When exploring the internal structure of heavy-duty vehicles, it’s crucial to understand the intricate arrangement of various elements. This understanding allows for a deeper appreciation of how different components function together to ensure efficient operation. Every piece plays a vital role in the overall performance, making it essential to have a clear layout for effective maintenance and repairs.

To gain insights into how all sections are organized, it is helpful to have a detailed illustration. Such layouts not only assist mechanics but also vehicle owners in identifying key areas that require attention. With a precise visual reference, complex mechanical systems become more manageable, enabling smoother troubleshooting and part replacement when necessary.

Overview of Key Components in the 4700 Model

This section provides an introduction to the main structural and functional elements found in this vehicle model. Each element plays a crucial role in ensuring the smooth operation, stability, and performance of the machine. Understanding these features is essential for maintenance, upgrades, and overall functionality improvements.

Engine and Transmission

The heart of the vehicle, the powertrain, consists of components designed to deliver optimal power and torque. Its layout includes mechanisms responsible for power generation and transmission to the wheels, ensuring efficient energy conversion.

- Power generation system

- Torque transmission mechanisms

- Cooling and lubrication features

Suspension and Braking System

Critical to handling and safety, the suspension ensures a smooth ride, while the braking system provides control and stability during operation. These systems work in tandem to manage weight distribution and ensure safe stopping power.

