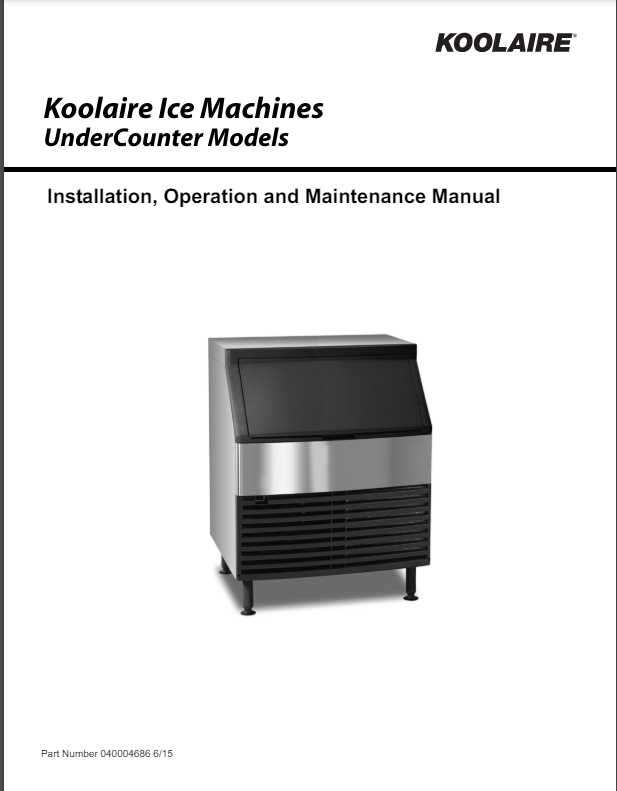

Understanding the intricacies of cooling equipment can greatly enhance its performance and longevity. By examining the various elements that make up these systems, one can gain insight into their functionality and how each component contributes to the overall operation. This knowledge is invaluable for both troubleshooting and maintenance tasks.

Within these systems, individual elements work in harmony to regulate temperatures effectively. Each component has a specific role, influencing how the unit adapts to varying conditions and demands. Proper familiarity with these parts not only aids in quick diagnostics but also supports efficient replacements or upgrades when necessary.

Exploring these units in detail reveals a complex interaction between their mechanical and electrical aspects. Recognizing the placement and purpose of each element helps in identifying potential issues early and in implementing solutions that prevent future malfunctions. A well-maintained setup ultimately ensures consistent operation and reduced downtime.

