In the realm of small engine maintenance and repair, a comprehensive grasp of the various components and their arrangements is essential. These intricate systems work in harmony to ensure optimal performance, and a visual representation can greatly enhance one’s understanding.

Breaking down the intricate assemblies allows enthusiasts and professionals alike to identify each element’s role. By exploring how these components interact, one can ultimately improve diagnostic skills and troubleshooting efficiency.

Furthermore, delving into these visual guides not only aids in repair tasks but also fosters a deeper appreciation for the engineering involved. A clear layout serves as a valuable reference for both seasoned technicians and newcomers to the field.

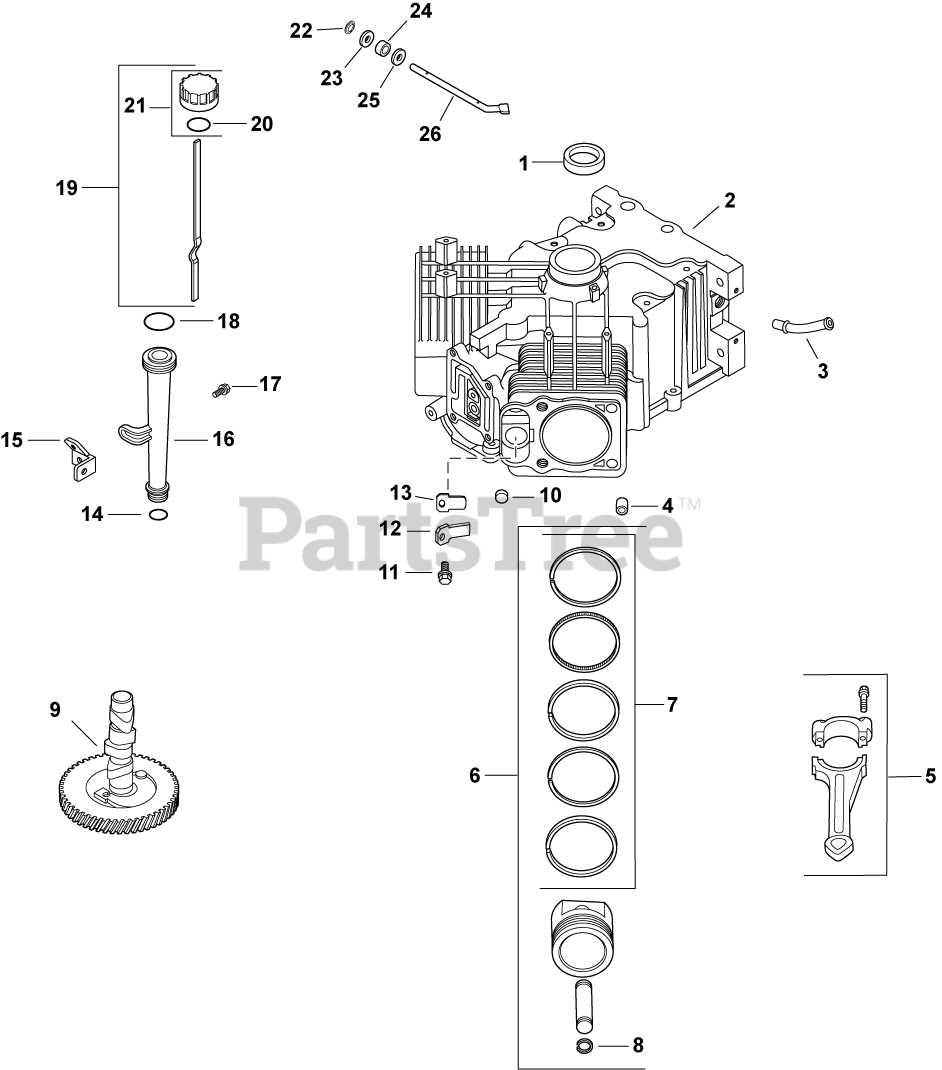

Kohler Motor Parts Overview

This section provides an insight into the essential components that make up a specific engine system. Understanding these elements is crucial for maintenance and repair, ensuring optimal performance and longevity. Each component plays a vital role in the overall functionality and efficiency of the unit.

Key Components

The following table outlines some of the fundamental elements commonly found within the engine assembly. Each item is essential for various operations, contributing to the engine’s reliability and effectiveness.

| Component | Description |

|---|---|

| Cylinder | The chamber where fuel and air mix and ignite, creating power. |

| Piston | A moving component that compresses the fuel-air mixture and transfers energy to the crankshaft. |

| Crankshaft | Converts linear motion of the piston into rotational motion, driving the output. |

| Camshaft | Controls the timing of valve openings and closings, crucial for engine operation. |

| Fuel System | Delivers the necessary fuel to the combustion chamber, ensuring efficiency. |

Importance of Regular Maintenance

Regular inspection and upkeep of these critical components can significantly enhance the overall performance of the engine. Identifying wear and tear early can prevent costly repairs and ensure the engine operates smoothly for years to come.

