In the realm of heavy machinery, the efficiency of various operations often hinges on the interplay between components designed for seamless integration. The functionality of these mechanisms significantly influences productivity and versatility on the job site. A well-structured approach to understanding these elements can enhance both performance and safety.

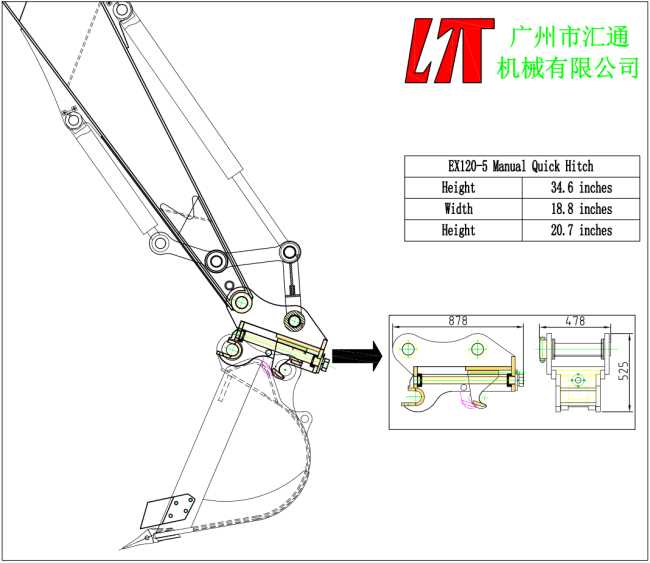

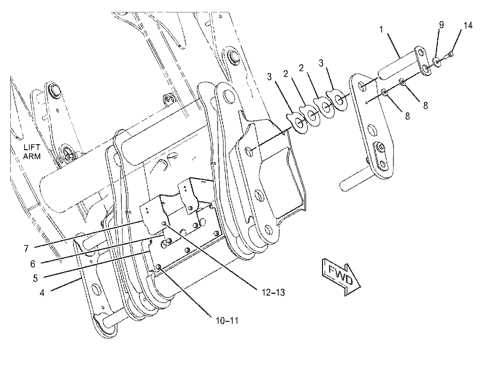

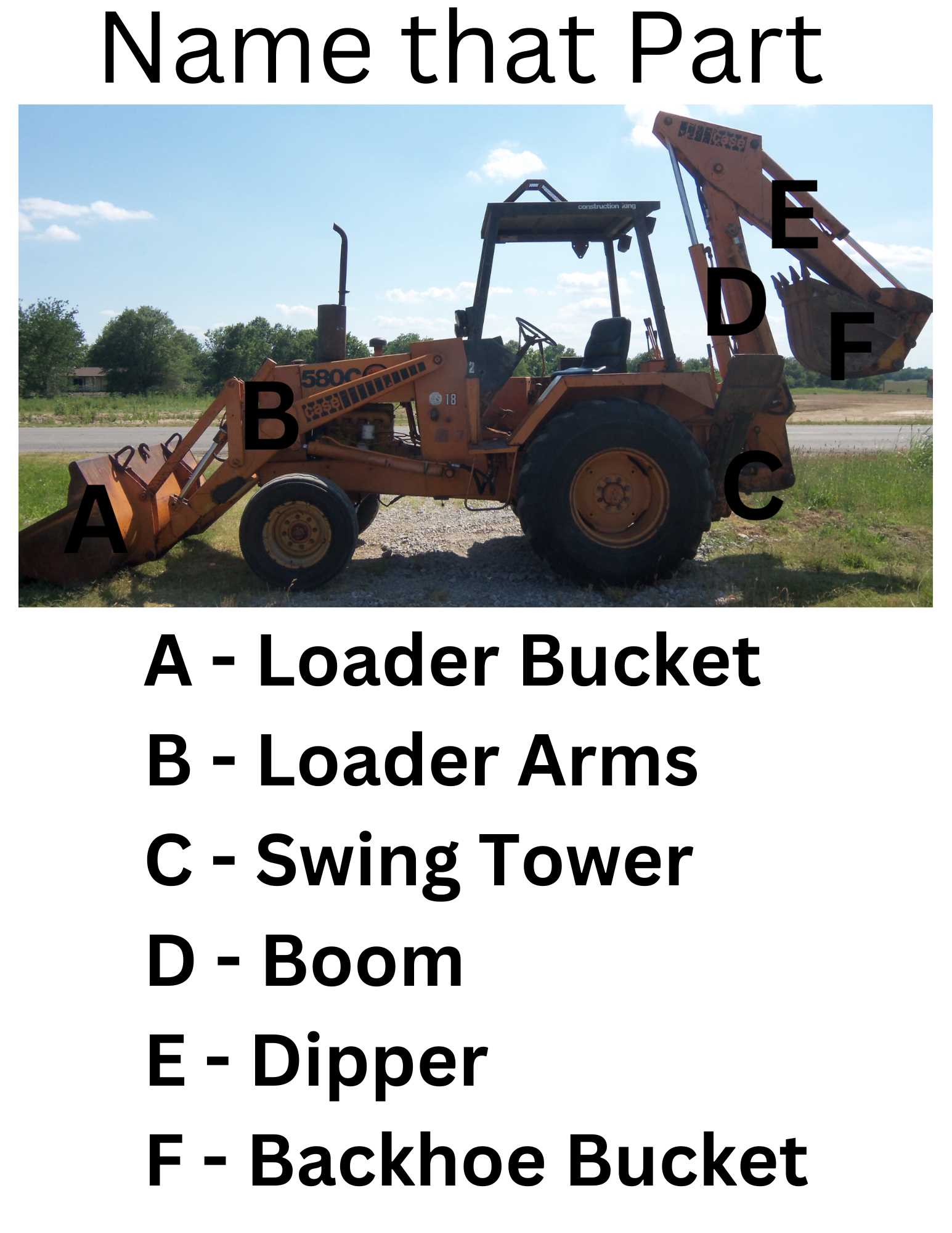

Detailed illustrations and schematics serve as vital resources for operators and technicians, allowing for a clearer comprehension of assembly and maintenance. By delving into the intricate relationships between different components, one can gain insights into how they interact and contribute to the overall system’s effectiveness. This knowledge is essential for anyone involved in the operation or servicing of machinery.

Furthermore, familiarity with the structural aspects and variations of these attachment systems not only aids in troubleshooting but also empowers users to make informed decisions regarding upgrades or replacements. A thorough exploration of these components can unveil the nuances that define optimal operation and longevity in demanding environments.

Understanding JRB Excavator Quick Couplers

In the realm of heavy machinery, the efficiency and versatility of attachments play a crucial role in enhancing productivity. A particular mechanism facilitates the rapid exchange of tools, allowing operators to switch between various implements seamlessly. This adaptability not only streamlines workflow but also significantly reduces downtime on job sites.

Key components of this system are engineered to ensure a secure and reliable connection between the main unit and the attachment. Understanding the functionality of these elements is essential for maintaining optimal performance. Regular inspections and maintenance can prevent wear and tear, ensuring longevity and reducing the likelihood of operational failures.

Moreover, familiarity with the installation process and safety protocols associated with this mechanism is vital. Proper usage not only enhances the effectiveness of tasks but also protects the operator and machinery from potential hazards. Training and knowledge about the specific features of the attachment system can lead to more efficient and safer operations.

Components of Quick Coupler Systems

