When it comes to maintaining outdoor machinery, having a clear understanding of its components is essential for optimal performance. This section offers a detailed exploration of the various elements that contribute to the functionality of your tools, enabling users to enhance their upkeep practices.

In the intricate world of machinery, each piece plays a vital role in the overall operation. By examining these components closely, enthusiasts can not only ensure their devices run smoothly but also make informed decisions regarding repairs and replacements.

Furthermore, grasping the layout of these essential parts allows for a deeper insight into the mechanics at play. This knowledge empowers users to delve into troubleshooting processes, ultimately leading to a more effective maintenance routine and prolonged equipment lifespan.

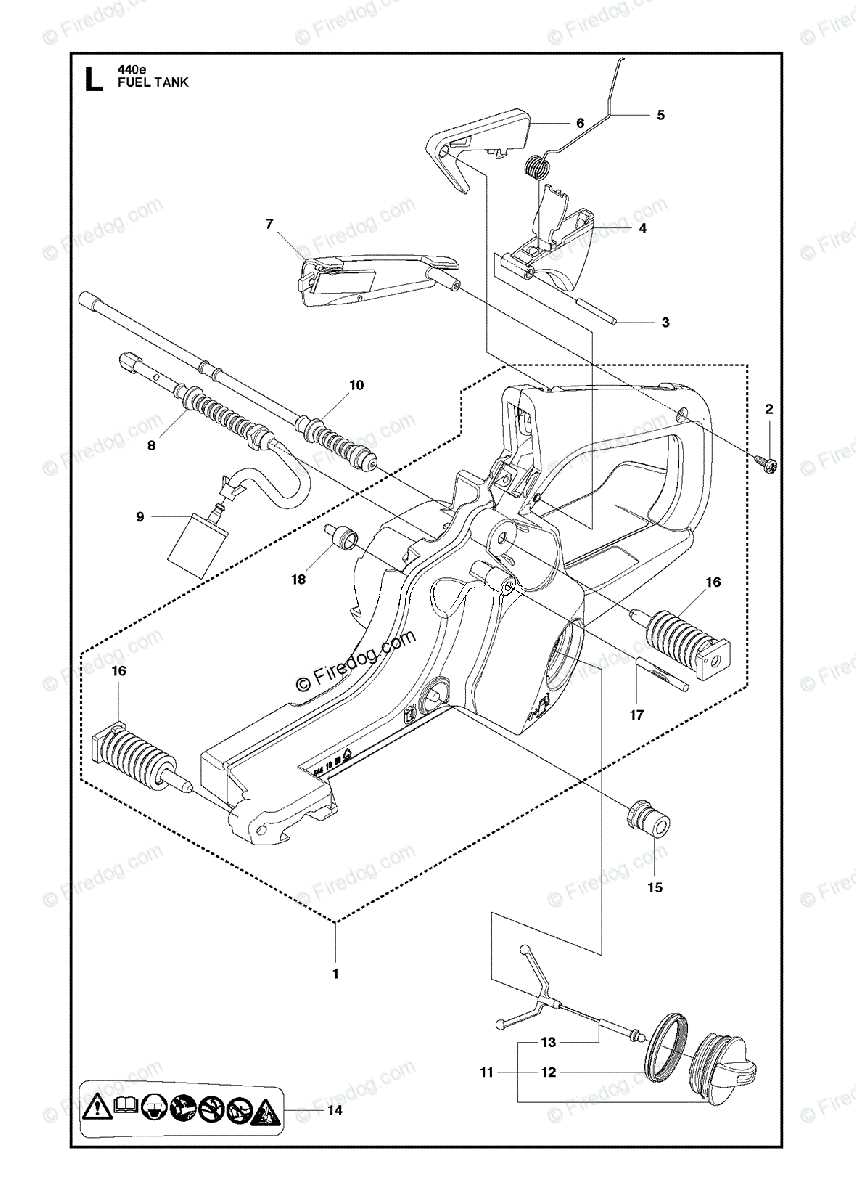

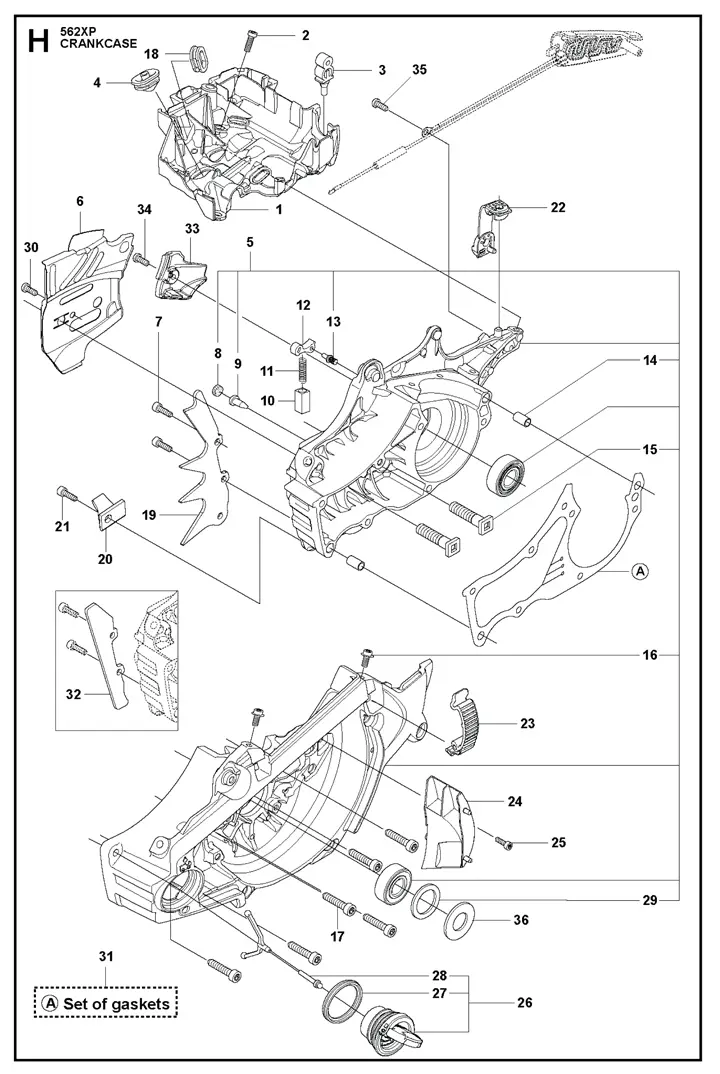

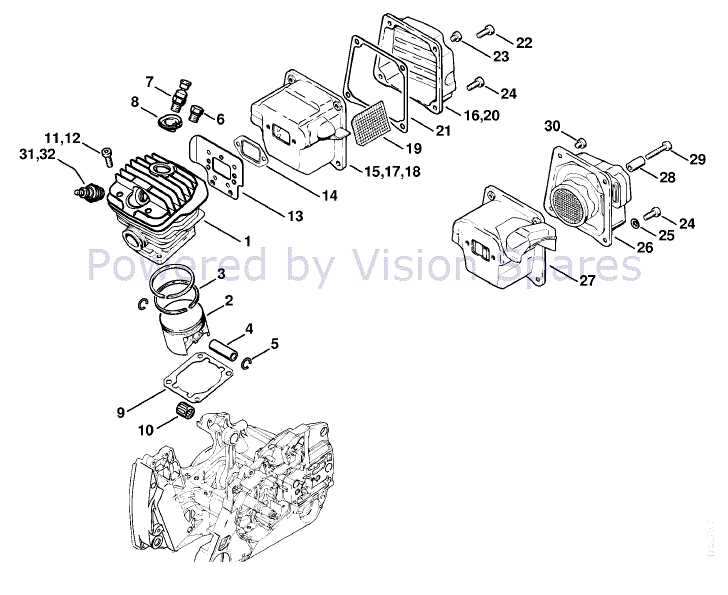

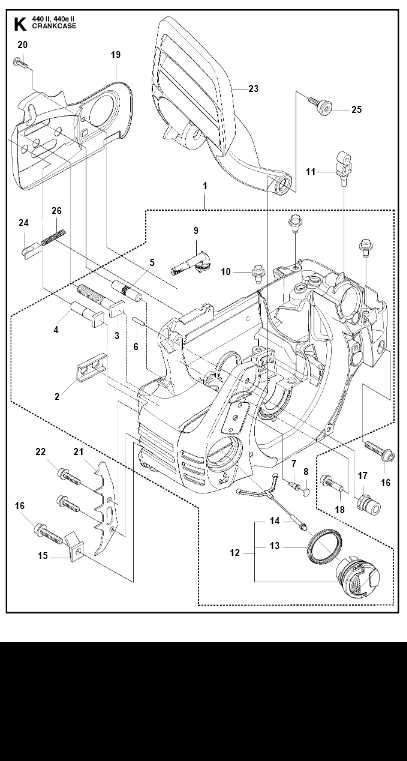

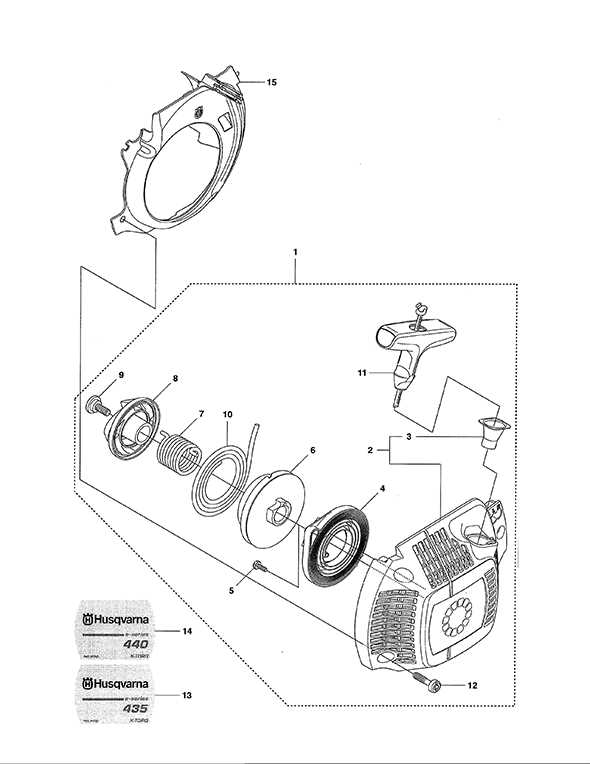

Understanding Husqvarna 440 Components

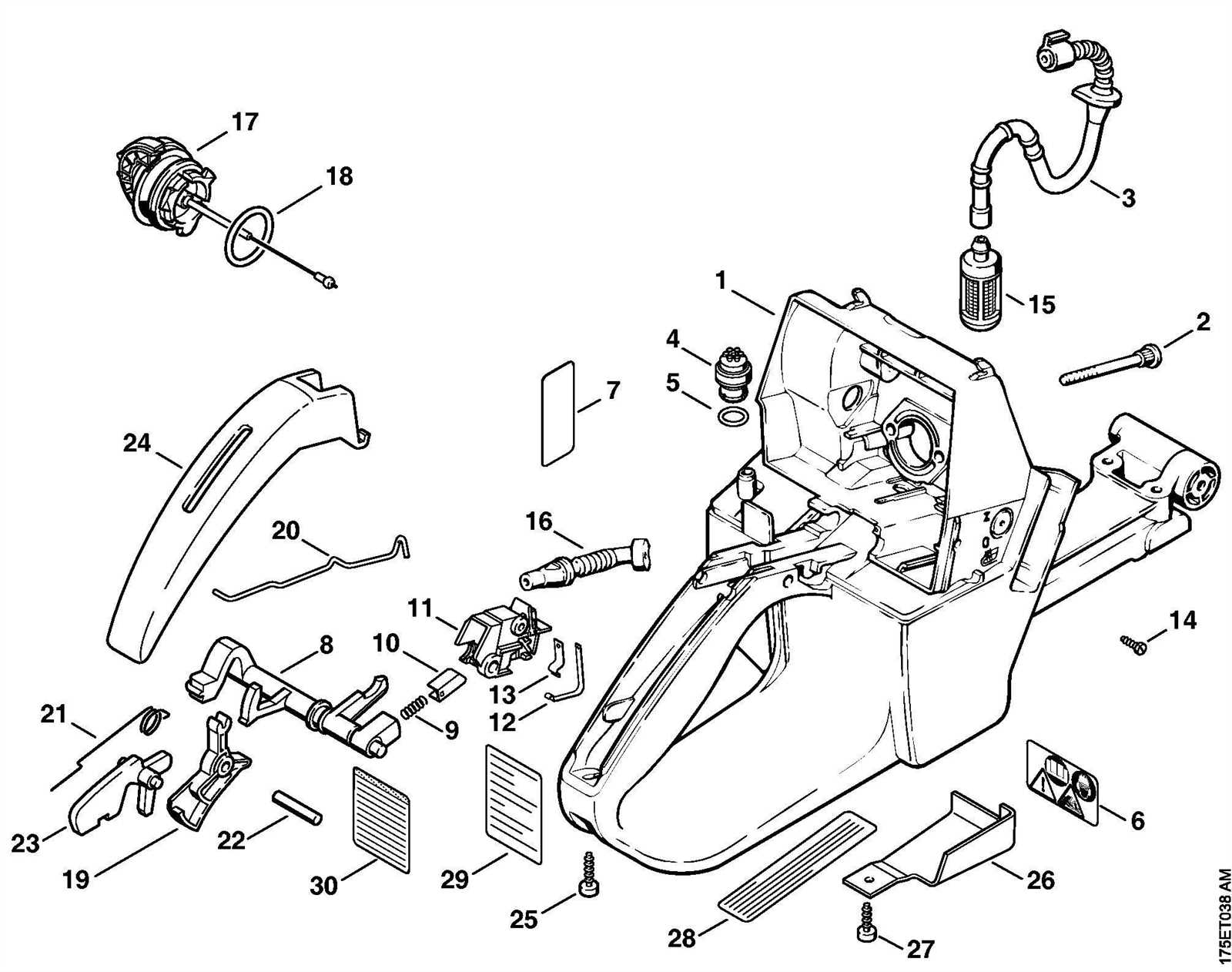

When working with a chainsaw, knowing the key elements that make up its structure is crucial for efficient operation and maintenance. Each component plays a vital role in ensuring smooth functionality, safety, and durability. From the engine to the cutting system, every part must work harmoniously together. Understanding the interactions between these parts can help users troubleshoot issues, perform timely repairs, and optimize the tool’s performance.

Engines are the heart of any chainsaw. They convert fuel into energy, which drives the cutting chain at high speeds. Components such as the carburetor, spark plug, and air filter contribute to the engine’s performance by ensuring proper fuel combustion and air intake. Any irregularities in these components can affect the engine’s power and efficiency.

The cutting system consists of several parts that are directly involved in cutting through wood or other materials. The chain, bar, and sprocket are key elements that need regular attention. A well-maintained chain, combined with an appropriately tensioned bar, ensures smoother and faster cutting operations.

