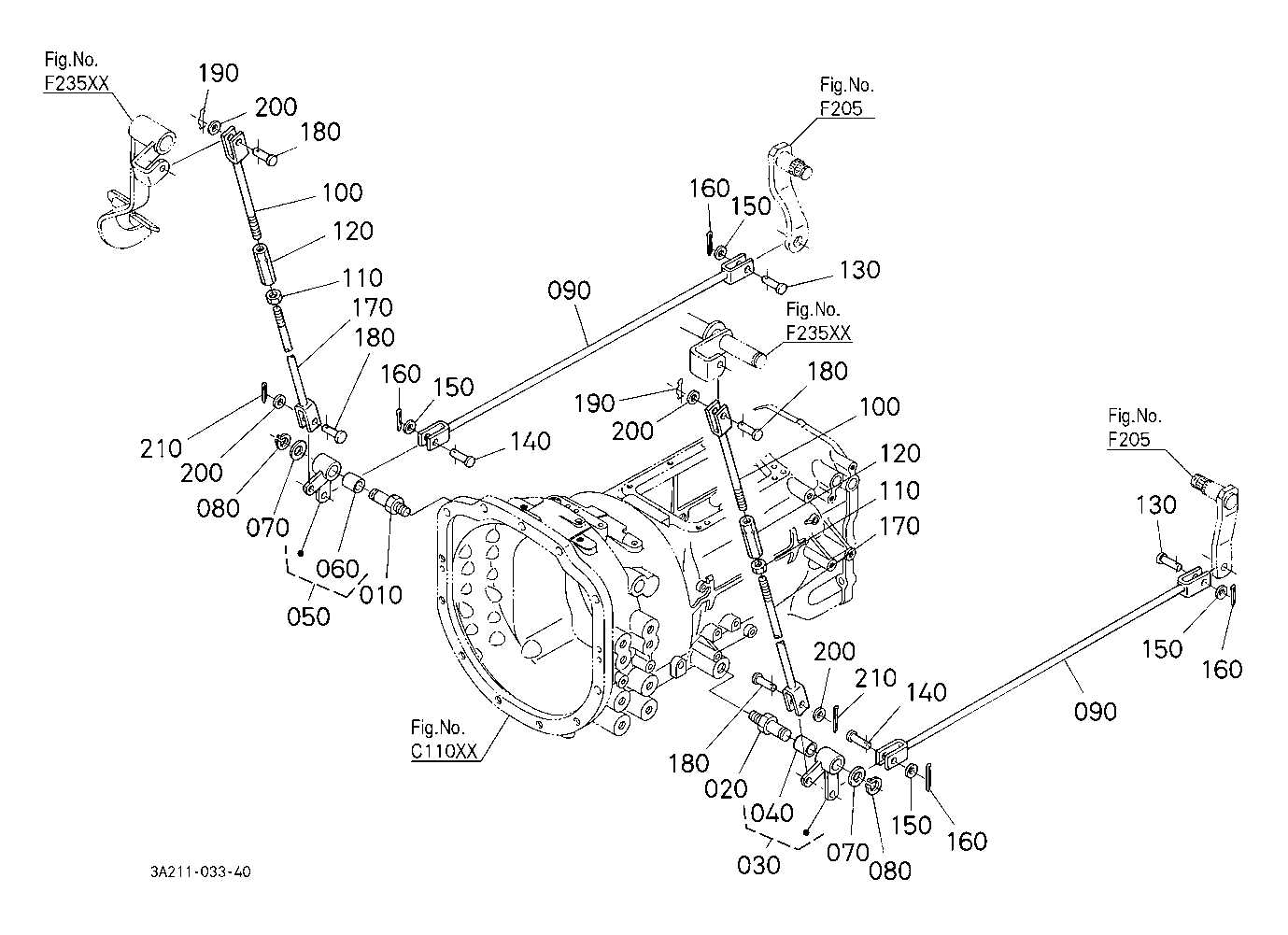

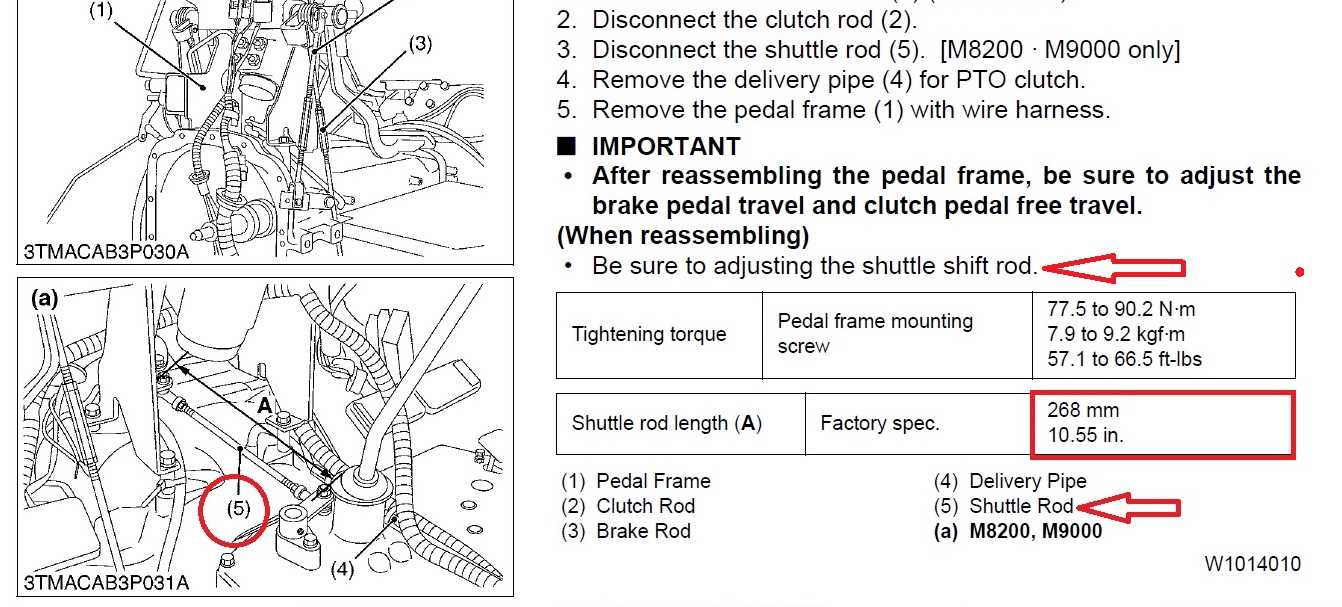

When maintaining or repairing machinery, having a clear visual reference of its components is essential. These references provide a detailed representation of how different elements fit together, ensuring that each part is properly understood and installed. This becomes especially crucial when dealing with complex systems, as it minimizes errors and saves time during the process of assembly or disassembly.

Enhanced Understanding of Component Layout

Visual guides allow users to quickly identify individual parts and their placement within a larger system. With a well-structured illustration, even the most intricate designs can be understood with ease. This makes it easier to diagnose issues and determine what needs to be replaced or repaired. Without such visual references, identifying problems can become time-consuming and error-prone.

Efficient Repair and Maintenance

Having access to a precise visual representation can streamline repair and maintenance tasks significantly. By clearly showing how components are interconnected, it reduces the likelihood of mistakes and ensures that work is completed more quickly. Efficiency is key in any repair job, and with accurate guides, the entire process becomes more predictable and straightforward.

