The intricate world of small engine maintenance relies heavily on visual representations that detail the various elements within a mechanical system. These illustrations serve as essential tools for both novice and experienced technicians, offering a clear guide to the arrangement and interaction of components.

By familiarizing oneself with these layouts, users can enhance their understanding of how individual parts contribute to overall functionality. Such knowledge is crucial for effective troubleshooting, repair, and replacement, ensuring that machinery operates smoothly and efficiently.

In this exploration, we will delve into the specifics of these visual aids, highlighting their importance in the context of engine upkeep. Emphasizing clarity and accessibility, we aim to empower readers to navigate the complexities of mechanical systems with confidence.

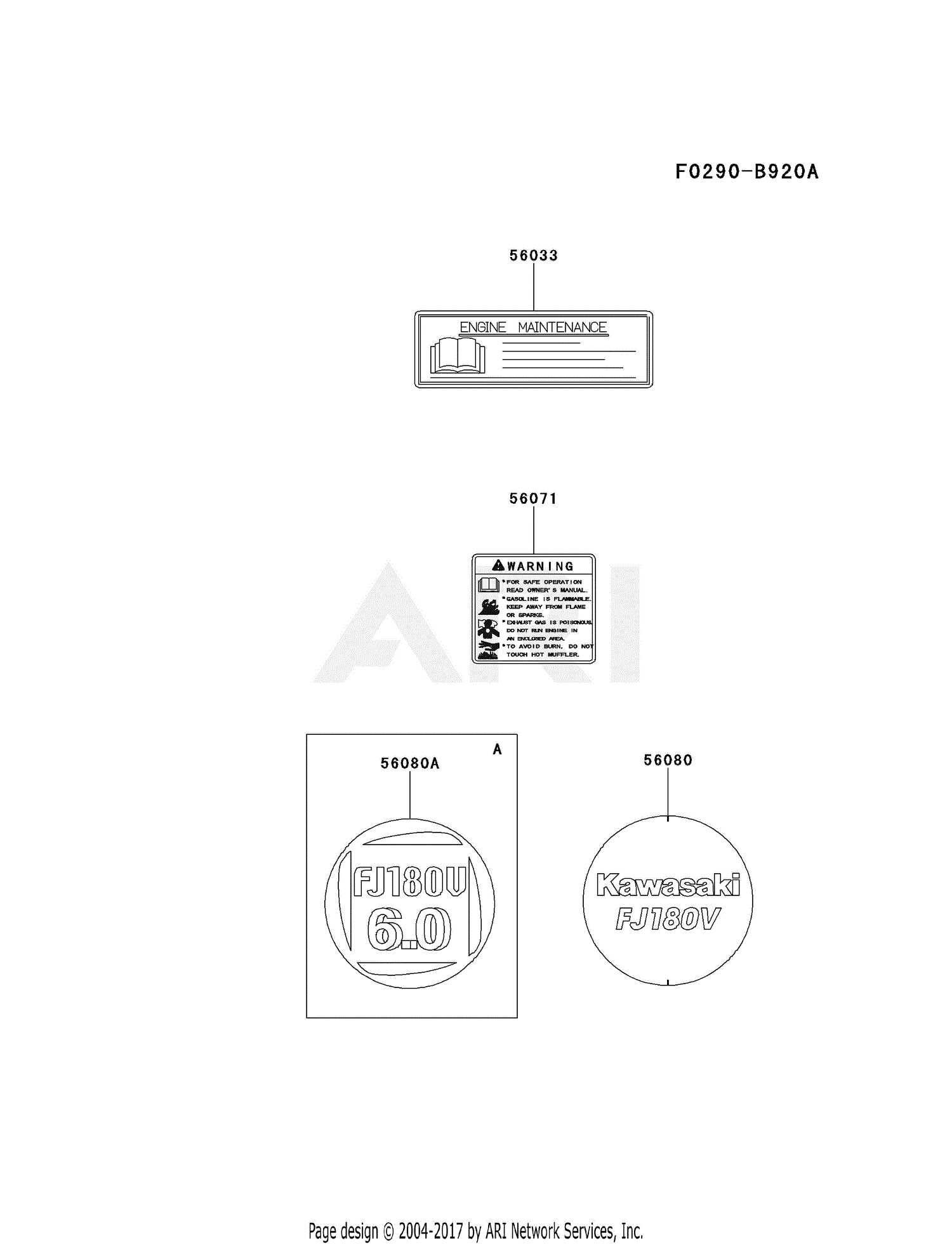

Kawasaki FJ180V Overview

This section provides a comprehensive understanding of a specific engine model renowned for its reliability and performance. It is widely utilized in various applications, making it a popular choice among users seeking efficiency and durability. This overview covers essential features, specifications, and common applications.

