In the realm of intricate machinery, comprehending the individual elements is crucial for effective maintenance and optimization. Each component plays a vital role in the overall functionality, and a clear representation of these parts enhances understanding and facilitates troubleshooting.

By exploring the layout of these essential pieces, one can gain insights into how they interact and contribute to the system’s performance. This knowledge empowers users to identify potential issues and implement solutions swiftly, ensuring the equipment operates at its best.

Ultimately, delving into the arrangement and connections of these elements not only aids in repairs but also fosters a deeper appreciation of engineering design. This exploration serves as a valuable resource for both novices and experienced technicians alike.

Understanding Kdte334gps0 Components

Gaining insight into the various elements of a specific appliance is crucial for effective maintenance and troubleshooting. Each component plays a vital role in ensuring the overall functionality and efficiency of the system. By familiarizing oneself with these individual parts, users can better address issues that may arise over time.

Key elements of this system include various mechanical and electronic components that work together seamlessly. Understanding their purpose and how they interact can significantly enhance one’s ability to perform repairs or replacements when necessary. For instance, certain parts may be responsible for power distribution, while others contribute to operational efficiency or safety.

Moreover, recognizing the relationships between these components can aid in diagnosing problems more effectively. For instance, a failure in one area can often impact the performance of others, making it essential to consider the whole assembly rather than isolated elements. This holistic approach not only streamlines the repair process but also extends the lifespan of the unit.

Importance of Accurate Diagrams

Precision in visual representations plays a crucial role in various fields, enhancing understanding and communication. Clear illustrations facilitate the interpretation of complex systems, ensuring that users can effectively engage with the material. When details are accurately depicted, the likelihood of errors diminishes, leading to better outcomes in both learning and practical applications.

Enhancing Clarity and Understanding

Well-crafted visual aids provide clarity by breaking down intricate concepts into manageable components. This simplification aids individuals in grasping relationships and functions, which might otherwise remain obscure. By presenting information in a structured manner, these representations serve as valuable tools for education and training.

Reducing Errors and Miscommunication

Accurate visuals significantly reduce the risk of mistakes that can arise from misinterpretation. When all elements are clearly defined, stakeholders can align their understanding, minimizing confusion during implementation or analysis. This alignment is vital in ensuring that projects proceed smoothly and efficiently, ultimately leading to successful outcomes.

Common Issues with Kdte334gps0 Parts

When dealing with complex machinery, certain challenges often arise that can affect performance and reliability. Identifying and addressing these common pitfalls is crucial for maintaining optimal functionality. Understanding the typical problems can help users take proactive measures to prevent more serious complications.

Frequent Challenges

Several recurring issues can hinder the efficiency of components. These can stem from manufacturing defects, wear and tear, or improper installation. Recognizing these signs early on is vital for troubleshooting.

Maintenance Tips

Regular upkeep can mitigate many of the common problems faced. Implementing a routine check and ensuring all components are correctly aligned can enhance longevity and performance.

| Issue | Possible Cause | Solution |

|---|---|---|

| Decreased Efficiency | Wear and tear | Regular maintenance and timely replacements |

| Noise During Operation | Improper alignment | Check and adjust alignment |

| Frequent Breakdowns | Manufacturing defects | Consult manufacturer for replacements |

Step-by-Step Assembly Guide

This guide provides a comprehensive approach to assembling your device efficiently and correctly. By following these clear instructions, you will ensure that each component is placed accurately, allowing for optimal performance and longevity.

Step 1: Gather Your Tools

Before you begin, make sure you have all the necessary tools at hand. This includes a screwdriver, pliers, and any specific instruments required for assembly. Having everything organized will streamline the process.

Step 2: Prepare Your Workspace

Set up a clean, well-lit area to work. A flat surface will help prevent any parts from rolling away or getting lost during assembly.

Step 3: Identify Each Component

Familiarize yourself with each piece involved in the assembly. This understanding will help you recognize where each item fits in the overall structure.

Step 4: Start with the Base

Begin by attaching the foundational element, ensuring it is securely fixed. This will serve as the base for all subsequent parts.

Step 5: Attach Additional Elements

Proceed to connect the other components sequentially. Be cautious to follow the recommended order, as this will prevent complications later on.

Step 6: Double-Check Connections

Once all parts are in place, review each connection carefully. Ensure that everything is tight and aligned to avoid any operational issues.

Step 7: Finalize Assembly

After confirming that all components are correctly positioned, finish by securing any last elements. Clean your workspace and dispose of any excess materials.

Step 8: Test the Device

Finally, power on your assembly to ensure everything functions as expected. If you encounter any issues, revisit the earlier steps to troubleshoot.

Tools Needed for Repairs

When undertaking maintenance or restoration tasks, having the right equipment is essential for achieving effective results. This section outlines the various implements that will facilitate the repair process, ensuring that you are well-prepared for any challenge that arises.

Essential Tools

- Wrenches: A variety of sizes to handle different fasteners.

- Screwdrivers: Both flathead and Phillips for versatility.

- Pliers: Useful for gripping, twisting, and cutting wires.

