When it comes to maintaining heavy-duty landscaping equipment, comprehending the intricacies of its components is essential. Every machine relies on a precise arrangement of parts that work harmoniously to ensure optimal performance and longevity. A thorough understanding of these elements can lead to more effective maintenance and enhanced functionality.

Identifying the various sections and their relationships within your mower empowers users to troubleshoot issues and make informed decisions during repairs. By diving deep into the configuration, one can uncover the ultimate solutions for enhancing efficiency and durability.

This exploration not only aids in immediate repairs but also fosters a greater appreciation for the engineering behind these powerful tools. A meticulous review of each segment ensures that operators can operate their equipment safely and effectively.

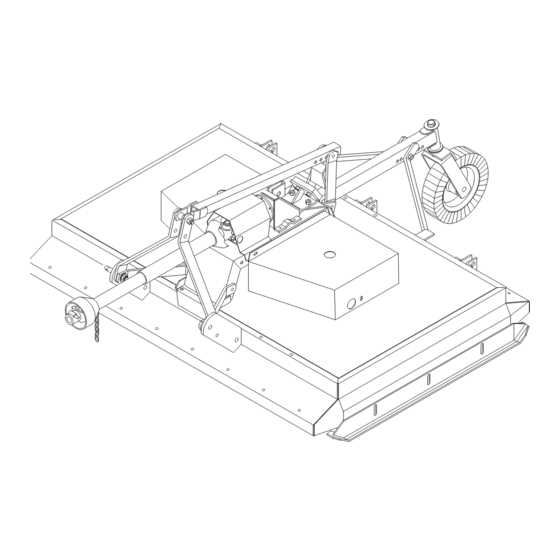

Understanding King Kutter Brush Hog Design

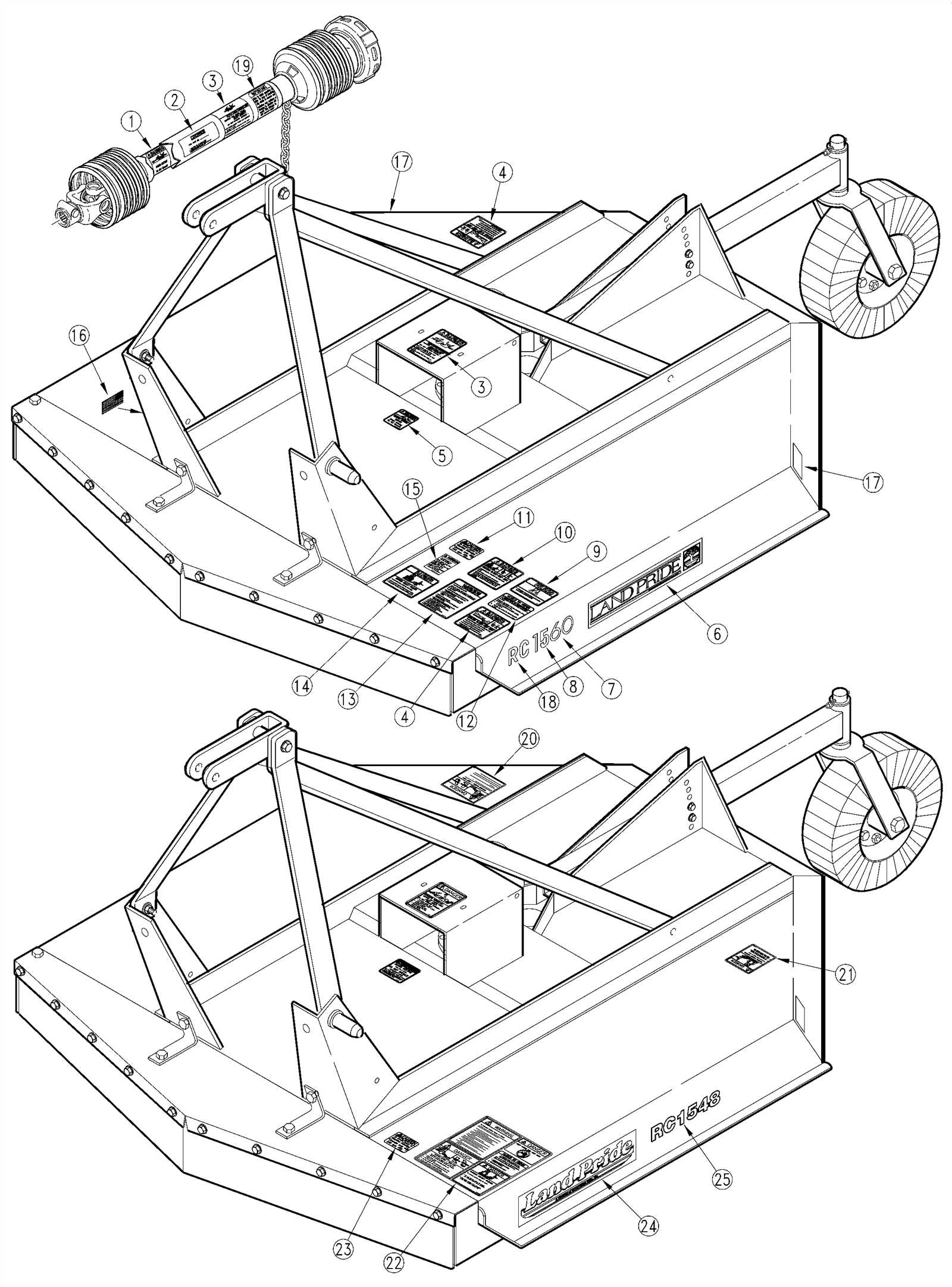

The design of robust mowing equipment plays a crucial role in enhancing efficiency and durability during land maintenance. By examining the structural components and their functionalities, users can appreciate how each element contributes to the overall performance. This knowledge empowers operators to make informed decisions about maintenance and repairs, ultimately extending the lifespan of their machinery.

Essential components such as the frame, cutting blades, and drivetrains are meticulously crafted to withstand rigorous conditions. The integration of these elements ensures optimal cutting efficiency, allowing for versatile applications across various terrains. Understanding how these parts interact helps in troubleshooting issues that may arise during operation.

Moreover, the engineering principles behind the design facilitate ease of use and safety. Features like adjustable heights and protective guards enhance user experience while minimizing risks. Familiarity with these attributes fosters a deeper appreciation for the innovation that drives modern mowing solutions.