Key Features

The highlighted engine is characterized by its robust design and advanced engineering. Key attributes include:

| Feature | Description |

|---|---|

| Engine Type | 4-stroke, air-cooled |

| Displacement | 179 cc |

| Power Output | Approximately 6.5 HP |

| Fuel Type | Gasoline |

Common Applications

This engine model is commonly found in various equipment, making it versatile for numerous tasks. Typical applications include:

- Residential lawn mowers

- Pressure washers

- Generators

- Other outdoor power equipment

Importance of Parts Diagrams

Understanding the structure and components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools that enhance clarity and facilitate the identification of individual elements within a complex system.

Here are some key reasons why these visual aids are vital:

- Enhanced Understanding: They provide a clear view of how different components interact, making it easier to grasp the overall assembly.

- Efficient Repairs: By pinpointing specific elements, technicians can quickly locate issues, reducing downtime.

- Accurate Ordering: Clear visuals help ensure that the correct replacements are ordered, minimizing errors in procurement.

- Streamlined Assembly: They serve as a guide during the reassembly process, helping to avoid mistakes.

- Educational Tool: New users can learn about the structure and function of each part, improving their technical knowledge.

In summary, these visual representations play an integral role in maintenance, ensuring efficiency and accuracy in both repairs and learning processes.

Common Issues with FJ180V Engines

Engines of this type are known for their reliability, yet they can encounter a variety of common problems that affect performance and longevity. Understanding these issues can help users maintain their equipment and address any malfunctions promptly.

Fuel System Troubles: One frequent challenge involves the fuel system, particularly clogged filters or issues with the carburetor. Contaminated fuel can lead to poor engine performance, resulting in starting difficulties or uneven operation.

