The intricate design of a chainsaw includes various elements that work together to enhance its functionality. Understanding how these components interact can significantly improve the user experience and maintenance practices. Each part plays a crucial role, contributing to the overall efficiency and performance of the tool.

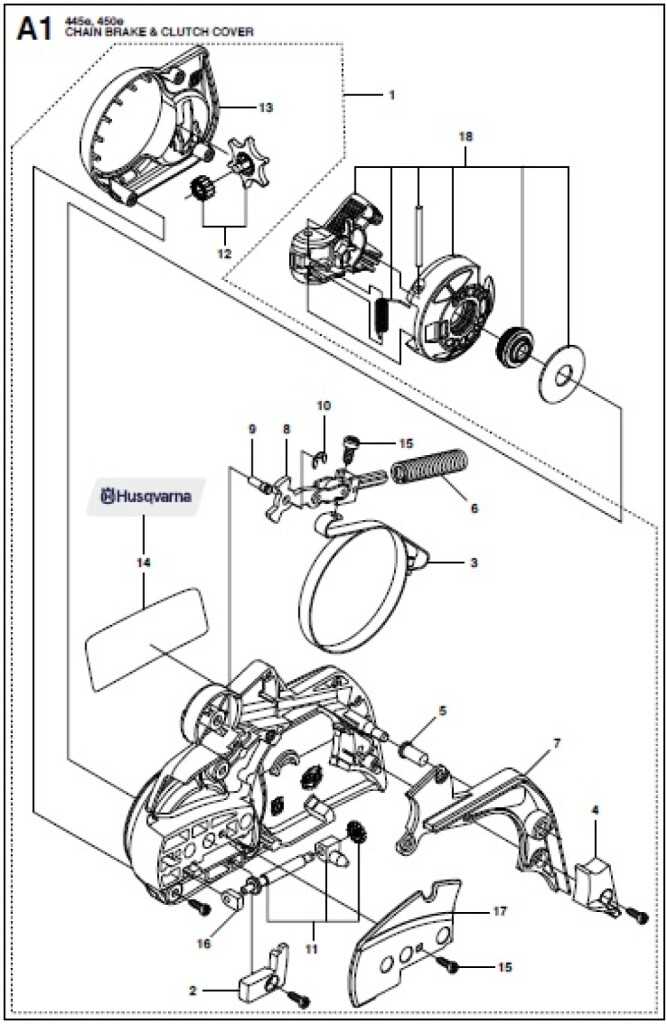

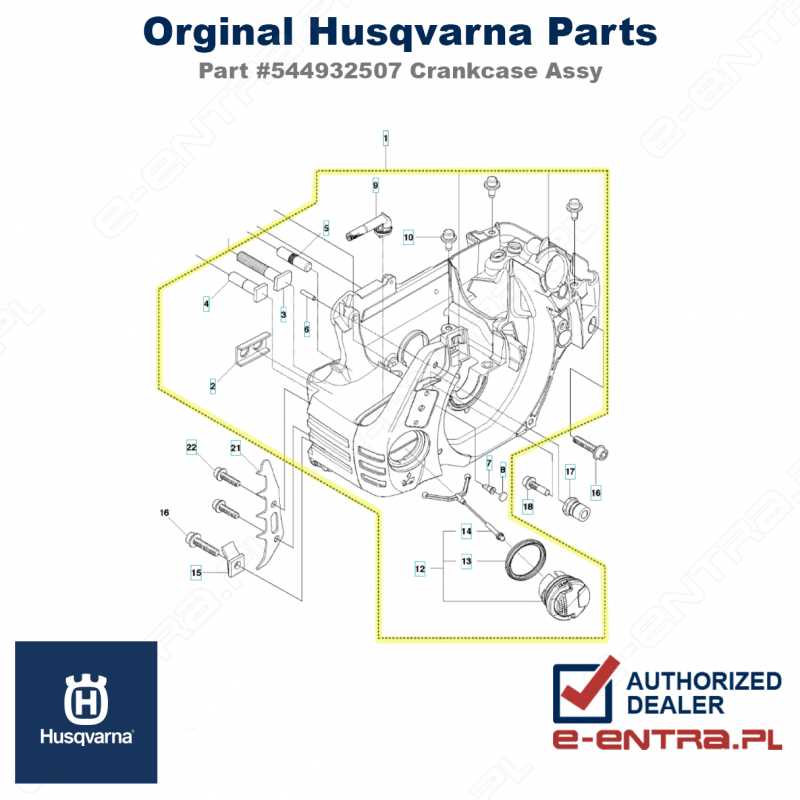

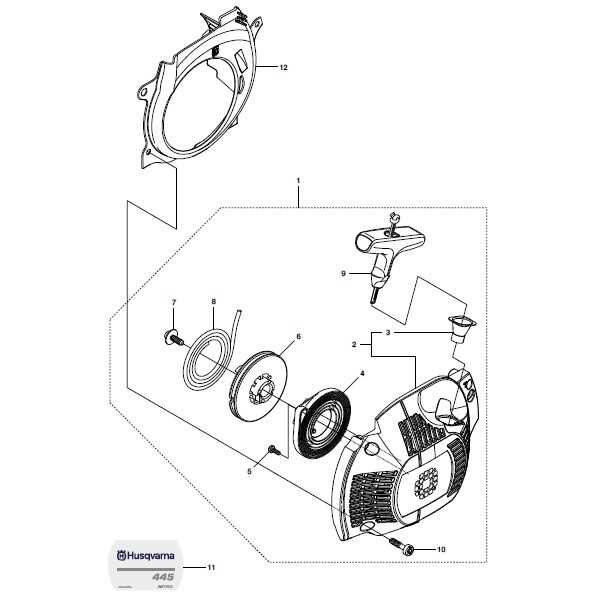

In this section, we will delve into a detailed overview of the specific components utilized in this particular chainsaw model. By examining the arrangement and function of each element, users can gain valuable insights into the machine’s operation, facilitating more effective troubleshooting and repairs.

