When maintaining and repairing outdoor power equipment, having a clear understanding of its individual components is crucial. Identifying each part’s function and how it fits into the overall system can simplify troubleshooting and ensure proper operation. This knowledge becomes especially important when attempting to replace damaged or worn-out parts, as it helps you identify what needs to be fixed or replaced and how to do it efficiently.

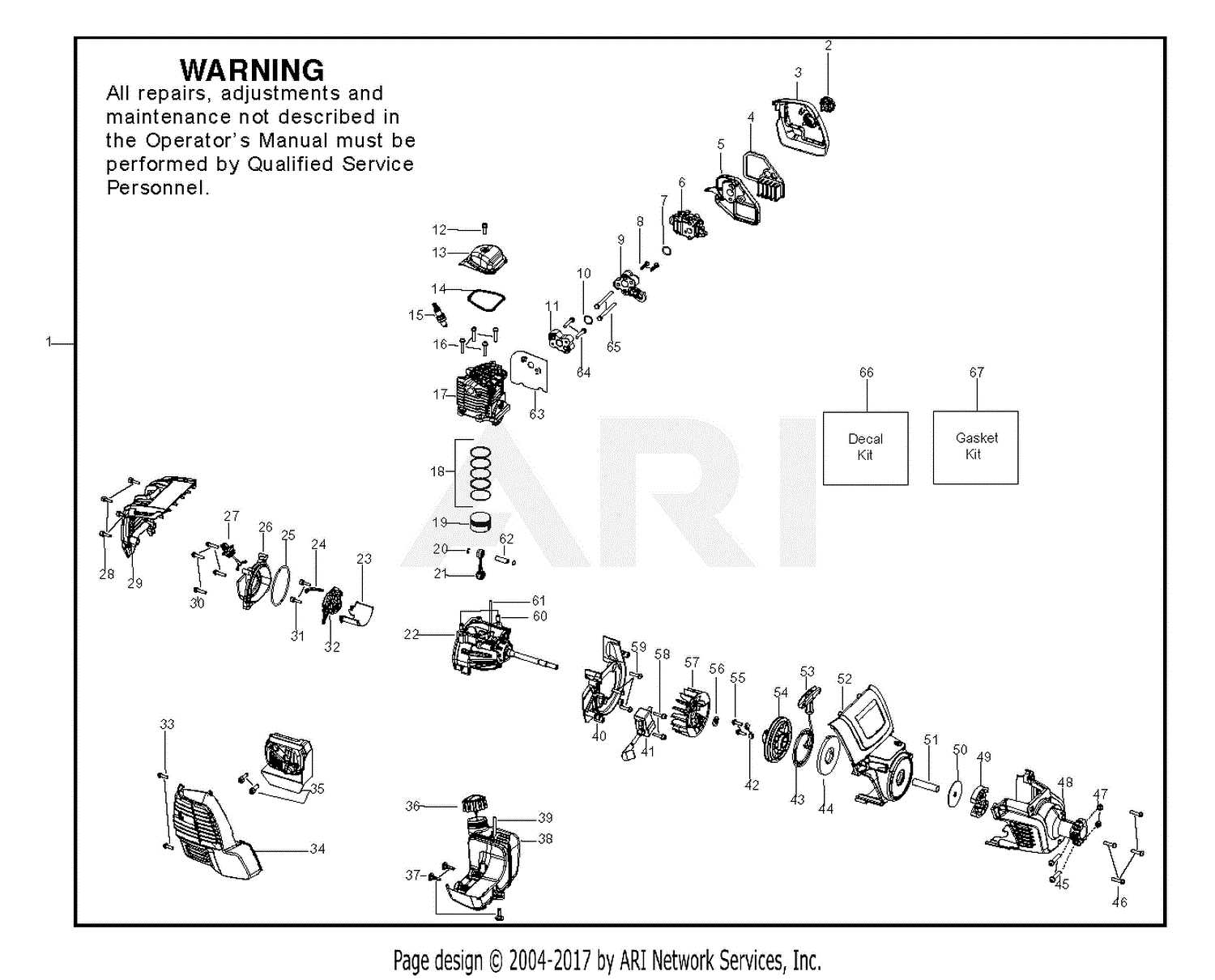

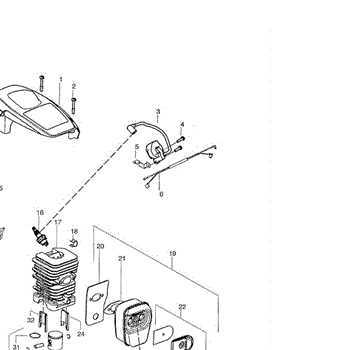

Detailed schematics provide a visual representation of the internal and external components, making it easier for users to locate and understand the function of each piece. Such diagrams are invaluable when handling repairs or upgrades, as they offer a straightforward guide that complements the user manual. Whether you’re a seasoned mechanic or a novice looking to make simple fixes, these detailed illustrations make the process more accessible.

