When it comes to maintaining and servicing complex machinery, having a clear understanding of its structure is essential. The layout of critical elements, whether it’s for regular upkeep or repairs, provides a roadmap to ensure that each piece functions as intended. Knowing the position and relationship between various elements can make all the difference in ensuring seamless operation.

In this context, a detailed overview of the various mechanical parts plays a crucial role. Each element, no matter how small, contributes to the overall efficiency of the system. Being familiar with their arrangement and interactions allows for precise interventions, ensuring that the machinery continues to perform at its best.

Additionally, understanding how the different components fit together can significantly aid in troubleshooting. Whether you’re fine-tuning performance or replacing worn-out parts, a well-organized visual layout can save time and reduce guesswork. This knowledge helps maintain optimal functionality, ensuring that the equipment remains reliable over time.

Overview of the Husqvarna MZ61 Model

This robust and high-performing model is known for its efficiency in maintaining large outdoor areas, offering a balance of power and control. It is designed to provide excellent results in both residential and commercial settings, delivering precision in handling even the most demanding terrain. The equipment stands out for its reliability and durability, ensuring long-term use with minimal maintenance.

Key Features

With a powerful engine and an advanced cutting system, this machine ensures superior performance. Its ergonomic design enhances operator comfort, allowing extended use without fatigue. The model incorporates modern technology to provide precise cutting and easy maneuverability, making it a top choice for professionals and homeowners alike.