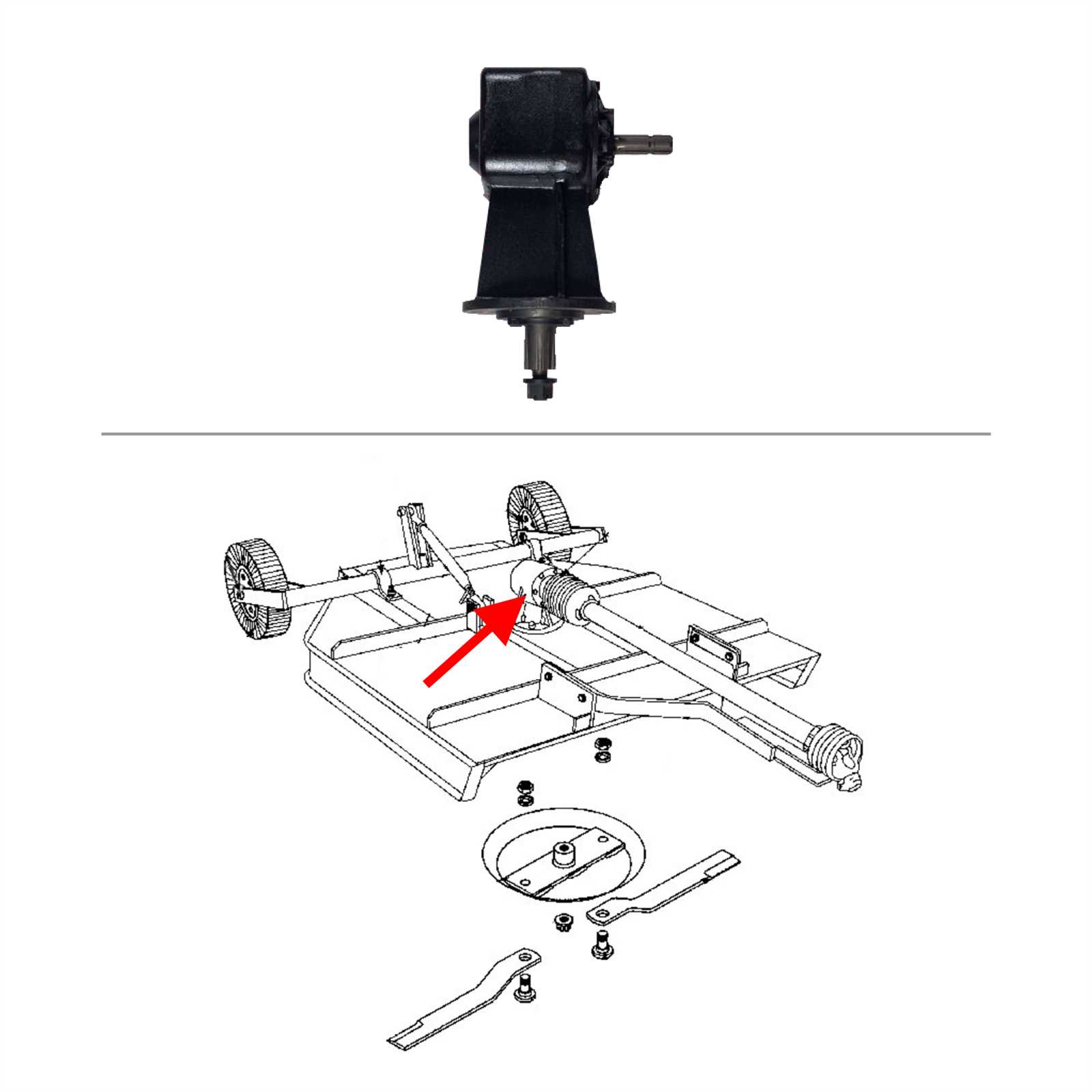

Essential Components of Brush Hog

Understanding the key elements of this vital agricultural tool is crucial for effective maintenance and operation. Each component plays a significant role in ensuring efficiency and durability while tackling heavy vegetation. Familiarity with these parts can enhance performance and prolong the lifespan of the machine.

Cutting Mechanism

The cutting mechanism is the heart of the equipment, designed to handle tough grass and shrubs. Its sharp blades rotate at high speeds, providing a clean cut and promoting healthy land management practices.

Frame Structure

A robust frame supports the entire apparatus, ensuring stability during operation. It is engineered to withstand heavy loads and harsh conditions, contributing to the overall resilience and effectiveness of the tool.

Benefits of Using King Kutter Products

Choosing reliable equipment can greatly enhance efficiency and productivity in land management tasks. When selecting tools, it’s essential to consider durability, performance, and ease of use, as these factors can significantly impact your operations.

Durability and Longevity

One of the standout features of these products is their robust construction. Users often appreciate:

- High-quality materials that withstand harsh conditions

- Reduced maintenance needs due to reliable design

- Long-term investment value, as they often outlast competitors

Enhanced Performance

These tools are engineered for optimal functionality, providing users with numerous advantages:

- Efficient cutting capabilities that save time

- Versatility to tackle various terrains and vegetation types

- Improved safety features to protect operators during use

Overall, selecting these high-quality implements can lead to more effective land management practices and greater satisfaction in the long run.

Maintenance Tips for Longevity

Proper upkeep of machinery is crucial for ensuring its durability and efficiency over time. Regular attention to maintenance tasks not only enhances performance but also extends the lifespan of your equipment. This section outlines essential practices to keep your tools running smoothly.

Regular Inspections

Conducting frequent inspections allows you to identify potential issues before they escalate. Check for wear and tear on components, ensuring everything is in working order. Pay special attention to blades and other critical parts that endure significant stress during operation. Early detection can prevent costly repairs and downtime.

