In the realm of outdoor machinery, having a comprehensive grasp of the various elements that make up your device is essential for optimal performance and maintenance. This knowledge not only empowers users to troubleshoot issues effectively but also enhances the longevity of their equipment. By familiarizing oneself with the intricate assembly of each part, one can ensure smooth operation and avoid common pitfalls associated with improper usage.

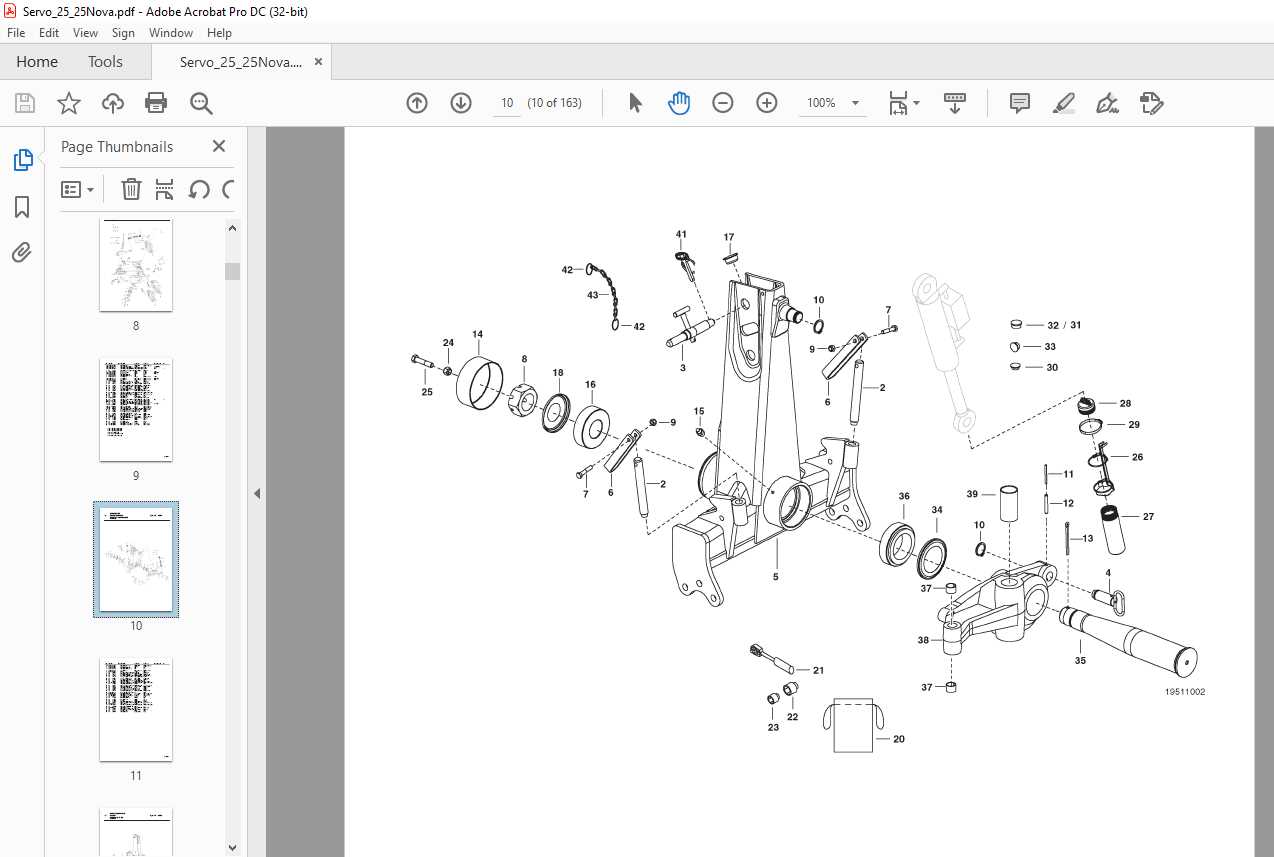

When it comes to machinery, the significance of a detailed visual representation of its components cannot be overstated. Such illustrations serve as valuable resources, offering insights into the specific functions and placements of each element. This clarity helps users identify parts that may require attention or replacement, thus facilitating timely repairs and efficient upkeep.

Moreover, understanding the interplay between different components can lead to a more informed approach to maintenance. Recognizing how parts work together fosters a deeper appreciation of the machine’s design, ultimately leading to better handling and enhanced performance. In this guide, we will explore the essential aspects of these visual aids, equipping you with the knowledge to manage your outdoor equipment effectively.

Overview of the Chainsaw Model

This section provides a comprehensive look at a popular chainsaw model designed for both professional and residential use. With its robust performance and user-friendly features, it caters to a variety of cutting tasks, making it a reliable choice for enthusiasts and professionals alike.

Key Features

Equipped with a powerful engine, this model ensures efficient operation. Its lightweight design facilitates ease of handling, while the ergonomic grip enhances comfort during extended use. Additionally, advanced safety features are integrated to protect the user, ensuring a secure experience.

Maintenance and Support

Regular maintenance is essential to prolong the life of this tool. Users can find resources and guides that cover routine checks and servicing. Support from the manufacturer is readily available, making it easier to resolve any issues that may arise.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations of individual elements help users identify, troubleshoot, and replace parts efficiently. These illustrations serve as invaluable tools for both novice and experienced users, enhancing comprehension and facilitating smoother operations.