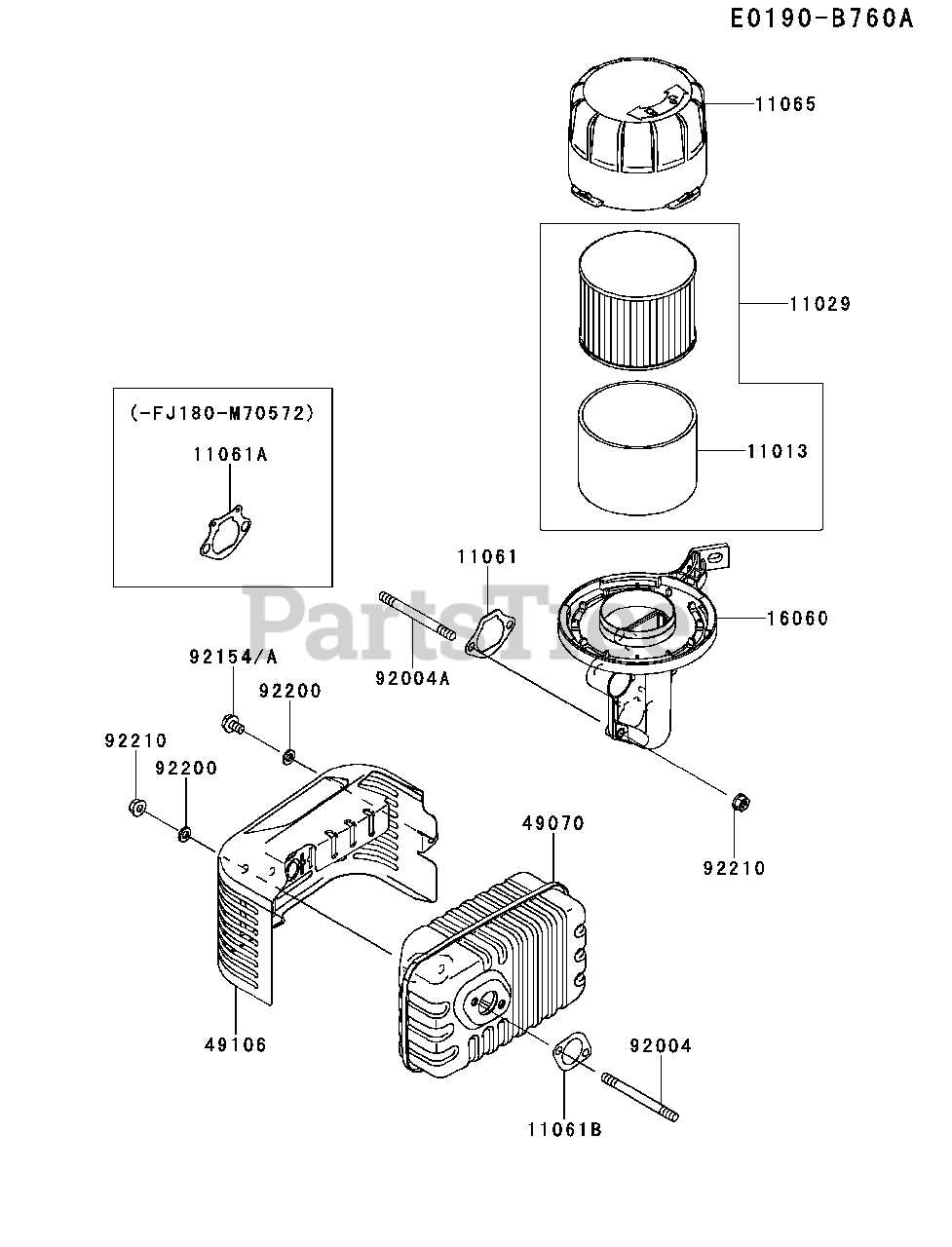

Overheating: Another significant concern is overheating, often caused by insufficient cooling or blocked vents. Regular maintenance of the cooling system is essential to prevent damage and ensure efficient operation.

Oil Leaks: Users may also experience oil leaks, which can stem from worn gaskets or seals. These leaks not only decrease efficiency but can also lead to serious engine damage if not addressed promptly.

Electrical Failures: Electrical components can fail, leading to ignition issues or erratic performance. Ensuring that connections are clean and secure can mitigate these problems.

Noise and Vibration: Unusual noise or vibration often indicates underlying mechanical issues, such as worn bearings or misalignment. Regular inspection can help identify and rectify these concerns before they escalate.

By being aware of these common issues and their symptoms, users can take proactive steps to ensure their engines run smoothly and efficiently for years to come.