- Weight distribution management

- Shock absorbers and springs

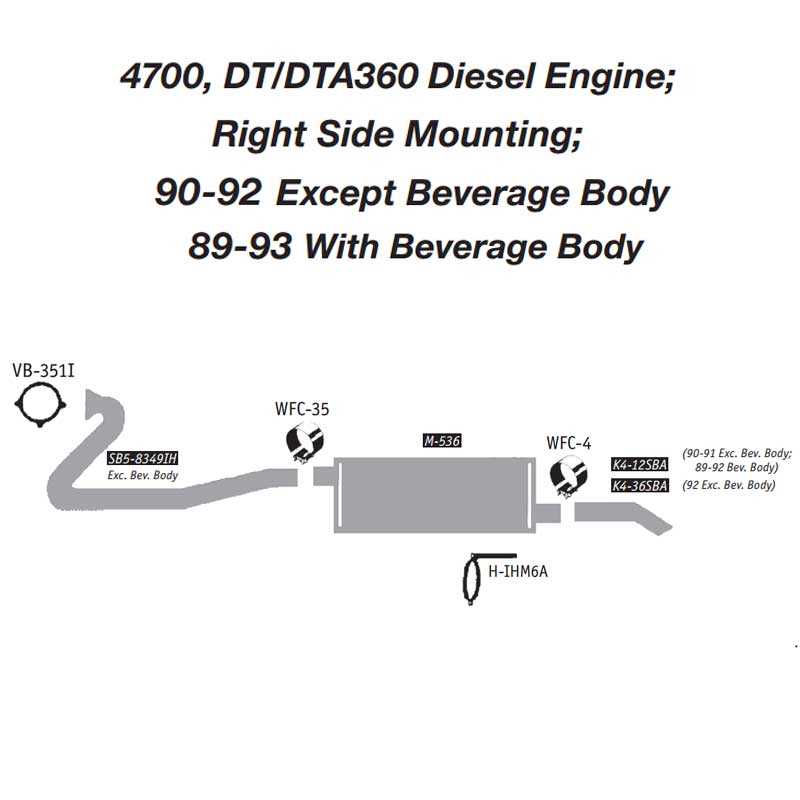

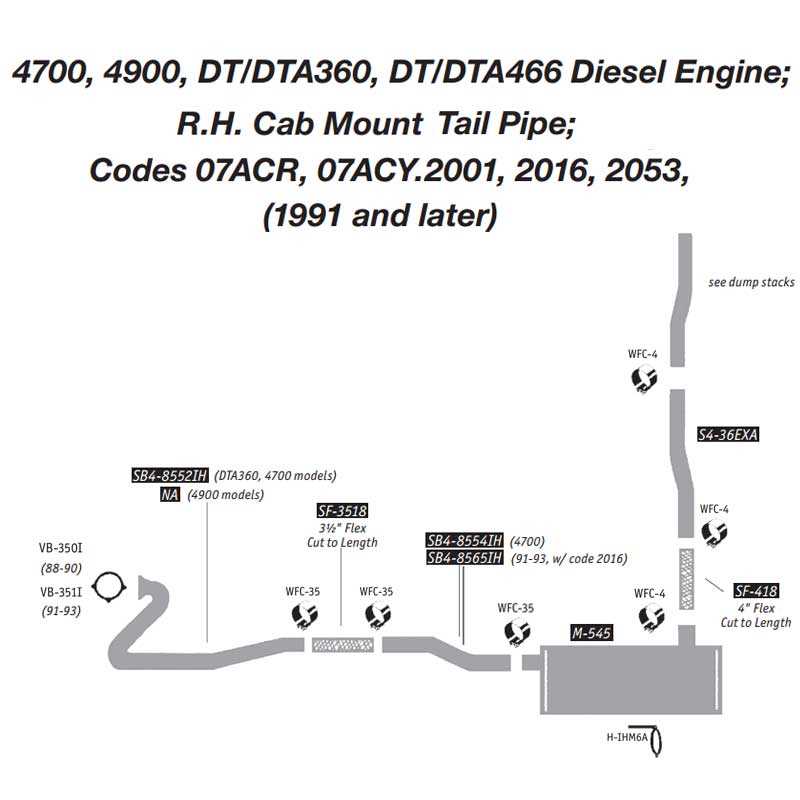

Engine System and Related Parts Explained

The structure of the motor and its associated mechanisms plays a vital role in ensuring the smooth operation of the vehicle. Understanding the core components and how they work together is key to maintaining overall performance. This section will delve into the various elements that make up this system, highlighting their roles in energy generation and distribution.

Power Generation Unit: At the heart of the system is the power source, which transforms fuel into mechanical energy. This transformation is essential for propelling the vehicle forward and ensuring that all other systems function effectively.

Cooling Mechanisms: To prevent overheating during operation, specialized equipment is incorporated to regulate temperatures. This ensures that the motor can run efficiently without the risk of damage from excessive heat.

Fuel Delivery System: This part of the setup is responsible for supplying the power unit with the necessary energy source in a controlled manner. A precise balance is maintained to optimize efficiency and performance.

Air Circulation Components: Proper airflow is essential for the combustion process, and several devices work in unison to provide the motor with the clean air needed for fuel ignition.

Exhaust Pathways: After combustion, waste gases are expelled through a carefully designed channel, ensuring that the vehicle meets environmental standards while maintaining performance.

Chassis Structure and Essential Elements

The foundation of any vehicle lies in the design and arrangement of its support frame. This section delves into the composition and key components that provide stability, ensuring the overall integrity of the structure. Understanding how these elements interact is crucial for maintaining performance and longevity.

Main Support Framework

The primary frame serves as the backbone, bearing the weight of the vehicle and its cargo. It is built to withstand various stresses, from uneven terrain to heavy loads. Reinforcements along key sections help distribute pressure evenly, enhancing durability.

Critical Connection Points

Strategically placed joints and fasteners ensure that all components of the support system remain securely linked. These points are designed to manage both movement and load distribution, preventing excessive wear and tear. Proper maintenance of these areas is vital for long-term reliability.

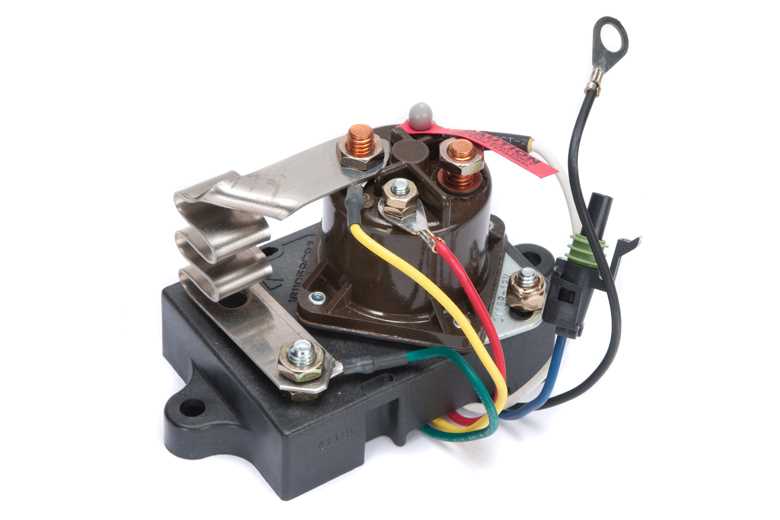

Electrical System Layout for the 4700 Truck

The electrical configuration of this vehicle is an essential aspect of its functionality, ensuring that all components operate seamlessly. From the power source to the distribution network, this system supplies energy to critical areas, allowing for reliable performance in both driving and operational scenarios. Understanding how energy is routed throughout the structure is key to effective maintenance and troubleshooting.