With this guide, you will be equipped with the necessary tools to tackle maintenance tasks with confidence. Understanding how each element fits into the larger machinery allows for a more informed and effective approach to upkeep. The clarity provided by component layouts can significantly reduce errors and streamline the repair process, leading to a more efficient and longer-lasting machine performance.

Poulan Pro PP4218A Overview

This section provides a comprehensive look at a specific model designed for outdoor maintenance tasks. Renowned for its reliability and performance, this tool is well-suited for both residential and commercial use. Users can expect a combination of efficiency and ease of operation, making it a popular choice among enthusiasts and professionals alike.

Key features of this model include a robust engine, which ensures powerful performance during heavy-duty tasks. Additionally, the ergonomic design promotes comfort, allowing users to operate for extended periods without fatigue. The device is equipped with a series of safety features that enhance its usability and protect the operator.

Maintenance is simplified with easy access to essential components, ensuring that users can keep their equipment in top condition. This model not only meets the demands of various projects but also incorporates innovative technology to improve overall user experience.

Essential Components of the Chainsaw

A chainsaw is a powerful tool made up of various key components that work together to ensure optimal performance and durability. Each part plays a crucial role in the operation, from the engine that powers the saw to the cutting mechanism that makes it effective for cutting through wood. Understanding these fundamental elements is essential for maintenance, repair, and safe usage of the device.

Engine: The heart of any chainsaw, the engine powers the entire system. Typically, chainsaws are equipped with either gas-powered or electric engines. The engine converts fuel or electricity into mechanical energy, which drives the other components such as the chain and bar.

Guide Bar: This long metal bar serves as the support structure for the chain. It helps maintain the chain’s alignment and provides a track along which the chain moves during operation. The guide bar comes in various lengths to suit different tasks, from light pruning to heavy-duty tree cutting.

Cutting Chain: The cutting chain is the component that actually does the work of cutting through wood. It is made up of a series of sharp teeth, which are connected by links, and moves along the guide bar as the engine powers it. The chain must be regularly sharpened and maintained to ensure effective cutting.

Clutch: The clutch system connects the engine to the chain, engaging or disengaging power depending on whether the chainsaw is idling or in operation. When the throttle is pressed, the clutch engages, allowing the chain to move and cut through materials.

Throttle: The throttle controls the speed of the engine, and thus the speed of the chain. By adjusting the throttle, the operator can increase or decrease the cutting speed depending on the material being cut and the required precision.

Air Filter: The air filter prevents dirt, dust, and debris from entering the engine, ensuring that it runs efficiently. A clean filter is essential for maintaining the chainsaw’s performance and extending its lifespan.

