Maintaining a pristine lawn often requires specialized machinery designed for efficiency and ease of use. This article delves into the intricate assembly of a specific type of landscape maintenance equipment, highlighting the various essential elements that contribute to its functionality. By comprehensively examining these components, users can better appreciate the engineering behind their tools and ensure optimal performance.

Familiarizing oneself with the individual parts of such equipment can lead to more effective maintenance and troubleshooting. Understanding how each element interacts with the others not only enhances operational efficiency but also aids in identifying potential issues before they escalate. This knowledge empowers users to take charge of their equipment, prolonging its lifespan and enhancing its performance.

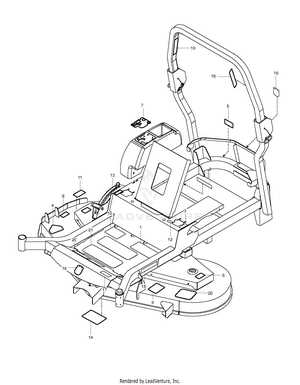

Whether you are a seasoned landscaper or a weekend warrior, having a clear visual representation of the equipment’s construction can be invaluable. It allows for a more straightforward approach to repairs and upgrades, ultimately saving time and resources. In the following sections, we will explore the various components involved, providing insight into their functions and significance in overall equipment performance.

Understanding Husqvarna Mower Components

When it comes to effective landscaping, having a deep understanding of the various components involved in a cutting machine can significantly enhance its performance and longevity. Each element plays a crucial role in ensuring optimal functionality, from the engine to the cutting deck, and familiarity with these parts enables better maintenance and troubleshooting. This section will explore the key components that contribute to the efficiency and effectiveness of these machines.