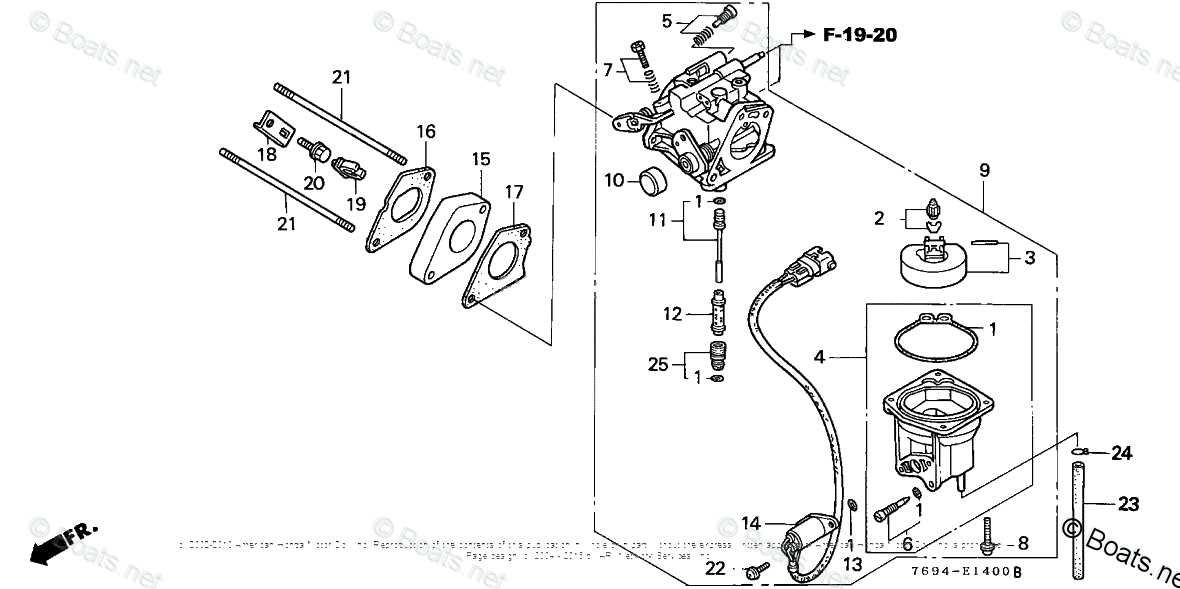

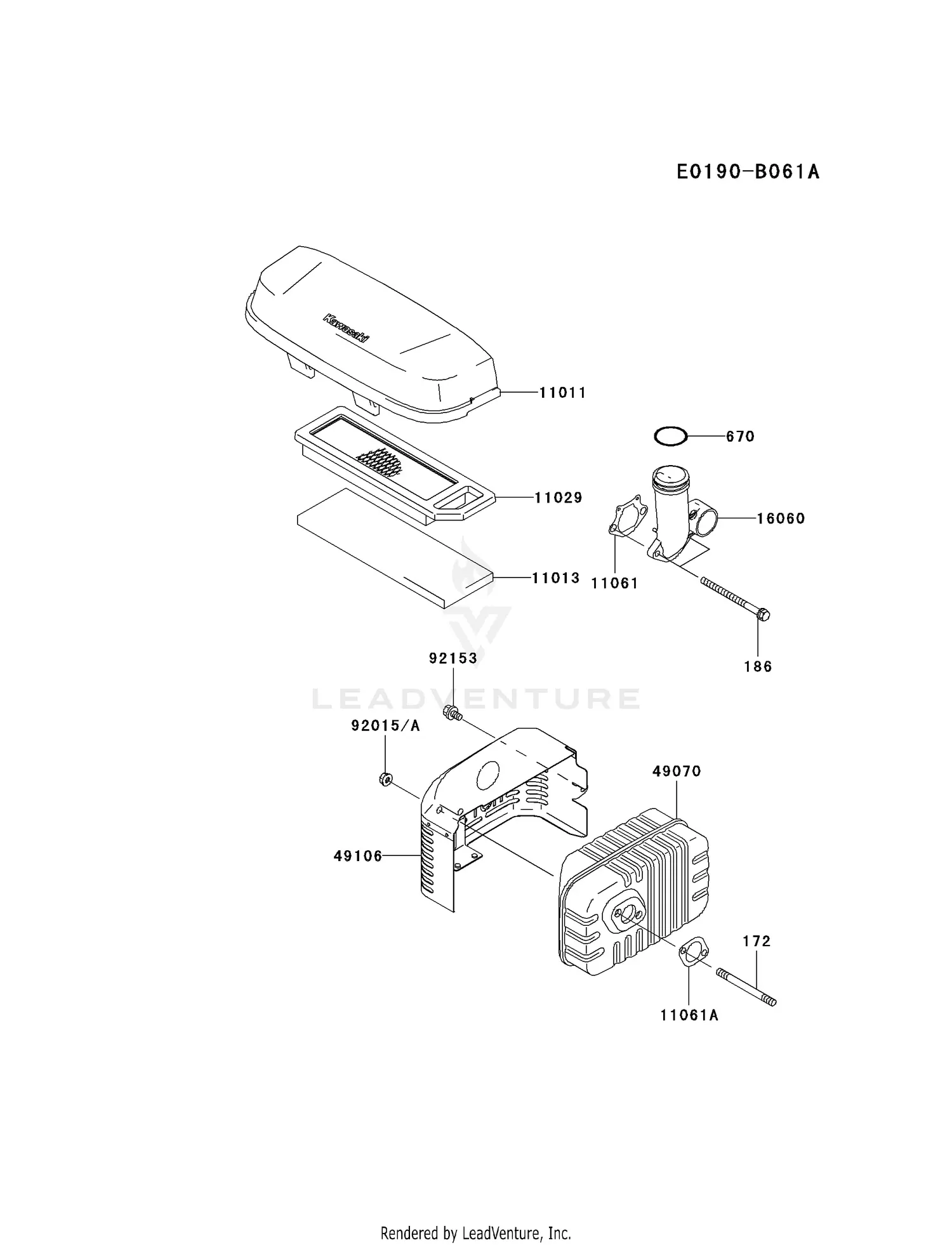

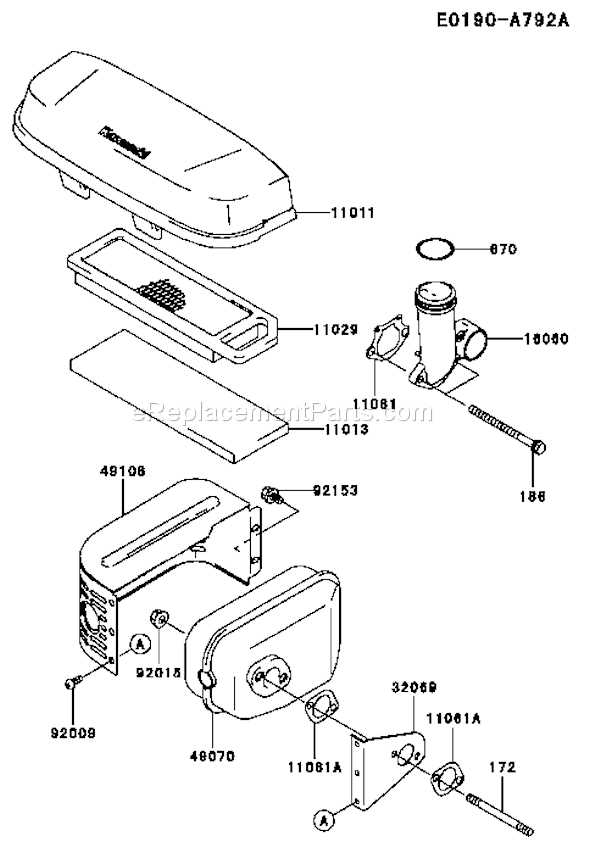

Identifying Key Components

Understanding the essential elements of a machine is crucial for effective maintenance and operation. Recognizing these components allows users to troubleshoot issues efficiently and ensure optimal performance.