- Socket Set: Ideal for loosening and tightening bolts.

- Utility Knife: For precise cuts in various materials.

Additional Supplies

- Measuring Tape: Ensures accuracy in dimensions.

- Safety Gear: Gloves and goggles to protect yourself.

- Lubricants: Helps in reducing friction on moving parts.

- Cleaning Materials: Rags and brushes for maintaining cleanliness.

- Storage Containers: Keeps small items organized and easily accessible.

Where to Find Replacement Parts

Finding suitable components for your equipment can be a crucial task, ensuring optimal performance and longevity. Various sources are available for acquiring these essential items, making it easier for users to maintain their devices effectively.

Online Retailers: Numerous e-commerce platforms specialize in offering a wide range of components, allowing for easy comparison of prices and options. Popular sites often feature customer reviews, aiding in informed decisions.

Manufacturer Websites: Visiting the official sites of manufacturers can yield reliable options, as they frequently provide authentic items that are compatible with your equipment.

Local Stores: Local hardware or specialty shops can be valuable resources, often stocking necessary components and providing personalized assistance to help you find exactly what you need.

Community Forums: Engaging with online communities can also be beneficial, as experienced users often share insights on where to source specific items and may offer leads on rare finds.

By exploring these avenues, you can ultimately ensure that your equipment remains in peak condition for years to come.

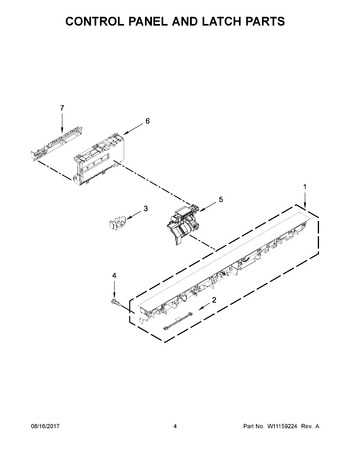

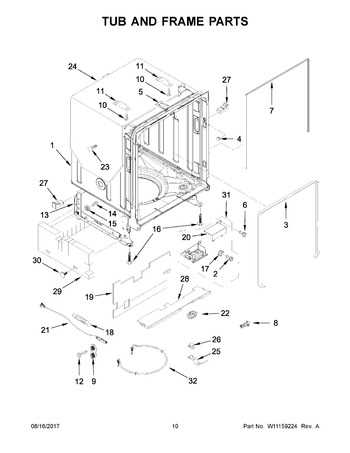

How to Read Parts Diagrams

Understanding visual schematics is essential for anyone looking to grasp the intricacies of mechanical assemblies. These illustrations provide a simplified representation of components and their relationships within a system. Mastering the interpretation of these visuals can significantly enhance your troubleshooting and repair skills.

Begin by familiarizing yourself with the key symbols and notations commonly used in these illustrations. Each element is typically represented by a specific shape or line type, conveying vital information about its function and connectivity. Take note of the legend or key, as it will guide you in decoding the various components displayed.

Next, analyze the arrangement of elements. Observe how they are connected and how they interact with one another. This spatial organization often indicates the sequence of assembly or disassembly, which can be crucial when undertaking repairs or modifications.

Additionally, pay attention to any accompanying annotations or labels. These details often provide insights into specifications such as sizes, materials, or part numbers, helping you identify the exact components you may need to work with. Understanding these annotations is vital for ensuring compatibility and accuracy during maintenance.

Lastly, practice makes perfect. The more you engage with these visuals, the more intuitive your understanding will become. Over time, you’ll be able to quickly identify necessary components and their relationships, empowering you to approach mechanical tasks with confidence.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficient performance of your equipment. By following a structured maintenance routine, you can significantly extend the lifespan of your machinery and minimize the risk of unexpected failures.

- Regular Inspections: Schedule routine checks to identify any signs of wear or damage early.

- Cleanliness: Keep all components clean to prevent dust and debris from causing malfunctions.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and prevent overheating.

- Environment Control: Ensure that the operating environment is suitable, protecting your equipment from extreme temperatures and moisture.

- Use Quality Parts: When replacements are necessary, choose high-quality components to maintain performance standards.

Implementing these strategies can lead to a more reliable operation and a longer functional life, ultimately saving time and resources in the long run.

Expert Insights on Troubleshooting

When encountering issues with complex machinery, understanding the root cause is essential for effective resolution. Expert insights can streamline the troubleshooting process, enhancing efficiency and minimizing downtime. Here, we will explore key strategies and common pitfalls to watch for during diagnostics.

Key Strategies for Effective Troubleshooting

- Begin with a systematic approach: Document symptoms and changes.

- Utilize diagnostic tools: Leverage technology to pinpoint problems.

- Consult technical manuals: Reference guides for detailed specifications.

- Engage with community forums: Learn from others’ experiences and solutions.

Common Pitfalls to Avoid

- Skipping initial assessments can lead to overlooked issues.

- Relying solely on guesswork increases the chance of errors.

- Neglecting routine maintenance exacerbates underlying problems.

- Failing to update knowledge on recent advancements can hinder troubleshooting.