In the realm of outdoor machinery, comprehending the intricate assembly of components is essential for effective maintenance and repair. Each machine is a complex network of parts that work harmoniously to deliver optimal performance. Familiarity with this arrangement not only enhances operational efficiency but also aids in troubleshooting and ensuring longevity.

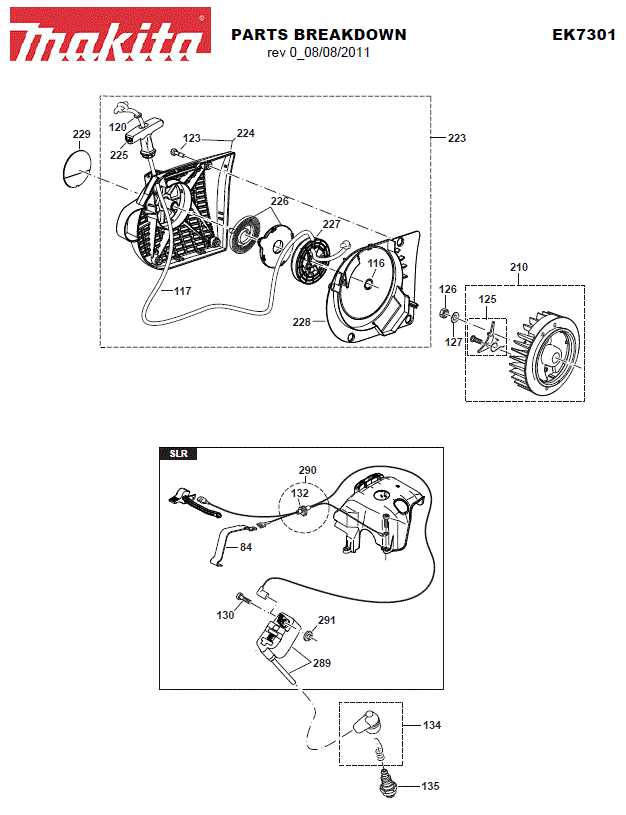

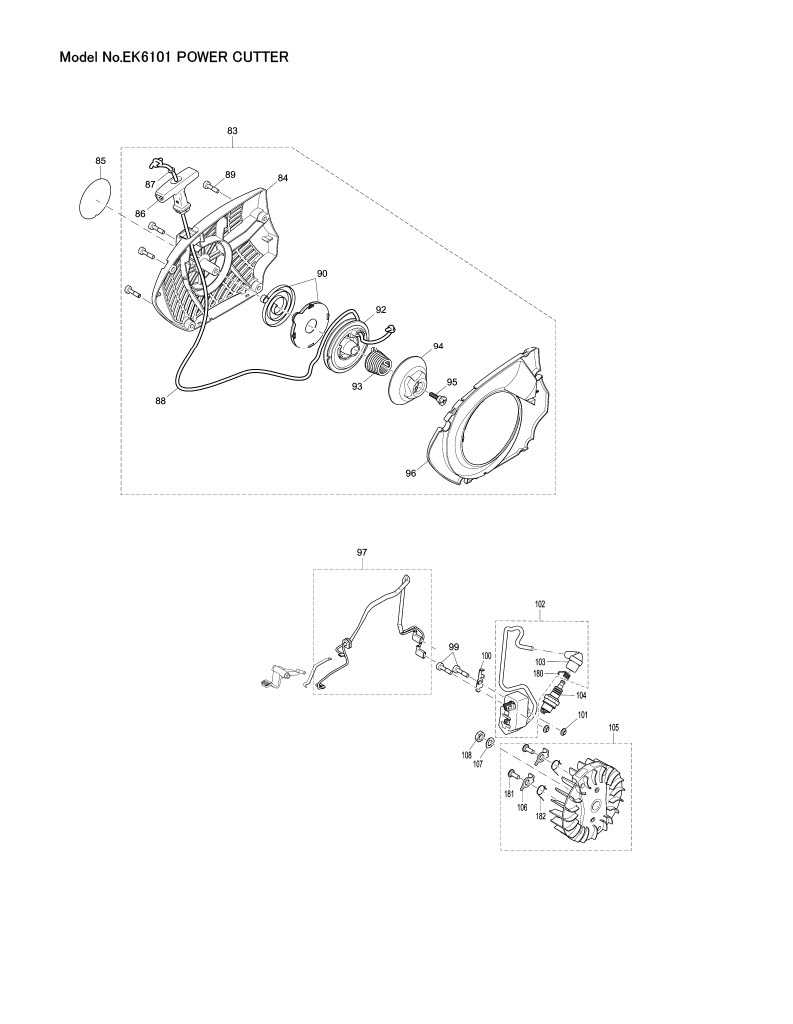

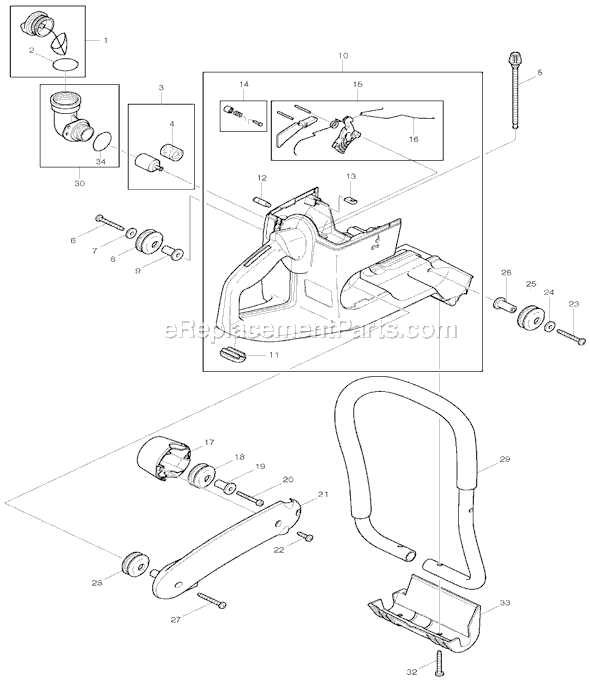

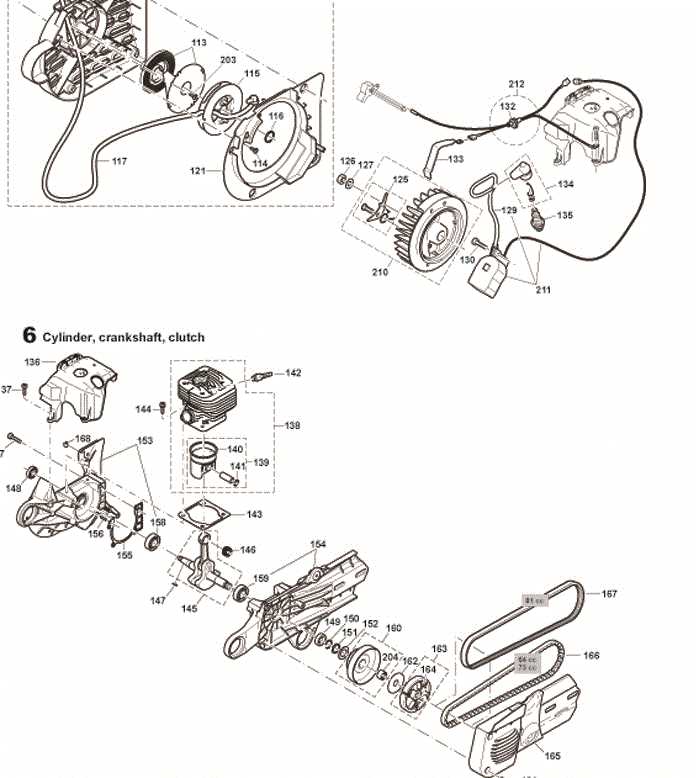

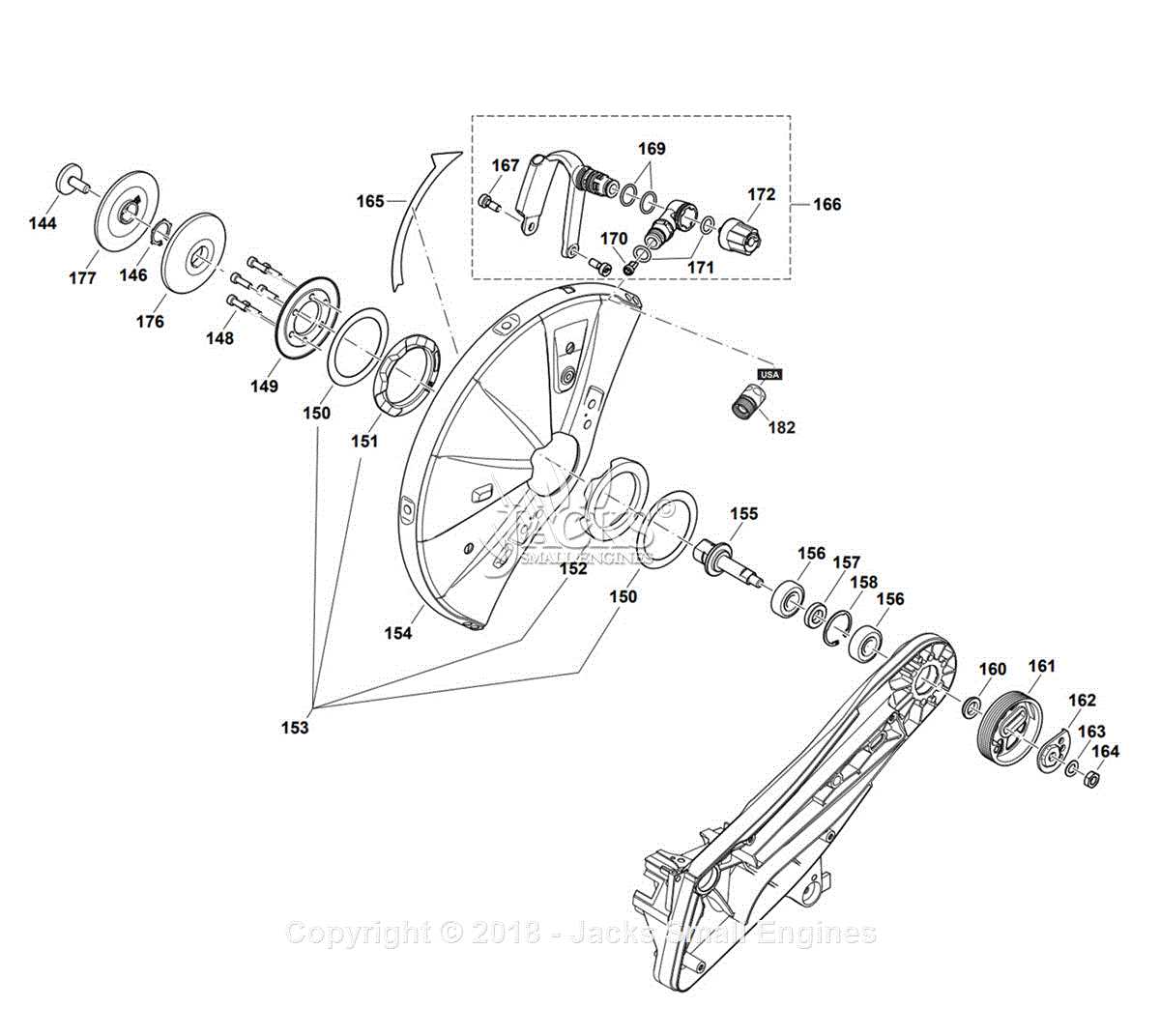

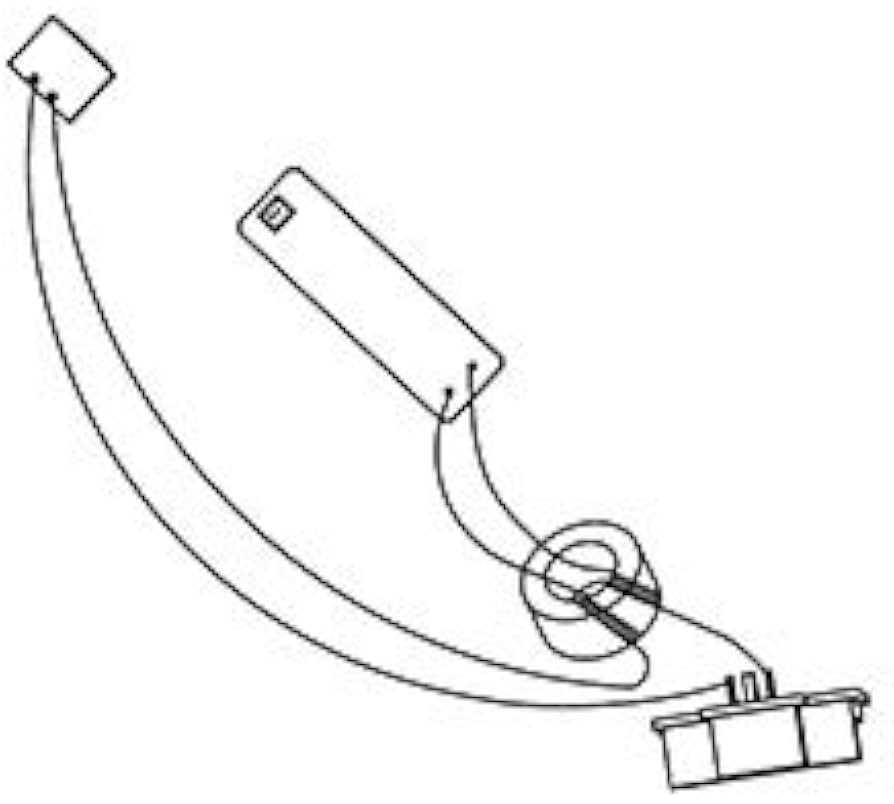

The significance of having a clear visual representation of the equipment’s internal structure cannot be overstated. Such illustrations serve as a valuable reference for users, enabling them to identify individual elements and their functions. This knowledge empowers owners to take proactive steps in preserving their machinery, minimizing downtime, and reducing repair costs.

By exploring the layout of the various sections, one can gain insights into how each piece contributes to the overall functionality. Whether for routine maintenance or major overhauls, understanding these configurations fosters confidence and competence in handling outdoor equipment. This guide aims to illuminate these connections, providing a comprehensive overview for enthusiasts and professionals alike.