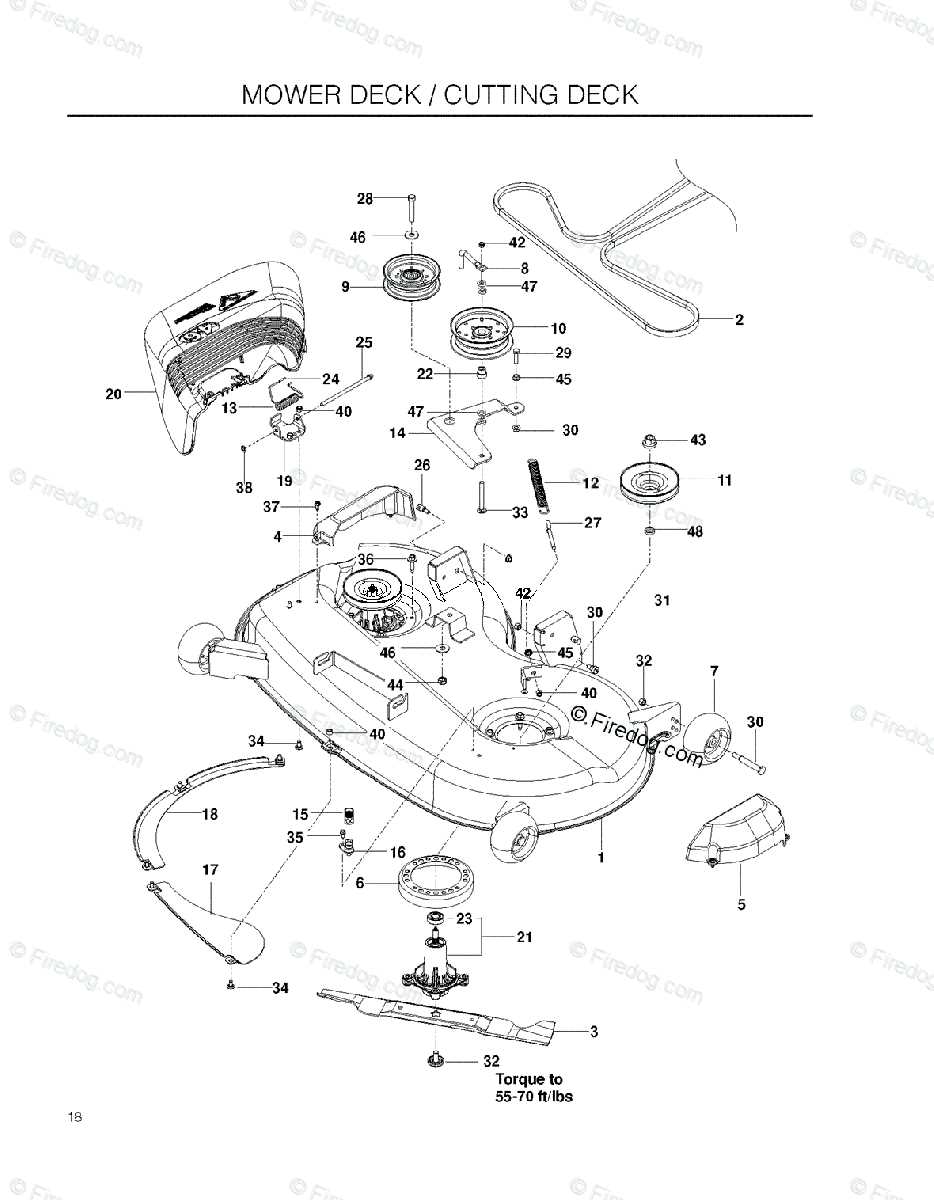

Main Elements of the Cutting System

The cutting system is central to the operation of any landscaping device. It comprises various components that work in harmony to deliver a precise and uniform cut. Understanding these elements can help users make informed decisions about maintenance and upgrades.

