In the realm of agricultural machinery, comprehending the various elements that make up your equipment is crucial for effective maintenance and operation. Each component plays a significant role in ensuring optimal performance, contributing to the overall functionality and reliability of the machine.

When it comes to enhancing efficiency, a clear illustration of the individual elements can be invaluable. Such representations assist in identifying the location and purpose of each segment, making it easier to manage repairs or upgrades as needed.

Whether you’re a seasoned professional or a novice operator, familiarizing yourself with the intricate details of your machinery will empower you to make informed decisions regarding maintenance and repairs. This knowledge not only prolongs the lifespan of the equipment but also enhances productivity in the long run.

When operating heavy machinery, it’s not uncommon to encounter various challenges that may hinder performance. Understanding these issues can help in identifying the necessary components for repair or replacement, ensuring smooth operation and longevity of the equipment.

Some frequent challenges include:

- Engine overheating due to cooling system failures.

- Hydraulic leaks affecting functionality and efficiency.

- Electrical malfunctions leading to operational disruptions.

- Wear and tear on tires or tracks resulting in decreased traction.

- Fuel system problems causing poor performance.

To address these issues, it’s essential to recognize which components may require replacement. Here are some common components that might need attention:

- Cooling fan or radiator for overheating issues.

- Seals and hoses for hydraulic leaks.

- Fuses and wiring harnesses for electrical problems.

- Tires or tracks for wear and grip enhancement.

- Fuel filters and injectors for optimizing performance.

Regular maintenance and timely replacements of these components can significantly reduce downtime and enhance the efficiency of the machine.

Maintenance Tips for Long-lasting Performance

Regular upkeep is essential for ensuring optimal functionality and extending the lifespan of your machinery. Adopting a consistent maintenance routine not only enhances performance but also minimizes the risk of unexpected breakdowns.

Perform Routine Inspections: Regularly check all components for signs of wear and tear. This includes examining belts, hoses, and fluids to ensure everything is in proper working order. Addressing minor issues promptly can prevent larger problems down the line.

Keep It Clean: Dirt and debris can accumulate in various parts of the equipment, leading to overheating and inefficient operation. Regular cleaning of filters, air intakes, and surfaces helps maintain airflow and cooling efficiency.

Follow Manufacturer Guidelines: Adhere to the recommended service intervals and procedures outlined in the user manual. These guidelines are designed to ensure that all critical systems receive appropriate attention and care.

Use Quality Replacement Parts: When replacements are necessary, opt for high-quality components that meet the manufacturer’s specifications. Using substandard parts can compromise performance and lead to further damage.

Store Properly: If the machinery is not in use for an extended period, store it in a dry, sheltered location to protect it from the elements. Additionally, consider draining fluids to prevent corrosion and degradation.

Implementing these practices will contribute to the longevity and reliability of your equipment, ensuring it performs efficiently for years to come.