Understanding the Makita EK6101 Diagram

Grasping the intricacies of a tool’s schematic representation is essential for effective maintenance and repair. This visual guide illustrates the various components and their interconnections, offering insight into how each element functions within the overall system. Familiarity with this layout not only aids in troubleshooting but also enhances your ability to perform routine servicing with confidence.

When examining the schematic, it’s important to identify key sections, which are typically categorized into several groups. Below is a simplified overview of the primary categories you may encounter:

| Component Group | Description |

|---|---|

| Engine Assembly | The heart of the tool, responsible for generating power. |

| Fuel System | Includes elements that manage fuel intake and combustion efficiency. |

| Electrical System | Involves components that support ignition and electronic control. |

| Cutting Mechanism | Comprises parts that interact to achieve cutting action. |

| Safety Features | Ensures the user’s protection during operation. |

By familiarizing yourself with these categories and their respective roles, you can streamline the repair process and enhance the longevity of the equipment. Whether you are a novice or an experienced user, understanding this representation will empower you to make informed decisions about maintenance and repairs.

Key Components of the EK6101

This section focuses on the essential elements that contribute to the performance and functionality of the equipment. Understanding these components is crucial for effective maintenance and optimal operation.

| Component | Description |

|---|---|

| Engine | The heart of the machine, providing the necessary power for operation. |

| Fuel System | Ensures the proper delivery of fuel to the engine, affecting efficiency and performance. |

| Cutting Blade | Essential for executing precise cuts, its design impacts the quality of work. |

| Handle Assembly | Provides stability and control, crucial for user safety during operation. |

| Air Filter | Prevents dust and debris from entering the engine, promoting longevity. |

| Ignition System | Facilitates the start-up process, ensuring reliable engine performance. |

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repairs. These illustrations serve as guides, helping users identify individual pieces and their relationships within a system. Mastering the art of interpreting these visuals can enhance both troubleshooting and assembly processes.

To effectively read these representations, consider the following steps:

- Familiarize Yourself with the Layout:

- Identify the key sections and labels.

- Note the orientation and scale of the illustration.

- Understand the Symbols:

- Learn what each symbol or line represents.

- Consult a legend if available to clarify meanings.

- Identify Key Components:

- Locate the main elements and their connections.

- Pay attention to any highlighted areas indicating specific focus.

- Cross-Reference with Manuals:

- Use user guides for additional context and details.

- Look for assembly instructions that correspond to the visual representation.

By following these steps, anyone can gain confidence in navigating and utilizing these essential visual aids for repairs and maintenance.

Common Issues and Replacement Parts

In any machinery, wear and tear can lead to various complications that require attention. Understanding these common challenges and knowing how to replace the necessary components can significantly enhance performance and longevity. This section aims to explore typical problems and the appropriate replacements to ensure optimal functionality.

Frequent Problems

One of the most prevalent issues involves the engine failing to start, often caused by fuel delivery problems or ignition system malfunctions. Additionally, overheating can occur due to insufficient cooling or blocked air vents. Regular maintenance can help mitigate these concerns.