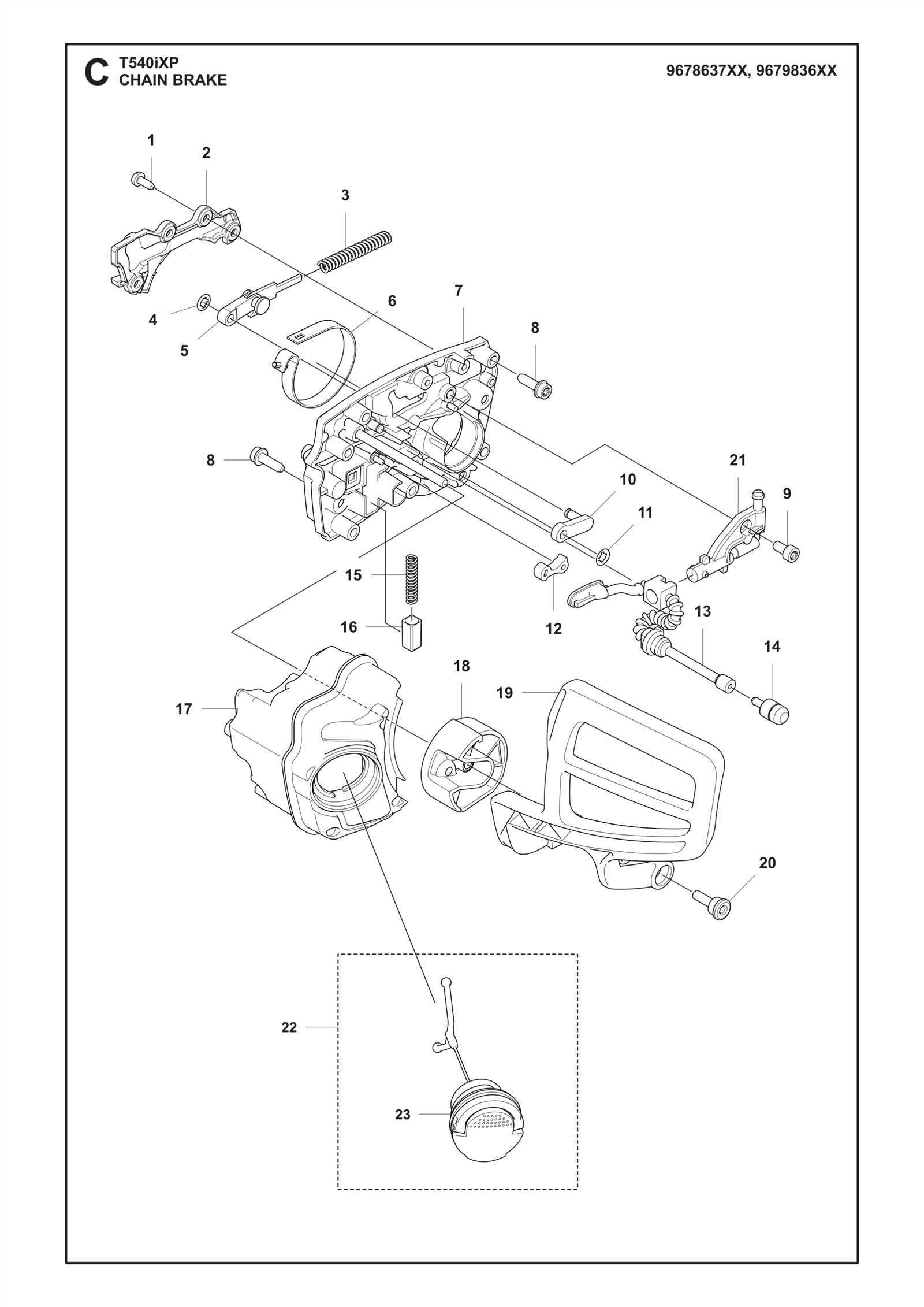

Safety mechanisms such as the chain brake and throttle lock are essential for protecting the user. These parts help prevent accidents during operation and maintain control over the tool, especially when dealing with tough materials.

Understanding each of these components and their respective roles is critical for any operator who aims to maximize the performance and longevity of their chainsaw. Proper care, timely replacements, and knowing when a specific component requires attention can prevent unnecessary wear and prolong the tool’s life.