| Component | Function |

|---|---|

| Engine | Provides the necessary power to operate the machine. |

| Cutting Deck | Houses the blades and determines the cutting width. |

| Blades | Rotate at high speed to efficiently cut grass. |

| Spindles | Support and drive the blades, ensuring stability. |

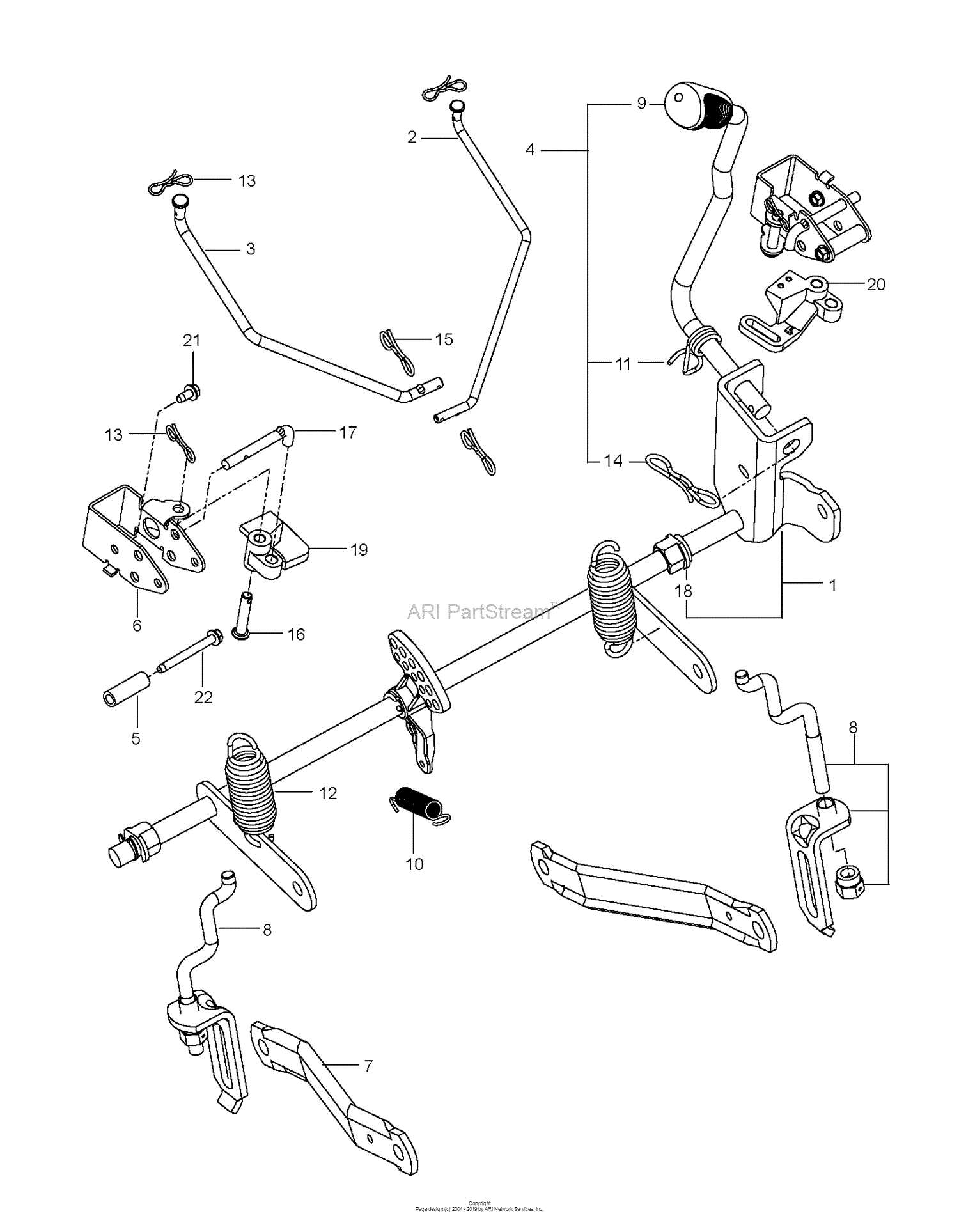

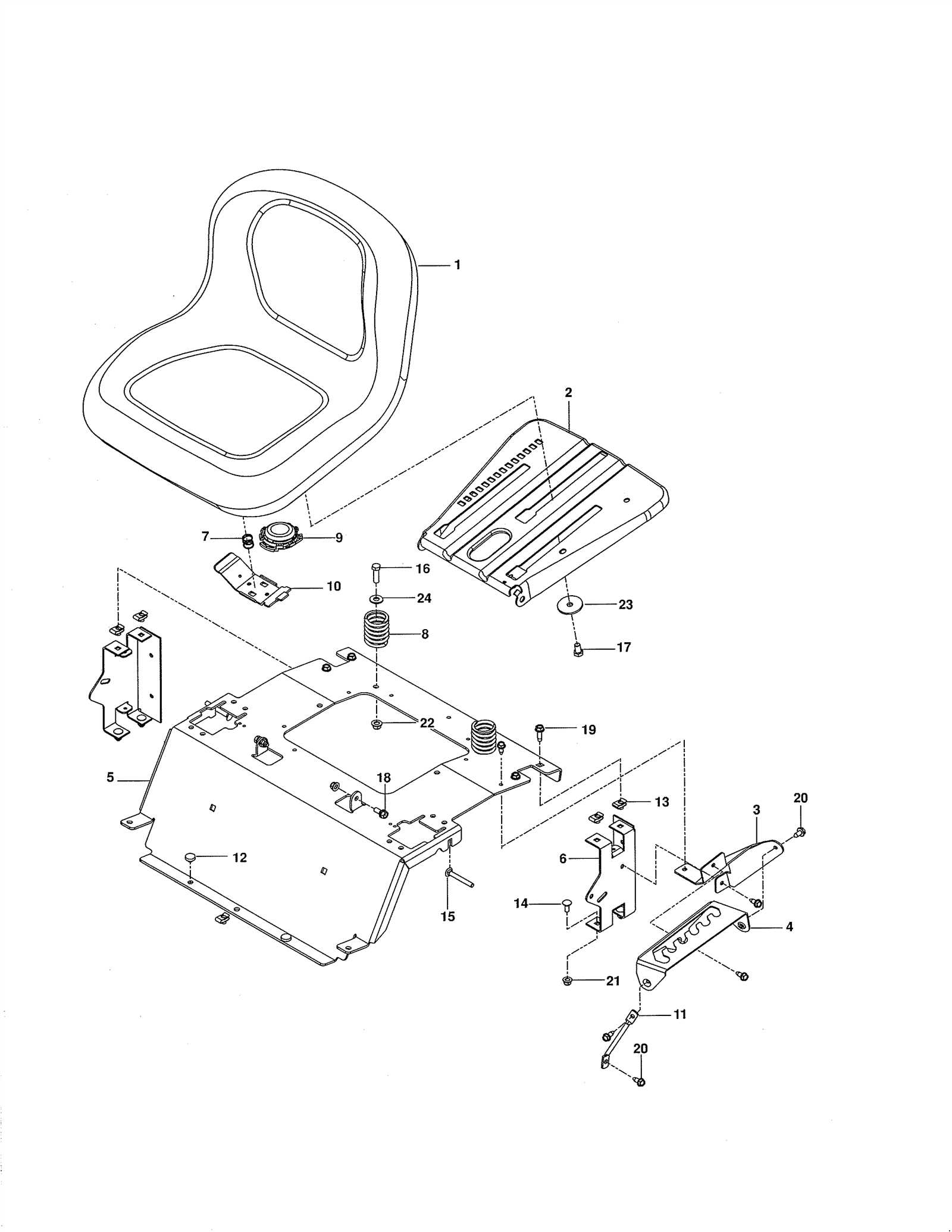

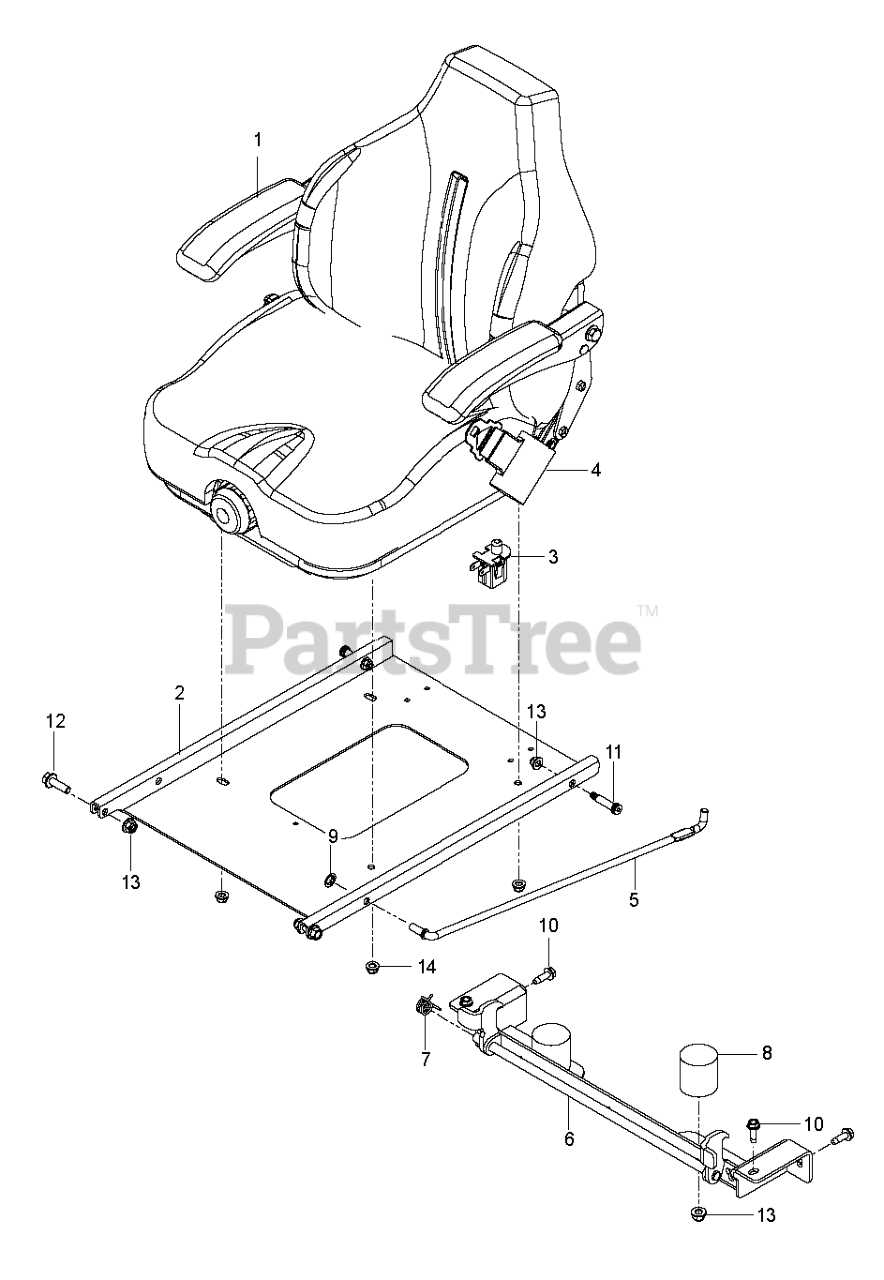

Support and Control Systems