Moreover, detailed illustrations promote accuracy in repairs and minimize the risk of errors. When users can clearly see how components fit together, they are better equipped to address issues without unnecessary guesswork. This ultimately leads to longer equipment lifespan and improved performance.

| Benefits | Description |

|---|---|

| Enhanced Understanding | Visual aids clarify the function and placement of each component. |

| Reduced Errors | Clear visuals minimize mistakes during assembly or repair tasks. |

| Time Efficiency | Quick identification of parts leads to faster troubleshooting. |

| Cost Savings | Accurate repairs prevent unnecessary part purchases and reduce downtime. |

Common Issues with Poulan Pro 500E

When dealing with outdoor power equipment, users often encounter various challenges that can impact performance and efficiency. Understanding these frequent problems can help in troubleshooting and maintenance, ensuring a smoother experience during use.

Starting Difficulties: One of the most common complaints involves issues with starting the device. This can stem from a variety of factors, including fuel quality, spark plug condition, or air filter blockage. Regular checks and maintenance can mitigate these problems.

Power Loss: Users may notice a reduction in power during operation. This can be attributed to clogged fuel lines, a dirty carburetor, or issues with the ignition system. Cleaning and replacing components as necessary can restore optimal performance.

Excessive Vibration: Unusual vibrations while operating can indicate mechanical problems, such as loose screws or a malfunctioning blade. Ensuring all parts are secure and in good condition is essential for safe and efficient use.

Overheating: Overheating can occur due to prolonged use without adequate breaks or issues with the cooling system. Regular maintenance and allowing the unit to cool down can prevent this issue from arising.

Addressing these common challenges through regular inspection and maintenance can significantly enhance the longevity and reliability of outdoor equipment.

Where to Find Replacement Parts

When seeking components for your outdoor equipment, it’s essential to explore multiple avenues to ensure you find the right items for your needs. Various sources offer a range of options, from local retailers to online platforms, making it easier to locate what you’re looking for.

Local hardware stores often carry a selection of essential components, allowing you to examine items firsthand and consult knowledgeable staff. Alternatively, specialty shops dedicated to outdoor machinery might provide a more comprehensive inventory, catering specifically to your equipment’s requirements.

For those who prefer the convenience of online shopping, numerous e-commerce websites specialize in machinery components. These platforms typically feature detailed descriptions and customer reviews, helping you make informed choices. Additionally, manufacturer websites can be invaluable, offering original items and expert guidance.

Lastly, consider browsing second-hand marketplaces, where you may discover rare or discontinued items at competitive prices. By exploring these diverse resources, you can ultimately find the perfect components to keep your equipment running smoothly.

Understanding Parts Terminology

In the realm of machinery and equipment, comprehending the language of components is essential for effective maintenance and repair. Familiarity with specific terminology not only aids in identifying individual elements but also enhances communication among users and professionals. This knowledge empowers individuals to navigate technical manuals and discussions with confidence.

When referring to various elements, it is crucial to distinguish between different classifications. For instance, terms like assembly, attachment, and accessory denote various types of units that serve distinct functions within a machine. Understanding these classifications can simplify the process of locating the right items needed for servicing or upgrading.

Moreover, recognizing the significance of compatibility is vital. Not all components are interchangeable, and knowing which parts align with specific models can prevent unnecessary frustration and ensure optimal performance. Thus, having a grasp of terms related to fit and functionality can make a significant difference in achieving satisfactory results.

Additionally, familiarization with the common nomenclature used for repairs can enhance one’s ability to follow instructions and troubleshoot issues. Terms like fastener, gear, and housing each convey specific roles within the overall system, and knowing them can facilitate quicker resolutions.

Ultimately, mastering the language of machinery components lays the groundwork for successful interactions, whether in purchasing, discussing, or maintaining equipment. This foundational knowledge serves as a stepping stone for both novice users and experienced technicians alike.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires consistent care and attention. By following a set of maintenance practices, you can significantly extend the lifespan of your tools and ensure they operate at peak efficiency. Regular upkeep not only prevents unexpected breakdowns but also enhances safety during usage.

Routine Checks

Performing regular inspections is crucial. Look for signs of wear and tear, and address any issues promptly. Regularly checking components can help identify potential problems before they escalate.

Cleaning and Lubrication

Keeping your equipment clean and well-lubricated is essential for smooth operation. Remove dirt and debris after each use, and apply appropriate lubricants to moving parts. This minimizes friction and reduces the risk of damage.

| Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Weekly | Check for loose or damaged parts. |

| Cleaning | After Each Use | Remove dust, dirt, and debris. |

| Lubrication | Monthly | Use recommended lubricants on moving parts. |

| Replace Filters | Every Season | Ensure optimal air and fuel flow. |

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing issues with your equipment. By following systematic steps, you can identify problems and apply effective solutions to restore functionality.

Preparation

- Gather necessary tools: wrenches, screwdrivers, and replacement components.

- Ensure the workspace is clean and organized for efficiency.

- Review the user manual for specific guidance related to your model.

Troubleshooting Steps

- Inspect the device for visible signs of wear or damage.

- Check all connections to ensure they are secure and intact.

- Test the power source to confirm it is functioning properly.

- Replace any damaged or worn-out parts as identified.

- Reassemble the unit and conduct a final test to verify repairs.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components can significantly enhance the performance and longevity of your machinery. These authentic pieces are designed specifically for your equipment, ensuring optimal compatibility and reliability.

Here are some key advantages of choosing OEM components:

- Quality Assurance: Original components are manufactured to strict standards, ensuring high quality and durability.

- Perfect Fit: Designed for specific models, these parts guarantee a seamless fit, minimizing the risk of malfunctions.

- Enhanced Performance: Using genuine components helps maintain the efficiency of your equipment, leading to better overall performance.

- Warranty Protection: Many manufacturers provide warranties on their original parts, offering additional peace of mind.

- Long-Term Cost Savings: Although they may have a higher upfront cost, OEM components often lead to fewer repairs and replacements over time.

In summary, opting for original components not only ensures that your machinery operates at its best but also contributes to its long-term sustainability and reliability.