Lubrication and Cleaning

Keeping machinery well-lubricated is essential for reducing friction and wear. Use appropriate lubricants on moving parts to maintain optimal performance. Additionally, regular cleaning is vital to remove dirt and debris that can affect functionality. Routine maintenance not only enhances efficiency but also contributes to a longer service life for your equipment.

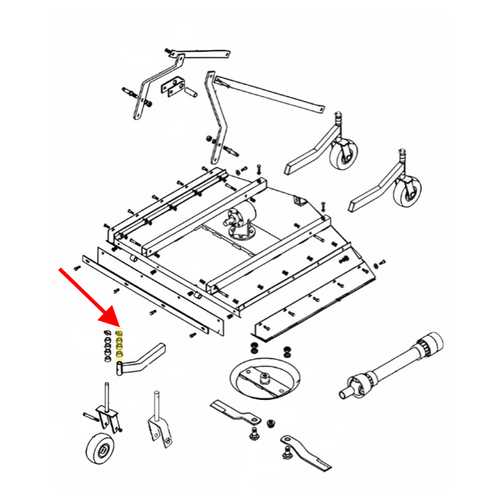

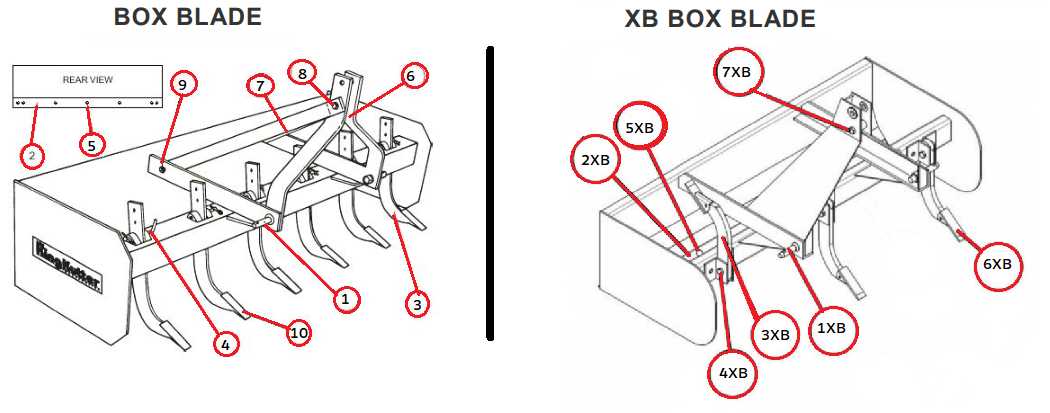

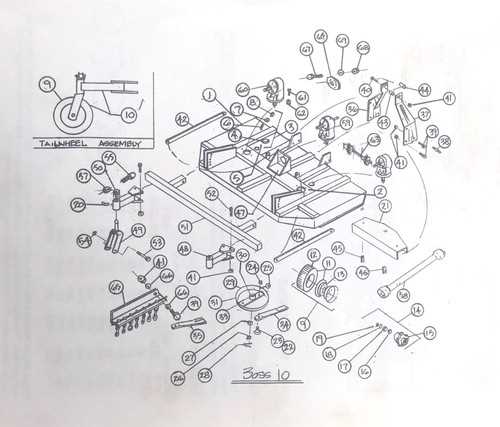

How to Read Parts Diagrams

Understanding visual representations of components can greatly enhance your ability to assemble, repair, or maintain equipment. These illustrations provide crucial information that allows users to identify individual elements and their relationships within a system. Mastering the interpretation of these visuals can streamline your projects and reduce potential errors.

Here are some key strategies to effectively interpret these visual guides:

- Familiarize Yourself with Symbols: Each illustration employs specific icons or drawings to represent different components. Take time to learn these symbols to facilitate easier recognition.

- Pay Attention to Labels: Clear annotations often accompany the visuals. These labels indicate the names or numbers of the elements, aiding in accurate identification.

- Understand the Layout: Components are usually arranged logically. Recognizing the flow or sequence can help you understand how parts connect and function together.

- Consult the Legend: Many illustrations include a key or legend. This section decodes any symbols or colors used, providing essential context.