In addition to the cutting mechanism, various support and control systems enhance the usability and functionality of the equipment. These components ensure that the machine operates smoothly and responds effectively to user inputs.

| Component | Function |

|---|---|

| Transmission | Transfers power from the engine to the wheels for movement. |

| Steering System | Allows the operator to control the direction and maneuverability. |

| Seat | Provides comfort and support for the operator during use. |

| Controls | Enable the user to adjust speed, direction, and cutting height. |

Importance of Parts Diagrams

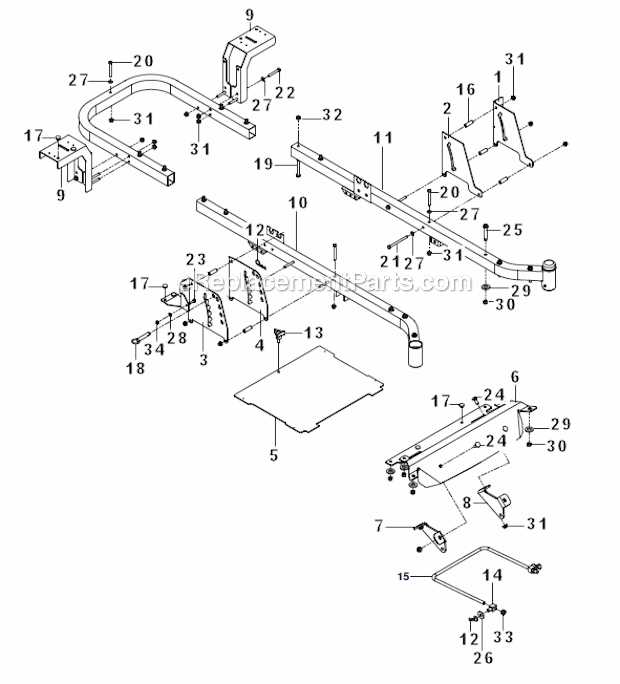

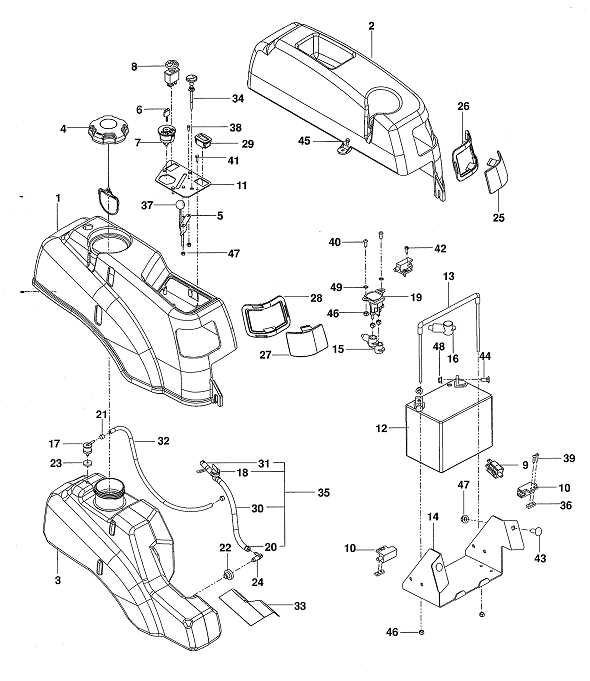

Understanding the structure and components of machinery is essential for effective maintenance and repair. Visual representations that detail the arrangement and function of each element provide valuable insights for both professionals and enthusiasts. These illustrations serve as a roadmap, simplifying complex systems and ensuring that users can identify and address issues efficiently.