Essential Components for Replacement

When addressing these issues, certain key components may need to be swapped out. Fuel filters should be replaced periodically to maintain efficient fuel flow. Ignition coils may also require replacement if starting issues persist. Regular checks of these elements can lead to smoother operation and extended service life.

Benefits of Using Genuine Parts

Opting for authentic components in machinery and tools ensures optimal performance and longevity. Genuine parts are designed specifically for the equipment, providing a perfect fit and enhancing overall functionality.

Here are some key advantages of choosing original components:

- Reliability: Authentic components undergo rigorous testing to meet high standards of quality, reducing the likelihood of failures.

- Performance: Using original parts helps maintain the intended performance levels, ensuring that the equipment operates as designed.

- Durability: Genuine components are made from high-quality materials, resulting in longer life spans compared to counterfeit alternatives.

- Warranty Protection: Many manufacturers offer warranties on their equipment, which can be voided if non-genuine parts are used.

- Safety: Original components are engineered to comply with safety regulations, minimizing the risk of accidents during operation.

In summary, investing in genuine components is crucial for maintaining the efficiency and safety of your tools, ultimately leading to cost savings in the long run.

Maintenance Tips for the EK6101

Proper upkeep of your equipment ensures optimal performance and longevity. Regular attention to key components can prevent breakdowns and enhance efficiency, making your tasks smoother and more enjoyable.

Regular Cleaning

Keep the machine free of debris and dirt. After each use, wipe down surfaces and remove any buildup that may hinder performance. This simple step can significantly prolong the life of your tool.

Inspection and Lubrication

Periodically check for wear and tear on moving parts. Lubricate essential components to reduce friction and prevent premature damage. Addressing minor issues early can save time and costs in the long run.

Where to Find Parts Online

When seeking replacement components for your equipment, the internet offers a wealth of resources. Whether you are looking for specific items to enhance performance or to replace worn-out elements, numerous platforms cater to these needs. Understanding where to search can save time and ensure you find the right pieces for your machinery.

Specialized Retailers

Many online retailers specialize in providing high-quality components for various tools and machinery. These sites often have extensive catalogs, allowing users to filter by brand, model, or type of item. Be sure to check the credibility of the retailer by reading customer reviews and verifying their return policies.

Marketplaces and Auction Sites

In addition to specialized retailers, online marketplaces can be a great option for finding what you need. These platforms allow individuals and businesses to sell new or gently used items. While this can lead to good deals, it’s crucial to examine the seller’s ratings and product descriptions carefully to avoid any issues.

In summary, exploring various online avenues will help you locate the necessary components efficiently. From specialized websites to broader marketplaces, a little research can lead you to the ideal solution for your repair or upgrade needs.

Comparing Aftermarket vs. Original Parts

The decision between utilizing alternative components and genuine offerings is crucial for maintaining equipment performance and longevity. Each option presents its own set of benefits and drawbacks, impacting both functionality and cost-effectiveness.

Quality and Performance

Original components are engineered to meet specific standards set by the manufacturer, ensuring optimal performance and durability. In contrast, aftermarket options can vary widely in quality. While some alternatives may provide satisfactory performance, others may lead to issues that compromise the overall efficiency of the machinery.

Cost Considerations

One of the most significant factors influencing choice is price. Aftermarket items generally offer a more budget-friendly solution, which can be attractive for those looking to save money. However, opting for genuine parts may result in fewer repairs and a longer lifespan, ultimately proving to be a wise investment.

Resources for Repair Guides

When it comes to maintaining and restoring equipment, having access to quality resources can significantly enhance the repair process. Whether you are a seasoned technician or a DIY enthusiast, various materials can help you understand the inner workings of your tools and facilitate effective troubleshooting. These resources often include manuals, instructional videos, and community forums that provide invaluable insights and practical tips.

Manuals and Documentation

User manuals and technical documentation are essential for any repair project. They offer detailed information about the tool’s components, operational guidelines, and safety precautions. Many manufacturers provide downloadable PDFs of their manuals online, making it easy to find the exact document you need. These manuals often include exploded views that help you identify individual parts and their functions.

Online Communities and Forums

Engaging with online communities and forums can be an excellent way to gain knowledge and share experiences with fellow repair enthusiasts. Platforms like Reddit, specialized repair websites, and social media groups often feature discussions, troubleshooting tips, and shared repair stories. These communities can be particularly helpful when you encounter unique issues or need advice on specific repairs.