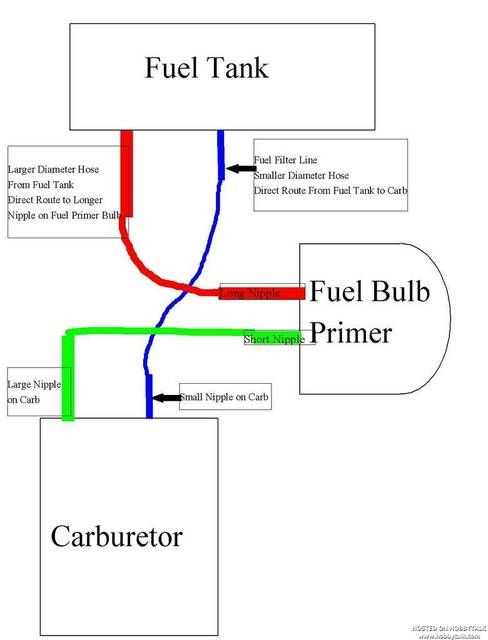

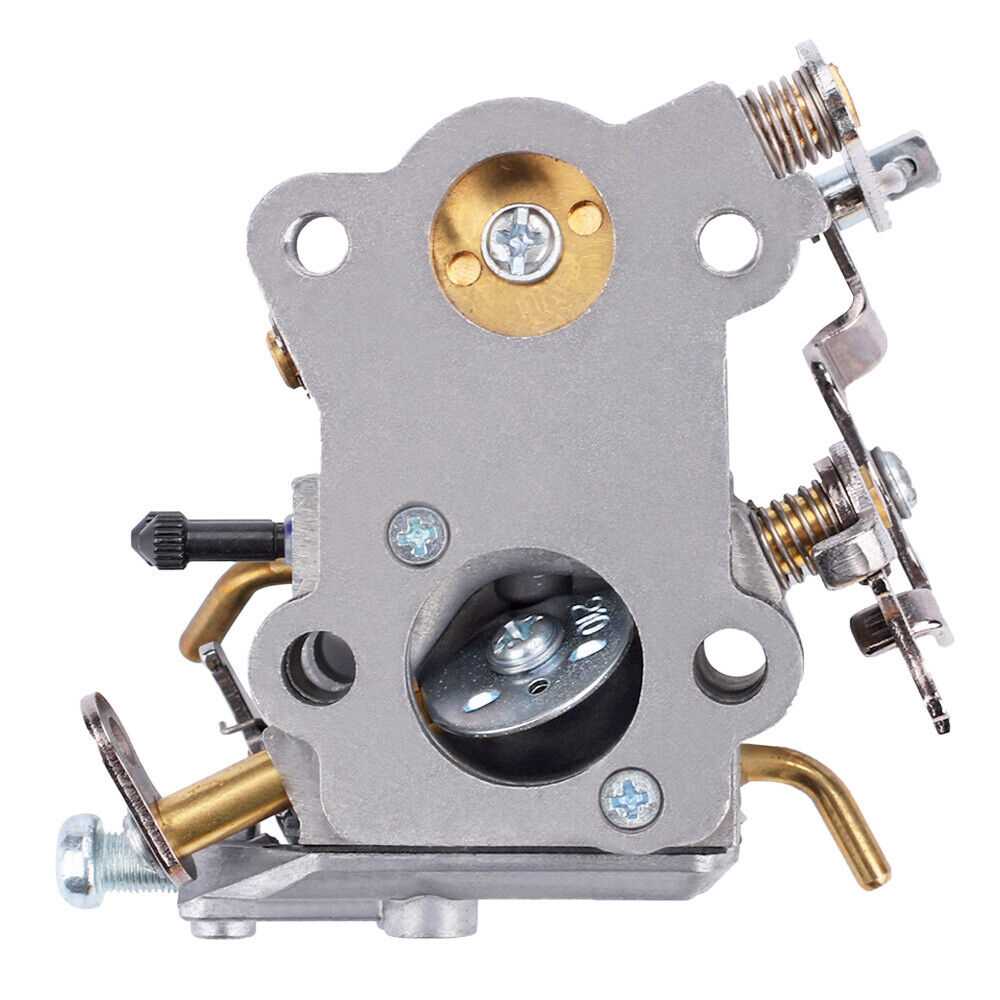

Fuel System: The fuel system consists of the fuel tank, fuel lines, and carburetor. It supplies the engine with the necessary fuel to operate. Proper fuel mixture and maintenance of the fuel system are vital to prevent engine issues.

Chain Brake: This safety feature stops the chain from moving if the chainsaw kicks back, preventing potential injury. It’s an essential component for user protection, especially when working in unpredictable conditions.

By familiarizing yourself with these core components, you can better care for your tool, troubleshoot issues, and ensure that each element is functioning at its best, providing you with safe and efficient operation every time you use it.

Understanding the Parts Diagram

When working with machinery or tools, it’s essential to have a clear visual representation of all the components involved. Such visuals provide a detailed map that allows users to identify, replace, or maintain various elements effectively. These diagrams are typically organized in a way that illustrates how each part fits together, ensuring a smoother repair or assembly process.

Interpreting this visual map requires familiarity with the names and functions of the different parts. Each component is usually numbered or labeled for easy reference, and understanding the relationship between these elements can save time and effort during maintenance or repair tasks. By analyzing the layout, users can quickly identify which specific parts need attention without the need for guesswork.

Knowing how to read and use this guide is crucial for anyone looking to maintain or troubleshoot equipment effectively. It ensures that replacements are accurate, and reassembly is done correctly, reducing the risk of damage or operational failure. In essence, these visual references act as a blueprint for proper maintenance, enhancing overall efficiency and longevity of the equipment.

Common Issues and Solutions

Every mechanical device can encounter challenges over time, leading to decreased performance or functionality. Understanding these common problems and their remedies can significantly enhance the longevity and efficiency of your equipment.