Clarity in Communication: Visual aids enhance communication between manufacturers, technicians, and users. They eliminate ambiguity, making it easier to convey information about specific components and their relationships within the system.

Facilitating Repairs: When issues arise, having access to a detailed visual reference can significantly expedite the troubleshooting process. Users can quickly locate problematic areas and determine the necessary actions for resolution, ultimately saving time and reducing frustration.

Preventive Maintenance: Regular upkeep is crucial for the longevity of any equipment. Visual references enable users to recognize wear and tear, ensuring timely replacements before minor issues escalate into major problems.

Education and Training: These illustrations are also invaluable for training purposes. New technicians can familiarize themselves with the equipment by studying the layout and function of its components, thus enhancing their understanding and skills.

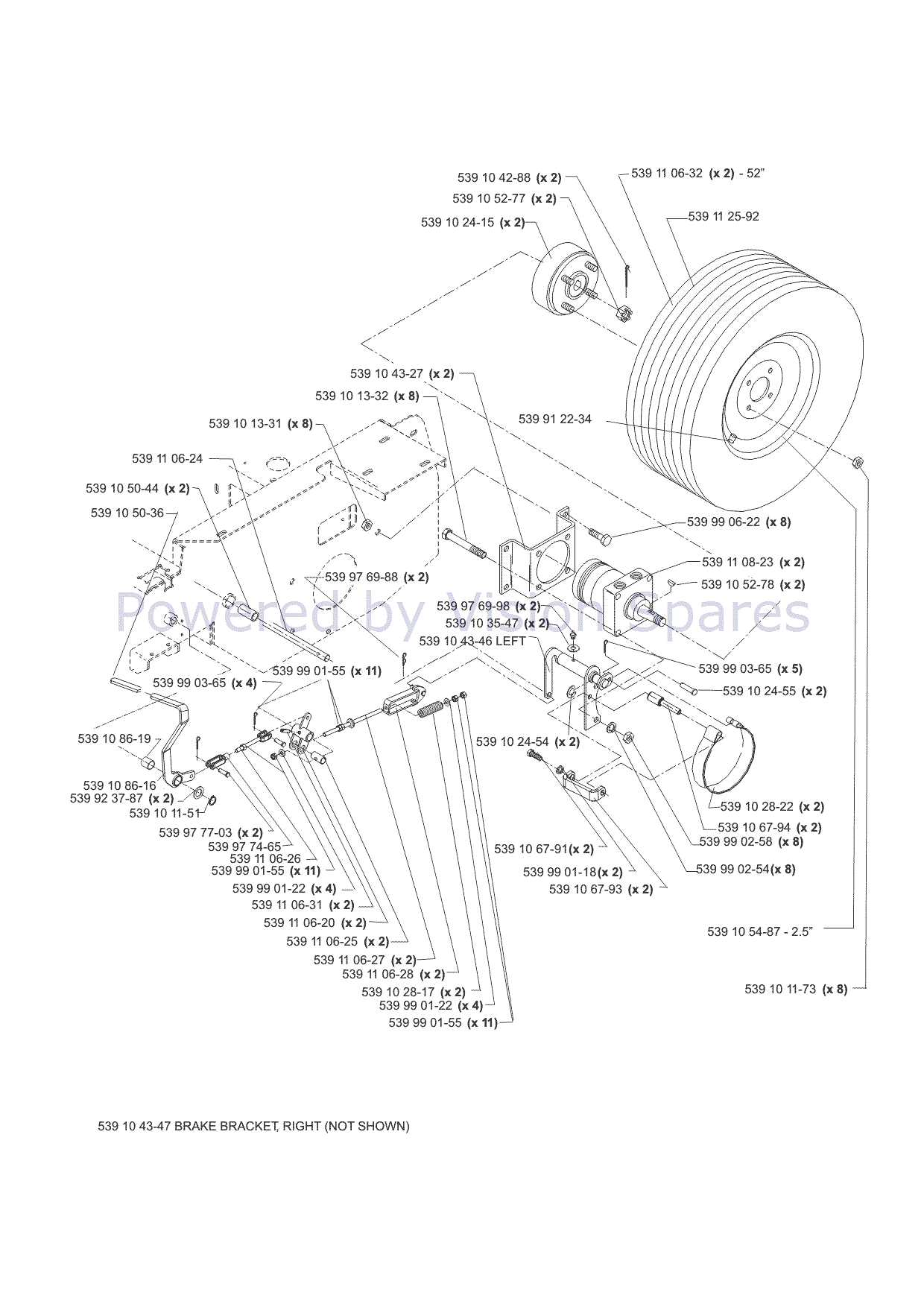

Key Components of Zero Turn Mowers

Understanding the essential elements of advanced lawn care machines is crucial for optimal performance and maintenance. Each component plays a vital role in the overall functionality, ensuring a smooth and efficient operation. From the propulsion system to the cutting mechanism, every part contributes to achieving precise results in landscape management.

| Component | Description |

|---|---|

| Engine | The heart of the machine, providing the necessary power to drive all functions and features. |

| Transmission | This system enables the machine to move and maneuver effectively, allowing for agility in tight spaces. |

| Cutter Deck | The assembly responsible for grass trimming, designed for precision and adjustable height settings. |

| Wheels and Tires | These elements ensure stability and traction, enhancing control over the terrain during operation. |

| Control System | The interface through which the operator manages speed and direction, allowing for intuitive handling. |

| Chassis | The frame that supports all components, ensuring durability and structural integrity. |

Maintenance Tips for Mower Parts