Specifications

| Engine Type |

Commercial-grade, high-output |

| Cutting Width |

Large for optimal efficiency |

| Fuel Capacity |

Designed for extended operation |

Seat Type

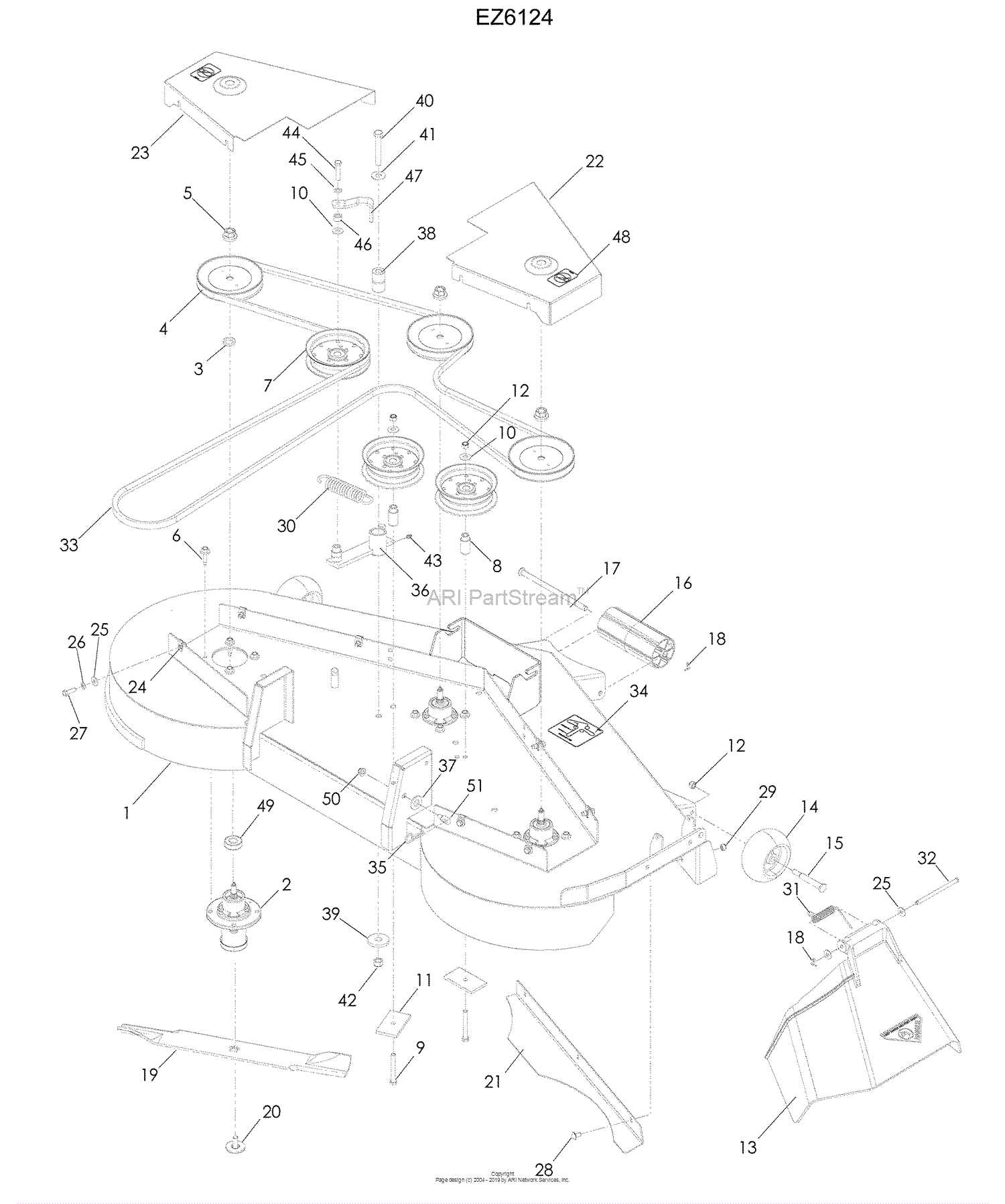

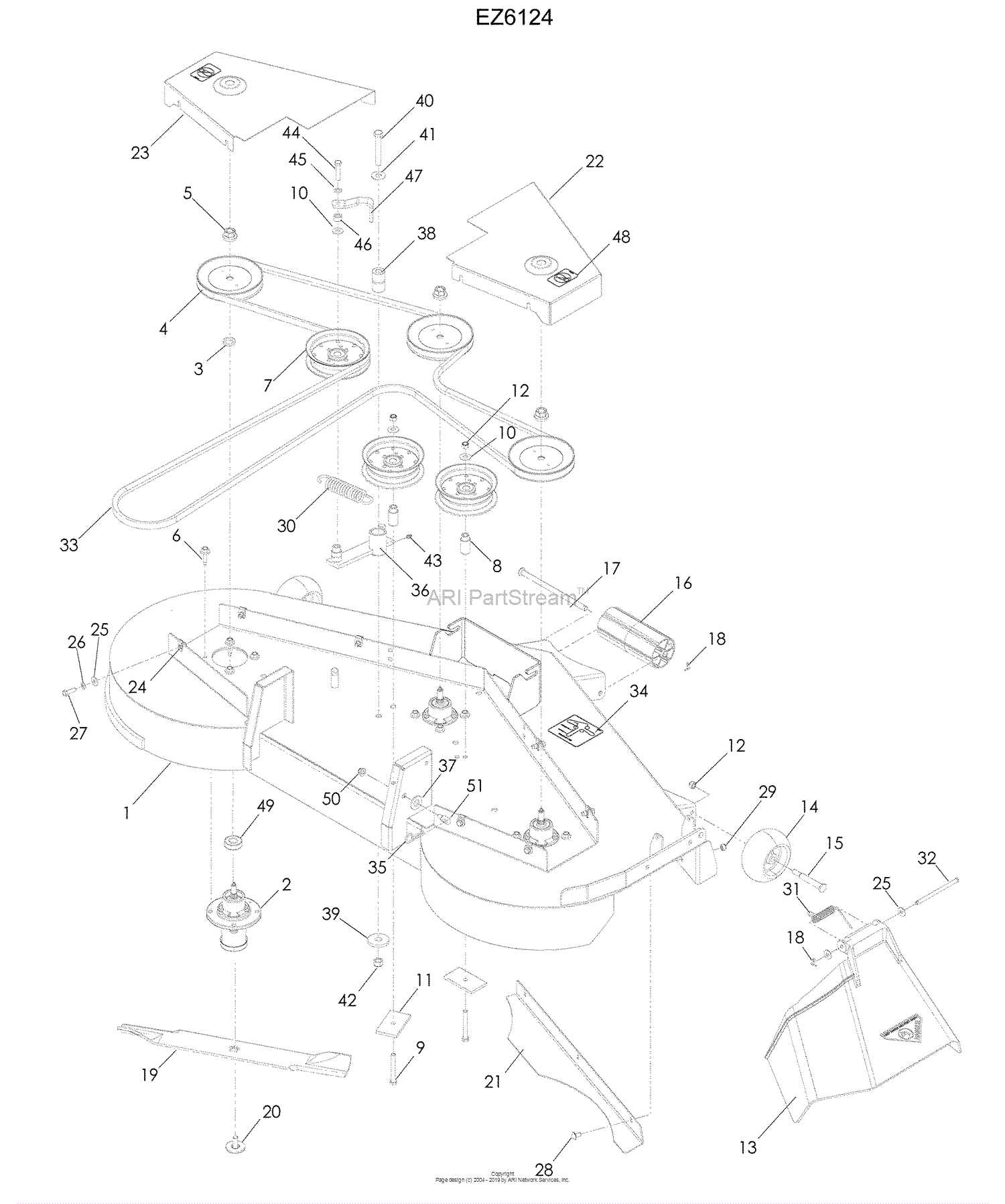

Main Components of the Husqvarna MZ61

The key elements of this zero-turn mower are designed for durability and efficient performance. Each part contributes to smooth operation, allowing for a precise and effective cutting experience. Understanding these elements is crucial for maintaining optimal performance and ensuring a long lifespan for the equipment.

| Component |

Description |

| Engine |

A powerful motor that drives the mower, providing the necessary strength for challenging tasks. |

| Cutting Deck |

The area responsible for cutting grass, with multiple blades for a clean, uniform finish. |

| Control Panel |

Where the operator can manage speed, direction, and other essential functions of the mower. |

| Transmission |

Ensures smooth movement and maneuverability, especially during sharp turns. |

Engine Specifications and Parts

The core of any high-performance machine lies in the strength and reliability of its engine. Understanding the essential features and components that ensure optimal functionality is crucial for maintaining long-term performance and efficiency.

Key elements of the engine, such as its displacement, power output, and cooling mechanisms, contribute significantly to its overall capability. Equally important are the various mechanical pieces that work in harmony to keep the engine running smoothly.

| Component |

Description |

| Displacement |

Indicates the total volume of all cylinders, typically measured in cubic inches or centimeters. |

| Power Output |

The horsepower or kilowatts generated by the engine under normal operating conditions. |

| Cooling System |

Ensures the engine remains at an optimal temperature, preventing overheating and ensuring efficient performance. |