Furthermore, these visual tools often include helpful notations and part numbers, which aid in sourcing the correct replacements, reducing the chances of ordering the wrong items. In the long run, these benefits not only save time but also reduce costs related to incorrect repairs or part replacements.

Common Issues with M6800 Components

When dealing with machinery, certain components are more prone to wear and tear, leading to potential malfunctions. Over time, specific parts of equipment may experience issues due to regular use, environmental conditions, or lack of maintenance. Identifying these problems early can help extend the lifespan of the machine and improve overall performance. Below are some common concerns found in mechanical systems and their corresponding elements.

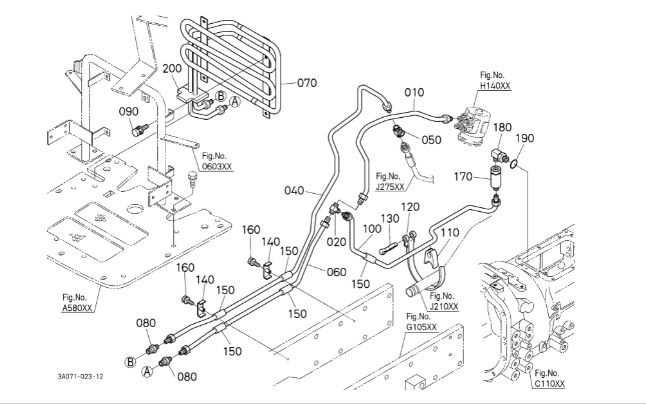

Hydraulic System Failures

The hydraulic system is vital for many operations, and failure in this area can significantly hinder functionality. Common issues include:

- Leaks: Hydraulic fluid leaks can occur in seals or hoses, reducing pressure and causing inefficiency.

- Pump malfunction: Over time, pumps may lose their ability to maintain proper pressure, resulting in sluggish movement or complete failure of hydraulics.

- Contamination: Dirt or debris entering the hydraulic fluid can damage internal components, leading to blockages or corrosion.