Regular upkeep of your cutting equipment is essential to ensure its longevity and optimal performance. By following simple maintenance practices, you can enhance efficiency, reduce wear, and prevent costly repairs. This guide offers valuable insights into maintaining various components to keep your machine running smoothly.

Inspecting and Cleaning Components

Routine checks and cleaning are fundamental aspects of equipment maintenance. Examine the blades, filters, and belts frequently for any signs of wear or debris. Remove grass clippings and dirt buildup from these elements to prevent potential issues. Keeping these parts clean not only improves functionality but also extends their lifespan.

Lubrication and Fluid Changes

Proper lubrication is crucial for moving parts. Apply appropriate lubricants to bearings and pivot points regularly to ensure smooth operation. Additionally, replacing engine oil and other fluids as recommended by the manufacturer is vital for maintaining engine health and performance. Regular fluid checks can prevent overheating and mechanical failures.

Common Issues and Troubleshooting

When operating a lawn care machine, encountering problems can hinder performance and lead to frustration. Understanding the most common complications and knowing how to address them can enhance the overall efficiency and lifespan of the equipment. This section outlines typical issues that may arise and offers practical solutions for each.

-

Engine Won’t Start:

If the engine fails to ignite, check the following:

- Ensure the fuel tank is filled with fresh gasoline.

- Inspect the battery for a proper charge.

- Examine the ignition switch and ensure it is functioning correctly.

-

Uneven Cutting:

An uneven cut can be frustrating. To rectify this:

- Check the blade sharpness; dull blades can cause poor cutting.

- Adjust the cutting height to ensure consistency across the lawn.

- Inspect the tire pressure; uneven inflation can affect the machine’s balance.

-

Excessive Vibration:

If excessive vibration occurs during operation, consider the following:

- Inspect the blades for damage or imbalance.

- Check for loose components that may require tightening.

- Examine the engine mounting for any signs of wear or looseness.