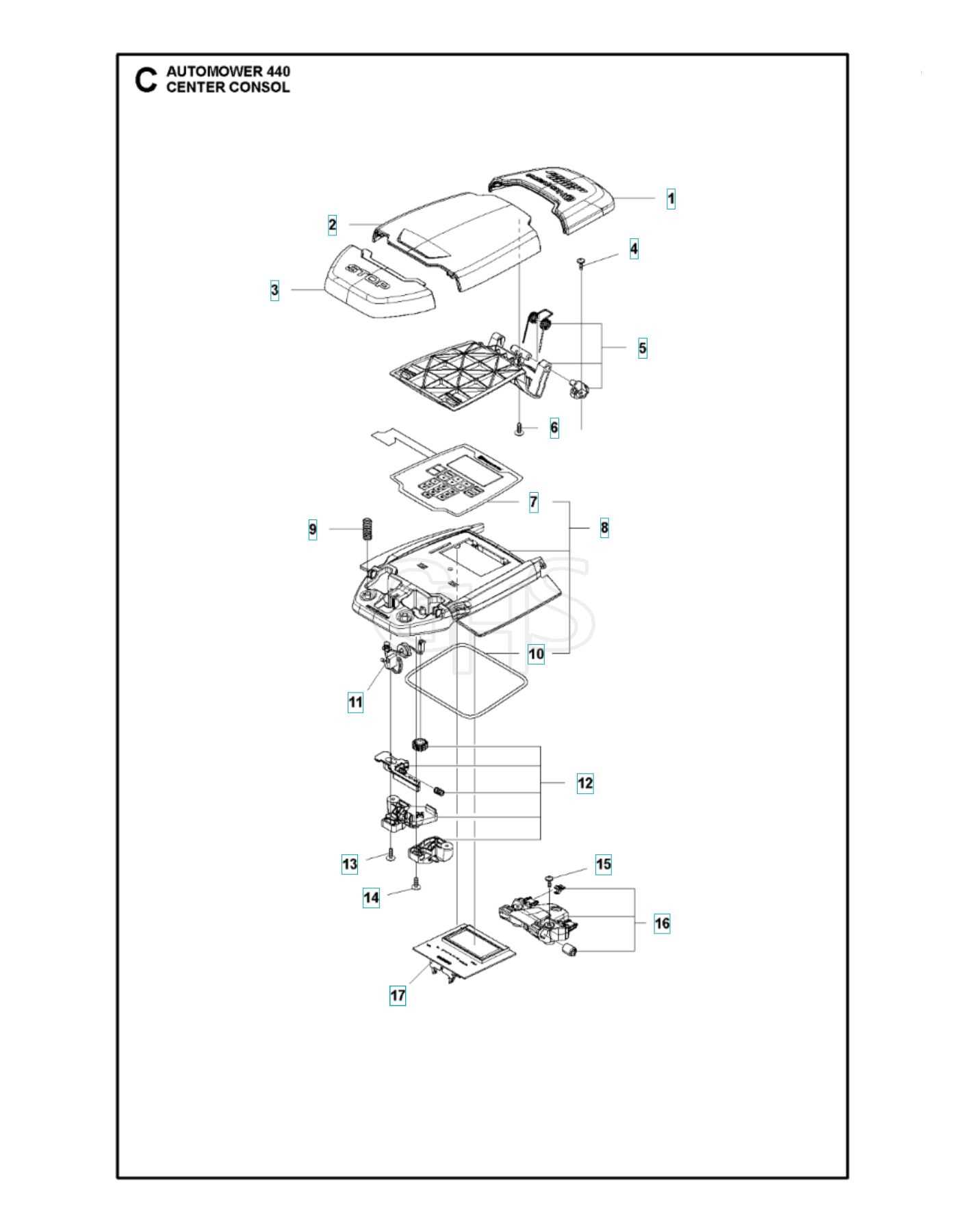

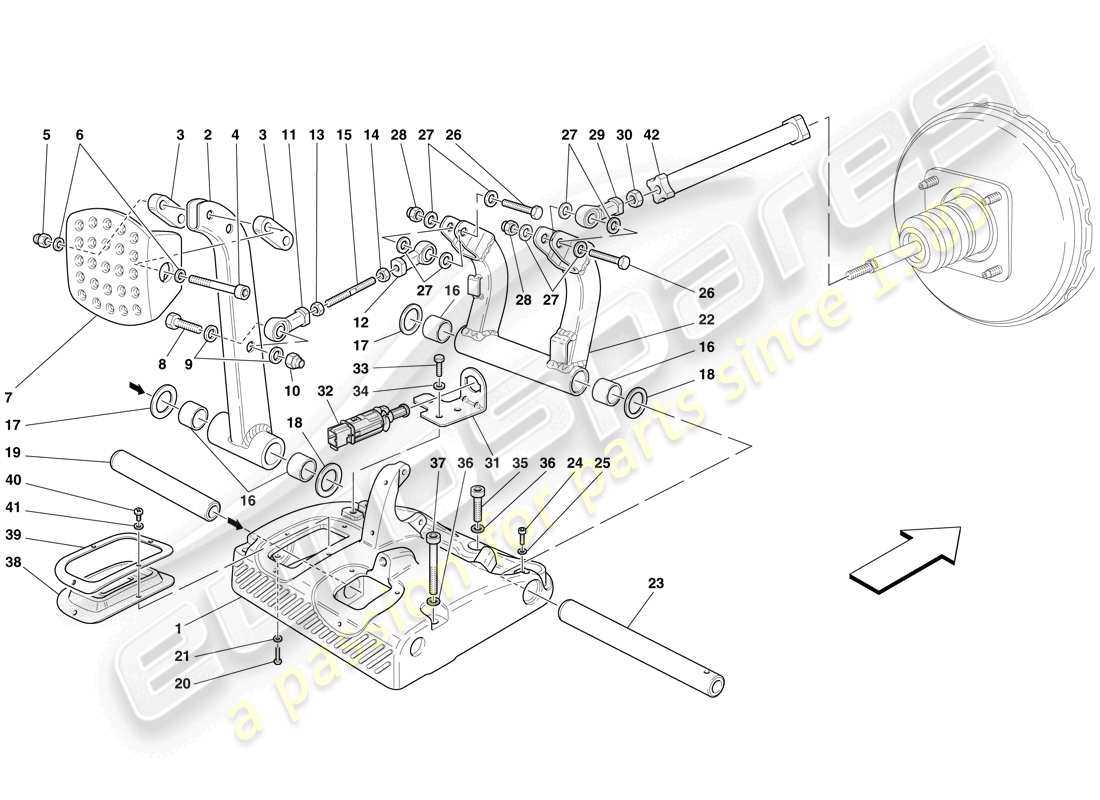

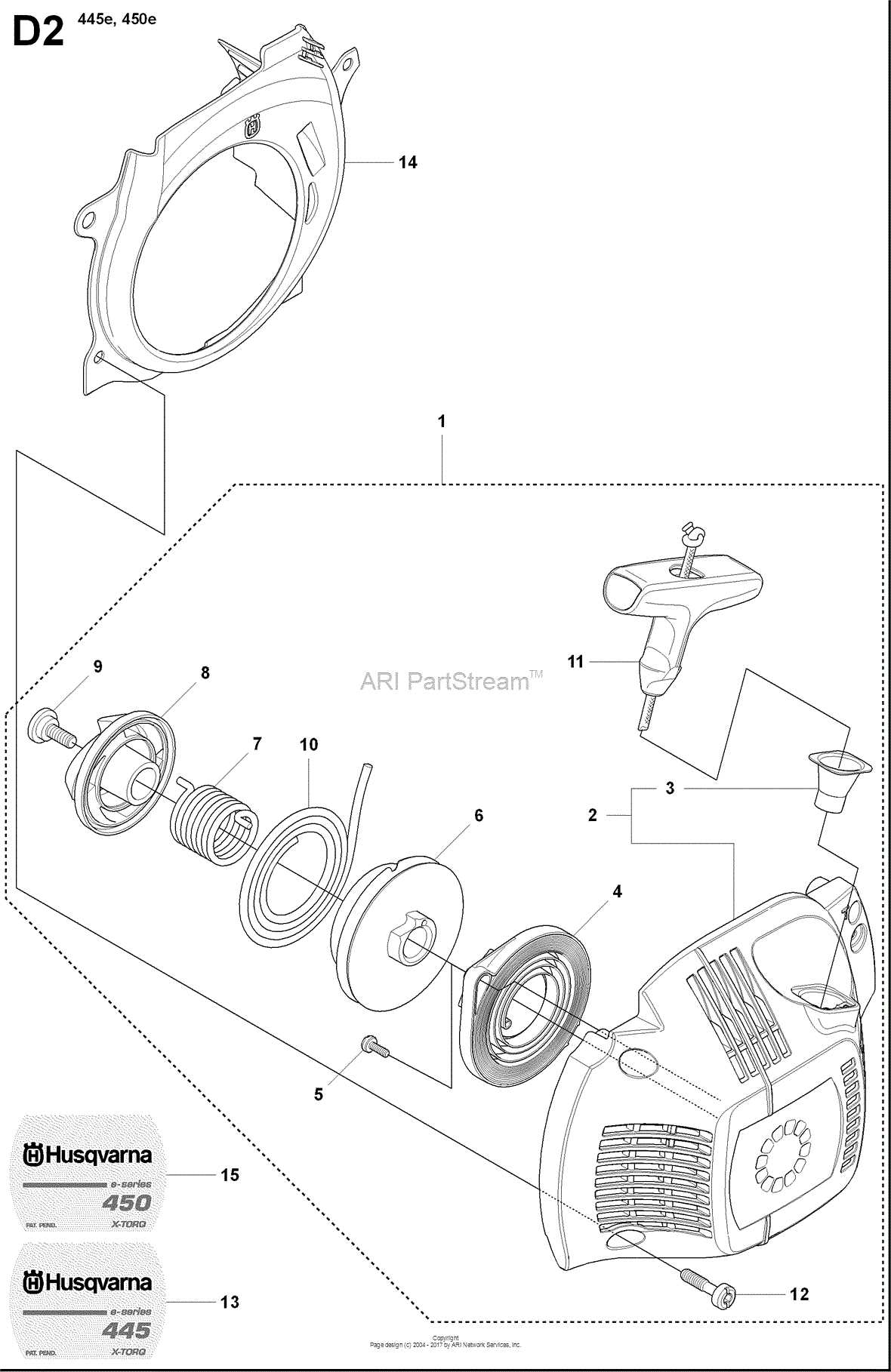

Importance of Parts Diagrams

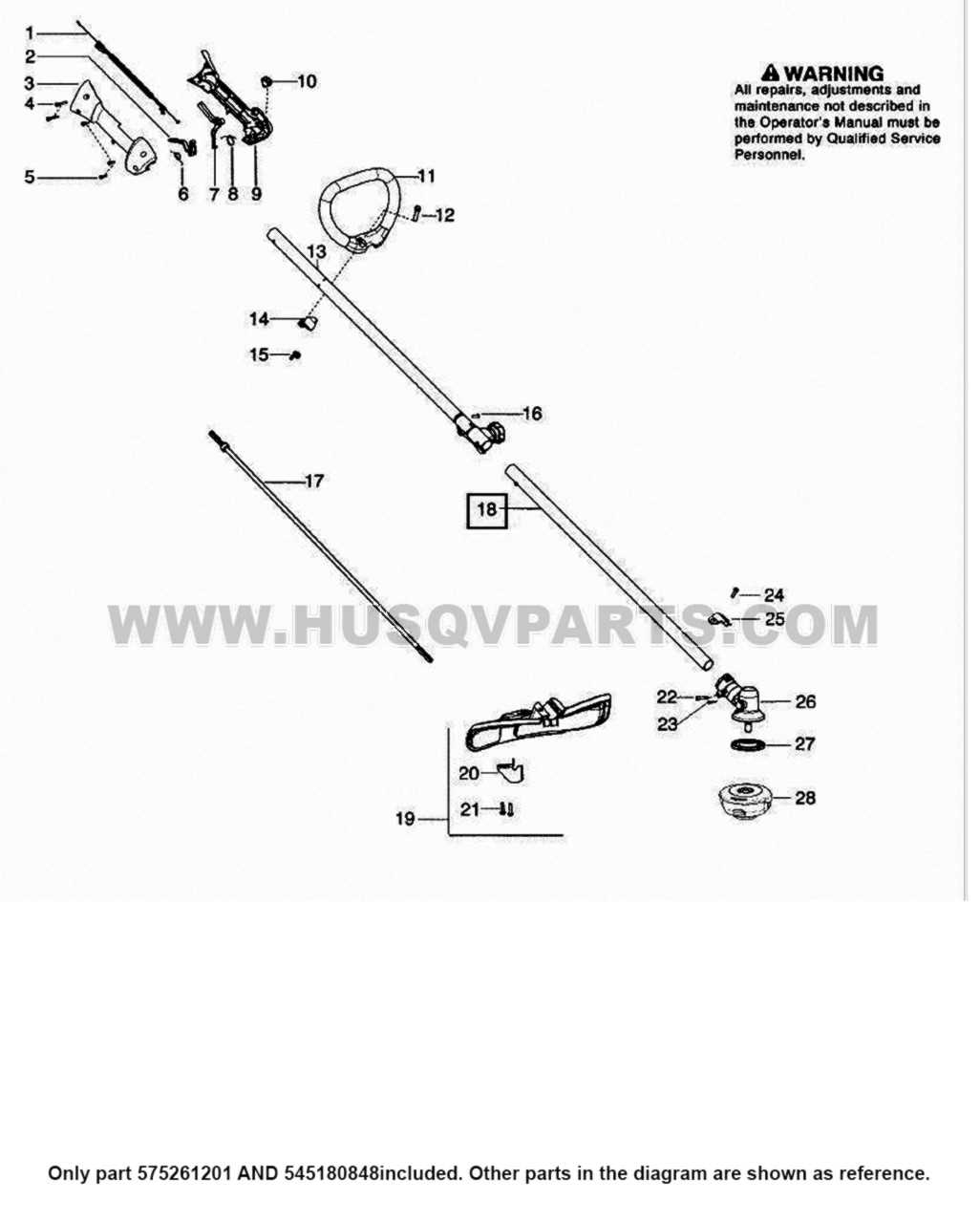

Visual representations of components play a crucial role in understanding the assembly and maintenance of equipment. They serve as essential guides for both novice and experienced users, enabling efficient troubleshooting and repairs.

Enhancing Understanding

Clear illustrations provide numerous benefits, including:

- Facilitating quick identification of individual elements.

- Streamlining the reassembly process after maintenance.

- Reducing errors by clarifying complex structures.

Boosting Maintenance Efficiency

Utilizing visual references can significantly improve the upkeep of machinery by:

- Enabling accurate ordering of replacement items.

- Assisting in the identification of wear and tear.

- Providing insights into the overall design for enhanced modifications.