In modern machinery, the efficient exchange of attachments plays a crucial role in enhancing productivity. Various elements work together to facilitate this seamless transition, ensuring that different tools can be utilized without hassle. Understanding these essential components can greatly improve operational effectiveness and versatility in construction tasks.

The primary mechanism includes a locking device, which secures attachments in place during operation. This ensures safety and reliability, preventing unintended detachment while in use. Additionally, an interface plate serves as the connection point, allowing different implements to be attached or removed with ease.

Hydraulic systems are integral, providing the necessary force to engage and disengage attachments. These systems are typically operated through controls located within the operator’s cabin, enhancing convenience and control. Furthermore, wear-resistant materials are utilized in construction to prolong the lifespan of these systems, reducing maintenance needs and downtime.

Lastly, sensors and indicators may be incorporated to monitor the attachment status, ensuring proper engagement and safety. Each of these components plays a vital role in the overall functionality, making operations smoother and more efficient in the field.

Importance of Proper Maintenance Practices

Benefits of Regular Upkeep

- Increases Equipment Lifespan

- Enhances Operational Efficiency

- Reduces Risk of Accidents

- Minimizes Repair Costs

Key Maintenance Practices

- Regular Inspections

- Timely Lubrication

- Prompt Repairs

- Thorough Cleaning

How to Identify Parts in Diagrams

Understanding visual representations is essential for anyone working with machinery. Identifying components accurately allows for efficient maintenance and repair. Familiarizing yourself with common symbols and layouts can greatly enhance your ability to interpret these illustrations.

Key Elements to Consider

- Labels: Look for annotations that describe each element. They often provide crucial information about functionality and specifications.

- Shapes: Different shapes typically represent different types of components. Recognizing these can help you categorize elements quickly.

- Connections: Pay attention to how items are linked. Arrows or lines may indicate movement, flow, or connections, which are vital for understanding operations.

Steps to Follow

- Review the Legend: If available, start with the legend or key that explains the symbols used in the illustration.