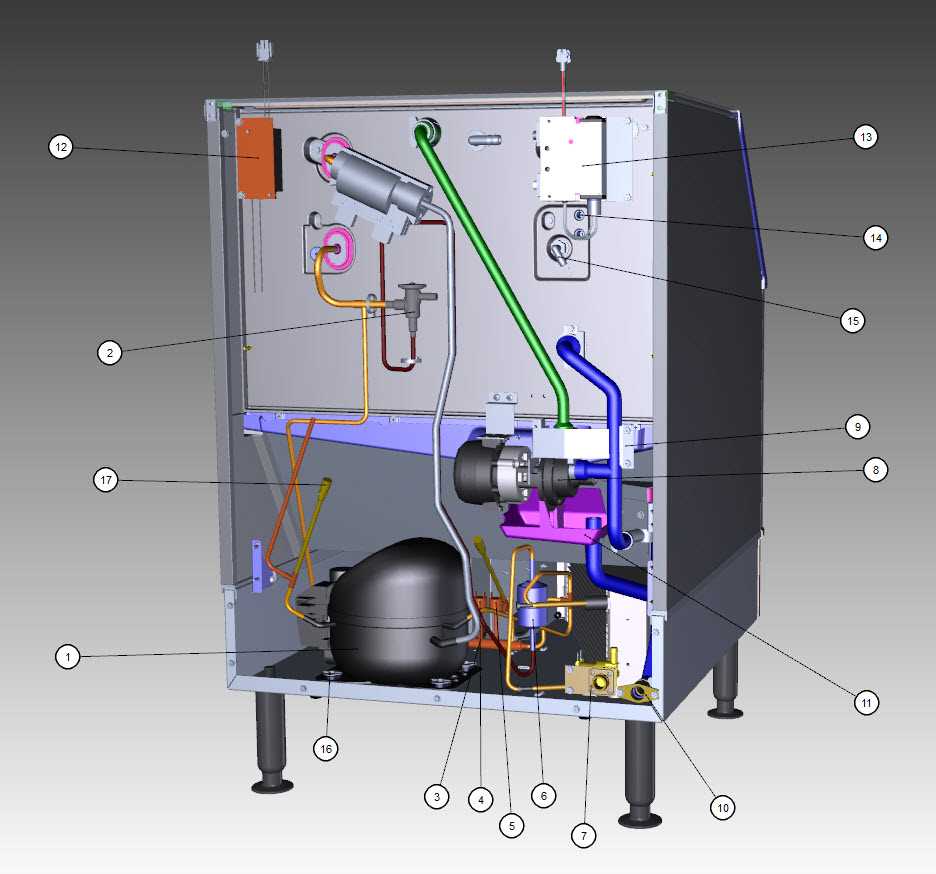

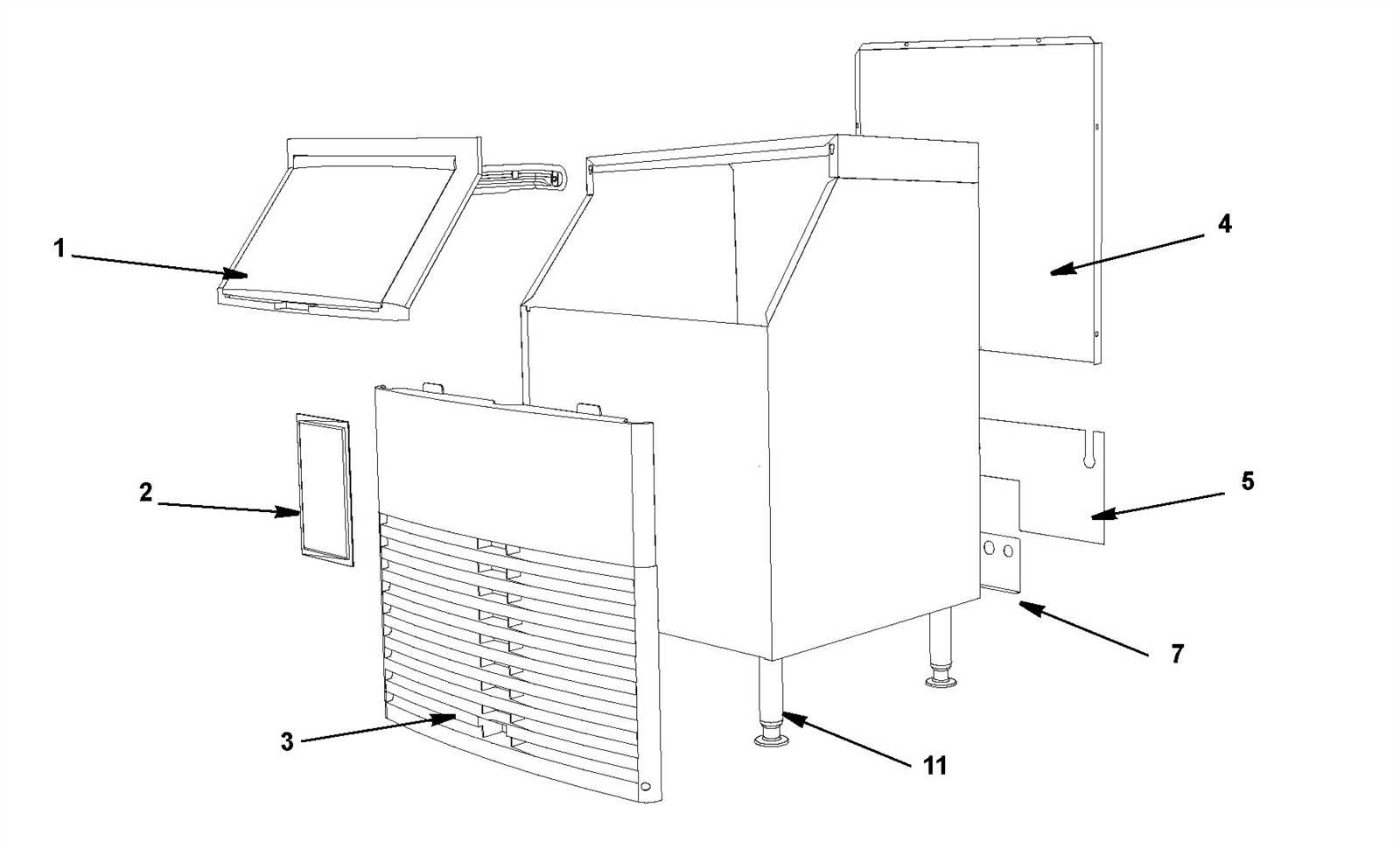

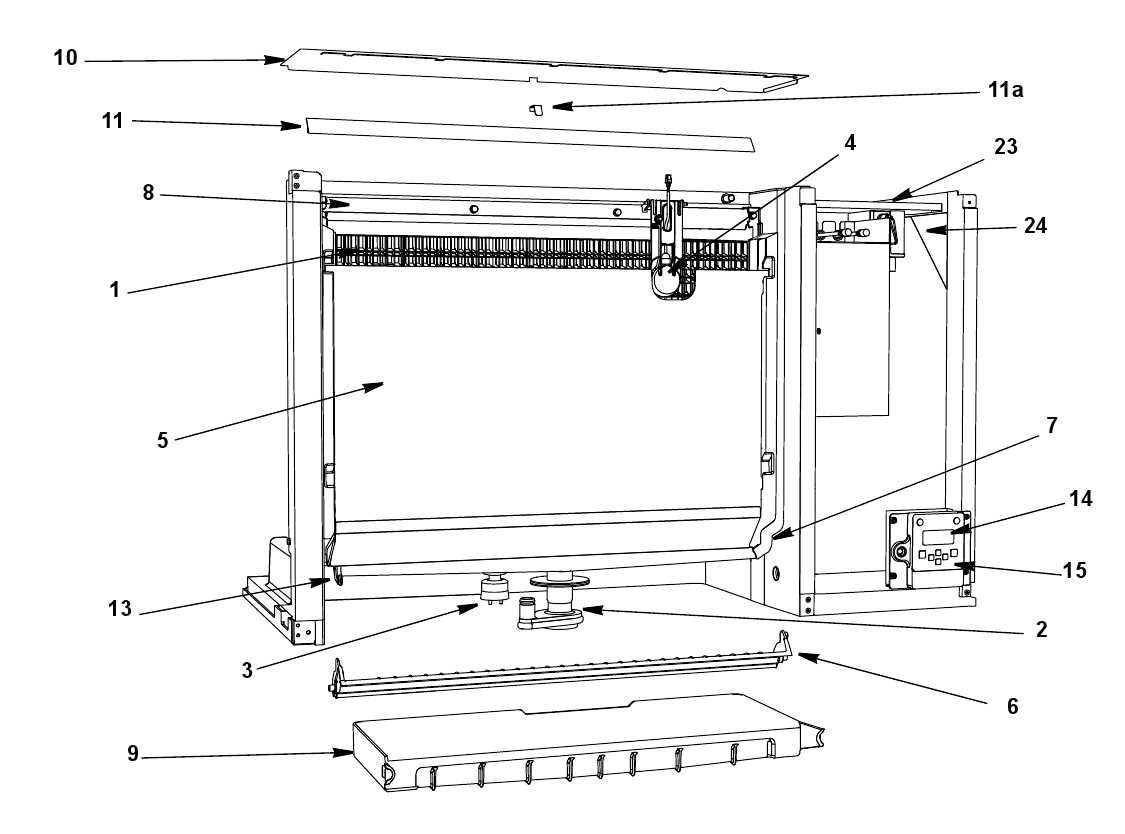

Exploring the Internal Structure

The intricate layout of this cooling unit involves a network of interconnected components that work in harmony to regulate temperature. Understanding the framework is essential to ensure smooth operation and to address any potential issues effectively.

Main Elements of the Setup

The core of this system consists of various essential elements that are strategically positioned to optimize performance. Each part plays a specific role in the overall functionality, contributing to the seamless control and distribution of cool air.