| Fuel System |

Manages the delivery of fuel to the engine, balancing efficiency and power. |

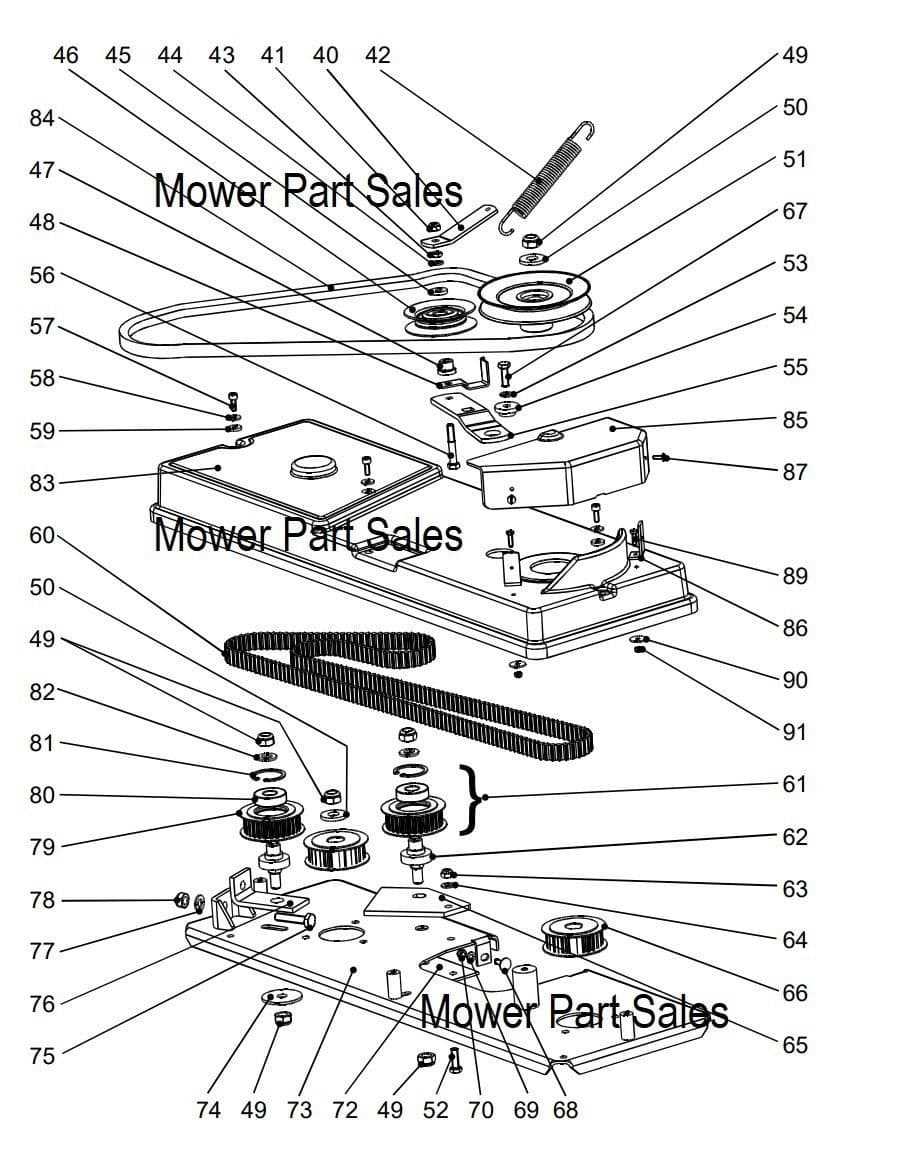

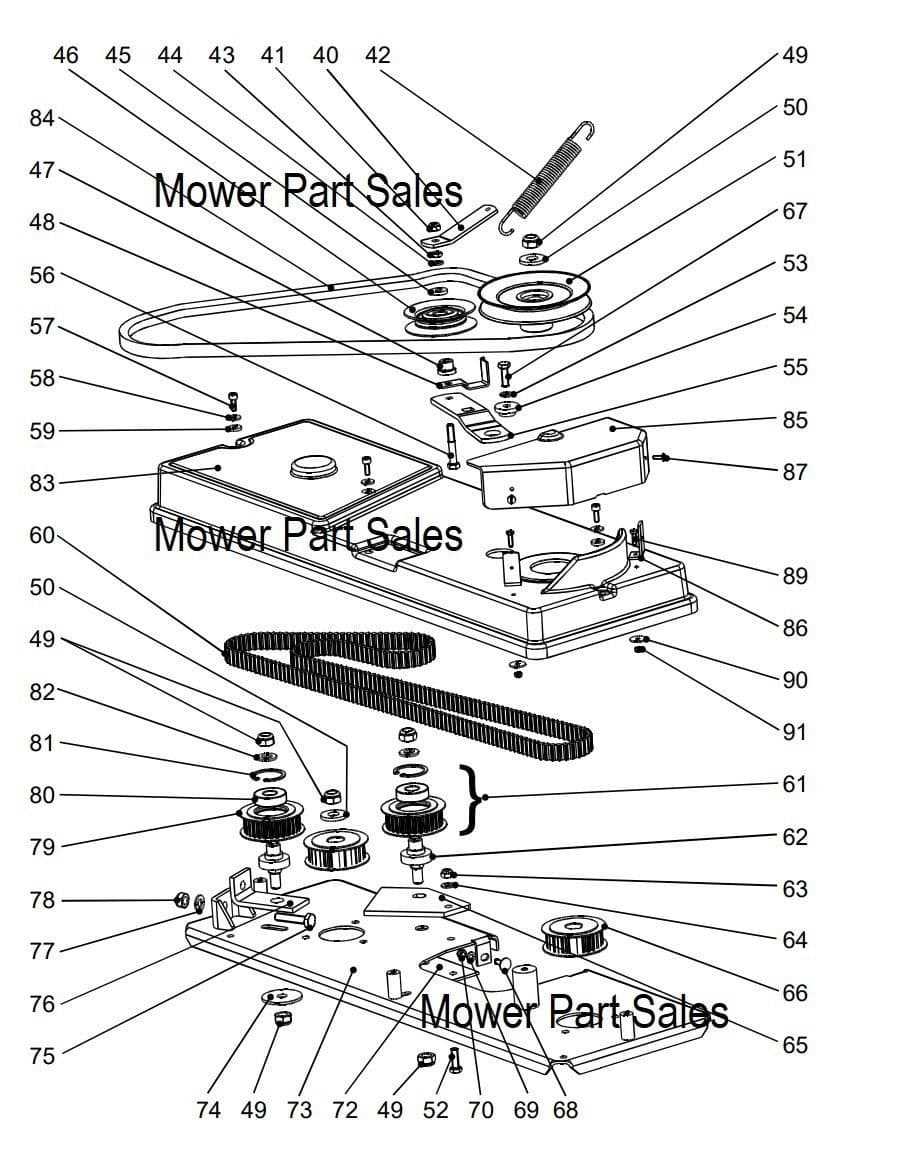

Blade Assembly and Related Parts

The blade system is an essential component of any lawn equipment, directly influencing cutting efficiency and overall performance. Understanding how the various elements of the cutting mechanism interact can help ensure smooth operation and maintenance. This section outlines the key elements involved in the blade system and the components that work together to deliver effective cutting results.