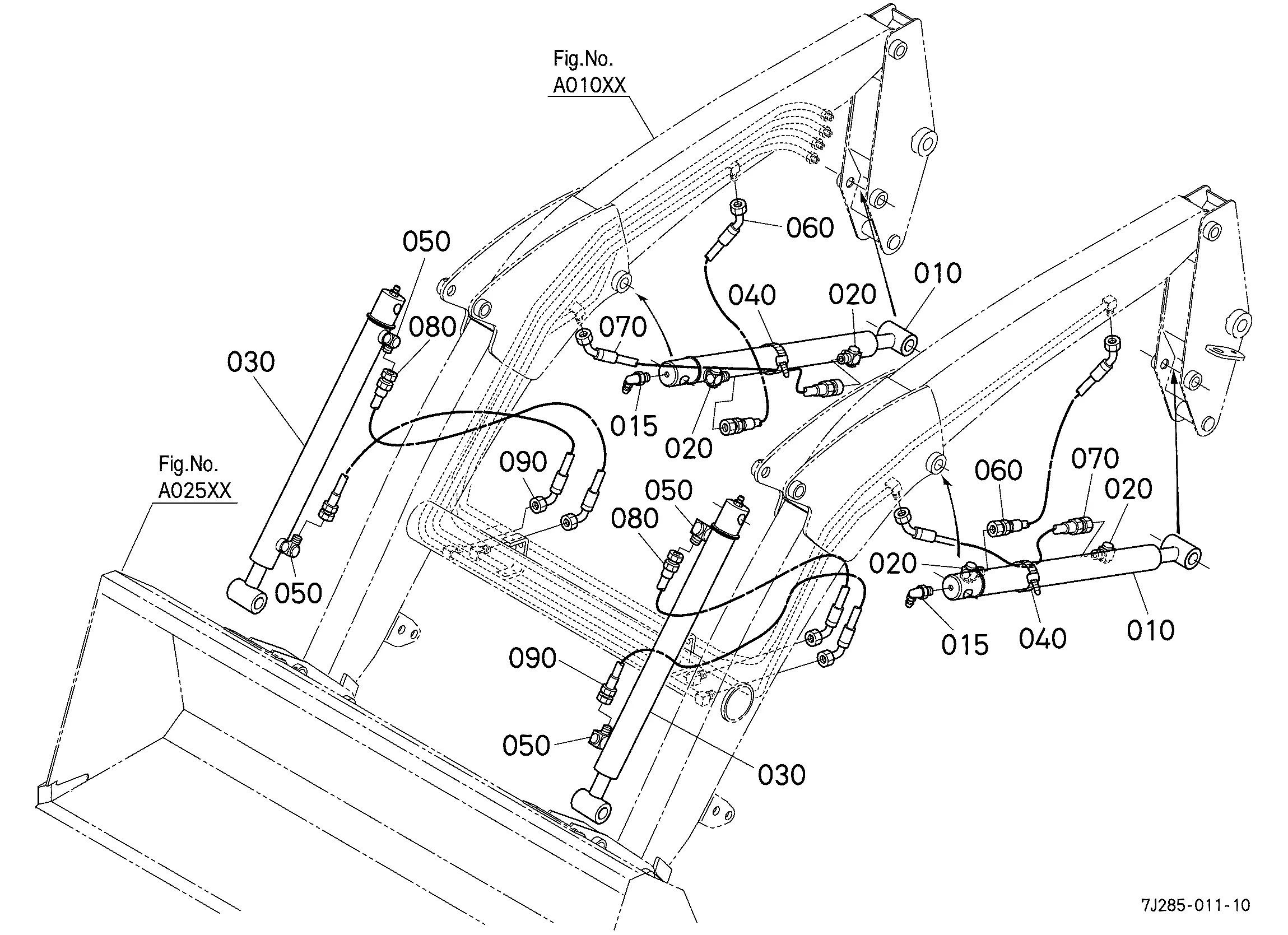

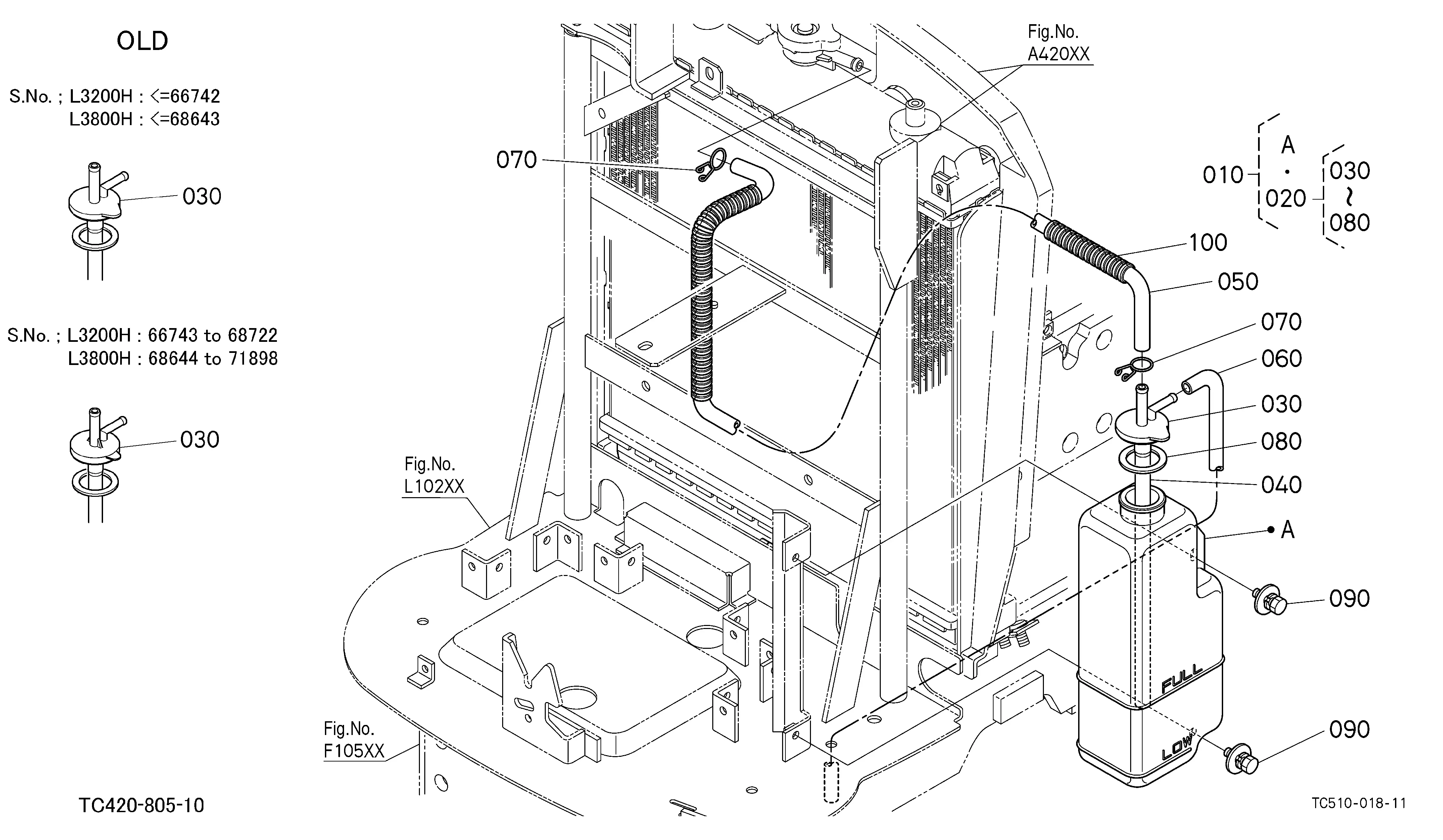

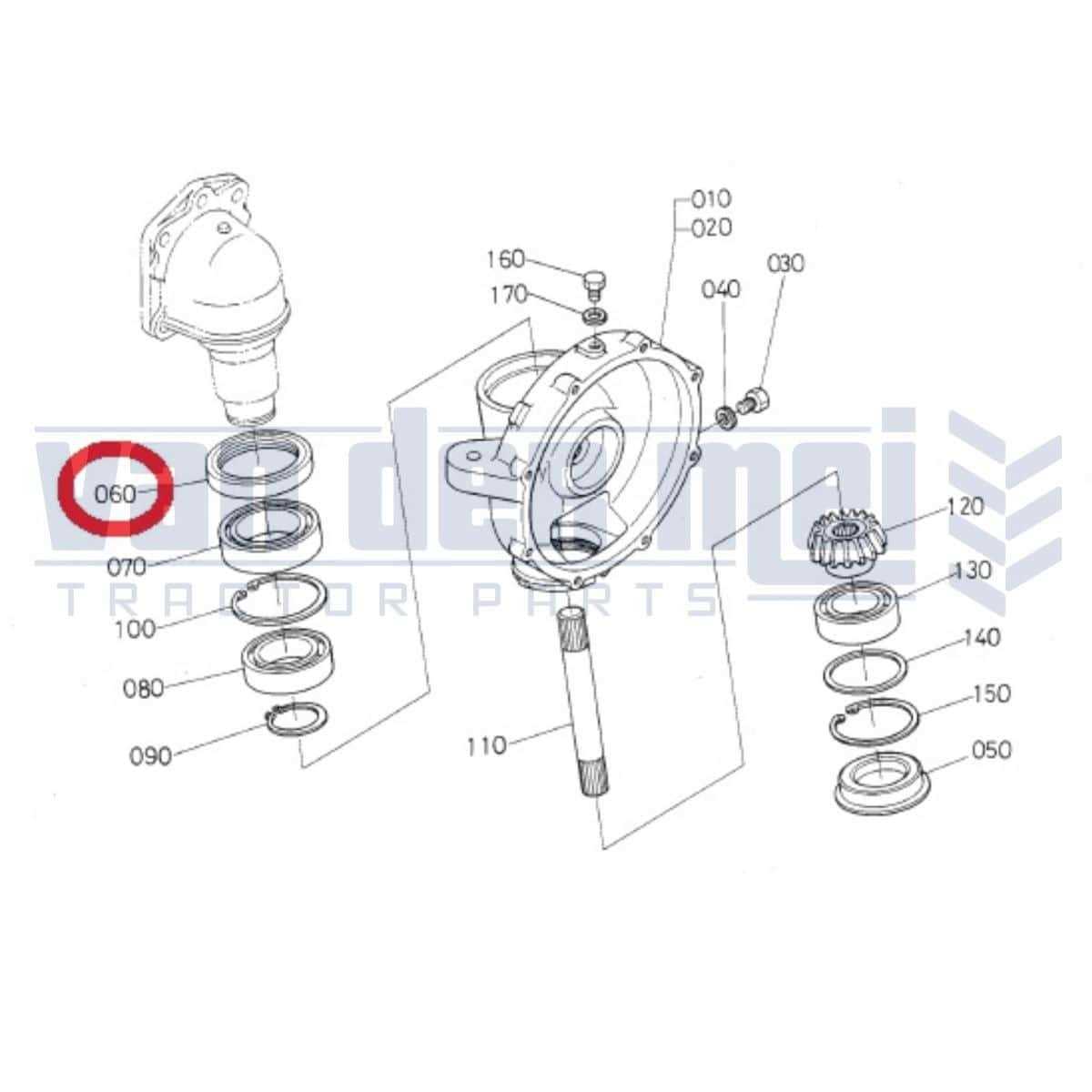

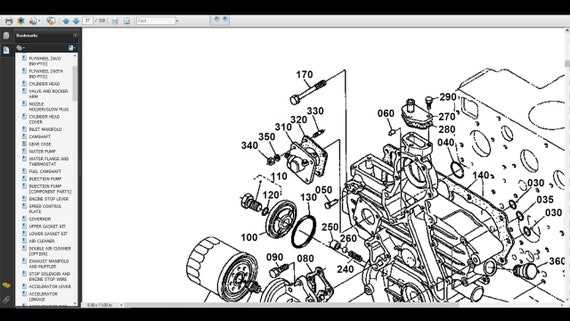

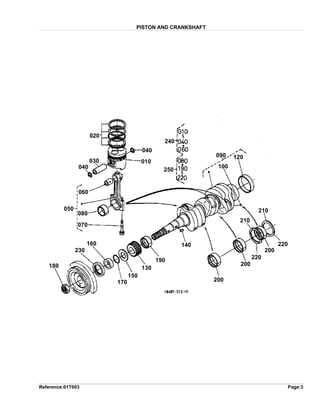

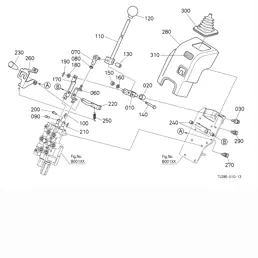

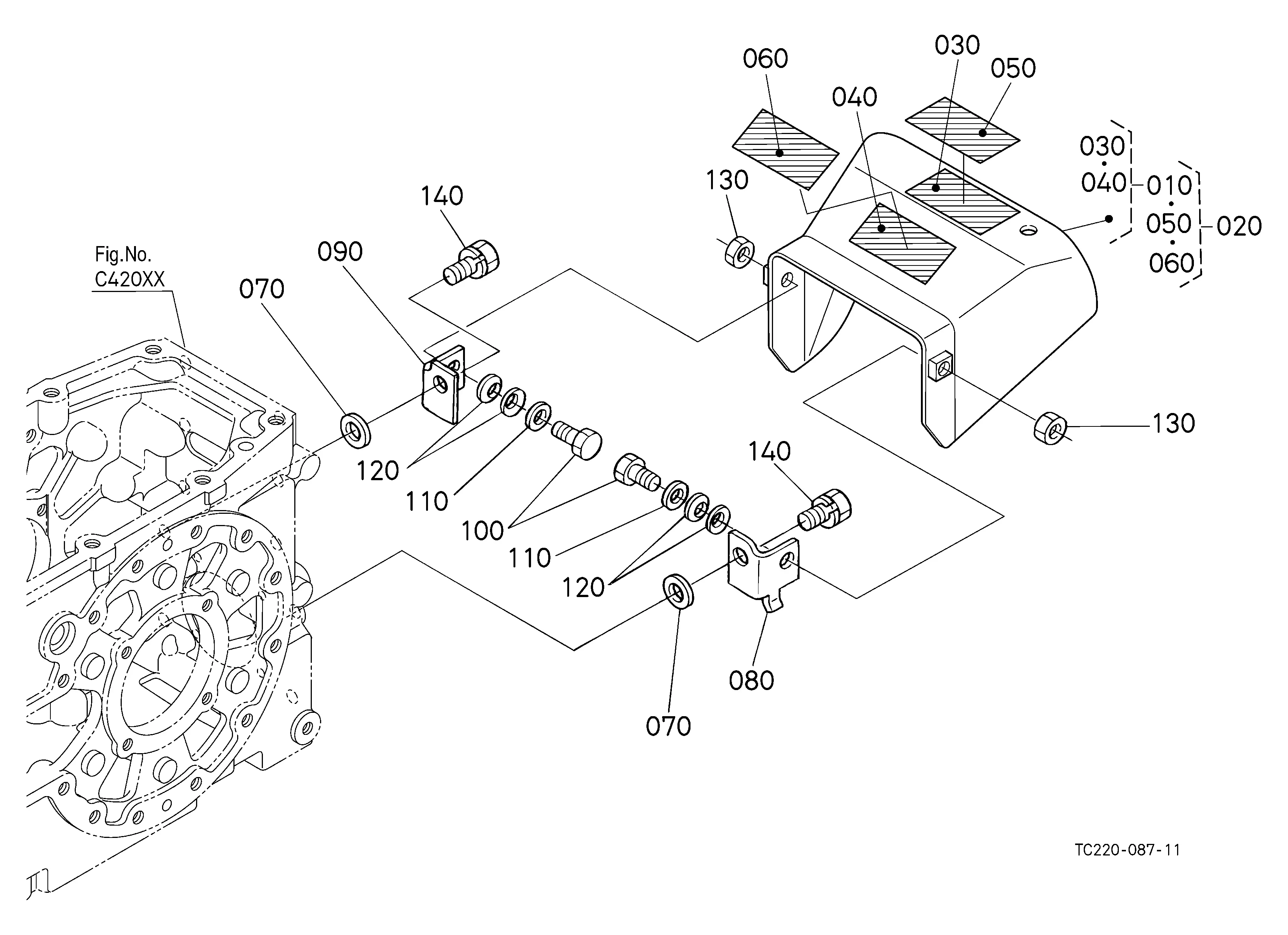

Exploring the Parts Diagram in Detail

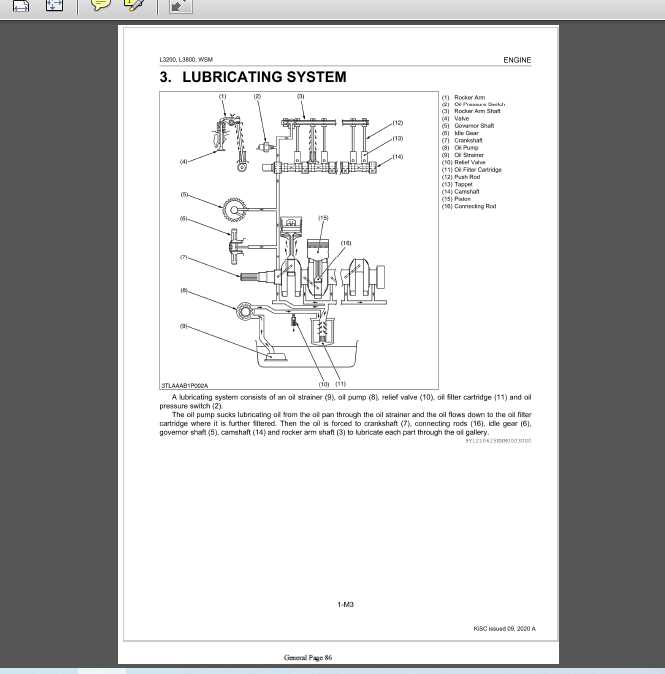

Understanding the components of a machine is crucial for efficient maintenance and repair. A detailed visual representation offers insights into the various elements that make up the system, highlighting their interconnections and functions. By analyzing this illustration, users can gain valuable knowledge about how each part contributes to the overall operation.

This visual reference serves as a guide for identifying essential features and functionalities. It not only simplifies the process of locating specific elements but also aids in comprehending how they work together to ensure optimal performance. Furthermore, recognizing the roles of different components can lead to more effective troubleshooting and enhancements.