Electrical Problems

Electrical systems are another area where issues frequently arise. Common electrical problems include:

- Battery issues: A failing battery may lead to starting problems or power loss during operation.

- Wiring damage: Worn or frayed wires can result in short circuits, malfunctioning lights, or faulty connections.

- Faulty alternator: If the alternator isn’t charging the battery properly, it can cause electrical failures and affect performance.

Where to Find OEM Parts

When looking for high-quality components for machinery, it’s essential to source them from reliable and authorized dealers. Original equipment manufacturers (OEM) offer products designed to meet the exact specifications required for optimal performance. Finding these items ensures that your equipment functions as intended, maintaining efficiency and longevity. There are several trusted sources where you can find authentic parts for your machinery, whether online or locally.

Authorized Dealers and Service Centers

The most reliable way to find genuine replacements is through authorized dealerships and service centers. These locations are directly connected to the manufacturer, ensuring that the parts you purchase are genuine and of the highest quality. Authorized centers often offer expert installation services as well, ensuring that each component is correctly installed and functions properly.

- Local dealerships often have a wide selection of parts in stock.

- Service centers can provide expert advice on which parts are best suited for your machine.

- Most offer warranties for the parts and labor involved in installations.

Online Retailers and Marketplaces

For convenience and sometimes better pricing, many online retailers and marketplaces specialize in OEM products. Reputable websites offer a vast catalog of parts for various models, with detailed specifications and customer reviews to guide your choice. When purchasing online, always verify the authenticity of the seller to avoid counterfeit products.

- Popular platforms such as Amazon and eBay may have listings from trusted sellers.

- Specialized websites for heavy machinery and farming equipment often stock OEM items.

- Look for websites that provide detailed product descriptions and return policies.

Benefits of Using Genuine Parts

Utilizing authentic components ensures optimal performance and longevity for machinery. When owners prioritize these original elements, they experience several key advantages that significantly enhance their operational efficiency.

- Quality Assurance: Genuine items are manufactured to stringent standards, guaranteeing reliability.

- Perfect Fit: Original parts are designed specifically for your equipment, ensuring seamless integration.

- Longevity: Using authentic components can extend the lifespan of your machinery, reducing the frequency of replacements.

- Warranty Protection: Many manufacturers offer better warranty terms when original parts are used, providing peace of mind.

- Resale Value: Equipment maintained with genuine items often retains higher resale value, appealing to potential buyers.

Investing in authentic components ultimately safeguards the performance and durability of your machinery, making it a wise choice for any owner.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of heavy machinery requires consistent care and attention. Regular maintenance not only extends the lifespan of equipment but also enhances performance, reduces downtime, and minimizes repair costs. Implementing a proactive maintenance routine can significantly impact the overall reliability of your machine.

Start with routine inspections to identify wear and tear on critical components. Checking fluid levels regularly, including oil, coolant, and hydraulic fluids, is essential for optimal operation. Clean filters and replace them as needed to maintain proper airflow and prevent clogging.

Pay attention to the operating environment. Keeping the machinery clean from dust and debris can prevent corrosion and other forms of damage. Furthermore, following the manufacturer’s recommended service intervals helps in addressing potential issues before they escalate.

Don’t underestimate the importance of using quality replacement components. Investing in reliable parts will ensure compatibility and performance, contributing to the machine’s longevity. Additionally, maintaining proper storage conditions when the equipment is not in use will protect it from environmental factors that can lead to deterioration.

Lastly, train operators on the best practices for using the machinery. Proper operation techniques can prevent unnecessary stress on parts and improve overall efficiency. By prioritizing maintenance, you can ensure that your machinery serves you well for many years to come.

Popular Upgrades for the M6800

Many owners of heavy-duty agricultural machinery look for ways to enhance performance, improve efficiency, and extend the life of their equipment. Upgrading certain components can significantly increase productivity and make operation smoother. Whether it’s boosting engine power, improving comfort, or enhancing functionality, there are numerous options available for those seeking to optimize their machines.

Engine and Fuel System Upgrades

Upgrading the engine components or fuel system can make a noticeable difference in both power output and fuel efficiency. Popular upgrades include performance-enhancing filters, high-efficiency fuel injectors, and improved exhaust systems that reduce emissions while increasing engine performance. These adjustments can help ensure smoother operation and potentially lower operational costs.

Hydraulic System Enhancements

Hydraulics play a key role in heavy machinery operations. Upgrading to a high-flow hydraulic pump or installing a more powerful hydraulic valve can boost lifting capabilities and improve overall hydraulic response. These improvements are especially beneficial when working with demanding attachments or performing tasks that require high precision.

Transmission and Drivetrain Modifications

Improving the transmission system can result in smoother shifts and more responsive control. Many operators opt for upgraded gear systems or better-quality drive shafts to handle tougher conditions. Enhanced drivetrain components reduce wear and tear, contributing to longer machine life and reduced maintenance requirements.