Power Source and Distribution

At the heart of the system lies the main power unit, which channels energy through a series of circuits. These circuits provide electricity to the lighting, engine control, and auxiliary features. Proper insulation and secure connections ensure that the current flows without interruptions or losses.

- Main power supply unit

- Primary and secondary distribution channels

- Safety mechanisms to prevent overloading

Control Modules and Wiring

Control modules manage various systems, from basic lighting to more advanced monitoring features. These modules communicate through a network of wires, transmitting signals to regulate performance. Each wire is assigned to specific functions, with color-coding and labeling used for easy identification during repairs or adjustments.

- Wiring harnesses connecting major systems

- Control units for engine and cabin functions

- Protective relays and fuses

Transmission and Gear Assembly Details

The system responsible for converting and directing power plays a critical role in the overall performance of any vehicle. Understanding how each element within this mechanism interacts is crucial for maintaining efficiency and longevity. The components work together to ensure smooth transitions between different states of motion, providing control over speed and torque.

Key components include the central mechanism that shifts states and the associated rotational elements that transfer force. These sections work in harmony, ensuring optimal function and seamless transitions. Regular inspection and upkeep are essential to avoid any wear and tear that might affect the synchronization of these elements.

Proper alignment and lubrication are vital for smooth operation. Even minor imbalances can lead to significant inefficiencies. This section will outline the core elements involved, their roles, and the importance of ensuring their functionality through regular checks.

Brake Mechanism and Component Breakdown

The braking system is a crucial element of any vehicle, ensuring safety and control during operation. Understanding its intricacies is essential for maintenance and troubleshooting. This section delves into the various components involved in the braking mechanism, providing insight into their functions and interconnections.

Key Components of the Braking System

- Brake Pedal: The initial point of engagement, allowing the driver to activate the braking system.

- Master Cylinder: Converts the mechanical force from the brake pedal into hydraulic pressure.

- Brake Lines: Transfer hydraulic fluid from the master cylinder to the brake calipers or wheel cylinders.

- Brake Calipers: Clamp down on the brake pads, creating friction against the brake disc to slow down or stop the vehicle.

- Brake Pads: The friction material that presses against the brake disc, responsible for slowing down the wheels.

- Brake Rotors: Disc components that work with the brake pads to create friction and dissipate heat during braking.

Understanding the Functionality

Each component plays a vital role in the overall effectiveness of the braking system. When the driver presses the brake pedal, the master cylinder generates hydraulic pressure that travels through the brake lines to the calipers. The calipers then press the brake pads against the rotors, creating the necessary friction to reduce speed. Regular inspection and maintenance of these elements are essential to ensure optimal performance and safety.

Suspension Parts and Their Functionality

The suspension system of a vehicle plays a critical role in ensuring comfort and stability while driving. This system comprises various components that work in harmony to absorb shocks from the road and maintain the vehicle’s alignment. Understanding these elements is essential for both maintenance and performance optimization.

Key components of the suspension system include:

- Shock Absorbers: These devices help control the impact and rebound movement of the vehicle’s springs, providing a smooth ride by minimizing the effect of road irregularities.

- Springs: Springs support the vehicle’s weight and absorb shocks, allowing for better control and stability. They can be of different types, including coil, leaf, and air springs.

- Control Arms: These link the vehicle’s chassis to the suspension system, allowing for controlled movement and alignment during driving.

- Sway Bars: Also known as anti-roll bars, these components help reduce body roll during cornering, enhancing stability and handling.

- Ball Joints: These flexible connectors allow for movement between the steering and suspension components, ensuring smooth operation and alignment.

Each of these elements plays a vital role in the overall performance and safety of the vehicle. Regular inspection and maintenance of the suspension components are necessary to ensure optimal functionality and to extend the lifespan of the system.