Key Functional Components

Several crucial elements operate together to maintain a balanced internal environment. From the compressor’s activity to the distribution channels, every detail is designed to enhance efficiency and reduce operational load. It’s important to familiarize oneself with these components for better maintenance and troubleshooting.

How to Maintain Key Machine Elements

Proper upkeep of essential components is crucial to ensuring smooth functionality and longevity. By focusing on routine inspections and timely interventions, you can prevent wear and tear, avoiding unnecessary breakdowns and extending the lifespan of your equipment.

Regular Cleaning is a fundamental step in maintaining these units. Keeping all segments free from debris not only enhances performance but also helps prevent internal damage that may result from buildup.

Lubrication of moving parts is necessary to reduce friction and ensure seamless operation. Applying the appropriate lubricants periodically will keep mechanical elements working efficiently.

Inspection of Electrical Connections is also vital. Check for loose or worn connections, as addressing these issues promptly can prevent malfunctions and ensure consistent power flow throughout the system.

Finally, monitor component wear regularly. Identifying and replacing worn-out sections in advance can significantly reduce the risk of sudden failures, keeping your system running at its best.

Preventing Wear on Essential Components

Maintaining the durability of critical elements within any mechanical system requires a proactive approach. By addressing common stress factors early and employing strategies to minimize their impact, the lifespan of these elements can be significantly extended. Regular inspections, combined with appropriate maintenance practices, ensure that each part functions optimally over time.

One effective method to reduce wear is through the use of proper lubrication. Ensuring that all moving sections have adequate lubrication reduces friction, which is a primary cause of material degradation. Regularly checking and replenishing lubricants can prevent unnecessary strain on these components.

Another key aspect is protecting the system from environmental factors that could accelerate deterioration. Exposure to moisture, dust, or extreme temperatures can quickly compromise the integrity of various elements. Implementing protective measures, such as sealing or temperature control, helps in maintaining their condition.

Finally, adherence to manufacturer-recommended maintenance schedules is crucial. Timely replacements and adjustments, based on specific guidelines, prevent minor issues from escalating into major problems. A disciplined approach to upkeep not only enhances performance but also reduces the risk of unexpected breakdowns.

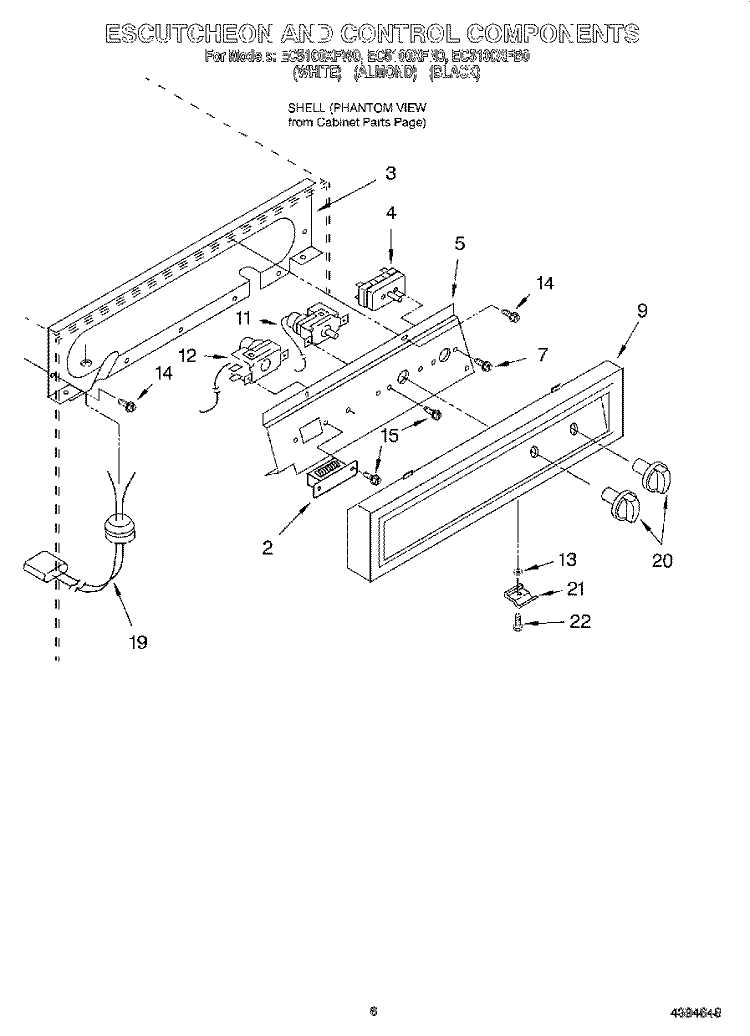

Installation Tips for Replacement Parts

When replacing components, it’s crucial to follow a methodical approach to ensure seamless integration and functionality. Understanding the proper techniques can help avoid common errors and extend the lifespan of the new additions.