-

Transmission Issues:

In case of transmission problems, troubleshoot with these steps:

- Inspect the fluid levels and top off if necessary.

- Examine the belts for wear and proper tension.

- Check for any obstructions in the drive system.

By following these guidelines, users can effectively address common issues, ensuring smooth operation and optimal performance.

How to Identify Replacement Parts

When maintaining and servicing outdoor equipment, recognizing the necessary components for replacement is essential. Understanding the specific elements that may require attention helps ensure optimal performance and longevity. Below are key strategies to effectively identify the right components for your machinery.

1. Consult the Owner’s Manual

Your first step should always be to refer to the owner’s manual that came with your equipment. This document typically contains:

- Detailed diagrams illustrating various components

- Specifications for each item

- Maintenance schedules and recommended replacement intervals

2. Examine Existing Components

In addition to the manual, physically inspecting the current elements can provide valuable insights. Look for:

- Part numbers printed directly on the components

- Signs of wear or damage that may indicate the need for replacement

- Color coding or unique shapes that distinguish specific items

Utilizing these methods will streamline the process of identifying which components need replacement, allowing for efficient maintenance and reliable performance of your equipment.

Benefits of Using Original Parts

Utilizing authentic components for your machinery ensures optimal performance and longevity. These original elements are designed specifically for your equipment, offering a perfect fit and superior quality compared to generic alternatives. Investing in genuine replacements can lead to significant advantages in functionality and reliability.

Here are some key benefits of choosing original components:

| Benefit | Description |

|---|---|

| Enhanced Performance | Original components are engineered to work seamlessly with your equipment, ensuring smooth operation and improved efficiency. |

| Durability | Authentic parts are manufactured with high-quality materials, providing better resistance to wear and tear, thus extending the lifespan of your machinery. |

| Warranty Protection | Using original components often preserves the warranty on your equipment, offering peace of mind in case of future repairs or issues. |

| Safety | Original elements adhere to strict safety standards, reducing the risk of malfunctions that could lead to accidents or injuries. |

| Resale Value | Maintaining your machinery with genuine parts can enhance its resale value, as potential buyers often prefer equipment that has been properly cared for. |

Comparing Aftermarket vs. OEM Parts

The choice between alternative components and original manufacturer items is a significant consideration for many individuals. Each option presents its own set of advantages and drawbacks, influencing overall performance, longevity, and cost-effectiveness. Understanding these differences is essential for making informed decisions that align with maintenance goals.

Alternative components are often marketed as more affordable solutions, making them attractive to budget-conscious consumers. However, the quality of these items can vary widely, which may impact their reliability and compatibility with existing machinery. Conversely, original items are specifically designed to fit and function within a particular system, ensuring a higher degree of reliability and performance consistency.

| Aspect | Alternative Components | Original Manufacturer Items |

|---|---|---|

| Cost | Generally lower | Typically higher |

| Quality | Variable | Consistently high |

| Compatibility | May vary | Perfect fit |

| Warranty | Often limited | Comprehensive |

| Availability | Widely available | Exclusive to manufacturer |

Ultimately, the decision between these two categories comes down to personal priorities. While some may prioritize cost savings, others may lean towards ensuring quality and reliability through original options. Evaluating the specific needs of the equipment and usage scenarios will help determine the most suitable choice.

Resources for Mower Parts Information

When it comes to maintaining your outdoor equipment, accessing accurate resources is crucial. Understanding the various components and their functions can enhance your ability to troubleshoot and replace any necessary elements effectively. Reliable information can help ensure that your machinery runs smoothly and efficiently, extending its lifespan.

Manufacturer Websites

Official websites often provide comprehensive details about equipment, including specifications, service manuals, and component listings. These platforms typically offer downloadable resources, ensuring you have access to the latest information directly from the source. It’s advisable to frequently check these sites for updates and new releases.

Online Forums and Communities

Participating in online discussions can be incredibly beneficial for acquiring knowledge about specific equipment. Enthusiast forums and social media groups allow users to share experiences, troubleshooting tips, and recommendations for components. Engaging with fellow users can provide insights that may not be readily available through traditional resources.