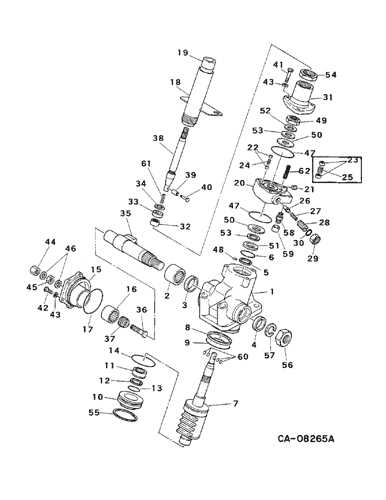

Steering System Components Overview

The steering mechanism is a vital aspect of any vehicle’s operation, ensuring smooth navigation and precise control. Understanding its various elements is crucial for effective maintenance and functionality. This section delves into the primary components that make up the steering system, highlighting their roles and interconnections.

Primary Elements of the Steering Mechanism

The main components include the steering wheel, which provides the driver with control; the steering column, which connects the wheel to the system; and the rack and pinion assembly, which translates rotational movement into lateral motion. These elements work together to facilitate easy maneuverability and responsiveness while driving.

Supporting Components

In addition to the primary parts, several supporting elements enhance the overall performance of the steering system. These include the power steering pump, which assists in reducing the effort needed to turn the wheel, and various linkages that transmit motion. Proper understanding and maintenance of these components are essential for ensuring optimal steering performance and safety on the road.

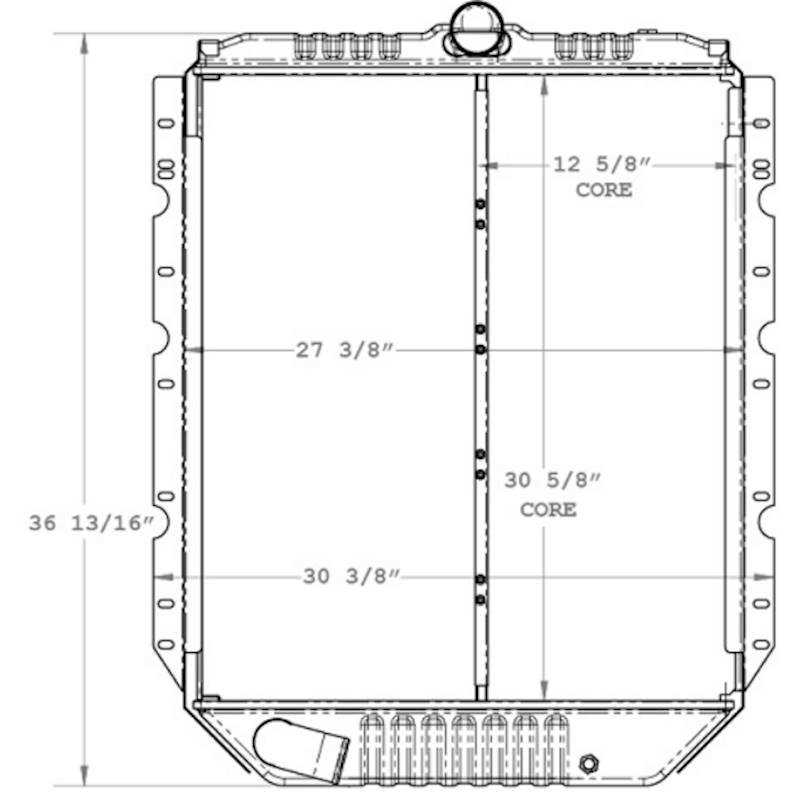

Cooling System Layout and Key Elements

The efficiency of any vehicle’s thermal management is crucial for optimal performance and longevity. A well-designed cooling arrangement ensures that the engine operates within a safe temperature range, preventing overheating and subsequent damage. This section delves into the primary components and configuration of the cooling assembly, highlighting its significance in maintaining engine health.

Core Components: The main elements of a cooling configuration typically include the radiator, water pump, thermostat, and coolant hoses. The radiator serves as a heat exchanger, dissipating excess heat from the coolant to the atmosphere. The water pump circulates the coolant throughout the system, ensuring a steady flow. The thermostat regulates the coolant temperature, opening and closing to maintain the desired heat level.

Flow Path: Understanding the flow path of the coolant is essential. Coolant is drawn from the engine into the water pump, which then sends it to the radiator for cooling. After passing through the radiator, the cooled fluid returns to the engine, completing the cycle. This continuous loop is vital for sustaining appropriate operating temperatures.

Importance of Maintenance: Regular maintenance of the cooling system is essential to prevent issues such as leaks, clogs, or pump failures. Periodic inspection of hoses and connections can help identify potential problems before they escalate, ensuring the system remains functional and efficient. Proper maintenance contributes to the overall reliability and performance of the vehicle.