Moreover, the illustration can be instrumental in ordering replacements or upgrades. When users are equipped with a clear understanding of the various elements, they can make informed decisions regarding necessary purchases, ensuring compatibility and longevity. Ultimately, a comprehensive overview fosters a deeper appreciation for the intricate design and engineering behind the machinery.

How to Use the Parts Diagram Effectively

Understanding the layout and components of machinery is crucial for maintenance and repairs. By utilizing a schematic representation, users can identify individual elements and their relationships within the assembly. This not only simplifies troubleshooting but also enhances the efficiency of the repair process.

To maximize the benefits of the schematic representation, follow these guidelines:

| Step | Description |

|---|---|

| 1 | Familiarize yourself with the layout to gain an overview of the assembly. |

| 2 | Locate specific components by referring to the reference numbers provided. |

| 3 | Use the visual aid to understand how parts interact and fit together. |

| 4 | Refer to accompanying documentation for detailed information on maintenance and replacement. |

| 5 | Keep the representation accessible during repairs for quick reference. |

By integrating these practices, individuals can enhance their understanding and effectiveness in handling machinery repairs and maintenance tasks.

Purchasing Genuine Kubota Parts

When it comes to maintaining your machinery, choosing authentic components is crucial for optimal performance and longevity. Reliable elements ensure that your equipment functions at its best and reduces the likelihood of future issues.

Investing in original components offers several advantages:

- Quality Assurance: Genuine products are manufactured to meet the highest standards, ensuring durability and reliability.

- Perfect Fit: These components are designed specifically for your model, ensuring seamless integration and operation.

- Warranty Protection: Utilizing original items often preserves your warranty, protecting your investment.

- Technical Support: Access to expert advice and support when using genuine components is typically more reliable.

To find the best sources for these authentic items:

- Visit authorized dealerships or service centers.

- Check reputable online retailers specializing in equipment components.

- Consult with fellow owners or online forums for recommendations on trustworthy suppliers.

By prioritizing genuine components, you are investing in the performance, reliability, and lifespan of your equipment.

Finding Reliable Suppliers and Resources

Locating trustworthy sources for machinery components is crucial for maintaining efficiency and performance. A well-informed approach can significantly enhance the likelihood of obtaining quality materials and services, which are essential for the longevity of equipment. This section will explore effective strategies for identifying reputable suppliers and useful resources that cater to your needs.

Researching Suppliers

Begin by conducting thorough research on potential vendors. Online reviews and ratings can provide insights into their reliability and customer service. Additionally, consider reaching out to fellow equipment owners or industry forums for recommendations, as personal experiences often yield valuable information.

Evaluating Quality and Service

When selecting a supplier, assess their product range and the quality of materials they offer. Request samples or specifications to compare with your requirements. Moreover, evaluate their customer support and after-sales service, as these factors can significantly impact your overall satisfaction and efficiency in sourcing components.