- Identify Groupings: Elements may be grouped based on function or location. Recognizing these clusters can simplify the assembly or disassembly process.

By employing these techniques, you will gain confidence in navigating and utilizing visual guides, making your tasks more efficient and effective.

Common Issues with Brush Hog Parts

Maintaining agricultural mowing equipment often reveals a variety of challenges that operators may face. Understanding these common problems can enhance performance and prolong the lifespan of the machinery. Addressing these issues promptly is crucial for ensuring effective land management.

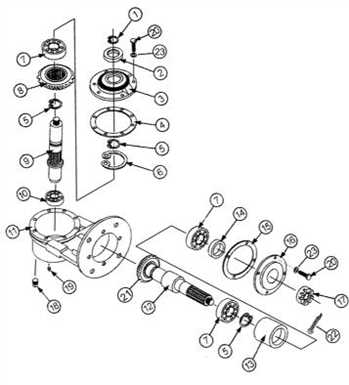

Frequent Mechanical Failures

One of the most prevalent challenges encountered involves mechanical malfunctions. Components may wear out due to extensive use, leading to reduced efficiency. For example, the cutting blades can become dull, necessitating regular sharpening or replacement to maintain optimal cutting performance. Additionally, wear on bearings and gears can result in operational hiccups, which can compromise the machine’s functionality.

Hydraulic System Complications

Another area of concern lies within the hydraulic system. Leaks or blockages can hinder the operation of the implement, affecting its lifting and lowering capabilities. Regular inspection of hydraulic lines and connections is essential to prevent fluid loss, which can lead to more serious issues if left unaddressed. Keeping this system in good condition is vital for smooth operation during tasks.

Finding Replacement Parts Easily

Locating suitable components for your machinery can often feel daunting, but it doesn’t have to be. With the right approach and resources, you can simplify the search process and ensure your equipment remains operational. Below are effective strategies to streamline your hunt for the necessary items.

- Utilize Online Resources: Websites dedicated to machinery parts often provide comprehensive catalogs. Look for platforms that specialize in your specific equipment type.

- Check Manufacturer Websites: Many manufacturers have a dedicated section for replacement items, including detailed specifications and compatibility information.

- Join Online Communities: Forums and social media groups focused on machinery can be invaluable. Members often share advice on where to find components and may even have leads on suppliers.

By employing these strategies, you can efficiently navigate the search for necessary items, minimizing downtime and enhancing productivity.

Upgrades and Modifications Available

Enhancing the functionality and performance of your machinery can significantly improve its efficiency and longevity. There are several options to consider that cater to various needs, from increased durability to improved handling.

Performance Enhancements

- Upgraded blades for better cutting efficiency.

- Improved gearbox for smoother operation.

- Reinforced frame for enhanced durability.

Custom Features

- Adjustable hitch systems for compatibility with different tractors.

- Additional safety features such as guards and shields.

- Custom paint and branding options for a personalized touch.

Customer Reviews and Feedback Analysis

Understanding customer experiences and insights is essential for evaluating product effectiveness and overall satisfaction. Analyzing reviews can reveal valuable information about the strengths and weaknesses of equipment, helping potential buyers make informed decisions. This section delves into the key themes and trends highlighted by users, offering a comprehensive overview of their feedback.

Key Themes from Customer Feedback

Feedback from users often revolves around several recurring themes. These include performance, durability, ease of use, and customer support. By categorizing comments, we can better grasp how well the equipment meets user expectations.

| Theme | Positive Feedback | Negative Feedback |

|---|---|---|

| Performance | Efficient and reliable in various conditions | Occasional issues with specific terrains |

| Durability | Long-lasting materials | Some parts may wear out faster than expected |

| Ease of Use | Simple setup and operation | Instruction manual could be clearer |

| Customer Support | Responsive and helpful representatives | Long wait times for assistance |

Overall Sentiment and Recommendations

Overall, the sentiment from users tends to be positive, with many expressing satisfaction with their purchases. However, constructive criticism is also present, indicating areas for improvement. Addressing these concerns can enhance user experience and foster greater loyalty among customers.