Cab and Comfort Upgrades

Increasing comfort for the operator is crucial for long hours of work. Installing ergonomic seats, improved air conditioning systems, and advanced suspension systems can minimize operator fatigue. Adding a high-quality sound system or modern digital displays for better monitoring also makes the cabin more user-friendly.

Wheels and Tires

Tires are a critical factor in determining traction and stability. Upgrading to specialized tires for specific terrain or task requirements can vastly improve performance. Heavy-duty tires designed for high flotation or deep traction are common choices for those working in rough or soft soils.

These popular upgrades not only enhance functionality but also help maintain the long-term value of machinery, ensuring they stay productive for years to come.

How to Read the Parts Diagram

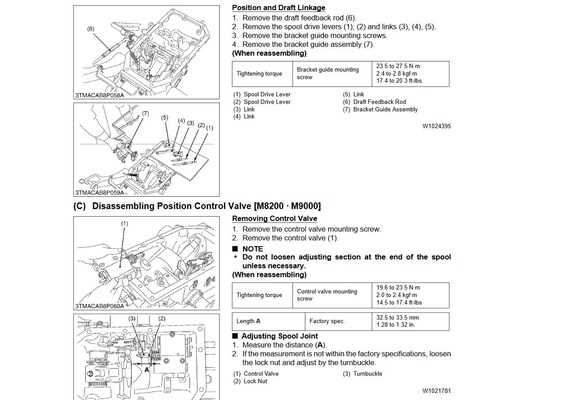

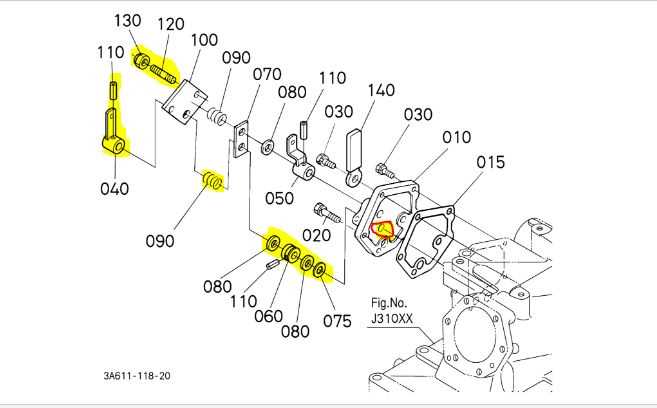

Understanding an assembly chart is essential for effective maintenance and repair tasks. This visual representation provides valuable insights into the various components and their interconnections, enabling users to identify specific items and their placements within the overall structure.

Familiarizing Yourself with the Symbols

The first step in interpreting an assembly chart is to become acquainted with the symbols and notations used. Each icon typically represents a distinct component, while lines or arrows indicate relationships and connections. Pay attention to the legend, which will clarify the meanings behind the symbols, ensuring a smooth reading experience.

Following the Flow of the Assembly

Once you’re comfortable with the symbols, the next step is to trace the flow of the assembly. Start from a defined point, often indicated by a bold line or a specific marker, and follow the connections. This approach helps in understanding how different parts interact and the order of assembly, making it easier to locate replacement components or troubleshoot issues.

Resources for Technical Support

When dealing with machinery and equipment maintenance, having access to reliable technical support resources is essential. Whether you’re looking for troubleshooting assistance, repair guidance, or replacement part details, there are multiple avenues available to ensure smooth operation and resolution of issues. It’s important to understand where to seek the right help and what types of resources are most effective in different situations.

Manufacturer’s Official Website is often the first stop. Most equipment manufacturers provide detailed online resources, including user manuals, FAQs, and troubleshooting guides. These resources can help users understand common issues and their solutions, making it a valuable tool for anyone working with machinery.

Authorized Service Centers offer professional assistance for more complex problems. These centers typically employ certified technicians who are well-trained in diagnosing and repairing specific models. Utilizing their expertise ensures that issues are addressed correctly and efficiently, especially for equipment under warranty.

Online Forums and Communities can be a great source of peer support. Many forums feature discussions on specific equipment models, where users share their experiences, tips, and solutions to common problems. Engaging with a community can provide valuable insights, and sometimes, others may have already encountered and solved the same issue you are facing.

Technical Support Helplines are available for those who prefer direct communication with professionals. Many companies offer phone or email support, where experts guide users through troubleshooting steps or offer advice on parts replacement and maintenance practices.

Instructional Videos and Tutorials found on platforms like YouTube can supplement written resources. These videos often walk users through repairs, part replacements, and maintenance tasks, offering a more visual approach for those who prefer hands-on learning.

Utilizing a combination of these resources can help ensure your equipment operates optimally and any technical challenges are resolved promptly and effectively.