Common Issues with Husqvarna 440

Understanding the frequent challenges faced by users of outdoor power equipment can significantly enhance performance and longevity. Many individuals encounter similar problems, which can often be resolved with proper maintenance and awareness of the device’s components.

Here are some of the most common issues:

- Starting Difficulties: Users may find it challenging to start the machine, often due to fuel issues or spark plug malfunctions.

- Chain Stalling: The cutting chain may stall or not rotate properly, which could be a result of improper tension or dull teeth.

- Fuel Leaks: Leakage can occur from various seals and gaskets, leading to inefficient operation and safety hazards.

- Overheating: Machines can overheat if airflow is obstructed or if the air filter is clogged, affecting overall functionality.

- Vibration Issues: Excessive vibrations might indicate a misaligned chain or worn components, impacting comfort and control during use.

Addressing these problems promptly can help maintain optimal performance and ensure a safe working environment. Regular inspections and adherence to maintenance schedules are essential for preventing these issues.

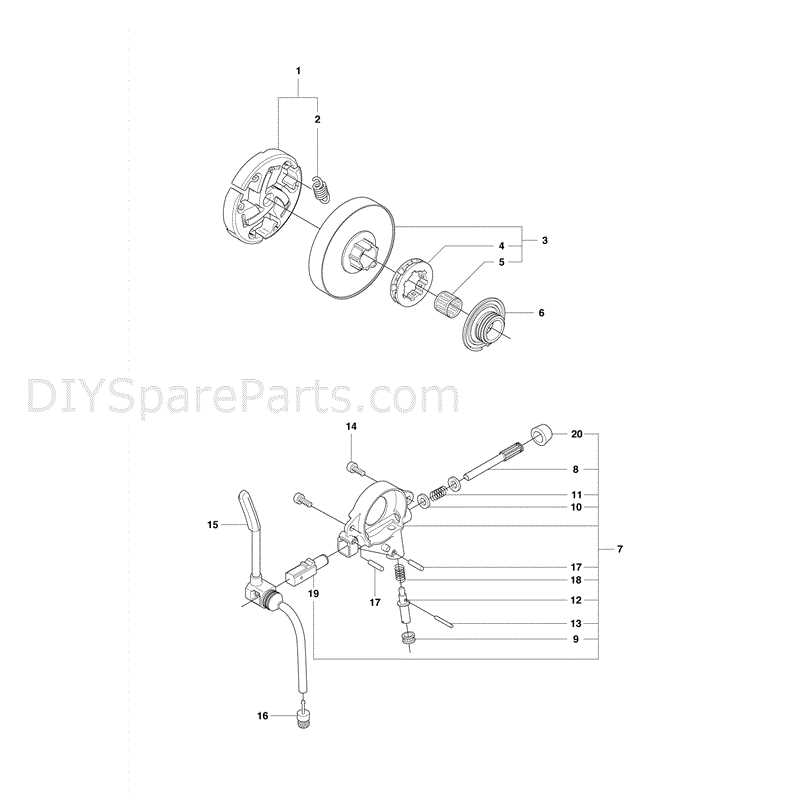

How to Identify Spare Parts

Understanding the components of your machinery is essential for effective maintenance and repairs. Knowing how to pinpoint the right replacements can enhance performance and extend the lifespan of your equipment.

- Refer to the User Manual: Always start with the documentation provided by the manufacturer. It often contains detailed information about each element.

- Examine Existing Components: Take a close look at the parts currently in use. Note any markings or numbers that can assist in identification.

- Consult Online Resources: Numerous websites offer detailed catalogs and specifications. Search using the model number to find exact matches.

- Visit Local Retailers: Speak with professionals at hardware or specialty stores. They can provide insights and may even help you find what you need.

- Utilize Community Forums: Engaging with fellow users online can lead to valuable recommendations and advice on identifying the necessary components.

Tools Required for Maintenance

Regular upkeep of your outdoor power equipment ensures optimal performance and longevity. Proper tools are essential for efficient and safe maintenance tasks. Whether you’re performing routine checks or addressing more detailed repairs, having the right set of instruments is crucial for the job.

Basic Tools

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Torque wrench

- Socket set

- Pliers

- Utility knife

- Air compressor (optional, for cleaning)

Specialized Tools

- Chain tensioning tool

- Chain sharpener or file

- Feeler gauges

- Fuel system cleaning kit

- Spark plug wrench

These tools ensure that the equipment remains in good working condition and can handle any necessary maintenance or minor repairs. Keeping them organized and easily accessible will save time and effort during the upkeep process.