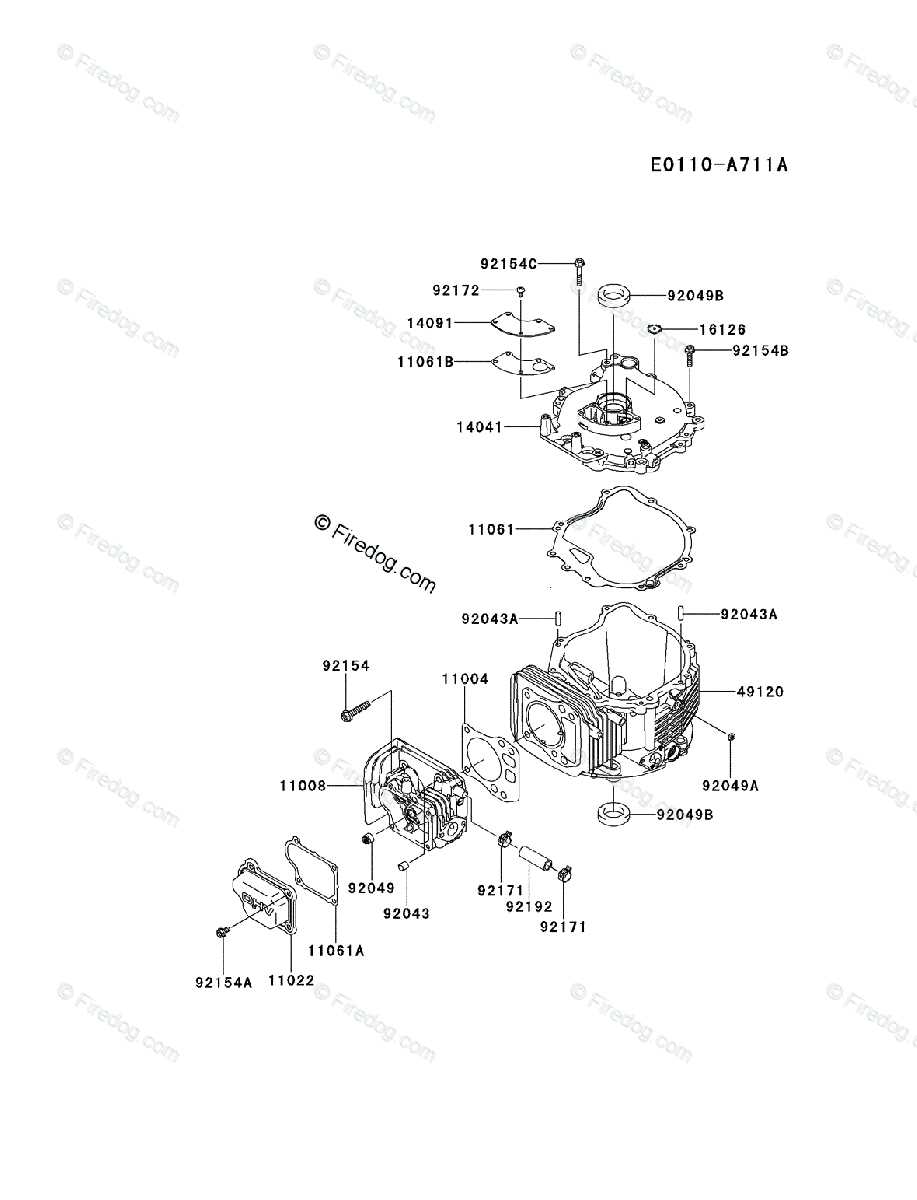

Engine Assembly

The engine assembly serves as the heart of the machinery, comprising vital parts such as the cylinder, piston, and crankshaft. Each component plays a significant role in converting fuel into mechanical energy, which powers the entire system.