Preparation and Safety Measures

Before starting the installation, gather all necessary tools and equipment to streamline the process. Disconnect any power sources to prevent accidents during the setup. Safety gear, such as gloves and protective eyewear, is recommended to avoid injury.

- Verify that the replacement components match the specifications of the existing setup.

- Carefully read through any manufacturer guidelines to understand specific requirements.

- Organize the work area to keep all tools and parts easily accessible.

Step-by-Step Installation Guide

- Remove the Old Component: Gently detach the outdated piece, taking care not to damage surrounding connections.

- Position the New Part: Align the replacement element properly before securing it in place.

- Secure Connections: Ensure all connections are tight and stable to prevent potential leaks or malfunctions.

- Test the System: Once the installation is complete, conduct a thorough check to verify that everything is functioning as expected.

Following these guidelines can significantly enhance the reliability and performance of the newly installed components, helping you maintain optimal operation for a longer period.

Guidelines for Proper Fitting

Ensuring that each component is securely installed is crucial for the overall performance of the system. Proper alignment and connection techniques can prevent potential issues, enhancing both efficiency and longevity.

Steps to Achieve a Secure Connection

- Inspect all elements before assembly to ensure they are free from damage or imperfections.

- Align the parts carefully, following the recommended configuration to avoid misplacement.

- Use appropriate tools to fasten components, ensuring a snug fit without over-tightening.

Common Mistakes to Avoid

- Avoid forcing connections that do not seem to align properly; this may cause damage.

- Ensure that each part is oriented correctly to match the intended setup.

- Regularly check for any signs of wear or loose connections, addressing them promptly.

Troubleshooting Common Mechanical Issues

Addressing frequent mechanical problems can enhance the performance and longevity of refrigeration systems. Understanding these challenges allows for effective solutions, minimizing downtime and ensuring optimal functionality.

Here are some common issues and their potential remedies:

- Insufficient Cooling:

- Check the temperature settings to ensure they are appropriate.

- Inspect the condenser coils for dirt or obstructions.

- Examine the airflow to ensure there are no blockages.

- No Water Supply:

- Verify that the water supply valve is open.

- Inspect for kinks in the water line that may restrict flow.

- Check the water filter for clogs that might impede water flow.

- Excessive Noise:

- Listen for unusual sounds that may indicate loose components.

- Tighten any loose screws or bolts that may be vibrating.

- Ensure that the unit is level to reduce operational noise.

- Frequent Cycling:

- Inspect the thermostat for proper calibration.

- Check for airflow issues that may cause overheating.

- Examine the compressor for signs of wear or malfunction.

By systematically identifying and resolving these mechanical challenges, you can maintain a reliable and efficient system that meets operational demands.

Identifying Faults in Machine Operation

Recognizing issues within operational systems is crucial for maintaining efficiency and performance. Various indicators can signal underlying problems, which can lead to decreased functionality and increased downtime. Understanding these signs can aid in timely intervention and repairs.

When assessing performance, consider the following common symptoms:

- Unusual noises during operation

- Inconsistent output or quality of produced items

- Frequent cycling on and off

- Overheating components

- Unresponsive control panel

To effectively diagnose problems, follow these steps:

- Conduct a visual inspection of the unit for any obvious signs of wear or damage.

- Monitor the operational parameters to identify any deviations from standard performance.

- Consult the manufacturer’s guidelines to verify correct settings and configurations.

- Test individual components to isolate the source of the malfunction.

- Document findings and any repairs made for future reference.

By systematically evaluating these aspects, one can swiftly identify and address faults, ensuring prolonged reliability and optimal performance of the equipment.