Importance of Understanding Diagrams

Comprehending visual representations is crucial for anyone involved in mechanical systems. These illustrations serve as essential tools for troubleshooting, assembly, and maintenance, providing clarity and guidance in complex setups.

Enhancing Problem-Solving Skills

Being able to interpret these visuals enables users to identify issues quickly and accurately. It fosters a deeper understanding of how components interact, which ultimately leads to more efficient resolutions.

Streamlining Maintenance Processes

Clear representations simplify routine checks and repairs, allowing for systematic approaches. Familiarity with these visuals promotes confidence, ensuring that tasks are completed effectively and safely.

Common Components in Kohler Engines

Understanding the essential elements that comprise these power sources is crucial for effective maintenance and repair. Each component plays a significant role in ensuring optimal performance and longevity.

Key Elements

Among the most vital components are the following:

| Component | Function |

|---|---|

| Cylinder | Houses the piston and facilitates combustion. |

| Piston | Converts energy from combustion into mechanical movement. |

| Crankshaft | Transforms the piston’s linear motion into rotational energy. |

| Fuel System | Delivers fuel to the engine for combustion. |

Additional Considerations

Each of these elements must work in harmony for the system to function efficiently. Regular inspection and maintenance of these components can prevent potential issues and enhance overall performance.

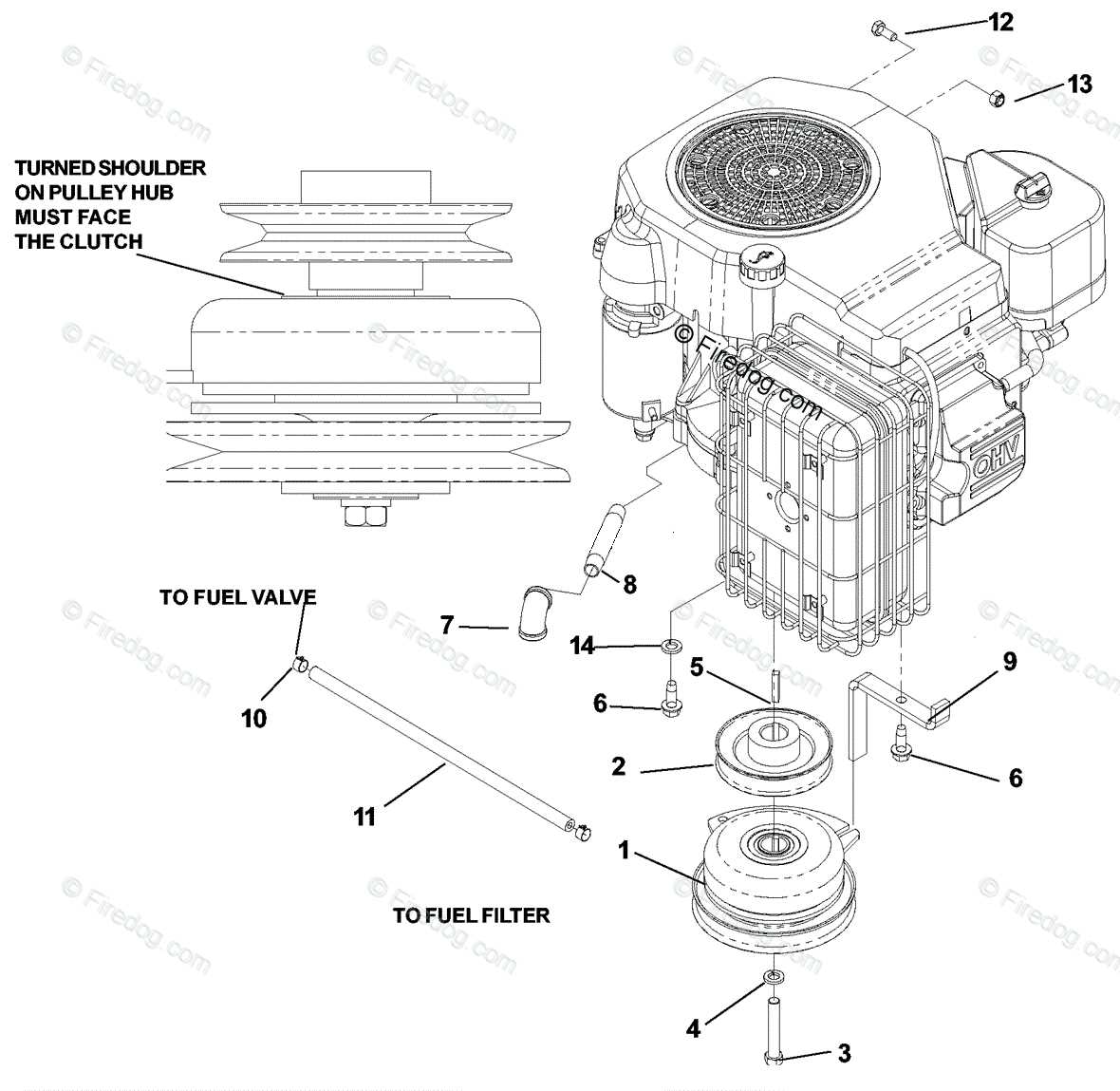

How to Read Motor Diagrams

Understanding technical illustrations is essential for anyone involved in machinery maintenance. These visuals provide crucial insights into the components and their relationships, allowing for effective troubleshooting and repair. Mastering this skill enhances your ability to navigate complex systems efficiently.