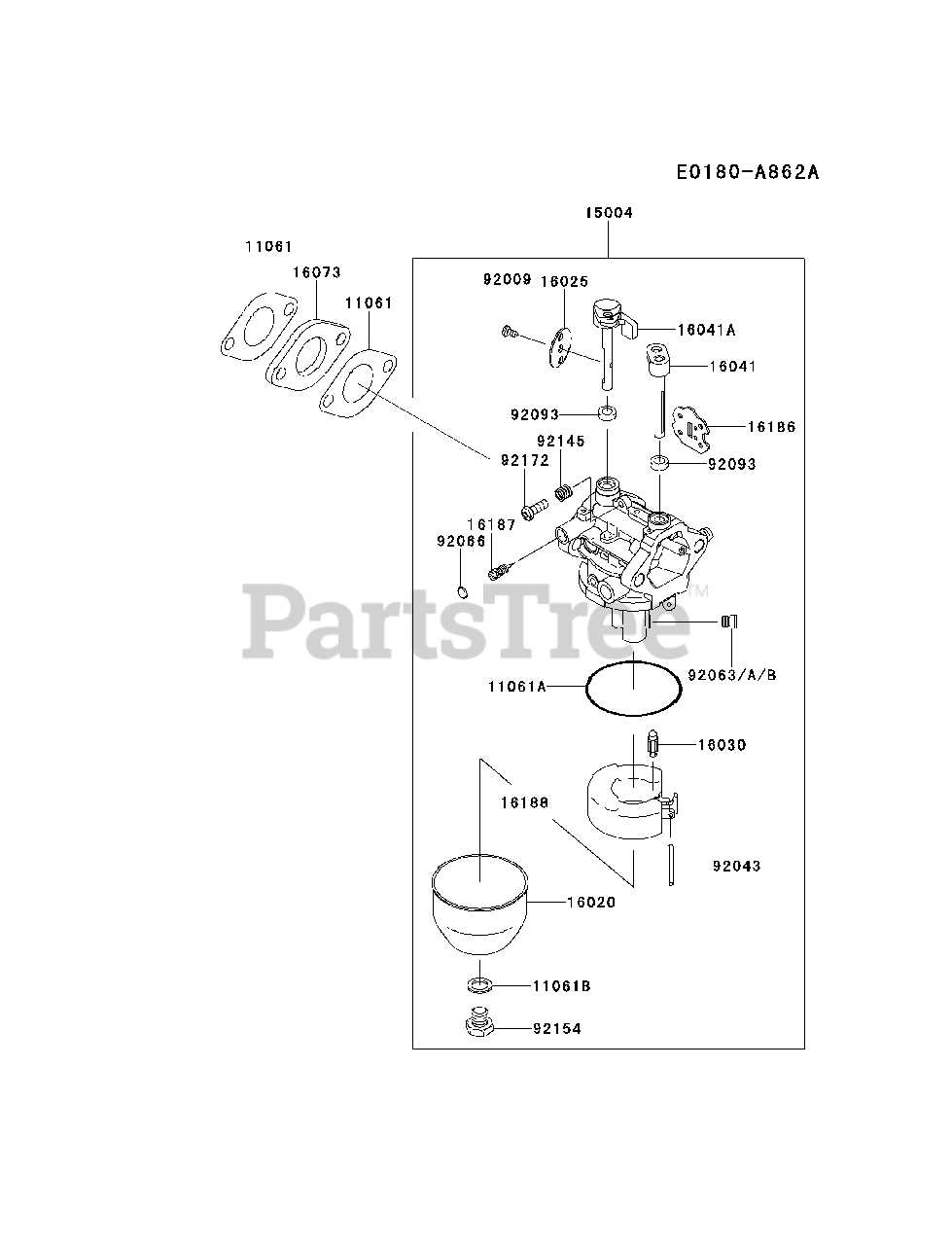

Fuel System

The fuel system is integral for delivering energy to the engine. It includes the fuel tank, filter, and carburetor, all of which work together to ensure a proper air-fuel mixture. Maintaining this system is essential for smooth operation and longevity.

Where to Find Replacement Parts

When it comes to maintaining machinery, sourcing high-quality components is crucial for optimal performance and longevity. Whether you’re in need of a specific item or looking to stock up on essentials, understanding where to find reliable replacements can save time and effort.

Online Retailers

The internet offers a plethora of options for obtaining spare components. Websites specializing in equipment supplies often feature a wide range of products, complete with descriptions and customer reviews. Be sure to choose reputable platforms that guarantee quality and provide secure payment methods.

Local Dealers and Service Centers

Visiting nearby distributors or service facilities can be beneficial, particularly for those who prefer to see items in person. These locations often have knowledgeable staff who can assist in identifying the correct replacements. Additionally, local suppliers may offer support for installation and maintenance.

For the best results, consider both online and local resources. Combining these options ensures access to a variety of choices while also providing the opportunity for expert advice.

Tips for Maintenance and Repair

Regular upkeep and prompt repairs are essential for prolonging the life of your equipment. Following a structured approach can help prevent issues and enhance performance. Here are some valuable suggestions to keep in mind.

- Routine Inspections: Conduct frequent checks to identify wear and tear. Look for signs of damage or leaks that could indicate underlying problems.

- Clean Components: Remove debris and buildup from essential parts. Keeping surfaces clean can prevent overheating and ensure efficient operation.

- Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule. Using the correct specifications for oil changes and filter replacements is crucial.

- Use Quality Replacement Parts: When repairs are needed, opt for high-quality components to maintain optimal performance and reliability.

Implementing these strategies will help you maintain your machinery effectively and minimize the likelihood of unexpected breakdowns.

Understanding Engine Specifications

Engine specifications play a crucial role in determining the performance and efficiency of any machinery. They encompass a variety of details that influence how an engine operates, including its power output, torque, fuel consumption, and operational capabilities. Grasping these specifications is essential for selecting the right engine for a specific application and ensuring optimal functionality.

Key components such as displacement, compression ratio, and horsepower are vital indicators of an engine’s capabilities. Displacement refers to the total volume of all the cylinders, which directly affects the power generated. The compression ratio indicates how much the fuel-air mixture is compressed before ignition, impacting efficiency and performance. Additionally, horsepower is a measure of the engine’s ability to do work, which can vary based on design and intended use.

Understanding these parameters allows for better decision-making when it comes to maintenance, modifications, and upgrades. It also aids in troubleshooting performance issues by providing insights into how different factors might be affecting the engine’s overall efficiency. A thorough knowledge of these specifications ultimately enhances the longevity and reliability of the equipment.

How to Use a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repairs. This guide will help you navigate these illustrations to identify and acquire the necessary items for your equipment.

Firstly, familiarize yourself with the layout. Typically, each section of the illustration corresponds to a specific area of the machine. Take note of any labels or numbers that can assist in locating particular elements.

Next, compare the visual elements with your actual equipment. This comparison will help you determine which components need replacement or servicing. Pay attention to the orientation and positioning of each part, as these details are crucial for correct assembly.

Moreover, it’s beneficial to refer to the accompanying list of components, which usually provides additional information such as part numbers and descriptions. This list can aid in ensuring you order the correct replacements without confusion.

Lastly, if you encounter any difficulties, consult manuals or online resources. These can offer further insights into troubleshooting or provide context that might be missing from the illustrations. Understanding these visuals thoroughly can significantly enhance your repair process.