Engine Starting Difficulties

One frequent issue is trouble starting the engine. This can be attributed to a weak battery, fuel contamination, or a clogged air filter. Solution: Check the battery condition, ensure fuel is clean, and replace or clean the air filter to facilitate proper airflow.

Overheating Problems

Overheating can cause significant damage if not addressed promptly. It may arise from insufficient lubrication or blocked cooling vents. Solution: Regularly check oil levels and ensure vents are clear to maintain optimal operating temperatures.

Replacement Parts Availability

When it comes to maintaining your equipment, accessibility of components plays a crucial role in ensuring optimal performance and longevity. Finding the right elements for repair or replacement is essential for any user, as it directly affects functionality and safety.

Numerous suppliers provide a wide range of compatible items, making it easier to restore your equipment to its full potential. Here is a summary of the most common categories of components along with their availability:

| Component Type | Availability | Suggested Sources |

|---|---|---|

| Engines | Widely Available | Online Retailers, Local Dealers |

| Blades | Commonly Found | Home Improvement Stores, Specialty Shops |

| Fuel Systems | Moderate Availability | Authorized Distributors, Online Platforms |

| Electrical Components | Readily Available | Electronics Stores, Online Retailers |

| Filters | Easy to Source | Local Service Centers, Retail Chains |

By knowing where to look and understanding the types of components needed, you can ensure that your equipment remains in excellent working condition for years to come.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the lasting performance of your equipment. By following a few simple guidelines, you can enhance its efficiency and extend its lifespan significantly. Consistent care not only minimizes wear and tear but also optimizes functionality, making your tools reliable for many years to come.

Routine Cleaning

Cleaning your equipment after each use helps prevent debris buildup that can lead to damage. Pay special attention to air filters and blades, ensuring they remain free from obstructions. A clean machine operates more efficiently and is less prone to issues.

Regular Inspections

Conducting periodic checks allows you to identify potential problems before they escalate. Look for signs of wear, such as frayed wires or loose components, and address them promptly. This proactive approach ensures that your equipment remains in optimal condition.

Safety Features of Poulan Pro

Ensuring user safety is paramount in the design of outdoor power equipment. Manufacturers implement various mechanisms and technologies to minimize the risk of accidents and enhance the overall user experience. These safety features play a critical role in protecting users from potential hazards while operating machinery.

Key Safety Mechanisms

Among the essential safety features are the following:

| Feature | Description |

|---|---|

| Chain Brake | Automatically stops the chain when a sudden movement is detected, preventing injuries. |

| Throttle Lock | Prevents accidental throttle engagement, ensuring control during operation. |

| Safety Goggles | Recommended protective eyewear to shield eyes from debris and potential hazards. |

| Ergonomic Handle | Designed for a comfortable grip, reducing fatigue and enhancing control. |

Importance of User Awareness

In addition to built-in features, user education plays a vital role in safety. Familiarizing oneself with operational guidelines and understanding the equipment’s functionalities can significantly reduce risks. Regular maintenance checks and adherence to safety protocols further contribute to a secure working environment.

Upgrading Your Chainsaw Performance

Enhancing the efficiency of your cutting tool can significantly improve your work experience and productivity. By focusing on various components and adjustments, you can elevate the overall functionality, allowing for smoother operation and better results in your tasks.

Improving Engine Efficiency

One of the ultimate ways to boost performance is by tuning the engine. Regular maintenance, such as cleaning or replacing the air filter, can lead to optimal airflow, resulting in increased power output. Additionally, considering a high-performance spark plug can enhance combustion efficiency, providing a noticeable upgrade in cutting capability.

Upgrading the Bar and Chain

Another essential aspect involves the bar and chain. Choosing a chain with a lower gauge or a different pitch can affect the cutting speed and precision. Opting for a lightweight bar can also reduce fatigue during prolonged use, ultimately making your cutting tasks more efficient and enjoyable.

Where to Find Technical Support

Accessing reliable assistance is essential for anyone needing help with machinery. Whether you’re facing operational issues or require maintenance guidance, numerous resources can provide the necessary support. Identifying the right avenues can streamline the troubleshooting process and enhance your experience with the equipment.

Official Manufacturer Resources

The first place to seek help is the manufacturer’s official website. Here, you can often find comprehensive user manuals, FAQs, and contact information for customer service. Engaging with these resources ensures you receive accurate and up-to-date assistance tailored to your specific model.

Online Communities and Forums

Another valuable option is online forums and community groups dedicated to machinery enthusiasts. These platforms allow users to share experiences, tips, and solutions, fostering a collaborative environment where knowledge is freely exchanged. Participating in such communities can lead to discovering effective troubleshooting techniques and expert advice.