Identifying Symbols and Notations

Every illustration uses a unique set of symbols to represent various elements. Familiarize yourself with these icons, as they convey specific functions and connections. Key symbols often indicate electrical components, mechanical parts, or fluid pathways. Pay attention to any accompanying notations that clarify each element’s role.

Interpreting the Layout

The arrangement of components within the illustration is just as important as the symbols themselves. Look for flow directions, which can help you understand how energy or fluids move through the system. Analyzing this layout will give you a comprehensive view of how each part interacts, leading to a deeper understanding of the overall operation.

Finding Replacement Parts Easily

Locating suitable components for machinery can often be a daunting task, especially when faced with a wide array of options. However, with the right approach and resources, the process can be simplified significantly. Understanding the specifics of the equipment and utilizing effective strategies will make it easier to source the necessary replacements without unnecessary hassle.

One effective method is to refer to user manuals or service guides, which typically provide detailed information about compatible items. Additionally, leveraging online marketplaces and specialized retailers can broaden the search, offering a variety of alternatives to choose from. Joining forums or community groups focused on similar machinery can also yield valuable insights and recommendations from fellow enthusiasts.

Another useful tip is to keep track of part numbers and specifications. This ensures that you are searching for the correct items, reducing the chance of errors during procurement. By maintaining organized records, the process becomes more streamlined, allowing for quick references in the future.

Ultimately, combining these strategies will facilitate a smoother experience in acquiring the needed components, ensuring that your equipment remains operational and efficient.

Maintenance Tips for Kohler Motors

Regular upkeep is essential for ensuring the longevity and efficiency of your engine. Proper attention can prevent unexpected breakdowns and enhance performance. Here are some key recommendations to keep your equipment in top condition.

Routine Checks

- Inspect the oil level and quality frequently.

- Clean or replace the air filter as needed to ensure optimal airflow.

- Examine the spark plug for wear and carbon build-up; replace it if necessary.

Seasonal Maintenance

- Change the oil at least once a year or after a specific number of operating hours.

- Drain and replace fuel that has been stored for extended periods.

- Check for any loose connections or signs of wear on belts and hoses.

Following these guidelines will help maintain performance and extend the life of your equipment.

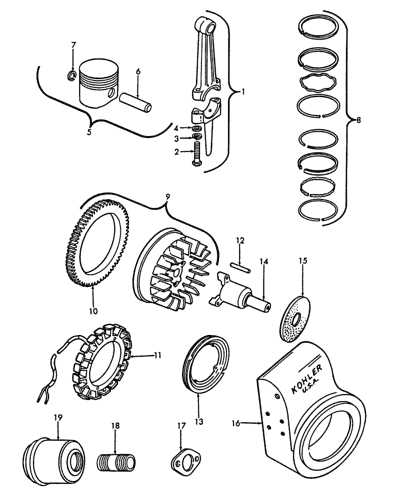

Visualizing Engine Assembly Process

Understanding the assembly of a power unit is crucial for ensuring optimal performance and longevity. This segment will explore the various stages involved in bringing together key components, highlighting the importance of precision and organization throughout the process.

Key Stages of Assembly

Each phase of assembly plays a pivotal role, and recognizing these stages can streamline the entire procedure. Here are the main steps:

| Stage | Description |

|---|---|

| Preparation | Gathering all necessary components and tools. |

| Assembly | Carefully fitting parts together according to specifications. |

| Testing | Conducting checks to ensure functionality and safety. |

Importance of Visualization

Visual aids can significantly enhance understanding during the assembly process. By illustrating each component’s role, individuals can better appreciate the intricate relationships between parts, leading to improved assembly outcomes and maintenance practices.

Online Resources for Parts Diagrams

Accessing comprehensive visual aids for machinery components is essential for both maintenance and repair tasks. The availability of online platforms that offer detailed representations can greatly enhance your understanding and efficiency when working on various equipment. These resources provide essential information for troubleshooting and ensuring optimal performance.

Official Manufacturer Websites

Many manufacturers maintain official sites that feature extensive catalogs and visual schematics of their products. These sites often include searchable databases, allowing users to find specific items quickly. Utilizing these resources can provide accurate details, ensuring that you have the correct specifications for your needs.

Community Forums and User Groups

Online communities and forums are valuable for sharing knowledge and resources. Engaging with other users can lead to discovering alternative diagrams and insights on component replacements. Participating in discussions can also provide tips and tricks based on real-world experiences, which can be invaluable for effective repairs.