- Break it Down: Segment the diagram into smaller sections to analyze each part individually.

- Cross-reference: Use manuals or reference materials to compare and verify the components you identify.

- Practice: Regularly engage with different illustrations to improve your recognition skills over time.

Common Issues with Quick Couplers

Interfacing tools and machinery often leads to complications that can affect productivity and safety. Understanding the typical problems associated with these connection devices is crucial for maintenance and operational efficiency. Users should be aware of potential challenges to ensure a seamless workflow.

Wear and Tear

Over time, the components that facilitate attachment can experience significant wear. This degradation may result in poor fitment and reduced performance. Regular inspection is essential to identify signs of fatigue, such as cracks or deformation, which can compromise functionality.

Misalignment

Another frequent issue involves misalignment during connection. When components are not properly aligned, it can lead to difficulties in engagement and disengagement. This misalignment not only affects the efficiency of the machinery but may also pose safety risks for operators. Proper training and awareness can mitigate these issues significantly.

Upgrading Your Excavator’s Coupler

Enhancing your machinery’s attachment system can significantly improve its versatility and efficiency on the job site. By investing in a modern connection mechanism, you can easily switch between various tools, maximizing productivity and reducing downtime. This upgrade not only streamlines operations but also ensures that your equipment remains competitive in an evolving market.

Benefits of a Modern Attachment System

One of the primary advantages of a contemporary connection mechanism is the ability to rapidly change tools without the need for additional manpower or extended downtime. This feature enables operators to adapt to different tasks swiftly, enhancing overall workflow. Furthermore, newer systems often come equipped with advanced safety features, minimizing the risk of accidents during attachment and detachment processes.

Considerations Before Upgrading

Before proceeding with the upgrade, it’s crucial to assess compatibility with your existing machinery and evaluate the specific needs of your projects. Consider factors such as load capacity, ease of use, and maintenance requirements. Consulting with professionals or reviewing manufacturer recommendations can provide valuable insights, ensuring that the new mechanism aligns with your operational goals.

Safety Tips for Using Quick Couplers

Ensuring safety during the operation of attachment systems is crucial for preventing accidents and promoting efficient work practices. Familiarizing oneself with proper usage techniques and safety measures can significantly reduce the risk of injury and equipment damage. This section outlines essential guidelines to enhance safety when utilizing these versatile connection mechanisms.

Pre-Operational Checks

Before commencing work, it is vital to perform thorough inspections of the attachment system. This includes checking for wear, damage, or any loose components that could compromise functionality.

| Inspection Item | What to Look For | Action Required |

|---|---|---|

| Connections | Loose fittings or cracks | Tighten or replace as necessary |

| Hydraulic Lines | Leaks or wear | Repair or replace immediately |

| Operating Mechanism | Obstructions or damage | Clear debris or replace parts |

Operational Guidelines

When operating, always maintain awareness of your surroundings. Ensure that the work area is clear of personnel and obstacles, and communicate effectively with team members to prevent misunderstandings. Following established procedures can help mitigate risks during attachment changes and operations.

Comparing Brands: JRB vs Others

This section explores the key distinctions among various brands in the attachment industry, focusing on performance, durability, and user experience. Understanding these differences can guide users in making informed decisions that enhance operational efficiency.

Key Factors to Consider

- Quality: Assess the materials and craftsmanship.

- Compatibility: Ensure that the attachments fit various machinery models.

- Price: Compare cost-effectiveness and value for money.

- Customer Support: Evaluate the level of service and warranty offered.

Brand Comparisons

- Brand A: Known for innovative designs but at a higher price point.

- Brand B: Offers budget-friendly options with decent durability.

- Brand C: Focuses on robust construction and reliability, appealing to heavy users.

Ultimately, evaluating these brands allows users to delve deeper into their needs and select the best fit for their operations.

Resources for Further Learning

This section aims to provide valuable materials and references for those looking to deepen their understanding of attachment systems and their components. Exploring these resources can enhance both theoretical knowledge and practical skills, ultimately leading to improved efficiency in operations.

Books: Consider investing in technical manuals and textbooks that focus on machinery and attachment mechanisms. These can serve as excellent foundational materials.

Online Courses: Numerous platforms offer specialized courses in equipment handling and maintenance. Engaging with these can provide hands-on experience and expert insights.

Forums and Community Groups: Joining online communities and discussion boards can facilitate knowledge exchange and problem-solving with fellow enthusiasts and professionals.

Videos and Tutorials: Platforms like YouTube host a variety of instructional videos that visually demonstrate installation and maintenance techniques, making complex concepts easier to grasp.

Manufacturer Websites: Visiting the official websites of manufacturers often yields valuable technical documents, user manuals, and troubleshooting guides tailored to specific models.