Blade Mechanism Overview

At the heart of the cutting system is the blade assembly, which consists of various interconnected parts designed for durability and precision. Proper alignment and periodic maintenance of these elements ensure optimal cutting performance. Below are the main components involved in the blade mechanism:

- Rotating blades designed for sharp and clean cuts

- Mounting hardware for secure attachment of the blades

- Blade housings that protect the mechanism and ensure safety

Supporting Components

In addition to the blades themselves, several supporting parts play a critical role in maintaining the functionality of the cutting system. These elements help distribute power, stabilize the assembly, and ensure smooth operation:

- Bearing assemblies that allow for smooth blade rotation

- Belt systems transferring power from the engine to the blades

- Drive System Components and Functions

The drive system in any machine plays a crucial role in ensuring smooth movement and efficient power transmission. Understanding the essential parts and how they work together helps to maintain optimal performance and prolong the lifespan of the equipment. Below, we explore the primary elements that make up the drive mechanism and their respective functions.

- Transmission: Responsible for transferring the power from the engine to the wheels or tracks, allowing the machine to move at various speeds.

- Drive Belt: Connects the transmission to the engine and ensures smooth power flow. Regular inspection is vital to avoid slippage or wear.

- Axles: These are the rotating shafts that connect the wheels to the transmission, enabling the movement and turning of the machine.

- Hydraulic System: In machines with hydrostatic drives, hydraulic pumps and motors replace traditional gear-driven transmissions, offering more precise control.

- Control Levers: These allow the operator to adjust speed, direction, and other driving aspects, making the machine more responsi

Fuel System and Key Elements

The fuel system plays a crucial role in the operation of outdoor power equipment, ensuring that the engine receives the necessary fuel for optimal performance. It consists of several interconnected components that work together to deliver fuel efficiently, allowing for smooth engine operation and improved functionality.

Essential Components

At the heart of the fuel system are the primary elements, including the fuel tank, pump, and carburetor. The fuel tank stores the gasoline, while the pump transfers the fuel from the tank to the engine. The carburetor mixes the fuel with air to create a combustible mixture, which is essential for ignition and combustion within the engine.

Maintenance Considerations

Regular maintenance of the fuel system is vital to prevent issues such as clogs and leaks. Checking for any signs of wear or damage in the components can help ensure the system operates smoothly. Additionally, using clean fuel and proper storage practices can extend the life of the fuel system, promoting efficient engine performance.

Electrical Parts and Connections

The electrical system of any lawn maintenance machine plays a crucial role in its overall functionality. Properly functioning components and secure connections ensure that the equipment operates smoothly and efficiently. Understanding these elements is essential for effective troubleshooting and maintenance.

Key components within the electrical system include the ignition system, battery, wiring harness, and various switches. Each element must work in harmony to facilitate the operation of the engine and other features. Regular inspection of these components can help identify potential issues before they lead to significant malfunctions.

Connections between the electrical components are vital for transferring power and signals throughout the machine. Corroded or loose connections can result in performance issues or even complete failure. Ensuring that all connections are clean and secure is a fundamental practice in maintaining the electrical system’s reliability.

Maintenance and Replacement Guidelines

Regular upkeep and timely substitution of components are essential for optimal performance and longevity of outdoor machinery. Adopting a structured maintenance schedule ensures that all systems function efficiently and reduces the risk of unexpected failures. By adhering to these guidelines, users can enhance the reliability and safety of their equipment.

It is advisable to consult the manufacturer’s recommendations for specific maintenance intervals and procedures. General practices include:

| Task |

Frequency |

Notes |

| Check oil level |

After every use |

Maintain proper lubrication for engine efficiency |

| Inspect air filter |

Monthly |

Replace if dirty to ensure optimal airflow |

| Sharpen blades |

Every 25 hours |

Ensure a clean cut and reduce strain on the engine |

| Check belts and cables |

Seasonally |

Look for wear and tear; replace if necessary |

| Clean the chassis |

After every use |

Remove debris to prevent rust and maintain appearance |

Staying vigilant with maintenance tasks can significantly extend the lifespan of outdoor equipment. When replacement is necessary, always opt for high-quality components to ensure compatibility and reliability.

|