Moreover, having a comprehensive understanding of the different sections and mechanisms within the tool can help users make informed decisions regarding replacements and upgrades. Knowledge of how these parts are organized and how they function together empowers individuals to maintain their equipment in optimal condition.

The primary focus of this section is to provide a comprehensive outline of the mechanical structure and components associated with a high-performance machine. This will include an explanation of various elements and their role in ensuring the device functions efficiently. Key assemblies, such as the engine, ignition system, and control mechanisms, will be highlighted in this diagram overview, detailing how they work together to provide optimal performance.

| Component Category | Description | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine Assembly | Overview of the engine’s internal and external parts, explaining their function and interrelation within the machine. | |||||||||||||

| Ignition System | Explanation of the electrical elements that contribute to the machine’s start-up and power generation. | |||||||||||||

| Control Elements |

| Component | Function |

|---|---|

| Engine | Generates power to drive the system |

| Component | Reference Number |

|---|---|

| Engine Cover | 1234 |

| Spark Plug | 5678 |

Common Issues and Solutions

There are a variety of mechanical challenges that can occur with multi-function outdoor tools. Many of these problems are easy to recognize and fix with the right approach. Below are some of the most frequent issues users face, along with practical steps for troubleshooting and resolving them efficiently.

- Starting problems: If the machine struggles to start, check the fuel mixture and ensure that the air filter is clean. Replacing the spark plug can also improve ignition performance.

- Engine stalling: Sudden engine shutdowns are often caused by fuel blockages or improper carburetor settings. Cleaning the fuel line or adjusting the carburetor may help stabilize operation.

- Power loss: A reduction in power output could be related to a clogged exhaust or worn-out components. Cleaning or replacing these parts may restore full functionality.

- Excessive vibration:

Maintenance Tips for Longevity

Proper upkeep of your equipment is essential for ensuring long-lasting performance and reducing the need for repairs. Regular care helps to maintain optimal functionality and prevent premature wear and tear. Below are several important practices that can extend the life of your tools.

Regular Cleaning and Inspection

After each use, clean your equipment thoroughly to remove debris, dirt, and residue. Inspect for any signs of wear or damage, paying close attention to moving parts and seals. Regular inspections help catch potential issues before they become major problems.

Lubrication and Sharpening

Apply lubricants to all moving components at regular intervals. Proper lubrication minimizes friction and prevents rust buildup, which could otherwise lead to breakdowns. Additionally, ensure that cutting edges are sharpened frequently to maintain efficiency and reduce strain on the motor.

Maintenance Task Frequency Clean debris and dirt After each use Replacement Parts: What You Need

When it comes to keeping your equipment in top condition, knowing what components to replace is essential for long-term performance. Identifying the right pieces for substitution ensures that your machine continues to operate smoothly and efficiently without unexpected breakdowns.

- Blades: Sharp, durable edges are vital for effective operation. Regular checks will help identify when they need swapping.

- Filters: Air and fuel filters keep your engine clean. Replacing them periodically prevents clogging and enhances engine health.

- Drive belts: Worn-out belts reduce efficiency. Monitoring their condition and changing them when needed maintains optimal power transmission.

- Spark plugs: A clean, functional spark plug ensures smooth ignition. Replacing it as part of routine maintenance avoids starting issues.

- Chains: For machines

Where to Find Quality Parts

When it comes to maintaining your equipment, it’s essential to find reliable components that ensure optimal performance. Sourcing high-grade replacements from reputable suppliers will keep your machinery running smoothly for longer periods. Knowing where to look can save both time and effort, preventing potential malfunctions down the line.

Authorized Dealers

One of the best ways to guarantee the quality of replacement pieces is to purchase from certified distributors. These sellers offer products that are made specifically for your machine, ensuring compatibility and durability. Working directly with trusted dealers also gives access to warranties and professional advice.

Online Resources

Another convenient option is utilizing trusted online platforms. Many websites specialize in offering genuine components for various tools and machinery. Make sure to verify the authenticity of the product by checking reviews and ratings from previous buyers before making a purchase.

Assembly Instructions for Beginners

Assembling equipment can be an intimidating task for those with little experience. However, following a clear set of instructions makes the process straightforward and manageable, even for first-time users. In this section, we’ll guide you through the essential steps, ensuring that everything is set up properly and safely.

Preparation and Tools

Before starting, gather all necessary tools. Ensure that you have access to the right equipment, such as wrenches and screwdrivers, and check that all parts are present. Proper preparation is key to a smooth assembly process.

Step-by-Step Process

Begin by organizing the components into groups. This will help you easily identify which parts go where. Follow the assembly guide carefully, attaching pieces one at a time, and double-check connections to avoid errors. Take your time, and consult diagrams if needed for additional clarity.