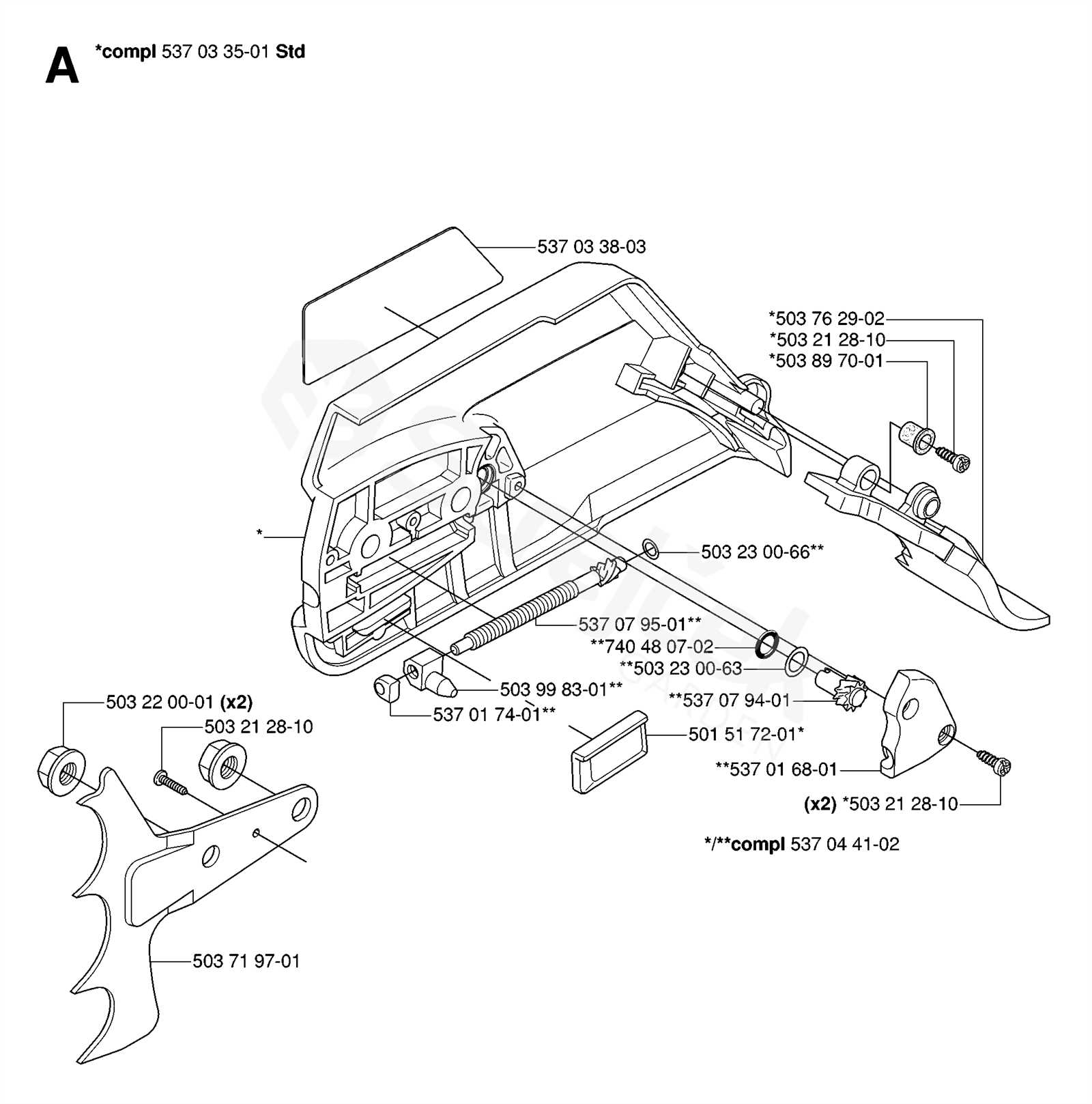

Step-by-Step Repair Process

Repairing your equipment can seem daunting, but with a structured approach, you can effectively tackle the task. This section will guide you through a systematic procedure, ensuring that you can address issues efficiently and confidently. By following each step, you will gain a clearer understanding of the components involved and how to restore functionality.

Preparation and Disassembly

Before starting any repairs, it’s crucial to prepare your workspace. Gather all necessary tools and parts, ensuring everything is within reach. Begin by safely disconnecting the power source. Next, carefully disassemble the unit, taking note of each component’s position. It can be helpful to refer to a visual reference for clarity. Keep track of screws and small parts by placing them in labeled containers.

Inspection and Replacement

Once disassembled, inspect each component for wear or damage. Look for cracks, fraying, or any signs of malfunction. Identify which parts need replacement and source quality alternatives. After obtaining the new components, replace the damaged parts, ensuring proper alignment and secure fittings. Follow the reverse order of disassembly to reassemble the unit. Double-check each step for accuracy before reconnecting the power source.

Where to Find Original Parts

Finding authentic components for your outdoor equipment is essential for maintaining performance and reliability. Ensuring that you use genuine items not only enhances functionality but also prolongs the lifespan of your machine. Here are some reliable sources to consider when seeking high-quality replacements.

Authorized Dealers

Your first stop should be certified retailers who specialize in outdoor machinery. These establishments typically carry a comprehensive selection of genuine components and can provide expert advice on compatibility and installation.

Official Websites

Tips for Long-lasting Performance

Maintaining optimal functionality of your equipment requires attention to several key aspects. By following a few straightforward practices, you can ensure that your machine operates efficiently over time.

- Regular Maintenance: Schedule routine check-ups to clean and lubricate components, preventing buildup that can cause wear and tear.

- Use Quality Fuel: Opt for high-grade fuel to enhance performance and reduce the risk of engine issues.

- Proper Storage: Store your equipment in a dry, sheltered environment to protect it from moisture and extreme temperatures.

Implementing these strategies will not only extend the lifespan of your device but also improve its overall efficiency.

- Inspect Components: Frequently examine key parts for signs of damage or wear.

- Follow Operating Guidelines: Adhere to the manufacturer’s instructions for use to avoid misuse that can lead to damage.

- Replace Worn Parts: Identify and replace any worn-out components promptly to maintain optimal performance.

By prioritizing these practices, you can enjoy reliable performance and prolong the life of your machinery.

Resources for Further Learning

Expanding your knowledge in the realm of outdoor power equipment can greatly enhance your understanding and maintenance skills. There are numerous resources available that provide detailed insights into components, troubleshooting techniques, and best practices for upkeep. Engaging with these materials can empower you to make informed decisions and improve your hands-on abilities.

| Resource Type | Description | Link |

|---|---|---|

| Online Manuals | Access user guides and maintenance manuals for comprehensive information on equipment. | Visit here |

| Video Tutorials | Watch step-by-step videos that demonstrate repairs and maintenance techniques. | Watch here |

| Community Forums | Join discussions with fellow enthusiasts to share tips and experiences. | Join here |

| Manufacturer Websites | Explore official resources for detailed product information and updates. | Explore here |